The global laser rust removal machine market is experiencing robust growth, driven by increasing demand for eco-friendly, precise, and efficient surface cleaning solutions across industries such as automotive, aerospace, and heritage conservation. According to Mordor Intelligence, the industrial laser cleaning equipment market is projected to grow at a CAGR of over 18.5% from 2024 to 2029, fueled by the rising adoption of laser-based technologies as alternatives to abrasive and chemical cleaning methods. Similarly, Grand View Research estimates that the broader laser cleaning market was valued at USD 768.3 million in 2022 and is expected to expand at a CAGR of 17.3% from 2023 to 2030. This surge in market momentum has catalyzed the emergence of innovative manufacturers specializing in high-performance laser rust removal systems. As businesses prioritize operational efficiency and sustainability, the competitive landscape is evolving rapidly. Below is a data-driven overview of the top 9 laser rust removal machine manufacturers leading this transformation.

Top 9 Laser Rust Removal Machine For Sale Manufacturers (2026 Audit Report)

(Ranked by Factory Capability & Trust Score)

#1 FOX P CL – laser for removing rust

Website: pulsar-laser.com

Key Highlights: An innovative laser cleaner that revolutionizes the maintenance and restoration of large vehicles and industrial equipment….

#2 P-laser Industrial laser cleaning

Website: p-laser.com

Key Highlights: Clean smarter with laser light. Fully cleaning rust of machine parts with the help of laser cleaning. WHY LASER CLEANING? Embrace the future of sustainable ……

#3 Laserax

Website: laserax.com

Key Highlights: Laserax works with the world’s leading manufacturers to implement laser cleaning, welding, texturing, and marking solutions….

#4 SFX Laser

Website: sfxlaser.com

Key Highlights: SFX Laser is a 20+ years professional laser equipment manufacturer including laser cleaning machine, laser welding machine, fiber laser engraver, ……

#5 Argento Lux

Website: argentolux.com

Key Highlights: Our Laser Ablation is the most cost-effective, efficient, and safest method of industrial cleaning, rust removal, paint removal, and surface preparation….

#6 Laser Cleaning and Laser Ablation Systems

Website: laserphotonics.com

Key Highlights: Remove rust and surface contaminants with our laser cleaning & laser ablation systems. Experience superior cleaning tech, automation, and eco-friendly ……

#7 ZAC Laser Machine

Founded: 2004

Website: zaclaser.com

Key Highlights: ZAC laser is the professional manufacture since 2004 which sell many laser machines such as laser rust removal-laser cleaning machine, laser engraver-laser ……

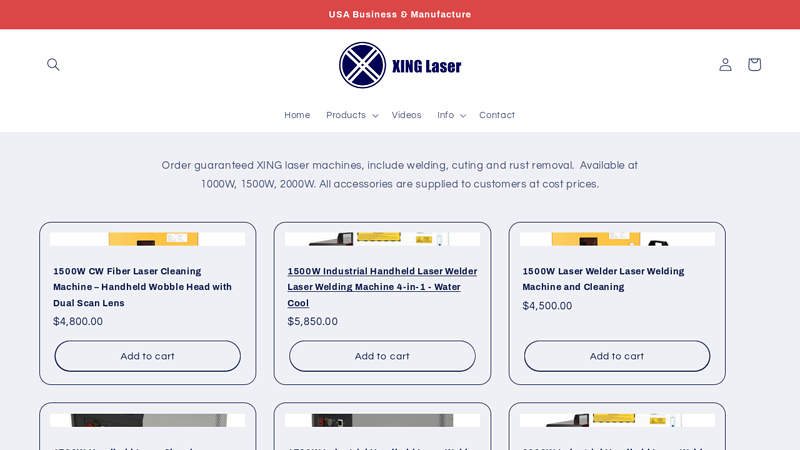

#8 Products

Website: xinglaser.com

Key Highlights: Order guaranteed XING laser machines, include welding, cuting and rust removal. Available at 1000W, 1500W, 2000W. All accessories are supplied to customers ……

#9 Full List of Laser Machines

Website: hantencnc.com

Key Highlights: … 200W 300W laser rust removal machine | Laser Rust Cleaner Machine. USD $930 – USD $1,250. 20W All-in-one Laser Marking Machine for Sale | Special Offer!…

Expert Sourcing Insights for Laser Rust Removal Machine For Sale

2026 Market Trends for Laser Rust Removal Machines for Sale

As industries globally shift toward sustainable and precision-based cleaning solutions, the market for laser rust removal machines is poised for significant growth by 2026. This analysis explores key trends shaping the demand, innovation, and distribution of laser rust removal machines for sale in the coming years.

Rising Demand Across Industrial Sectors

By 2026, the adoption of laser rust removal machines is expected to accelerate across automotive, aerospace, shipbuilding, and heavy manufacturing sectors. These industries are increasingly prioritizing non-abrasive, eco-friendly surface treatment methods to replace traditional sandblasting and chemical stripping. The precision and minimal substrate damage offered by laser technology make it ideal for maintaining structural integrity while achieving high-quality surface preparation.

Advancements in Laser Technology and Portability

Technological improvements are driving the development of more compact, energy-efficient, and user-friendly laser rust removal systems. Fiber laser systems, in particular, are becoming more powerful and affordable, enabling wider market penetration. Expect to see an increased number of portable and handheld laser rust removal machines for sale by 2026, catering to on-site maintenance and field operations. Enhanced automation, AI-assisted targeting, and real-time monitoring features will further improve operational efficiency.

Environmental and Regulatory Drivers

Stricter environmental regulations worldwide are pushing companies to adopt greener alternatives. Laser rust removal produces no secondary waste, chemicals, or airborne particulates, aligning with sustainability goals and compliance requirements. As governments in North America, Europe, and parts of Asia tighten emissions and waste disposal standards, the demand for laser-based solutions is projected to surge, boosting the market for machines for sale.

Cost Reduction and ROI Improvements

Although initial investment costs remain higher than traditional methods, prices for laser rust removal machines are expected to decline by 2026 due to mass production, improved component sourcing, and competition among manufacturers. Concurrently, lower operational costs—such as reduced labor, disposal fees, and rework—enhance the return on investment (ROI), making these systems more attractive to small and mid-sized enterprises.

Expansion of Online Sales and Global Distribution

The digital marketplace for industrial equipment is expanding rapidly. By 2026, a growing number of laser rust removal machines will be available for sale through e-commerce platforms, specialized B2B marketplaces, and direct manufacturer websites. This trend increases accessibility for buyers worldwide, especially in emerging markets such as Southeast Asia, Latin America, and Africa, where industrial modernization is on the rise.

Competitive Landscape and Market Consolidation

The market is witnessing increased competition among Chinese, European, and North American manufacturers. Companies like IPG Photonics, Han’s Laser, and Laser Photonics are leading innovation, while new entrants focus on niche applications and affordability. Strategic partnerships, mergers, and product differentiation are expected to shape the landscape, resulting in a broader range of models for sale with varying power outputs, portability, and automation levels.

Conclusion

By 2026, the market for laser rust removal machines for sale will be defined by technological innovation, environmental sustainability, and expanding global accessibility. As industries embrace clean and efficient maintenance practices, laser rust removal is set to transition from a premium solution to a standard tool in industrial surface treatment. Buyers can expect a more diverse, capable, and cost-effective selection of machines, accelerating adoption across multiple sectors.

Common Pitfalls When Sourcing Laser Rust Removal Machines: Quality and Intellectual Property Concerns

Logistics & Compliance Guide for Laser Rust Removal Machine For Sale

Product Classification & Export Documentation

Before shipping a laser rust removal machine internationally, proper product classification is essential. This equipment typically falls under HS Code 8515.21 (Laser machines for industrial use) or similar, depending on the region. Confirm the correct classification with your local customs authority. Required export documentation includes a commercial invoice, packing list, bill of lading/air waybill, and an export declaration. For certain destinations, a Certificate of Origin may also be needed to qualify for tariff preferences.

Laser Safety Certification & Regulatory Compliance

Laser rust removal machines are subject to strict safety regulations due to their high-power lasers. Ensure the machine complies with international standards such as IEC 60825-1 (Safety of Laser Products). In the U.S., compliance with the FDA/CDRH (Center for Devices and Radiological Health) regulations is required, including product registration and reporting. For the EU market, CE marking under the Machinery Directive (2006/42/EC) and the Laser Products Standard (EN 60825) is mandatory. Include a laser safety manual, warning labels, and interlock systems as per these standards.

Battery & Electrical Equipment Regulations

If the machine includes rechargeable batteries (e.g., lithium-ion), additional transport regulations apply. Under IATA Dangerous Goods Regulations (for air freight) and IMDG Code (for sea freight), lithium batteries must be shipped in compliance with specific packaging, labeling, and state-of-charge requirements. Electrical components must also meet regional standards such as UL (U.S.), CSA (Canada), or CE (Europe). Provide technical specifications, circuit diagrams, and certification documents to customs and end-users.

Packaging & Handling for Safe Transport

Due to its sensitive optical components and heavy-duty structure, the laser rust removal machine must be securely packaged to prevent damage. Use custom wooden crates with internal foam or foam-in-place cushioning to protect against shock and vibration. Clearly label packages with “Fragile,” “This Side Up,” and “Do Not Stack” indicators. Include desiccants to prevent moisture damage during transit, especially for ocean shipments. Secure all moving parts and cover optical components with protective caps.

Import Regulations & Duties by Region

Import requirements vary by country. For example, in the European Union, ensure the machine meets REACH and RoHS directives restricting hazardous substances. In China, importers may need CCC (China Compulsory Certification) for electrical safety. In Canada, compliance with ICES-001 (EMI/EMC) regulations is required. Research destination-specific import duties, taxes (e.g., VAT, GST), and licensing needs. Provide buyers with all necessary documentation to facilitate smooth customs clearance.

End-User Verification & Restricted Parties Screening

Due to the potential dual-use nature of high-power lasers, implement end-user verification procedures. Screen buyers against national and international restricted party lists (e.g., U.S. OFAC, EU Consolidated List). Avoid sales to embargoed countries or entities involved in military applications without proper export licenses. Maintain records of customer due diligence to comply with anti-proliferation and export control regulations such as ITAR or EAR (if applicable).

After-Sales Support & Warranty Compliance

Provide clear warranty terms that comply with local consumer protection laws, such as the EU Consumer Rights Directive or U.S. Magnuson-Moss Warranty Act. Include multilingual user manuals, safety instructions, and software documentation. Offer remote technical support and spare parts logistics. Ensure service and repair processes respect data privacy laws (e.g., GDPR) if the machine includes connected or data-collecting features.

Environmental & Disposal Compliance

Inform buyers about proper end-of-life disposal procedures. Laser machines may contain hazardous materials regulated under WEEE (Waste Electrical and Electronic Equipment) in the EU or similar programs elsewhere. Provide take-back options or recycling instructions to support environmental compliance and corporate responsibility goals.

In conclusion, sourcing a laser rust removal machine for sale offers a forward-thinking, efficient, and environmentally friendly solution for industries seeking advanced surface cleaning technologies. With benefits such as precision cleaning, minimal substrate damage, reduced waste, and long-term cost savings, laser rust removal is increasingly becoming a preferred alternative to traditional methods like sandblasting or chemical treatments.

When sourcing these machines, it is essential to evaluate factors such as laser power, portability, ease of use, safety features, manufacturer reputation, and after-sales support. Additionally, considering certifications, warranty terms, and compatibility with your specific applications will ensure a reliable and effective investment.

As the technology continues to evolve and become more accessible, businesses that adopt laser rust removal systems position themselves at the forefront of innovation, sustainability, and operational efficiency. Ultimately, careful research and due diligence in selecting the right supplier and model will maximize return on investment and support long-term success in industrial maintenance and restoration processes.