The global laser paint removal market is experiencing robust growth, driven by increasing demand for precision surface preparation in aerospace, automotive, and cultural heritage restoration industries. According to Grand View Research, the global laser cleaning market—of which paint removal is a significant segment—was valued at USD 868.3 million in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 17.4% from 2023 to 2030. This surge is fueled by the shift toward eco-friendly, non-abrasive cleaning methods that minimize waste and reduce operational downtime. Additionally, advancements in fiber laser technology have enhanced removal efficiency while preserving substrate integrity, making laser systems increasingly cost-effective over the long term. As industrial players prioritize sustainability and automation, the demand for high-performance laser paint removers continues to rise, positioning key manufacturers at the forefront of this technological evolution. The following six companies represent leading innovators in the space, recognized for their technical capabilities, global reach, and strong R&D investment in laser depainting solutions.

Top 6 Laser Removedor De Pintura Manufacturers (2026 Audit Report)

(Ranked by Factory Capability & Trust Score)

#1 Commercial & Industrial Laser Cleaning Service

Website: lasercleaning.co.nz

Key Highlights: Laser Cleaning provides mobile laser cleaning services for the commercial, industrial and specialist cleaning sectors throughout New Zealand….

#2 Laserax

Website: laserax.com

Key Highlights: Laserax works with the world’s leading manufacturers to implement laser cleaning, welding, texturing, and marking solutions.Missing: removedor pintura…

#3 PULSAR Laser

Website: pulsar-laser.es

Key Highlights: La máquina láser de eliminación de óxido y pintura FOX P CL está diseñada para materiales metálicos de grandes dimensiones. Por ejemplo, carrocerías de …Missing: removedor manuf…

#4 Eliminación de pintura con limpiador láser

Website: laserdmk.com

Key Highlights: El eliminador de pintura con limpieza láser no produce gases nocivos ni polvo, que pueden causar dificultad para respirar e irritación de la piel, a diferencia ……

#5 Removedor de óxido láser para aceite de pintura de óxido de metal

Website: hglaserfactory.com

Key Highlights: Removedor de óxido láser para aceite de pintura de óxido de metal ; Frecuencia. 50-20000Hz ; velocidad limpia. Menor o igual a 40M²/Hora. Menor o igual a 60 M²/ ……

#6 Laser Paint Stripper

Website: linxuanlaser.com

Key Highlights: El removedor de pintura láser elimina de manera rápida y eficaz la pintura del casco del barco sin causar corrosión ni daños mecánicos a la estructura. Esto ……

Expert Sourcing Insights for Laser Removedor De Pintura

2026 Market Trends for Laser Paint Removers

Rising Industrial Demand Drives Adoption

By 2026, the laser paint remover market is projected to experience significant growth, primarily fueled by increasing demand in aerospace, automotive, and marine industries. These sectors are prioritizing precision surface preparation and non-destructive maintenance, where traditional methods like sandblasting or chemical stripping pose risks to sensitive substrates. Laser technology enables selective paint removal without damaging underlying composite materials or metal alloys, aligning with OEM standards for structural integrity. Regulatory pressures to reduce hazardous waste and volatile organic compound (VOC) emissions are further accelerating the shift toward eco-friendly laser solutions.

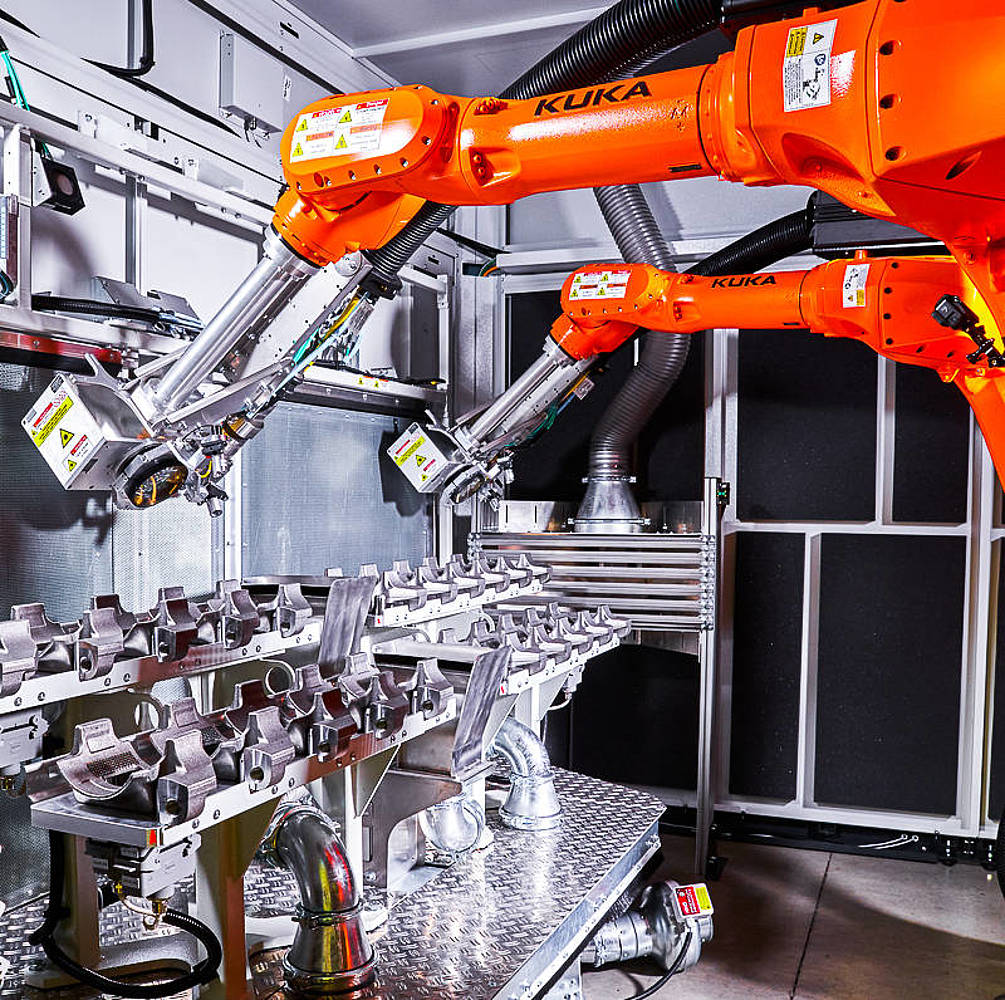

Technological Advancements Enhance Efficiency and Accessibility

Ongoing innovations in pulsed fiber lasers and robotic integration are making laser paint removal systems faster, safer, and more cost-effective. By 2026, expect wider adoption of portable and handheld laser units, expanding usability beyond large-scale facilities to field maintenance and restoration applications. Artificial intelligence (AI)-driven scanning systems will improve targeting accuracy, reducing processing time and minimizing human error. Additionally, advancements in real-time monitoring and fume extraction are addressing safety concerns, making compliance with occupational health standards more achievable.

Regional Growth and Competitive Landscape

North America and Europe are leading the market due to stringent environmental regulations and high investment in advanced manufacturing. However, Asia-Pacific is emerging as a high-growth region, particularly in China and Japan, driven by expanding aerospace and automotive sectors. Key players are focusing on strategic partnerships, product diversification, and after-sales support to capture market share. As prices for laser systems gradually decline due to economies of scale, small and medium enterprises (SMEs) are expected to adopt this technology more broadly by 2026.

Sustainability and Regulatory Tailwinds

Environmental regulations such as REACH, RoHS, and EPA standards are pushing industries to abandon chemical-based stripping methods. Laser paint removal produces minimal secondary waste and eliminates the need for toxic solvents, positioning it as a sustainable alternative. This regulatory tailwind, combined with corporate sustainability goals, is likely to make laser systems a preferred choice across industrial maintenance and restoration workflows in 2026.

Common Pitfalls When Sourcing Laser Paint Removers (Quality and Intellectual Property)

Sourcing laser paint removers from international suppliers—particularly from regions known for competitive manufacturing such as China—can present significant challenges related to product quality and intellectual property (IP) protection. Understanding these pitfalls is essential for businesses aiming to acquire reliable, compliant, and legally secure equipment.

Quality Inconsistencies and Lack of Standardization

One of the most frequent issues when sourcing laser paint removers is inconsistent product quality. Suppliers may advertise high-performance systems, but delivered units often fall short in critical areas:

- Underpowered or Misrepresented Specifications: Some manufacturers exaggerate laser wattage, beam accuracy, or removal efficiency. Units may lack proper calibration, resulting in uneven paint stripping or substrate damage.

- Poor Build Quality: Components such as cooling systems, optical lenses, and housings may be constructed with substandard materials, leading to frequent breakdowns and shortened equipment lifespan.

- Inadequate Safety Features: Reputable laser systems include safety interlocks, protective enclosures, and compliance with international standards (e.g., IEC 60825). Sourced units may omit these, posing operational hazards and liability risks.

- Lack of Certification: Many imported laser systems lack necessary certifications (CE, FDA, RoHS), indicating non-compliance with safety and environmental regulations in target markets.

To mitigate these risks, buyers should insist on third-party testing, request performance demonstrations, and verify compliance documentation before purchase.

Intellectual Property Infringement Risks

Laser paint removal technology often involves proprietary designs, software algorithms, and optical configurations protected by patents and trade secrets. Sourcing from unverified suppliers increases the risk of IP violations:

- Counterfeit or Cloned Systems: Some manufacturers reverse-engineer patented technologies without authorization, producing illegal copies of established brands. Purchasing such systems may expose the buyer to legal liability, especially in regulated industries.

- Unlicensed Software and Firmware: Laser control systems may include pirated or unlicensed software, which could lead to malfunctions, security vulnerabilities, or legal action from original developers.

- Voided IP Protections: Using or distributing infringing technology can invalidate a company’s own IP rights or disqualify them from government or defense contracts requiring IP compliance.

Due diligence is critical: conduct patent landscape reviews, verify supplier legitimacy, and include IP warranties in procurement contracts.

Inadequate After-Sales Support and Technical Documentation

Even if a laser paint remover initially performs well, long-term usability depends on reliable support:

- Missing or Poorly Translated Manuals: Technical documentation may be incomplete or inaccurately translated, complicating installation, maintenance, and training.

- Limited Spare Parts Availability: Suppliers may not stock replacement components, leading to extended downtime.

- Unresponsive Customer Service: Time zone differences, language barriers, and lack of local service centers can delay troubleshooting and repairs.

Procurement agreements should require comprehensive documentation, service-level agreements (SLAs), and access to technical support.

Conclusion

Sourcing laser paint removers requires careful evaluation beyond price and delivery terms. Ensuring quality, verifying intellectual property compliance, and securing post-purchase support are essential to avoid operational setbacks and legal exposure. Partnering with reputable suppliers, conducting on-site audits, and leveraging legal protections can significantly reduce these common pitfalls.

Logistics & Compliance Guide for Laser Removedor De Pintura

Product Classification and HS Code

The Laser Removedor De Pintura (Laser Paint Remover) is typically classified under the Harmonized System (HS) code 8543.70, which covers “Electrical machines and apparatus, having individual functions, not specified or included elsewhere in this chapter.” However, classification may vary depending on the specific technical design and primary function. It is essential to confirm the correct HS code with local customs authorities or a licensed customs broker to ensure accurate tariff application and compliance.

Import Regulations and Documentation

Importing a Laser Removedor De Pintura requires adherence to national and international regulations. Required documentation typically includes:

– Commercial invoice

– Packing list

– Bill of lading or air waybill

– Certificate of origin

– Technical specifications and user manual

– CE marking certificate (if applicable)

– FDA or equivalent regulatory approval for laser devices (if required by destination country)

Ensure all documentation is accurate and available in the official language of the importing country.

Laser Safety and Regulatory Compliance

Laser devices are subject to strict safety regulations due to potential health risks. The Laser Removedor De Pintura must comply with:

– IEC 60825-1: Safety of laser products – Equipment classification and requirements

– FDA 21 CFR Part 1040.10 (for U.S. imports): Performance standards for laser products

– CE Marking (for EU markets): Compliance with the EU’s Laser Products Directive and Machinery Directive

Verify that the device carries appropriate warning labels, safety interlocks, and laser classification (e.g., Class 4 laser), and that it includes a laser safety manual.

Packaging and Handling Requirements

Due to its sensitive optical and electronic components, the Laser Removedor De Pintura must be packaged to prevent damage during transit:

– Use shock-absorbent, anti-static materials

– Secure all moving parts and laser heads

– Clearly label packages with “Fragile,” “This Side Up,” and “Laser Equipment”

– Include desiccants if shipping to humid climates to prevent condensation

Follow manufacturer guidelines for crating and transportation.

Transportation and Shipping Modes

Choose the appropriate shipping method based on urgency, cost, and destination:

– Air Freight: Recommended for urgent deliveries; requires compliance with IATA Dangerous Goods Regulations if batteries (e.g., lithium-ion) are included

– Sea Freight: Cost-effective for bulk shipments; ensure container is temperature and humidity controlled

– Ground Transport: Suitable for regional distribution; secure equipment to prevent shifting

Always declare the shipment as containing laser equipment and high-power electronic devices.

Customs Clearance and Duties

Customs clearance may be delayed if documentation is incomplete or if the device is misclassified. Key considerations:

– Pay applicable import duties and VAT based on HS code and declared value

– Some countries impose additional testing or inspection for electronic and laser equipment

– Provide proof of electromagnetic compatibility (EMC) and radio frequency (RF) compliance if required

Work with a customs agent familiar with industrial laser equipment.

End-Use Certification and End-User Declarations

Certain countries require an End-User Declaration (EUD) to confirm the Laser Removedor De Pintura will be used for legitimate industrial or commercial purposes and not for military or prohibited applications. This is particularly relevant when exporting to regions with strict dual-use regulations.

Warranty, Service, and Spare Parts Logistics

Plan for after-sales support by:

– Establishing service centers or partnering with local technicians

– Stocking critical spare parts (e.g., laser diodes, cooling units) in key markets

– Ensuring repair shipments comply with import rules for warranty replacements (often duty-free under specific conditions)

Maintain a logistics strategy for reverse logistics and equipment returns.

Environmental and Disposal Compliance

At end-of-life, the Laser Removedor De Pintura must be disposed of according to WEEE (Waste Electrical and Electronic Equipment) directives in the EU or equivalent local regulations. Ensure proper recycling of electronic components, batteries, and laser modules to prevent environmental harm.

Summary and Best Practices

To ensure smooth logistics and compliance:

– Verify HS code and import requirements for each destination

– Prioritize safety certification and labeling

– Use specialized packaging and insured transport

– Partner with experienced freight forwarders and customs brokers

– Maintain up-to-date regulatory documentation and stay informed about changes in laser equipment legislation

Conclusión sobre el sourcing de un removedor de pintura por láser

La búsqueda y selección de un sistema removedor de pintura por láser requiere una evaluación cuidadosa de varios factores técnicos, económicos y operativos. Este tipo de tecnología representa una solución avanzada, eficiente y respetuosa con el medio ambiente en comparación con métodos tradicionales como el chorro de arena o el uso de químicos. Al final del proceso de sourcing, se concluye que:

-

Efectividad y precisión: Los sistemas de eliminación láser ofrecen un alto grado de control, permitiendo la remoción selectiva de capas de pintura sin dañar el sustrato, lo cual es especialmente valioso en industrias como la aeroespacial, automotriz y de restauración.

-

Sostenibilidad: Al no generar residuos químicos ni partículas abrasivas, esta tecnología reduce significativamente el impacto ambiental y cumple con regulaciones ecológicas cada vez más estrictas.

-

Costo-beneficio a largo plazo: Aunque la inversión inicial es elevada, el ahorro en mano de obra, mantenimiento y disposición de residuos, junto con la mayor vida útil de los equipos tratados, justifican el costo en aplicaciones industriales continuas.

-

Disponibilidad y proveedores: Existen proveedores especializados a nivel global, tanto en Europa como en Asia y América del Norte. Es fundamental evaluar el soporte técnico local, la posibilidad de capacitación y la garantía del equipo antes de tomar una decisión.

-

Personalización y escalabilidad: Las soluciones láser pueden adaptarse a diferentes tamaños de piezas y volúmenes de producción, lo que las hace versátiles para distintos escenarios industriales.

En resumen, el sourcing de un removedor de pintura por láser debe orientarse hacia un equilibrio entre calidad técnica, soporte postventa y viabilidad económica. Esta tecnología no solo mejora la eficiencia operativa, sino que también posiciona a las empresas como líderes en innovación y sostenibilidad industrial.