The global laser technology market is experiencing robust expansion, driven by increasing demand across industrial, medical, and cosmetic applications—segments where precision laser removal tools play a pivotal role. According to a 2023 report by Mordor Intelligence, the global laser system market was valued at USD 15.6 billion and is projected to grow at a CAGR of 6.8% from 2024 to 2029. This growth is fueled by advancements in laser accuracy, rising automation in manufacturing, and expanding applications in material processing and dermatology. As industries prioritize non-contact, high-precision removal and ablation solutions, the need for reliable laser removal tool manufacturers has intensified. In this competitive landscape, a select group of companies are leading innovation, scalability, and technological integration. Based on market presence, product performance, and technological investment, here are the top 9 laser removal tool manufacturers shaping the future of laser-based precision systems.

Top 9 Laser Removal Tool Manufacturers (2026 Audit Report)

(Ranked by Factory Capability & Trust Score)

#1 Laser Machine – Laser Equipment Manufacturer

Website: dplaser.com

Key Highlights: DPLASER is a leading manufacturer & factory of industrial laser welding, laser cutting, laser marking and laser cleaning machines….

#2 Laser Processing Solutions

Website: novantaphotonics.com

Key Highlights: Discover laser processing solutions by Novanta, experts in advanced Laser technology. Learn more about our industrial & medical laser solutions….

#3 FOX P CL – laser for removing rust

Website: pulsar-laser.com

Key Highlights: An innovative laser cleaner that revolutionizes the maintenance and restoration of large vehicles and industrial equipment….

#4 Laserax

Website: laserax.com

Key Highlights: Laserax works with the world’s leading manufacturers to implement laser cleaning, welding, texturing, and marking solutions….

#5 P-laser Industrial laser cleaning

Website: p-laser.com

Key Highlights: we engineer and manufacture the most advanced—and most powerful—pulsed industrial laser cleaning systems on the market, built for both manual and automated ……

#6 Laser Photonics

Website: laserphotonics.com

Key Highlights: Laser Photonics manufactures reliable, safe, and eco-friendly Laser Cleaning, Laser Cutting, Laser Engraving, Laser Marking, and Laser Welding solutions….

#7 SFX Laser

Website: sfxlaser.com

Key Highlights: SFX Laser is a 20+ years professional laser equipment manufacturer including laser cleaning machine, laser welding machine, fiber laser engraver, ……

#8 Clean Laser Systems

Website: cleanlaser.de

Key Highlights: IPG | cleanLASER has been developing and producing high-precision laser systems for cleaning and industrial surface treatment for more than 20 years….

#9 IPG Photonics

Website: ipgphotonics.com

Key Highlights: IPG Photonics manufactures high-performance fiber lasers, amplifiers, and laser systems for diverse applications and industries. Discover your solution….

Expert Sourcing Insights for Laser Removal Tool

H2: 2026 Market Trends for Laser Removal Tools

The global market for laser removal tools is poised for significant transformation by 2026, driven by technological innovation, expanding applications, and shifting industry demands. Key trends shaping the landscape include:

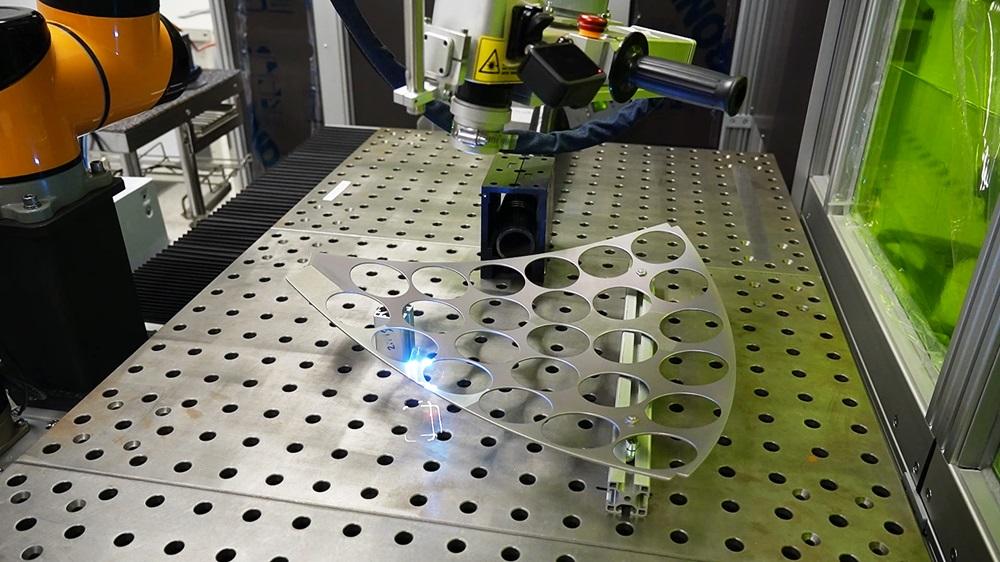

1. Surge in Industrial Automation and Robotics Integration

By 2026, laser removal tools will increasingly be integrated into automated production lines and robotic systems. Industries such as aerospace, automotive, and electronics manufacturing are adopting laser ablation for precision coating removal, rust elimination, and surface preparation. The growing emphasis on Industry 4.0 and smart factories will accelerate demand for laser systems that offer consistency, reduced human error, and seamless compatibility with IoT-enabled workflows.

2. Advancements in Ultrafast and Fiber Laser Technology

Ultrafast (picosecond and femtosecond) and high-power fiber lasers will dominate technological development. These systems offer superior precision, minimal heat-affected zones, and the ability to remove delicate coatings without damaging substrates. By 2026, expect wider commercial availability of compact, cost-efficient ultrafast lasers, making them accessible to mid-sized enterprises and expanding their use in medical device manufacturing and heritage conservation.

3. Expansion into New Application Segments

Beyond traditional roles in paint and corrosion removal, laser tools are entering emerging sectors:

– Electronics Recycling: Selective removal of conformal coatings and solder layers for PCB reclamation.

– Green Energy: Maintenance of solar panels and wind turbine blades, enabling sustainable upkeep without chemical solvents.

– Medical and Dental: Precision cleaning of surgical instruments and dental implants, driven by sterility and non-contact advantages.

4. Emphasis on Sustainability and Regulatory Compliance

Stringent environmental regulations (e.g., VOC emission limits) are driving industries away from chemical stripping methods. Laser removal, being dry and chemical-free, aligns with ESG (Environmental, Social, and Governance) goals. By 2026, companies will prioritize laser solutions to meet compliance standards and reduce hazardous waste, particularly in aerospace and defense sectors.

5. Growth in Portable and Handheld Systems

Demand for mobile laser removal tools will rise, especially in maintenance, repair, and overhaul (MRO) operations. Advances in battery technology and thermal management will enable lighter, more ergonomic handheld devices. These systems support on-site applications in shipbuilding, infrastructure, and field servicing, improving operational flexibility.

6. Regional Market Diversification

While North America and Europe remain key markets due to advanced manufacturing and strict environmental laws, Asia-Pacific—led by China, Japan, and South Korea—will see the fastest growth. Increasing industrial automation, rising investments in high-tech manufacturing, and government support for green technologies will fuel regional adoption.

7. Cost Reduction and Market Democratization

As production scales and component costs decline (e.g., diodes, optics), laser removal tools will become more affordable. This trend will open the market to small and medium-sized enterprises (SMEs), broadening the user base beyond large OEMs and specialized service providers.

Conclusion

By 2026, the laser removal tool market will be characterized by smarter, greener, and more accessible technology. Integration with automation, expansion into eco-sensitive applications, and ongoing cost reductions will drive sustained growth, positioning laser ablation as a cornerstone of modern, sustainable surface treatment solutions.

Common Pitfalls When Sourcing Laser Removal Tools (Quality, IP)

Sourcing laser removal tools—particularly for applications like semiconductor manufacturing or precision engineering—requires careful evaluation to avoid costly mistakes. Two critical areas where organizations often encounter challenges are quality assurance and intellectual property (IP) risks. Overlooking these aspects can lead to operational disruptions, legal exposure, and compromised product integrity.

Quality-Related Pitfalls

1. Inadequate Verification of Performance Specifications

Many suppliers may advertise high-power or precision laser tools without providing verifiable test data. Relying solely on datasheet claims without independent validation can result in tools that fail to meet process requirements, such as insufficient beam stability or inaccurate pulse control.

2. Poor Build Quality and Material Selection

Low-cost suppliers may use substandard materials for critical components (e.g., lenses, cooling systems, or laser diodes), leading to premature failure, inconsistent performance, or safety hazards. Tools not designed for industrial environments may degrade quickly under continuous operation.

3. Lack of Certification and Compliance

Some sourced tools may not comply with international safety and quality standards (e.g., ISO 13485, IEC 60825 for laser safety). Using non-compliant equipment can expose organizations to regulatory penalties and increase liability risks.

4. Insufficient After-Sales Support and Calibration Services

Reliable laser tools require regular maintenance and recalibration. Sourcing from vendors without local technical support or service networks can lead to extended downtime and increased total cost of ownership.

Intellectual Property (IP)-Related Pitfalls

1. Risk of Infringing Patented Technology

Laser removal systems often incorporate patented optical designs, control algorithms, or beam delivery mechanisms. Sourcing from manufacturers that do not license or respect existing IP can expose the buyer to infringement lawsuits, especially in regulated or litigious markets.

2. Unclear Ownership of Customized Solutions

When working with suppliers to modify or co-develop tools, contracts may fail to explicitly assign IP rights. This can result in disputes over ownership, limiting your ability to scale, modify, or protect the technology.

3. Use of Open-Source or Third-Party Code Without Compliance

Embedded software in laser control systems may use open-source components without proper licensing compliance. This can lead to forced disclosure of proprietary modifications or legal action if license terms are violated.

4. Inadequate Protection of Sourced Designs

When sourcing custom tools, failure to secure confidentiality agreements or IP assignment clauses may allow the supplier to reuse your design for competitors, eroding your competitive advantage.

Mitigation Strategies

To avoid these pitfalls, organizations should:

– Conduct thorough due diligence on suppliers, including site audits and reference checks.

– Require third-party testing and certification documentation.

– Engage legal counsel to review IP clauses in procurement contracts.

– Include clear warranties, service level agreements (SLAs), and IP ownership terms in sourcing agreements.

Proactively addressing quality and IP concerns ensures reliable performance, regulatory compliance, and long-term protection of technological investments.

Logistics & Compliance Guide for Laser Removal Tool

This guide outlines the key logistics and compliance considerations for the safe handling, transportation, storage, and regulatory adherence of Laser Removal Tools. These devices, commonly used in medical, aesthetic, and industrial applications, are subject to strict regulations due to their use of high-energy laser radiation.

Regulatory Classification

Laser Removal Tools are classified under international and national regulatory frameworks based on laser safety standards. In the United States, the Food and Drug Administration (FDA) regulates these devices under 21 CFR Part 1040.10 and 1040.11. Internationally, compliance with the International Electrotechnical Commission (IEC) 60825-1 standard for laser product safety is required. Devices are categorized by laser class (typically Class 4 for removal tools), which dictates safety controls, labeling, and operational protocols.

Shipping and Transportation

Transport of Laser Removal Tools must comply with hazardous material regulations if applicable, particularly due to high-voltage components, batteries, or laser classification. While lasers themselves are not typically classified as hazardous materials under IATA or IMDG regulations when not powered, proper packaging is essential to prevent damage. Use original manufacturer packaging or equivalent shock-resistant, electrostatic-protective materials. Clearly label units with appropriate warnings (e.g., “Laser Radiation,” “Do Not Operate,” “Fragile”). Air, sea, and ground shipments should include documentation confirming compliance with relevant safety standards.

Import/Export Compliance

Exporting or importing Laser Removal Tools requires adherence to the regulations of both origin and destination countries. In the U.S., exports must comply with the Department of Commerce’s Export Administration Regulations (EAR), and may require a license depending on the technology’s specifications and destination. The FDA requires an export certificate for medical laser devices shipped abroad. Similarly, the European Union mandates CE marking under the Medical Devices Regulation (MDR) or Machinery Directive, as applicable. Ensure all documentation—commercial invoice, packing list, conformity certificates, and technical files—is accurate and complete.

Storage Requirements

Store Laser Removal Tools in a secure, climate-controlled environment, protected from moisture, dust, temperature extremes (typically 10°C to 40°C), and direct sunlight. Keep units in their protective casing when not in use. Access should be restricted to trained personnel only. Batteries, if removable, should be stored separately according to local regulations for lithium-ion or other battery types to reduce fire risk.

Handling and Installation

Only trained and authorized personnel should handle and install Laser Removal Tools. Prior to installation, verify that the facility meets electrical, ventilation, and safety requirements. Install in accordance with the manufacturer’s instructions and local building codes. Implement laser safety protocols including controlled access, use of protective eyewear, and installation of warning signs in operational areas.

Safety and Compliance Documentation

Maintain up-to-date compliance documentation including:

– FDA 510(k) clearance or PMA (for medical devices)

– CE Certificate of Conformity

– IEC 60825-1 and IEC 60601-1 (for medical electrical equipment) test reports

– Laser safety officer (LSO) designation and training records

– Standard Operating Procedures (SOPs) for operation and maintenance

End-of-Life and Disposal

Dispose of Laser Removal Tools in accordance with local, national, and international environmental regulations, including WEEE (Waste Electrical and Electronic Equipment) in the EU and EPA guidelines in the U.S. Lasers, optical components, and batteries may require special handling. Coordinate with certified e-waste recyclers or the manufacturer’s take-back program to ensure safe decommissioning and data security (if the device contains stored information).

Training and Audits

Ensure all operators and logistics personnel receive appropriate training on laser safety, handling procedures, and regulatory compliance. Conduct regular internal audits to verify ongoing compliance with safety standards, shipping protocols, and storage practices. Maintain logs of training, maintenance, and incident reports for regulatory review.

Adherence to this guide ensures the safe, legal, and efficient lifecycle management of Laser Removal Tools across global supply chains.

Conclusion: Sourcing a Laser Removal Tool

After a thorough evaluation of available laser removal tools in the market, it is evident that selecting the right equipment requires careful consideration of application needs, precision requirements, safety standards, and cost-effectiveness. The optimal laser removal solution should offer high accuracy, minimal thermal impact on surrounding materials, and compatibility with the targeted substrates—whether for industrial coating removal, medical applications, or precision manufacturing.

Vendor reliability, technical support, maintenance requirements, and compliance with regulatory standards (such as FDA, CE, or OSHA) are critical factors in the sourcing decision. Additionally, emerging technologies offering automation, handheld portability, or integrated safety features may provide long-term operational advantages.

Ultimately, sourcing the most suitable laser removal tool involves balancing performance, durability, and total cost of ownership. By aligning technical specifications with operational goals and conducting pilot testing where feasible, organizations can make informed procurement decisions that enhance efficiency, safety, and productivity in their respective fields.