The global laser rust removal market is experiencing robust growth, driven by increasing demand for precision cleaning solutions in industrial maintenance, automotive, aerospace, and heritage conservation sectors. According to Mordor Intelligence, the laser cleaning equipment market is projected to grow at a CAGR of over 16% from 2023 to 2028, with rust and oxide removal emerging as one of the fastest-growing applications. This surge is fueled by the shift from traditional abrasive and chemical methods toward eco-friendly, non-contact technologies that reduce waste and improve operational safety. As industries prioritize sustainability and efficiency, manufacturers of laser para remover óxido (oxide removal lasers) are expanding their technological capabilities and production capacity. Based on market presence, innovation, and global reach, the following eight manufacturers stand out as leaders in delivering high-performance laser solutions for rust and oxide removal.

Top 8 Laser Para Remover Oxido Manufacturers (2026 Audit Report)

(Ranked by Factory Capability & Trust Score)

#1 ZAC Laser Machine

Founded: 2004

Website: zaclaser.com

Key Highlights: ZAC laser is the professional manufacture since 2004 which sell many laser machines such as laser rust removal-laser cleaning machine, laser engraver-laser …Missing: remover man…

#2 Rust Removal with Laser Cleaning

Website: laserax.com

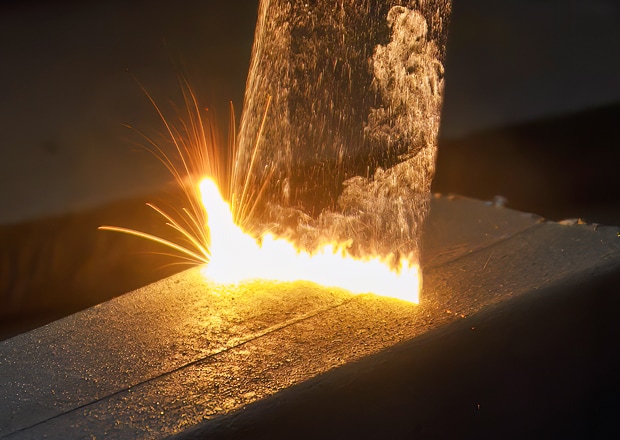

Key Highlights: Laser rust removal is a non-contact method that continuously removes rust while drastically lowering maintenance costs….

#3 Understanding Laser Rust Removal

Website: lasermarktech.com

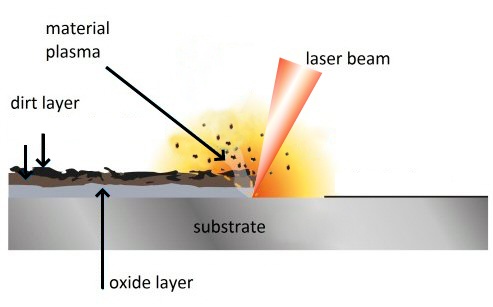

Key Highlights: Laser rust removal is a non-contact cleaning process that uses a laser beam to remove rust, oxide layers, and other contaminants from surfaces….

#4 What is Laser Rust Removal & How Does it Work?

Website: keyence.eu

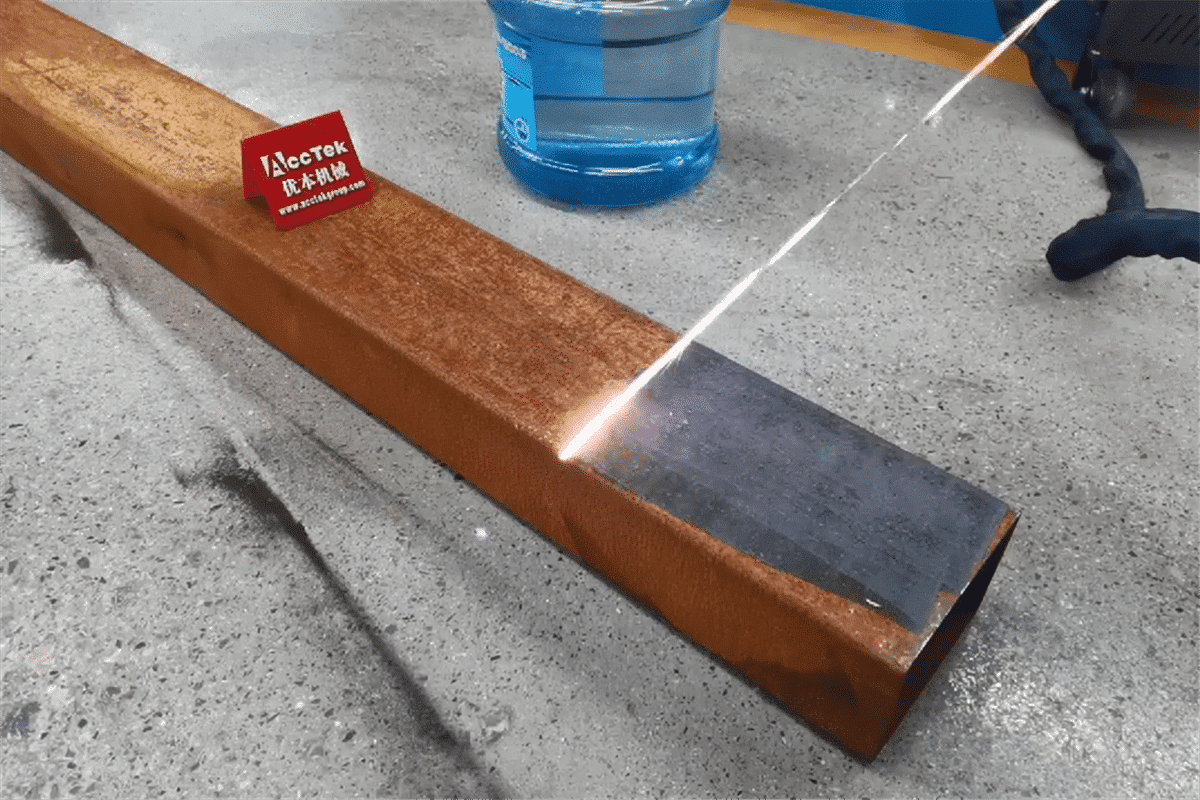

Key Highlights: Laser rust removal is a laser cleaning process that utilises laser ablation. Laser ablation is achieved by using a laser cleaner with a high peak power and ……

#5 Limpiadoras láser manuales

Website: ipgphotonics.com

Key Highlights: Eliminación de óxido. La ablación láser manual es un método rápido y flexible para eliminar el óxido de metales ferrosos como aceros, aceros inoxidables y ……

#6 Máquina de limpieza láser para la eliminación de óxido

Website: bogonglaser.com

Key Highlights: In this article, we will explain how laser rust removal works, its benefits and limitations, typical applications, and safety tips. Laser ……

#7 PULSAR Laser

Website: pulsar-laser.es

Key Highlights: Muy eficaz para eliminar óxido y pintura. El limpiador láser FOX P CL de PULSAR Laser está diseñado para aplicaciones de limpieza de alta resistencia, ……

#8 China Industrial Laser Cleaning Machine for Sale Offer Best Prices

Website: dwlaser.net

Key Highlights: Laser cleaning machine, also known as laser rust removal machine, laser rust removal gun, laser blasting machine, laser derusting machine, ……

Expert Sourcing Insights for Laser Para Remover Oxido

H2: 2026 Market Trends for Laser Paint and Rust (Oxide) Removal Technology

The global market for laser-based paint and rust (oxide) removal systems—commonly referred to as “Laser Para Remover Óxido” in Spanish-speaking regions—is projected to experience significant growth and transformation by 2026. Driven by advancements in laser technology, increasing environmental regulations, and growing demand for precision surface treatment in industrial sectors, this market is poised for innovation and expansion.

1. Rising Adoption Across Key Industries

By 2026, the aerospace, automotive, maritime, and heritage restoration industries are expected to be the primary adopters of laser oxide removal systems. The technology’s ability to selectively remove rust, paint, and coatings without damaging underlying substrates makes it highly attractive for maintenance and refurbishment operations. In the aerospace sector, for instance, demand is fueled by the need for non-abrasive, residue-free surface preparation for aircraft components.

2. Environmental and Regulatory Drivers

Stringent environmental regulations are accelerating the shift from traditional abrasive blasting and chemical stripping methods to eco-friendly alternatives. Laser cleaning emits no secondary waste, requires no chemicals, and produces minimal particulate matter when coupled with filtration systems. Governments in Europe and North America are increasingly incentivizing green manufacturing technologies, further boosting the appeal of laser rust removers by 2026.

3. Technological Advancements and Cost Reductions

Ongoing improvements in fiber laser efficiency, portability, and automation are making laser oxide removal systems more accessible. By 2026, mid-power (500W–2kW) fiber lasers are expected to dominate the market due to their optimal balance of performance and operational cost. Integration with robotics and AI-driven path planning allows for autonomous rust detection and removal, particularly in large-scale industrial applications such as ship hull maintenance.

4. Regional Growth Dynamics

Europe is expected to lead the market in 2026, driven by strong industrial automation and environmental compliance standards. Germany, France, and the UK are investing heavily in laser cleaning R&D. Meanwhile, Asia-Pacific—particularly China and South Korea—is witnessing rapid adoption in automotive and electronics manufacturing, supported by government initiatives promoting Industry 4.0 technologies.

5. Challenges and Market Barriers

Despite positive momentum, high initial equipment costs and a lack of skilled operators remain barriers to widespread adoption, especially among small and medium-sized enterprises (SMEs). However, the growing availability of rental services and turnkey solutions is expected to mitigate these challenges by 2026.

6. Competitive Landscape

The market is becoming increasingly competitive, with key players such as Clean Laser (Germany), Laser Photonics (USA), and Advalor (UK) expanding their product lines and geographic reach. Strategic partnerships with industrial automation firms are expected to drive innovation and market penetration.

Conclusion

By 2026, the Laser Para Remover Óxido market will be characterized by technological maturity, regulatory support, and growing industrial demand. As laser systems become more efficient, affordable, and intelligent, they are set to replace conventional cleaning methods in critical applications, marking a pivotal shift toward sustainable and precision-driven surface treatment across global industries.

Common Pitfalls When Sourcing Laser Para Remover Óxido (Quality and IP Considerations)

When sourcing a laser for removing oxidation (commonly referred to as “Laser Para Remover Óxido”), buyers often encounter several critical challenges related to both quality and intellectual property (IP). Awareness of these pitfalls is essential to ensure performance, reliability, and legal compliance.

Quality-Related Pitfalls

1. Inconsistent Laser Performance and Output Power

Many low-cost suppliers advertise high-power lasers, but actual output often falls short of specifications. This leads to inefficient oxide removal, inconsistent results, or frequent rework. Always verify power ratings through third-party testing reports or on-site demonstrations.

2. Poor Beam Quality and Focus Control

Effective oxide removal requires precise beam focus and stability. Inferior lasers may suffer from beam divergence or poor spot quality, reducing cleaning efficiency and potentially damaging the underlying substrate.

3. Lack of Robust Build Quality and Cooling Systems

Industrial laser cleaning systems operate under demanding conditions. Units with inadequate thermal management or substandard components are prone to overheating and premature failure, increasing downtime and maintenance costs.

4. Absence of Safety Features and Certifications

Reputable systems include safety interlocks, protective housings, and compliance with international standards (e.g., IEC 60825). Sourcing from unverified suppliers may result in non-compliant equipment, exposing users to safety risks and regulatory penalties.

5. Insufficient After-Sales Support and Spare Parts Availability

Many overseas suppliers offer attractive upfront pricing but lack local technical support, training, or spare parts access. This can lead to extended downtimes and increased total cost of ownership.

Intellectual Property (IP) Risks

1. Use of Counterfeit or Reverse-Engineered Components

Some manufacturers replicate proprietary laser designs or use counterfeit optical components without authorization. These systems may infringe on patents and trademarks, exposing the buyer to legal liability, especially in regulated markets.

2. Unclear IP Ownership and Licensing

When integrating laser systems into larger machinery or processes, unclear IP rights can restrict usage, resale, or modification. Always request documentation confirming legitimate IP licensing, particularly for core technologies like fiber lasers or control software.

3. Risk of Infringement in Export Markets

Using a laser system with questionable IP origins may result in customs seizures or legal action when exporting products or equipment. This is particularly critical in regions like the EU or North America, where IP enforcement is strict.

4. Lack of Transparency in Technical Documentation

Suppliers that withhold schematics, firmware details, or source code may be hiding IP violations. Transparent documentation is not only a sign of legitimacy but also critical for compliance, maintenance, and future upgrades.

Conclusion

To avoid these pitfalls, conduct thorough due diligence: verify technical specifications with independent tests, request proof of certifications, audit the supplier’s IP compliance, and prioritize vendors with strong service networks. Investing in a high-quality, legally sound laser system ensures long-term reliability, safety, and operational success.

H2: Logistics & Compliance Guide for Laser Para Remover Óxido (Laser Rust Remover)

This guide outlines the essential logistics and compliance considerations for the safe, legal, and efficient handling, transportation, storage, and use of Laser Para Remover Óxido (Laser Rust Remover). Adherence is crucial for operational integrity, regulatory compliance, and personnel safety.

1. Regulatory Classification & Documentation

- Product Identification: Ensure the product has a clear, unambiguous name (“Laser Para Remover Óxido” or its technical model name) and unique identifier (e.g., model number, SKU).

- Safety Data Sheet (SDS): Obtain and maintain the up-to-date SDS (MSDS) compliant with local regulations (e.g., GHS in most countries, OSHA HazCom 2012 in the US). Key SDS sections:

- Section 2 (Hazards Identification): Classify hazards (e.g., Laser Radiation Class 4 – EXTREME DANGER, Electrical Hazard, Fire Hazard from sparks/ignition, Potential for fumes/particulates from ablated material).

- Section 3 (Composition): Identify key components (laser source type – e.g., Fiber Laser, Nd:YAG; power supply; cooling system components; any consumables).

- Section 4 (First Aid): Procedures for laser exposure (eye/skin), electrical shock, inhalation of fumes.

- Section 7 (Handling & Storage): Critical for logistics (see below).

- Section 8 (Exposure Controls/PPE): Mandates specific PPE requirements.

- Section 9 (Physical/Chemical Properties): Includes power, wavelength, beam characteristics.

- Section 14 (Transport Information): Crucial for Logistics. Specifies UN number (if applicable – often UN 3481, BATTERY, LITHIUM ION if containing Li-ion batteries), proper shipping name, hazard class (e.g., Class 9, Miscellaneous Dangerous Goods for the laser hazard itself under some regulations, or primarily Class 8 for batteries), packing group, special provisions, and packaging instructions (e.g., IATA DGR, IMDG Code, ADR). Note: The laser device itself is often not a “dangerous good” for transport unless it contains batteries or hazardous materials; the primary hazard is operational.

- Compliance Certificates: Maintain valid certificates proving compliance with relevant standards:

- Laser Safety: IEC 60825-1 (Safety of laser products), FDA 21 CFR 1040.10/1040.11 (US), EN/IEC 60825 (EU), local equivalents. Certificate should confirm Class 4 laser output.

- Electrical Safety: IEC 61010-1 (Safety requirements for electrical equipment for measurement, control, and laboratory use), UL/CSA (North America), CE (EU – includes EMC Directive 2014/30/EU and potentially Low Voltage Directive 2014/35/EU).

- EMC (Electromagnetic Compatibility): IEC 61326-1.

- Import/Export Documentation: For international movement, prepare:

- Commercial Invoice

- Packing List

- Bill of Lading/Air Waybill

- Certificate of Origin

- Export License (if required by country/device type – check EAR/USML/ITAR implications, especially for high-power lasers)

- Import Permits (if required by destination country)

2. Packaging & Handling

- Transport Packaging:

- Use the original manufacturer’s packaging whenever possible. It is designed for shock, vibration, and environmental protection during transit.

- If repackaging is necessary, use heavy-duty, double-walled cardboard or a robust wooden crate with substantial internal cushioning (foam inserts, molded pulp, ample bubble wrap).

- Securely immobilize the laser unit, power supply, cables, and accessories within the packaging to prevent movement. Use blocking and bracing.

- Protect Optics: Ensure laser output windows and any sensitive lenses are covered with protective caps and cushioned.

- Mark “Fragile,” “This Side Up,” “Do Not Stack,” and include any required hazard labels based on the SDS (e.g., “Class 4 Laser Radiation,” “Dangerous Goods” label if batteries are shipped separately or included per regulations).

- Battery Handling: Lithium-ion batteries (if present) are HIGH RISK for transport. They must be:

- Removed from the device if possible (strongly preferred).

- Packed according to UN 38.3 testing requirements.

- Protected from short circuit (terminals taped, individual plastic bags).

- Packed in limited quantities per IATA/IMDG/ADR regulations (often max 2% State of Charge for air, specific watt-hour limits). Consult IATA DGR Section II or III strictly. Ship separately if not installed.

- Handling Procedures:

- Train personnel on the hazards (laser, electrical, weight, pinch points).

- Use appropriate mechanical aids (dolly, forklift) for heavy units. Never lift by cables or handles not designed for lifting.

- Avoid dropping, tipping, or applying impact.

- Maintain upright orientation unless specified otherwise by the manufacturer.

- Protect from extreme temperatures, moisture, dust, and direct sunlight during handling and loading/unloading.

3. Transportation

- Mode Selection: Standard ground freight (truck) is typical. Air transport is possible but requires strict adherence to IATA Dangerous Goods Regulations (DGR) for any lithium batteries. Sea freight subject to IMDG Code.

- Carrier Selection: Use carriers experienced in handling sensitive electronic equipment and, if applicable, certified Dangerous Goods (DG) shippers for battery transport. Provide them with the SDS Section 14 and completed Dangerous Goods Declaration if required.

- Vehicle Requirements: Ensure the transport vehicle provides shelter from weather, temperature extremes, and excessive vibration. Secure the load to prevent shifting. No smoking in the vicinity of the load.

- Documentation: Ensure all shipping documents (Bill of Lading, Air Waybill, DG Declaration if applicable) are accurate, complete, and accompany the shipment. Include a copy of the SDS.

4. Storage

- Location: Store in a dry, clean, well-ventilated, temperature-controlled indoor area (typically 5°C to 40°C / 41°F to 104°F, consult manual). Avoid areas prone to flooding, extreme heat (e.g., near boilers), or freezing.

- Environment: Protect from dust, moisture, corrosive atmospheres, direct sunlight, and electromagnetic interference.

- Security: Store in a secure area (locked cabinet or room) to prevent unauthorized access, especially given the Class 4 laser hazard. Restrict access to trained personnel only.

- Stacking: If stacking is permitted by the manufacturer, do not exceed the maximum stack height indicated on the packaging. Place heavier items on the bottom.

- Separation: Store away from flammable materials (solvents, fuels, combustible dust) due to spark/ignition risk during operation. Store lithium batteries separately in a non-combustible, fire-resistant container if not installed, following specific battery storage guidelines (cool, dry, 30-50% charge recommended).

5. Operational Use & On-Site Compliance

- Laser Safety Program: Implement a comprehensive program per ANSI Z136.1 (US) or IEC 60825 standards:

- Nominal Hazard Zone (NHZ): Establish and barricade the area where beam or diffuse reflections exceed the Maximum Permissible Exposure (MPE).

- Engineering Controls: Use interlocks, beam enclosures, curtains (specific for laser wavelength), and remote operation where feasible.

- Administrative Controls: Develop Standard Operating Procedures (SOPs), implement training, enforce authorized personnel only, and use warning signs/lights (“Laser On,” “Danger – Class 4 Laser”).

- Personal Protective Equipment (PPE): Mandatory use of Laser Protective Eyewear (LPE) specifically rated for the laser’s wavelength and power density (Optical Density – OD). Also required: flame-resistant clothing, gloves (cut/abrasion resistant), hearing protection (if noise levels are high), and respiratory protection (if fumes/particulates are generated – requires hazard assessment and potentially local exhaust ventilation).

- Ventilation: Use Local Exhaust Ventilation (LEV) at the point of ablation to capture generated fumes and airborne particulates (metal oxides, potential coatings). Conduct air quality monitoring if necessary.

- Electrical Safety: Ensure proper grounding. Use GFCI outlets if required. Follow lockout/tagout (LOTO) procedures during maintenance.

- Waste Management: Treat ablated material (rust, paint, coating particles) as hazardous waste if it contains regulated substances (e.g., lead, cadmium, chromium VI). Characterize the waste and dispose of according to local, state/provincial, and federal regulations (e.g., RCRA in the US). Use appropriate containment (sealed, labeled containers).

- Maintenance: Only trained, authorized personnel should perform maintenance. Follow manufacturer’s schedule and procedures strictly. Ensure LOTO is applied.

6. Key Compliance Requirements Summary

| Aspect | Key Requirement | Governing Standard/Regulation Example |

| :————– | :—————————————————————————— | :——————————————— |

| Laser Hazard| Class 4 Laser Safety Controls (Engineering, Admin, PPE) | ANSI Z136.1, IEC 60825-1, FDA 21 CFR 1040.10 |

| Electrical | Equipment Safety, Grounding, LOTO | IEC 61010-1, NFPA 70E, OSHA 1910.331-335 |

| EMC | Electromagnetic Emissions & Immunity | IEC 61326-1, FCC Part 15, EMC Directive 2014/30/EU |

| Transport | Packaging, Labeling, Documentation (esp. for Li-ion batteries) | IATA DGR, IMDG Code, ADR, 49 CFR (DOT) |

| Environment | Fume/Particulate Control, Waste Management (Hazardous Waste if applicable) | OSHA PELs, NIOSH RELs, RCRA, local EPA/EMA regs |

| Documentation| Up-to-date SDS, Compliance Certificates (Laser, Electrical, EMC), Shipping Docs | GHS, REACH (if applicable), Customs Regs |

7. Continuous Improvement

- Regular Audits: Conduct periodic audits of storage, handling, transport, and operational safety procedures.

- Training Updates: Provide refresher training on laser safety, PPE, and emergency procedures annually or after incidents.

- SDS Review: Review the SDS at least annually and whenever there is a change in the product or regulations.

- Incident Reporting: Establish a clear procedure for reporting and investigating any safety incidents (laser exposure, electrical incident, spill, fire).

Disclaimer: This guide provides general information. Always consult the specific manufacturer’s instructions, the latest version of the Safety Data Sheet (SDS), and all applicable local, national, and international regulations (OSHA, FDA, DOT, IATA, IMDG, ADR, local environmental agencies, fire codes) for the definitive requirements governing your specific Laser Para Remover Óxido model and location. Regulations vary significantly by jurisdiction.

Conclusión sobre el fuentes de láser para remover óxido

La selección de una fuente láser adecuada para la eliminación de óxido es crucial para garantizar un proceso eficiente, preciso y seguro. Los láseres de fibra, particularmente aquellos con longitud de onda en torno a 1064 nm, se han demostrado como la opción más efectiva y ampliamente utilizada para este tipo de aplicación. Ofrecen una excelente absorción por parte del óxido metálico, permitiendo la descomposición y evaporación del óxido sin dañar significativamente el sustrato metálico subyacente.

Además, las ventajas del uso de tecnología láser —como la ausencia de contacto físico, el bajo impacto ambiental (al no requerir productos químicos ni abrasivos), y la posibilidad de automatización— lo convierten en una solución sostenible y de alto rendimiento en comparación con métodos tradicionales como el chorro de arena o el cepillado mecánico.

Al considerar proveedores, es fundamental evaluar factores como la potencia del láser, la calidad del haz, la estabilidad del sistema, el soporte técnico y la experiencia del fabricante en aplicaciones industriales de limpieza láser. Empresas reconocidas en el sector ofrecen soluciones personalizables que se adaptan a diferentes tipos de metales y niveles de oxidación.

En conclusión, el uso de fuentes láser para la remoción de óxido representa una solución innovadora, eficiente y ecológica. Su implementación no solo mejora la calidad del proceso de limpieza, sino que también optimiza costos a largo plazo y cumple con estándares industriales y medioambientales cada vez más exigentes.