The global laser ablation market, which includes laser-based surface treatment technologies such as paint stripping, is experiencing robust growth due to increasing demand for precision, eco-friendly, and non-destructive cleaning methods in industrial applications. According to Grand View Research, the global laser cleaning equipment market was valued at USD 715.6 million in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 15.8% from 2023 to 2030. This surge is driven by shifting regulatory landscapes favoring chemical-free processes and rising adoption in automotive, aerospace, and heritage conservation sectors—where wood restoration plays a key role. As industries prioritize sustainability and efficiency, laser paint stripping machines are emerging as a preferred alternative to sandblasting and chemical removers, particularly for delicate materials like wood. This growing demand has catalyzed innovation among manufacturers specializing in fiber laser systems tailored for wood surface preparation and restoration. Below, we highlight the top 7 manufacturers leading this niche with advanced, data-backed performance metrics and industry recognition.

Top 7 Laser Paint Stripping Machine Wood Manufacturers (2026 Audit Report)

(Ranked by Factory Capability & Trust Score)

#1 Laser Cleaning Machine

Website: pulsar-laser.com

Key Highlights: Explore PULSAR Laser P CL laser cleaning machines for industrial rust removal and paint stripping. Compare SHARK P CL, PANDA P CL and FOX P CL….

#2 SFX Laser

Website: sfxlaser.com

Key Highlights: SFX Laser is a 20+ years professional laser equipment manufacturer including laser cleaning machine, laser welding machine, fiber laser engraver, ……

#3 P-laser Industrial laser cleaning

Website: p-laser.com

Key Highlights: Specializing in the production of premium-quality, Belgian-made industrial laser cleaning equipment, we take great pride in our craftsmanship and innovative ……

#4 Argento Lux

Website: argentolux.com

Key Highlights: Laser cleaning removes paint, contaminants, rust, and residues with a high-energy laser beam which leaves the substrate untouched. Our Laser Ablation is the ……

#5 Laser cleaning

Website: narran.cz

Key Highlights: We can design and integrate a laser cleaning system into production, build a robotic workstation or supply a mobile laser for a wide range of applications….

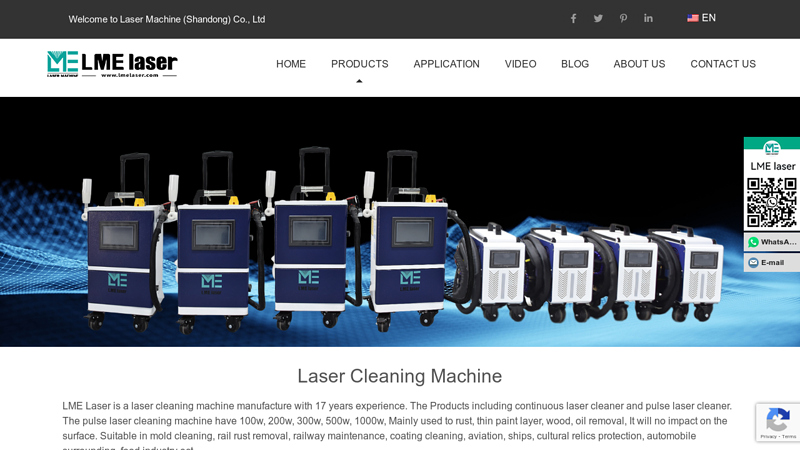

#6 Laser Cleaning Machine

Website: lmelaser.com

Key Highlights: LME Laser is a laser cleaning machine manufacture with 17 years experience. The Products including continuous laser cleaner and pulse laser cleaner….

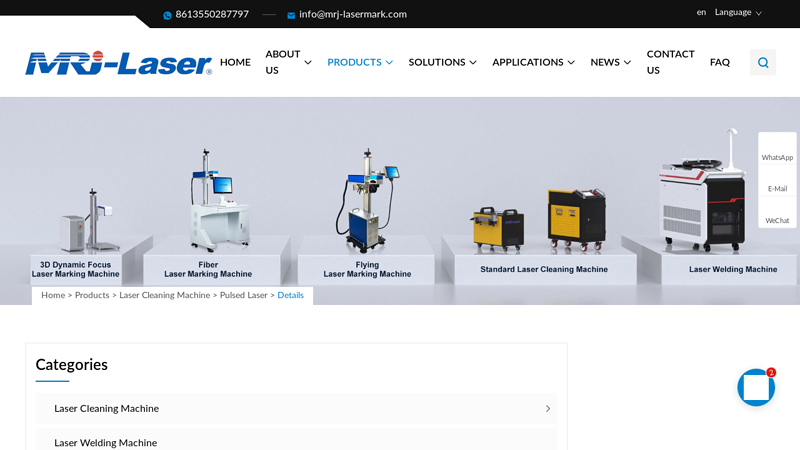

#7 Laser Stripping Machine For Wood White Paint Removal

Website: mrj-lasermark.com

Key Highlights: Look no further than our 1.5mj Laser Stripping Machine for Wood, designed specifically for swiftly removing white and other colored paints. This machine ……

Expert Sourcing Insights for Laser Paint Stripping Machine Wood

H2: 2026 Market Trends for Laser Paint Stripping Machines in Wood Restoration and Processing

The global market for laser paint stripping machines, particularly in wood applications, is poised for significant transformation by 2026, driven by technological advancements, environmental regulations, and growing demand in heritage conservation and high-end woodworking. Below is an in-depth analysis of the key trends expected to shape this niche yet rapidly evolving sector.

-

Increased Adoption in Heritage and Restoration Projects

By 2026, the use of laser paint stripping machines in historical wood structure restoration is expected to grow substantially. Institutions and governments are increasingly investing in the preservation of cultural heritage, where traditional methods like sandblasting or chemical stripping can damage delicate wooden surfaces. Laser technology offers precision and non-abrasive removal, making it ideal for restoring antique furniture, historic buildings, and museum artifacts without compromising structural integrity. -

Shift Toward Eco-Friendly and Sustainable Processes

Environmental regulations are tightening worldwide, especially in North America and the European Union. By 2026, industries will increasingly favor laser paint stripping over chemical or mechanical alternatives due to its minimal waste generation, lack of hazardous solvents, and reduced carbon footprint. This eco-friendly profile positions laser systems as a sustainable solution aligned with ESG (Environmental, Social, and Governance) goals, particularly in green-certified construction and woodworking sectors. -

Advancements in Fiber and Pulsed Laser Technology

Technological improvements in fiber and pulsed laser systems will enhance efficiency and accessibility. By 2026, expect more compact, portable, and user-friendly machines capable of selectively removing paint, varnish, or coatings from intricate wood grain patterns without thermal damage. Innovations in real-time monitoring and AI-assisted control systems will allow for automated adjustments based on wood type and coating thickness, significantly improving throughput and consistency. -

Growing Demand in High-Value Wood Manufacturing

The luxury furniture, yacht interiors, and premium architectural millwork industries are anticipated to adopt laser stripping at a faster pace. These sectors require flawless surface preparation before refinishing, and laser systems offer a clean, repeatable process that preserves wood quality. As consumer preferences shift toward custom, hand-finished wood products, manufacturers will invest in laser technology to maintain quality while meeting production demands. -

Cost Reduction and Market Democratization

Although currently a high-capital investment, the cost of laser paint stripping systems is expected to decline by 2026 due to increased competition, economies of scale, and modular system designs. This trend will make the technology more accessible to small and medium-sized enterprises (SMEs) in woodworking and restoration, expanding the market beyond large industrial users. -

Regional Market Growth and Regulatory Drivers

Europe is likely to remain the largest market due to strict environmental laws and strong heritage conservation efforts. North America will follow, with growth fueled by infrastructure renewal and green building initiatives. Meanwhile, Asia-Pacific—particularly China and Japan—will see rising adoption in high-end manufacturing and cultural preservation, supported by government funding and technological localization. -

Integration with Digital Workflows and Industry 4.0

By 2026, laser stripping machines are expected to integrate seamlessly with CAD/CAM systems and digital twin platforms, enabling end-to-end automation in wood refinishing workflows. IoT-enabled devices will provide remote monitoring, predictive maintenance, and performance analytics, improving operational efficiency and reducing downtime.

Conclusion:

The 2026 market for laser paint stripping machines in wood applications will be defined by precision, sustainability, and smart automation. As industries prioritize quality, compliance, and environmental responsibility, laser technology will transition from a specialized tool to a mainstream solution in wood surface preparation and restoration. Companies that innovate in usability, affordability, and integration will lead the next wave of market expansion.

Common Pitfalls When Sourcing Laser Paint Stripping Machines for Wood (Quality & IP Risks)

Sourcing laser paint stripping machines for wood applications requires careful due diligence to avoid significant quality issues and intellectual property (IP) risks. Overlooking these pitfalls can result in costly downtime, subpar performance, legal disputes, and reputational damage.

Poor Build Quality and Inadequate Performance

Many suppliers, especially those focusing on lower price points, may offer machines with substandard components and inconsistent engineering. This can manifest as unreliable laser output, premature component failure (e.g., diodes, cooling systems), and inadequate integration with wood processing workflows. Machines not specifically calibrated for wood substrates may cause charring, uneven stripping, or damage to the underlying material. Buyers often discover too late that the machine cannot maintain consistent performance over extended operational cycles.

Lack of Safety Features and Compliance

Laser systems pose inherent safety risks, particularly in industrial environments. Low-quality or non-compliant machines may lack essential safety interlocks, proper laser shielding, or certified fume extraction systems—especially critical when removing old paints that may contain hazardous materials like lead. Failure to meet regional safety standards (e.g., IEC 60825, FDA/CDRH in the U.S.) can lead to workplace violations, regulatory fines, and potential liability in the event of operator injury.

Insufficient Technical Support and Maintenance Access

Sourcing from suppliers with limited local presence or unclear service networks often results in delayed response times for maintenance and repairs. Lack of accessible technical documentation, training, or spare parts can lead to prolonged machine downtime. Some suppliers may use proprietary components or software, making it difficult or prohibited for third-party technicians to perform servicing, increasing long-term operational costs.

Intellectual Property Infringement Risks

A significant risk arises when sourcing from manufacturers that replicate or reverse-engineer established laser systems without proper licensing. These machines may incorporate patented optical designs, control software, or mechanical configurations protected under IP law. Purchasing such equipment exposes the buyer to potential legal action, customs seizures, or forced decommissioning of the machine. It may also void warranties and limit eligibility for insurance coverage.

Inadequate Verification of IP Ownership and Licensing

Buyers often fail to conduct proper due diligence on a supplier’s IP portfolio or licensing agreements. Reputable manufacturers will transparently provide information on patents, trademarks, and regulatory certifications. Absence of such documentation—or vague, unverifiable claims—should raise red flags. Engaging legal counsel to review supplier agreements and confirm freedom to operate is essential before procurement.

Misrepresentation of Specifications and Capabilities

Some suppliers exaggerate laser power, stripping speed, or automation capabilities in marketing materials. Performance claims may be based on ideal lab conditions rather than real-world wood surfaces with varying paint types and thicknesses. Without independent testing or third-party validation, buyers may receive equipment that fails to meet operational requirements, leading to project delays and financial loss.

By proactively addressing these quality and IP-related pitfalls—through rigorous supplier vetting, on-site demonstrations, legal review, and verification of certifications—buyers can mitigate risks and ensure a reliable, compliant, and legally sound investment in laser paint stripping technology for wood applications.

Logistics & Compliance Guide for Laser Paint Stripping Machines in Wood Applications

Product Classification and Regulatory Framework

Laser paint stripping machines used for wood applications fall under industrial laser systems and are subject to various international, national, and regional regulations. These include laser safety standards, electrical safety, environmental compliance, and trade controls. Proper classification ensures adherence to shipping, customs, and installation requirements.

Laser Safety Compliance (IEC 60825-1 and FDA 21 CFR Part 1040.10)

Laser systems must comply with the International Electrotechnical Commission (IEC) 60825-1 standard for laser product safety. In the United States, the Food and Drug Administration (FDA) enforces 21 CFR Part 1040.10, which governs laser radiation safety. Key requirements include:

– Proper laser classification (typically Class 1, 3B, or 4 depending on power)

– Installation of safety interlocks, emergency stop mechanisms, and beam enclosures

– Mandatory labeling with laser warning signs and technical specifications

– Submission of product reports to the FDA for U.S. market access

Electrical and Equipment Safety Standards

The machine must meet regional electrical safety standards such as:

– CE Marking (Europe): Compliance with the Low Voltage Directive (LVD 2014/35/EU) and Electromagnetic Compatibility (EMC) Directive (2014/30/EU)

– UL/CSA Certification (North America): Conformance with UL 61010-1 for safety of laboratory and industrial equipment

– Required Documentation: Include technical files, risk assessments, test reports, and user manuals in local languages

Environmental and Waste Management Considerations

Laser stripping of paint from wood generates particulate matter and potentially hazardous fumes (e.g., from lead-based or chemically treated paints). Compliance must include:

– Integration of HEPA filtration or fume extraction systems

– Adherence to EPA (U.S.) or REACH/CLP (EU) regulations regarding hazardous substance handling

– Proper disposal of collected debris as regulated waste where applicable

– Compliance with local air quality and occupational exposure limits (e.g., OSHA PELs)

International Shipping and Customs Documentation

For global logistics, accurate documentation is essential:

– Harmonized System (HS) Code: Typically 8515.21 or 8479.89 for industrial laser systems (verify locally)

– Commercial Invoice and Packing List: Include full technical specifications, value, and country of origin

– Certificate of Conformity (CoC): Required in many regions to verify compliance with local standards

– Export Controls: Check for ITAR or EAR restrictions if the laser exceeds certain power thresholds or has dual-use potential

Installation, Training, and Operational Compliance

End-users must receive:

– On-site installation support and safety commissioning

– Operator training on safe handling, emergency procedures, and PPE requirements (e.g., laser safety goggles)

– Documentation in the local language, including maintenance schedules and safety protocols

– Compliance with local occupational health and safety regulations (e.g., OSHA, EU-OSHA)

Maintenance and Regulatory Updates

Ensure ongoing compliance by:

– Scheduling regular safety inspections and performance calibrations

– Updating software and safety features per manufacturer advisories

– Monitoring changes in national or regional regulations affecting laser use or emissions

– Maintaining logs for audits and regulatory reviews

Summary and Best Practices

To ensure smooth logistics and compliance:

– Verify all certifications prior to shipment

– Partner with certified freight forwarders experienced in handling high-tech industrial equipment

– Provide comprehensive documentation kits for importers

– Conduct pre-shipment compliance audits for target markets

– Maintain clear communication with end-users regarding installation and safety obligations

Conclusion: Sourcing a Laser Paint Stripping Machine for Wood

Sourcing a laser paint stripping machine for wood presents a forward-thinking solution for precision restoration, conservation, and surface preparation in woodworking and heritage preservation industries. Laser technology offers distinct advantages over traditional methods—such as sandblasting, chemical stripping, or mechanical abrasion—by providing non-contact, eco-friendly, and highly controllable paint removal with minimal damage to the underlying wood substrate.

Key considerations when sourcing such a machine include laser power, wavelength compatibility with wood and paint types, safety features, automation capabilities, and ease of integration into existing workflows. While the initial investment is higher compared to conventional tools, the long-term benefits—reduced waste, lower environmental impact, compliance with health and safety regulations, and superior finish quality—justify the cost, particularly for high-value or delicate projects.

Additionally, choosing a reputable supplier with technical support, training, and service options is crucial for maximizing operational efficiency and ensuring a smooth adoption process. As laser technology becomes more accessible and advanced, investing in a laser paint stripping system positions businesses at the forefront of sustainable and precision-driven woodworking practices.

In conclusion, sourcing a laser paint stripping machine for wood is a strategic move toward innovation, environmental responsibility, and improved project outcomes, making it a valuable asset for restoration specialists, furniture manufacturers, and conservation experts alike.