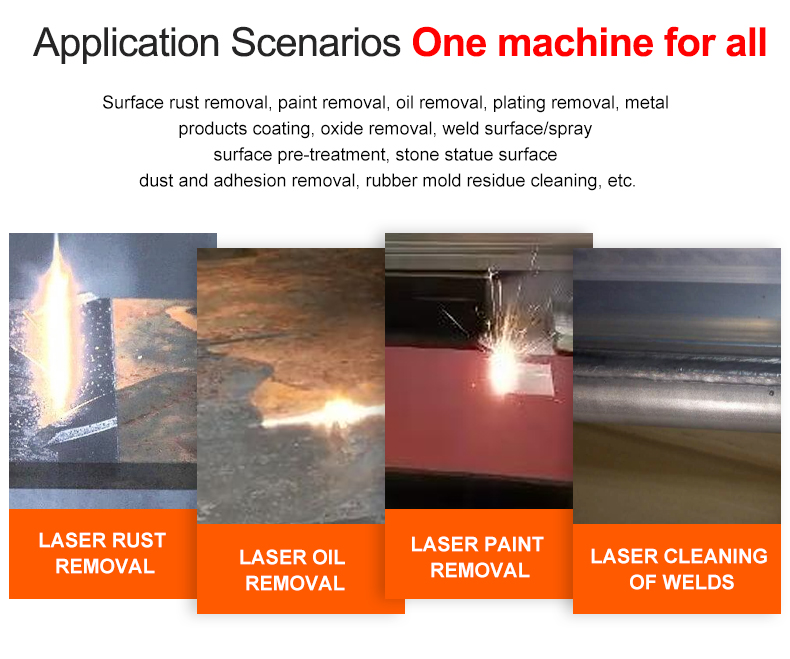

The global laser cleaning equipment market is experiencing robust growth, driven by increasing demand for eco-friendly, precision-based surface treatment solutions across industries such as automotive, aerospace, and manufacturing. According to Grand View Research, the global laser cleaning market size was valued at USD 291.9 million in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 22.4% from 2023 to 2030. This surge is fueled by the declining cost of fiber lasers, stricter environmental regulations on chemical cleaning methods, and the superior efficiency of laser rust removal in preserving substrate integrity. As industries shift toward automation and sustainable maintenance practices, laser rust removal has emerged as a cost-effective alternative to sandblasting and chemical treatments. With operational costs becoming a key decision factor, understanding the cost per hour of laser rust removal systems—shaped by laser power, uptime, energy consumption, and maintenance—is critical for procurement managers and operations leaders. This analysis highlights the top 8 manufacturers offering the most competitive and transparent hourly cost structures, combining performance data, energy efficiency metrics, and real-world operational insights to guide investment decisions in high-precision surface cleaning technology.

Top 8 Laser Rust Removal Cost Per Hour Manufacturers (2026 Audit Report)

(Ranked by Factory Capability & Trust Score)

#1 Laser rust cleaning technology

Website: cr4.globalspec.com

Key Highlights: I did a search on Alibaba and it looks like the prices of a China made machine is around $1K. I’m curious if anyone has personally used one of ……

#2 P-laser Industrial laser cleaning

Website: p-laser.com

Key Highlights: Clean smarter with laser light. Fully cleaning rust of machine parts with the help of laser cleaning. WHY LASER CLEANING? Embrace the future of sustainable ……

#3 Understanding Laser Cleaning Cost Per Hour and Total Investment

Website: umw.top

Key Highlights: In this example, the total cost of operating the laser cleaning machine is $34.27 per hour. This includes all operational costs and accounts for the machine’s ……

#4 How Much Does Laser Rust Removal Cost

Website: lasercleansystem.com

Key Highlights: Analysis of Third-Party Laser Cleaning Service Costs · Hourly Rate: This is the most common model, with typical rates ranging from $150 – $250 ……

#5 Understanding Laser Cleaning Cost Per Hour

Website: dwcnclaser.com

Key Highlights: Generally, the price is 2.5 US dollars per hour. For specific information, please refer to the service provider for accurate prices….

#6 Understanding Laser Cleaning Cost Per Hour And Its Benefits

Website: leapion.com

Key Highlights: The cost per hour for laser cleaning is typically between 40 – 140 €/hour. This varies depending on the model, the state of the laser being run, and the range ……

#7 Laser Cleaning Machine Usage Cost Analysis

Website: cnmarking.com

Key Highlights: Assuming an average electricity rate of $0.10 per kWh, the running cost for a 1000W machine would be approximately $1 – $1.50 per hour— ……

#8 Start a Laser Cleaning Business in Florida

Website: cleanlasertechnologies.com

Key Highlights: At Clean Laser Technologies, we manufacture powerful, U.S.-built machines that are backed by safety training, financing options, and lifetime tech support….

Expert Sourcing Insights for Laser Rust Removal Cost Per Hour

2026 Market Trends for Laser Rust Removal Cost Per Hour

As the industrial cleaning and surface preparation sectors evolve, laser rust removal is emerging as a leading technology due to its precision, environmental benefits, and efficiency. By 2026, several key market trends are expected to influence the hourly cost of laser rust removal services. These include technological advancements, increased market adoption, automation integration, and shifting regulatory landscapes.

Technological Advancements Driving Down Costs

One of the most significant factors affecting the cost per hour of laser rust removal by 2026 will be ongoing improvements in laser technology. Manufacturers are developing more energy-efficient, higher-power fiber lasers with improved beam quality and faster scanning systems. These enhancements allow for quicker rust removal with less operator intervention, boosting throughput and reducing labor costs per job. As a result, service providers can offer competitive hourly rates while maintaining profitability. Additionally, the integration of AI-guided systems and real-time monitoring will optimize performance, minimizing downtime and increasing cost-effectiveness.

Increased Market Adoption and Economies of Scale

The growing acceptance of laser rust removal across industries—such as automotive restoration, shipbuilding, aerospace, and heritage conservation—will contribute to economies of scale. As demand rises, manufacturers will produce laser systems at higher volumes, reducing unit costs. This scalability will lower both the capital investment and operational costs for service providers, which is expected to translate into more competitive hourly pricing for end users. By 2026, increased competition among service providers may further push down average hourly rates, which currently range from $80 to $200 depending on region and complexity.

Automation and Robotics Integration

The integration of robotic arms and automated mobile platforms with laser rust removal systems will be a defining trend in 2026. These automated systems reduce reliance on skilled labor, operate continuously with minimal supervision, and deliver consistent results. While the initial setup cost is high, the long-term operational cost per hour decreases significantly due to higher productivity and reduced human error. Industries investing in automation, such as automotive manufacturing and offshore platforms, are likely to see the most substantial reductions in effective hourly cleaning costs.

Environmental and Regulatory Pressures

Stricter environmental regulations worldwide are pushing industries away from abrasive blasting and chemical cleaning methods due to their harmful emissions and waste. Laser rust removal, being a dry, chemical-free, and low-noise process, aligns with sustainability goals. As compliance costs for traditional methods rise, companies are more inclined to adopt laser solutions—even at a higher initial hourly rate. However, by 2026, these regulatory incentives, combined with government subsidies for green technologies in certain regions, are expected to soften the total cost burden, making laser cleaning more accessible and cost-competitive on a per-hour basis.

Regional Variations and Service Models

The cost per hour of laser rust removal in 2026 will vary significantly by region. In North America and Western Europe, where labor and equipment costs are higher, hourly rates may remain elevated but will benefit from mature service networks and standardized pricing. In contrast, emerging markets in Asia and Eastern Europe may offer lower hourly rates due to lower operational costs and growing local manufacturing of laser systems. Additionally, new business models such as “Laser Cleaning as a Service” (LCaaS) may emerge, offering flexible, subscription-based or pay-per-use pricing that reduces the perceived hourly cost for clients.

Conclusion

By 2026, the hourly cost of laser rust removal is expected to decline moderately due to technological innovation, automation, and broader market adoption. While current prices reflect premium positioning, increased competition, improved efficiency, and regulatory support will make the technology more affordable and widely adopted. Businesses investing in or outsourcing laser cleaning services can anticipate better value, with average hourly rates trending downward—potentially reaching $60–$150 depending on application and region—while delivering superior, eco-friendly results.

Common Pitfalls When Sourcing Laser Rust Removal Cost Per Hour (Quality, IP)

When evaluating laser rust removal services based on cost per hour, businesses often focus solely on price while overlooking critical factors related to quality and intellectual property (IP). This narrow view can lead to hidden expenses, substandard results, and legal risks. Avoid these common pitfalls:

Overlooking Equipment Quality and Capabilities

Not all laser rust removal systems are equal. Low-cost providers may use outdated or underpowered lasers that deliver inconsistent results, require multiple passes, or damage the underlying substrate. Always verify the laser type (e.g., fiber laser wavelength and power), beam quality, and automation features. Poor equipment often leads to longer processing times and rework, increasing the effective hourly cost despite a lower quoted rate.

Ignoring Operator Skill and Process Standardization

The effectiveness of laser rust removal heavily depends on operator expertise. Inexperienced technicians may use incorrect settings, leading to incomplete cleaning or surface damage. Ensure the provider follows documented, standardized procedures and maintains trained, certified personnel. A provider with rigorous quality control may charge more per hour but delivers reliable, repeatable results that reduce long-term costs.

Failing to Define Quality Metrics and Acceptance Criteria

Without clearly defined quality benchmarks—such as surface profile (e.g., Sa 2.5), cleanliness standards (e.g., ISO 8501-1), or adhesion test results—it’s difficult to assess value. Ambiguity can lead to disputes or acceptance of subpar work. Insist on a written quality specification and validation method (e.g., visual inspection, profilometry) before agreeing to a per-hour rate.

Underestimating Throughput and Efficiency Variability

Hourly rates can be misleading if the actual throughput varies significantly. Factors like rust thickness, part geometry, and accessibility affect cleaning speed. Providers may quote based on ideal conditions, but real-world efficiency can be much lower. Request time studies or pilot runs on representative parts to estimate true cost per component, not just per hour.

Neglecting Intellectual Property and Data Security Risks

When outsourcing laser cleaning—especially for proprietary components or sensitive industries—IP protection is critical. Ensure contractual agreements include clauses on confidentiality, data handling, and ownership of process parameters or custom tooling developed during service. Failure to address IP can expose your designs or manufacturing processes to misuse or unauthorized replication.

Assuming All Maintenance and Downtime Costs Are Included

Some providers quote an hourly rate that excludes maintenance, consumables, or machine downtime. Clarify what is included in the rate. Unexpected costs for laser source replacement, optics cleaning, or system calibration can erode savings from a low hourly quote.

Not Conducting Pilot Testing or Site Audits

Relying solely on quotations without validating performance leads to poor decisions. Conduct pilot tests with your actual parts to evaluate cleaning quality, speed, and consistency. Visit the provider’s facility to assess their operational standards, safety protocols, and equipment condition—key indicators of long-term reliability.

By addressing these pitfalls, organizations can make informed sourcing decisions that balance hourly cost with quality assurance and IP protection, ensuring a truly cost-effective and secure laser rust removal solution.

Logistics & Compliance Guide for Laser Rust Removal Cost Per Hour

Understanding the cost per hour for laser rust removal involves more than just the machine’s operational rate. It encompasses logistics, regulatory compliance, equipment maintenance, and operational efficiency. This guide outlines key considerations to accurately assess and manage the total cost of ownership and operation.

Equipment Transportation and Setup

Transporting laser rust removal systems requires careful planning due to their size, weight, and sensitivity. High-powered laser units are often mounted on carts or trailers for mobility but need secure loading and climate-controlled transport to avoid damage. Upon arrival, site setup includes laser alignment, power supply connection (typically 220–480V), ventilation (for fume extraction), and safety perimeter installation. These logistics impact downtime and labor costs, directly affecting the effective hourly rate.

Regulatory and Safety Compliance

Laser rust removal systems operate under Class 4 laser safety standards (IEC 60825-1), requiring strict compliance with occupational health and safety regulations. Key compliance measures include:

- Laser Safety Officer (LSO) designation on-site for industrial applications.

- Use of laser safety eyewear with appropriate optical density for the laser wavelength (commonly 1064 nm for fiber lasers).

- Controlled access zones with warning signs and interlocks.

- Compliance with OSHA, ANSI Z136.1, and local regulations for laser use.

- Proper handling and disposal of removed rust particulates, which may be classified as hazardous waste depending on substrate coatings (e.g., lead-based paint).

Non-compliance can result in fines, work stoppages, or liability claims—factors that increase effective hourly costs.

Environmental and Waste Management

Laser ablation produces fine particulate matter requiring HEPA-filtered fume extraction systems. Captured waste must be tested for hazardous contaminants before disposal. In regulated environments (e.g., shipyards, chemical plants), waste classification under EPA or REACH guidelines may necessitate special handling procedures, adding to operational costs. Ensuring environmental compliance avoids penalties and supports sustainable operations.

Maintenance and Downtime Costs

Laser systems require routine maintenance: cleaning optical components, replacing filters, and calibrating beam delivery. Scheduled downtime for servicing (typically every 500–1,000 hours) must be factored into the hourly cost. Unexpected repairs or component failures (e.g., laser diodes, scanners) can further increase costs. A preventive maintenance plan helps stabilize the effective hourly rate.

Operator Training and Certification

Effective operation demands trained personnel proficient in laser safety, system calibration, and process parameters. Initial and ongoing training programs—often certified by equipment manufacturers or safety bodies—contribute to labor costs but reduce errors, rework, and safety incidents. Skilled operators optimize cleaning speed and quality, improving cost efficiency over time.

Power Consumption and Facility Requirements

Laser rust removal systems consume significant electrical power (5–20 kW depending on model). Facilities must support this load without voltage drops, potentially requiring electrical upgrades. Energy costs should be calculated per hour of operation. Additionally, adequate workspace with ventilation, lighting, and grounding is essential for continuous, compliant operation.

Insurance and Liability Coverage

Operators must carry liability insurance covering laser operations, including potential fire hazards or eye injuries. Equipment insurance should cover transport and on-site damage. Premiums vary based on risk assessment and are a recurring cost that influences the total hourly rate.

Conclusion: Calculating True Cost Per Hour

The effective cost per hour of laser rust removal includes:

- Equipment depreciation or leasing

- Labor (setup, operation, maintenance)

- Power consumption

- Safety and compliance measures

- Waste disposal

- Downtime and maintenance

- Insurance and training

Accurately tracking these factors ensures transparent pricing, regulatory adherence, and sustained operational efficiency in industrial cleaning applications.

Conclusion on Sourcing Laser Rust Removal Cost Per Hour:

The cost of laser rust removal per hour varies significantly based on several factors, including the power and quality of the laser system, regional labor and operational costs, service provider pricing models, and project-specific requirements such as rust severity and surface area. On average, professional laser rust removal services range from $80 to $150 per hour, while high-end industrial operations may exceed $200 per hour due to advanced equipment and specialized expertise.

When sourcing laser rust removal, it’s essential to balance cost with value—considering efficiency, precision, environmental benefits (no media blasting or chemicals), and reduced surface damage compared to traditional methods. In-house investment in laser equipment may be cost-effective for high-volume users, though it requires substantial upfront capital and maintenance. For most businesses, outsourcing to experienced service providers offers a scalable and economical solution.

Ultimately, the true cost-effectiveness of laser rust removal lies not only in the hourly rate but in long-term savings through improved safety, faster processing times, and extended asset lifespan. Conducting detailed vendor comparisons, requesting site-specific quotes, and verifying technician qualifications are critical steps in making an informed sourcing decision.