The global laser cleaning equipment market is undergoing significant expansion, driven by increasing demand for eco-friendly and precision-based surface treatment solutions across industries such as automotive, aerospace, and heavy manufacturing. According to a 2023 report by Mordor Intelligence, the laser cleaning market was valued at USD 412 million in 2022 and is projected to grow at a compound annual growth rate (CAGR) of over 19.8% from 2024 to 2029, reaching an estimated USD 1.2 billion by the end of the forecast period. This growth is largely attributed to stricter environmental regulations phasing out chemical and abrasive cleaning methods, alongside rising adoption of automation in industrial maintenance.

As laser rust removal technology becomes more accessible, cost-effectiveness and performance consistency are pivotal in manufacturer selection. A key trend emerging from Grand View Research’s 2023 analysis underscores that fiber laser-based systems now dominate the segment due to their reliability, lower operational costs, and minimal maintenance requirements. With industrial players prioritizing total cost of ownership (TCO)—including initial investment, power efficiency, maintenance, and uptime—evaluating leading manufacturers on transparent, data-backed pricing models is critical.

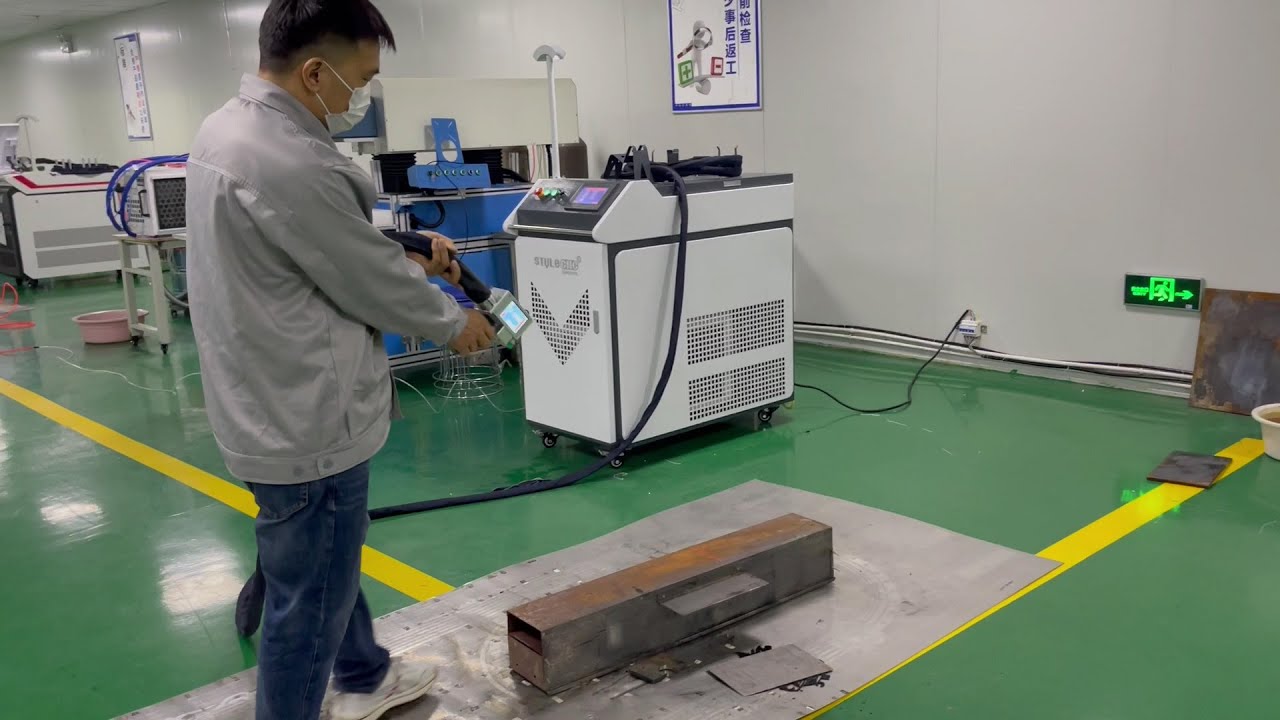

This analysis focuses on the top eight laser rust removal equipment manufacturers shaping the competitive landscape, comparing pricing structures, power outputs (ranging from 100W to 2000W), cleaning speeds (from 500 mm²/s to over 15,000 mm²/s), and return-on-investment timelines based on real-world deployment data. From established European innovators to high-growth Asian suppliers leveraging economies of scale, these companies are setting benchmarks not only in technology but also in affordability and total operational value.

Top 8 Laser Rust Removal Cost Manufacturers (2026 Audit Report)

(Ranked by Factory Capability & Trust Score)

#1 FOX P CL – laser for removing rust

Website: pulsar-laser.com

Key Highlights: An innovative laser cleaner that revolutionizes the maintenance and restoration of large vehicles and industrial equipment….

#2 P-laser Industrial laser cleaning

Website: p-laser.com

Key Highlights: We operate strictly B2B, delivering smart, efficient, and cost-effective laser solutions designed to meet the demands of modern industry. … Fully cleaning rust ……

#3 Industrial 1500W 2000W CW Laser Cleaning Machine Rusty Remove

Website: xinglaser.com

Key Highlights: XING Laser (6am Life LLC, DBA XING Laser) specializes in the development and manufacture of high-performance handheld laser cleaning and rust removal equipment….

#4 Laserax

Website: laserax.com

Key Highlights: Laserax works with the world’s leading manufacturers to implement laser cleaning, welding, texturing, and marking solutions….

#5 Argento Lux

Website: argentolux.com

Key Highlights: Laser cleaning removes paint, contaminants, rust, and residues with a high-energy laser beam which leaves the substrate untouched. Our Laser Ablation is the ……

#6 500W 1000W Pulse Laser Cleaning Machine Laser Metal Rust Oil …

Website: sfxlaser.com

Key Highlights: In stock Free deliverySingle Mode Laser Cleaner(Gaussian Beam): Suitable for strong adhesion cleaning such as Heavy rust, Oxide Layer, Thick paint, Galvanized layer removal and ……

#7 Why are Laser Rust Removal So Expensive?

Website: dplaser.com

Key Highlights: The cost of a laser rust removal machine varies depending on the type of laser and its configuration, ranging from a few thousand to tens of ……

#8 Laser Cleaning and Laser Ablation Systems

Website: laserphotonics.com

Key Highlights: Remove rust and surface contaminants with our laser cleaning & laser ablation systems. Experience superior cleaning tech, automation, and eco-friendly ……

Expert Sourcing Insights for Laser Rust Removal Cost

2026 Market Trends for Laser Rust Removal Cost

The global laser rust removal market is poised for significant transformation by 2026, driven by technological advancements, increasing environmental regulations, and growing demand for precision cleaning across key industries. These dynamics are directly influencing the cost structure of laser rust removal systems and services, with several key trends expected to shape pricing and accessibility.

Falling Equipment Acquisition Costs Due to Technological Maturity and Scale

By 2026, the upfront cost of purchasing laser rust removal systems is anticipated to decline moderately. This trend is primarily fueled by the maturation of fiber laser technology, which offers higher efficiency, longer lifespans, and reduced maintenance compared to earlier models. As production scales up to meet rising global demand—particularly in manufacturing, automotive, and shipbuilding sectors—economies of scale will lower component and assembly costs. Increased competition among manufacturers, including new entrants from Asia, will further pressure prices, making mid-range industrial systems more affordable for small and medium-sized enterprises (SMEs).

Rising Adoption Driving Down Service Costs and Improving ROI

While equipment costs are decreasing, the broader trend points toward declining cost-per-application due to expanded service adoption. More specialized laser cleaning service providers are expected to enter the market by 2026, creating competitive pricing for outsourced rust removal. This proliferation lowers barriers for companies unwilling or unable to invest in capital equipment. Additionally, improved laser efficiency and faster processing speeds will enhance throughput, reducing labor and operational time per job. These factors collectively improve the return on investment (ROI) for both equipment owners and service clients, making laser rust removal increasingly cost-competitive against traditional methods like sandblasting and chemical cleaning.

Total Cost of Ownership Advantages Strengthen Market Position

By 2026, the total cost of ownership (TCO) for laser rust removal will be a key driver of market growth. Unlike abrasive methods that require consumables (e.g., sand, media) and generate hazardous waste disposal costs, laser systems have minimal consumables and produce no secondary waste. This reduces long-term operational expenses and compliance costs related to environmental regulations—especially stringent in regions like the EU and North America. Lower maintenance needs and longer operational lifespans further enhance TCO benefits. As companies prioritize sustainability and regulatory compliance, the cost-effectiveness of laser solutions will become more compelling, even with higher initial investments.

Differentiation in Pricing Based on Power and Automation

The market will continue to segment based on power output and automation level, affecting cost structures. High-power systems (1,000W and above) capable of rapid rust removal on large-scale industrial assets will remain premium-priced, primarily targeting heavy industries. However, there will be growth in mid-power (300–600W) portable systems tailored for maintenance, restoration, and precision applications, offering a more balanced cost-performance ratio. Additionally, integration with robotics and AI-driven path planning will increase for automated production lines, adding to system cost but delivering significant labor savings and consistency—justifying the investment in high-volume settings.

Regional Cost Variations and Supply Chain Dynamics

Geographic disparities in laser rust removal costs will persist into 2026. Regions with strong domestic manufacturing—such as China and parts of Southeast Asia—will offer lower equipment prices due to reduced import tariffs and logistics costs. In contrast, markets like North America and Western Europe may see higher initial prices but benefit from comprehensive service networks and technical support. Supply chain resilience will also influence pricing; ongoing advancements in diode and fiber component manufacturing are expected to stabilize or reduce input costs, mitigating inflationary pressures seen in earlier years.

In conclusion, the 2026 landscape for laser rust removal cost will reflect a market transitioning from niche to mainstream adoption. While high-end systems remain capital-intensive, overall costs—both upfront and operational—are trending downward. The combination of technological improvements, competitive pressures, and favorable TCO will make laser rust removal a financially viable and increasingly preferred solution across diverse industrial applications.

Common Pitfalls When Sourcing Laser Rust Removal Systems: Quality and Intellectual Property Risks

Sourcing laser rust removal equipment can offer significant advantages in efficiency and environmental impact, but buyers often encounter critical pitfalls—especially concerning quality and intellectual property (IP). Overlooking these factors can lead to operational downtime, increased maintenance costs, and legal exposure. Below are key risks to watch for:

Overlooking Build Quality and Component Standards

Many suppliers, particularly in competitive price-driven markets, cut corners on materials and engineering. Subpar laser sources, optics, cooling systems, or mechanical frames can result in inconsistent rust removal performance, frequent breakdowns, and shortened equipment lifespan. Buyers may be attracted to lower prices but later face higher total cost of ownership due to repairs and lost productivity.

Inadequate Power Output and Beam Quality Verification

Some vendors exaggerate laser power ratings (e.g., advertising “1000W” systems that deliver significantly less effective output). Without independent verification or access to beam profiling data, buyers risk acquiring underperforming systems. Poor beam quality reduces precision and efficiency, making the equipment ineffective for industrial applications.

Insufficient Safety and Compliance Documentation

Laser systems must comply with international safety standards (e.g., IEC 60825). Some lower-tier suppliers may lack proper certification or provide incomplete documentation, creating liability risks and potential delays in deployment. Non-compliant systems can also fail regulatory inspections or insurance assessments.

Hidden IP Infringement in Core Technologies

A major risk when sourcing from lesser-known manufacturers—especially in regions with weaker IP enforcement—is the use of counterfeit or reverse-engineered components. This includes cloned laser modules, copied control software, or replicated optical designs. Using such equipment exposes the buyer to legal risks if the original IP holder pursues infringement claims.

Lack of Transparent Software Licensing and Ownership

The control software driving laser systems often contains proprietary algorithms. Buyers may unknowingly use pirated or unlicensed software, which can lead to operational vulnerabilities, no access to updates, or legal exposure. Ensure the supplier provides clear licensing terms and, if possible, proof of software ownership or authorization.

Absence of IP Warranty and Indemnification Clauses

Many standard supply contracts do not include warranties protecting the buyer from third-party IP claims. Without indemnification, businesses could be held liable for using infringing technology—even if unintentional. Always negotiate contractual terms that shift IP liability to the supplier.

Limited After-Sales Support and Spare Parts Availability

Poor-quality or IP-compromised systems often come with limited technical support and difficulty sourcing genuine spare parts. This leads to prolonged downtimes and forces users to rely on unreliable third-party replacements, further degrading system performance and safety.

Conclusion

To mitigate these pitfalls, conduct thorough due diligence: verify technical specifications with third-party testing, audit supplier IP credentials, demand compliance certifications, and include strong IP protections in procurement contracts. Investing time upfront ensures long-term reliability, legal safety, and optimal return on investment in laser rust removal technology.

Logistics & Compliance Guide for Laser Rust Removal Cost

Understanding the logistics and compliance aspects of laser rust removal is essential for accurate cost estimation and smooth project execution. These factors can significantly influence both the upfront and long-term expenses associated with adopting or outsourcing this technology.

Equipment Transportation and Setup

Shipping high-precision laser systems requires careful planning due to their size, weight, and sensitivity. Costs may include crating, specialized freight (e.g., lift-gate delivery), customs fees for international shipments, and insurance. Upon arrival, professional installation and calibration are often required, which may involve technician travel fees and downtime. These logistical expenses should be factored into the total cost of ownership.

Regulatory Compliance and Safety Standards

Laser rust removal systems must comply with national and international safety regulations such as those from OSHA (Occupational Safety and Health Administration) and IEC 60825 (laser safety standards). Facilities must implement protective measures including laser enclosures, interlocks, and personal protective equipment (PPE). Compliance may also require safety training programs, risk assessments, and certification—each contributing to operational costs.

Environmental and Waste Disposal Regulations

Unlike traditional blasting methods, laser rust removal produces minimal secondary waste, typically only ablated rust particles. However, proper collection and disposal of these particulates must comply with local environmental regulations (e.g., EPA guidelines in the U.S.). Depending on the substrate and coating, hazardous material handling procedures may apply, increasing compliance-related costs. Air filtration systems may also be required to meet indoor air quality standards.

Operator Certification and Training Requirements

Laser operation often requires certified personnel trained in laser safety (e.g., Certified Laser Safety Officer – CLSO). Training programs, recertification, and ongoing skill development contribute to labor costs. Inadequate training can lead to safety incidents or inefficient use of the equipment, indirectly increasing project costs.

Import/Export and Customs Duties

For companies sourcing laser equipment internationally, import duties, value-added taxes (VAT), and customs clearance fees can significantly impact acquisition costs. Tariff classifications for laser systems vary by country, and non-compliance may result in delays or penalties. Engaging a customs broker or legal expert may be necessary, adding to administrative expenses.

Facility Modifications and Infrastructure Needs

Laser systems may require specific electrical supply (e.g., 208V or 480V), cooling systems, and adequate ventilation. Retrofitting a facility to meet these requirements can involve substantial capital investment. Additionally, designated laser work zones with proper signage and access controls must be established to meet compliance standards.

Documentation and Audit Readiness

Maintaining detailed records of equipment maintenance, operator training, safety audits, and compliance certifications is often mandatory. Digital tracking systems or third-party audits may be required, particularly in regulated industries like aerospace or maritime. These administrative tasks, while indirect, contribute to the overall cost structure.

Insurance and Liability Coverage

Standard business insurance may not cover high-power laser operations. Specialized liability insurance is often needed to protect against accidents involving eye injury, fire, or damage to materials. Premiums vary based on risk assessment and facility setup, and must be included in the total cost evaluation.

By addressing these logistics and compliance considerations early, organizations can more accurately forecast the true cost of laser rust removal and avoid unexpected delays or penalties.

Conclusion on Sourcing Laser Rust Removal Cost

Sourcing laser rust removal services or equipment involves a careful evaluation of both upfront and long-term costs. While laser rust removal systems have a higher initial investment compared to traditional methods like sandblasting or chemical treatments, they offer significant advantages in terms of precision, environmental sustainability, reduced labor costs, and minimal substrate damage.

When sourcing, it is essential to consider not only the purchase price of the laser system but also operational expenses such as maintenance, energy consumption, operator training, and integration into existing workflows. Additionally, evaluating service providers versus in-house equipment acquisition can impact overall cost-effectiveness depending on usage frequency and scale.

Market research indicates that prices vary widely based on power output, portability, automation features, and brand reputation. Therefore, conducting a thorough cost-benefit analysis—including return on investment (ROI) over time—is critical for making an informed decision.

Ultimately, laser rust removal represents a forward-thinking, efficient, and eco-friendly solution, with costs gradually decreasing as the technology becomes more widespread. For businesses focused on long-term savings, process optimization, and environmental compliance, investing in laser rust removal can be a strategic and economically sound choice.