The global laser paint stripping machine market is experiencing robust growth, driven by increasing demand for precision surface preparation in aerospace, automotive, and heritage restoration industries. According to Grand View Research, the global laser cleaning equipment market—of which paint stripping is a significant segment—was valued at USD 1.2 billion in 2023 and is projected to grow at a compound annual growth rate (CAGR) of 22.4% from 2024 to 2030. This surge is fueled by the shift toward eco-friendly, non-abrasive cleaning methods and the growing adoption of laser technology in industrial maintenance. As regulatory pressures mount against chemical and mechanical stripping techniques, leading manufacturers are investing in advanced laser systems that offer minimal substrate damage, reduced waste, and improved operational safety. In this evolving landscape, nine key companies have emerged as innovators and market leaders, setting benchmarks in performance, reliability, and technological advancement in laser paint stripping solutions.

Top 9 Laser Paint Stripping Machine Manufacturers (2026 Audit Report)

(Ranked by Factory Capability & Trust Score)

#1 Laserax

Website: laserax.com

Key Highlights: Laserax works with the world’s leading manufacturers to implement laser cleaning, welding, texturing, and marking solutions….

#2 P-laser Industrial laser cleaning

Website: p-laser.com

Key Highlights: Specializing in the production of premium-quality, Belgian-made industrial laser cleaning equipment, we take great pride in our craftsmanship and innovative ……

#3 Clean Laser Systems

Website: cleanlaser.de

Key Highlights: Our laser systems are primarily in operation with mold and tool cleaning, paint stripping and decoating as well as cleaning and modification of metallic ……

#4 Laser Cleaning Machine

Website: pulsar-laser.com

Key Highlights: Explore PULSAR Laser P CL laser cleaning machines for industrial rust removal and paint stripping. Compare SHARK P CL, PANDA P CL and FOX P CL….

#5 SFX Laser

Website: sfxlaser.com

Key Highlights: SFX Laser is a 20+ years professional laser equipment manufacturer including laser cleaning machine, laser welding machine, fiber laser engraver, ……

#6 Argento Lux

Website: argentolux.com

Key Highlights: Our Laser Ablation is the most cost-effective, efficient, and safest method of industrial cleaning, rust removal, paint removal, and surface preparation….

#7 Industrial 1500W 2000W CW Laser Cleaning Machine Rusty Remove

Website: xinglaser.com

Key Highlights: XING Laser (6am Life LLC, DBA XING Laser) specializes in the development and manufacture of high-performance handheld laser cleaning and rust removal equipment….

#8 Laser Cleaning and Laser Ablation Systems

Website: laserphotonics.com

Key Highlights: Remove rust and surface contaminants with our laser cleaning & laser ablation systems. Experience superior cleaning tech, automation, and eco-friendly ……

#9 Handheld Laser Cleaning Machines

Website: ipgphotonics.com

Key Highlights: Handheld and portable laser cleaning machines designed for manual applications including rust removal, paint stripping, restoration, and more….

Expert Sourcing Insights for Laser Paint Stripping Machine

H2: 2026 Market Trends for Laser Paint Stripping Machines

The global market for laser paint stripping machines is poised for significant transformation by 2026, driven by technological advancements, increasing environmental regulations, and rising demand across key industries such as aerospace, automotive, and marine. This analysis explores the major trends expected to shape the laser paint stripping machine market in 2026, focusing on innovation, adoption drivers, regional dynamics, and competitive landscape shifts.

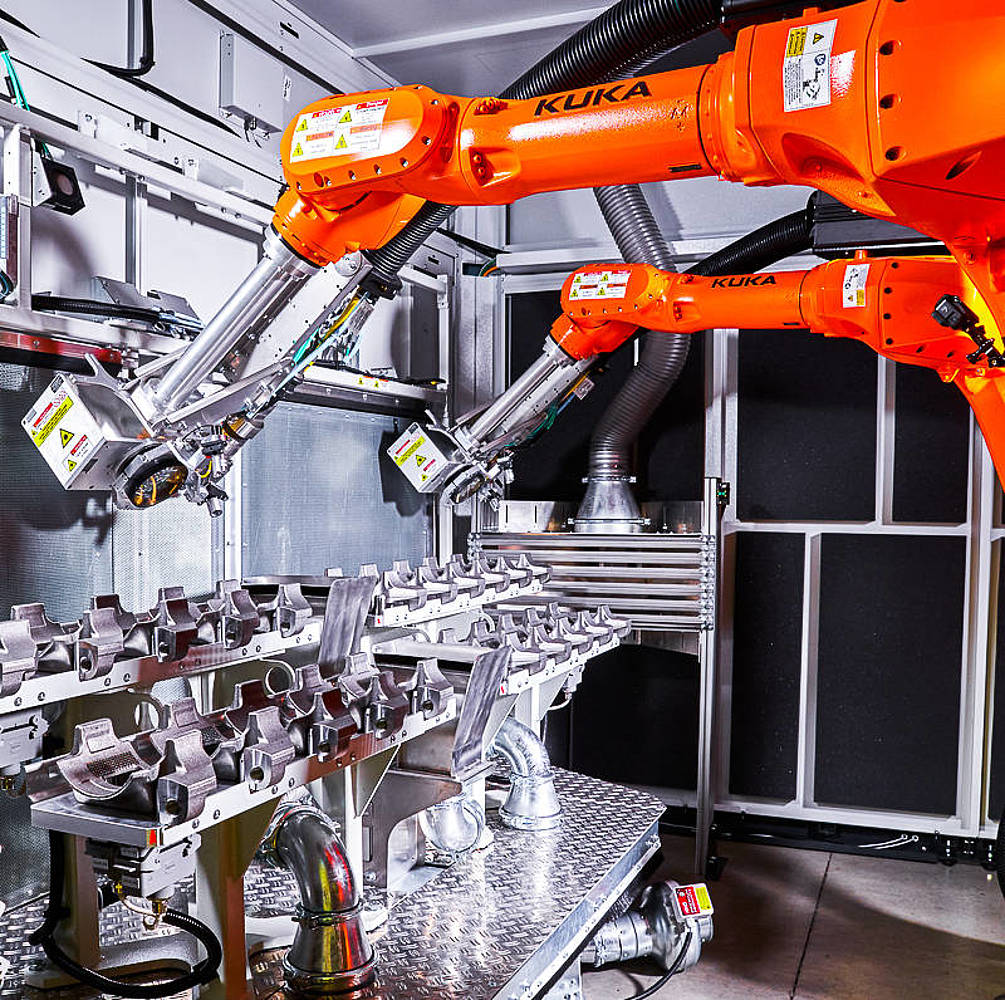

1. Technological Advancements and Automation Integration

By 2026, laser paint stripping machines are expected to feature enhanced automation and artificial intelligence (AI) integration. Manufacturers are investing heavily in smart systems that use machine learning algorithms to detect paint layers, optimize laser intensity, and minimize substrate damage. Robotic arms equipped with real-time monitoring sensors will become standard, enabling precision stripping in complex geometries—especially in aerospace components. These innovations will improve efficiency, reduce operational costs, and expand applicability across high-precision industries.

2. Growing Environmental and Regulatory Pressures

Stringent environmental regulations regarding chemical paint strippers and abrasive blasting methods are accelerating the shift toward eco-friendly alternatives. Laser paint stripping produces no hazardous waste, volatile organic compounds (VOCs), or secondary contamination, making it compliant with global environmental standards such as REACH and EPA guidelines. As governments tighten industrial emissions and waste disposal norms, industries will increasingly adopt laser systems to ensure regulatory compliance and improve sustainability profiles.

3. Expansion in Aerospace and Defense Applications

The aerospace sector remains the largest adopter of laser paint stripping technology. By 2026, rising aircraft fleet sizes, coupled with mandatory maintenance cycles, will fuel demand for non-destructive, high-precision stripping solutions. Military modernization programs and the need for rapid aircraft turnaround times will further boost investments in portable and modular laser systems. Original Equipment Manufacturers (OEMs) like Boeing and Airbus are expected to integrate laser stripping into standard maintenance protocols, driving market growth.

4. Increasing Adoption in Automotive and Marine Industries

Beyond aerospace, the automotive and marine sectors are emerging as key growth areas. In automotive manufacturing and restoration, laser systems offer fast, selective paint removal without damaging underlying materials. For marine vessels, laser technology enables efficient hull maintenance without dry-docking delays. As cost barriers decline and system portability improves, small and mid-sized enterprises in these sectors will increasingly adopt laser solutions.

5. Regional Market Dynamics

North America and Europe will continue to dominate the market in 2026 due to strong regulatory frameworks, advanced manufacturing infrastructure, and early technology adoption. However, the Asia-Pacific region—particularly China, India, and Japan—is expected to witness the highest growth rate. Expanding aerospace programs, rising defense spending, and booming automotive production will drive regional demand. Local manufacturing of laser components will also reduce costs and improve accessibility.

6. Competitive Landscape and Strategic Collaborations

The market will see intensified competition among key players such as IPG Photonics, Laser Photonics Corp, and 4D Systems. Companies are focusing on product differentiation through R&D, offering modular, handheld, and fully automated solutions. Strategic partnerships with aerospace MRO (Maintenance, Repair, and Overhaul) providers and integration with digital twin platforms are expected to become common. Additionally, mergers and acquisitions may accelerate as firms aim to consolidate technology portfolios and expand global reach.

7. Cost Reduction and ROI Improvements

Although initial investment in laser paint stripping machines remains higher than traditional methods, total cost of ownership (TCO) is improving. By 2026, declining prices of fiber lasers, increased energy efficiency, and reduced maintenance needs will enhance return on investment (ROI). As operational benefits become more quantifiable—such as labor savings, faster turnaround, and reduced waste disposal costs—adoption rates are expected to rise across diverse industrial segments.

Conclusion

By 2026, the laser paint stripping machine market will be characterized by rapid innovation, regulatory tailwinds, and expanding industrial adoption. Enabled by smarter, more affordable systems, the technology will transition from a niche solution to a mainstream surface preparation method. Companies that invest in scalable, environmentally compliant laser solutions will be well-positioned to capture growth in this evolving market landscape.

Common Pitfalls When Sourcing a Laser Paint Stripping Machine (Quality & Intellectual Property)

Sourcing a Laser Paint Stripping Machine (LPSM) requires careful evaluation beyond just price and specifications. Overlooking critical aspects related to quality and intellectual property (IP) can lead to significant operational, financial, and legal risks. Here are the key pitfalls to avoid:

Poor Build Quality and Component Sourcing

Many suppliers, particularly from less-regulated markets, may use substandard materials, components, or manufacturing processes to reduce costs. This results in machines with poor durability, inconsistent performance, and frequent breakdowns. Look out for vague descriptions of core components (laser source, cooling system, motion control), lack of certifications (e.g., CE, ISO), and absence of detailed technical documentation.

Inaccurate or Exaggerated Performance Claims

Suppliers may overstate key performance metrics such as stripping speed, surface finish quality, or material compatibility. Without independent verification or real-world testing data, it’s easy to end up with a machine that fails to meet your production requirements. Always request verifiable test results under conditions similar to your intended application.

Lack of Intellectual Property Transparency

Some manufacturers may use laser technology or system designs that infringe on existing patents. Sourcing from such suppliers exposes your company to legal liability, potential product seizures, or costly litigation. Ensure the supplier can provide documentation proving legitimate ownership or licensing of core technologies, especially the laser source and control software.

Inadequate After-Sales Support and Spare Parts Availability

A common issue with lower-cost or IP-compromised machines is limited access to technical support, training, and genuine spare parts. This can lead to extended downtime and increased long-term costs. Confirm the supplier offers comprehensive support, including remote diagnostics, on-site service, and a reliable supply chain for critical components.

Hidden Software Limitations or Licensing Issues

The control software is a critical part of an LPSM. Some machines may use unlicensed or poorly developed software with hidden limitations, bugs, or lack of updates. Verify software provenance, update policies, and whether the license allows full operational control without recurring fees or restrictions.

Failure to Comply with Safety and Regulatory Standards

Laser systems are subject to strict safety regulations (e.g., IEC 60825). Machines that cut corners on safety interlocks, enclosure design, or emission controls pose serious risks to operators and may fail regulatory inspections. Always confirm compliance with relevant safety standards and request third-party certification documentation.

Avoiding these pitfalls requires due diligence: conduct factory audits, request customer references, verify IP rights, and consider engaging independent technical experts during the sourcing process. Investing time upfront ensures a reliable, legally sound, and high-performance laser paint stripping solution.

Logistics & Compliance Guide for Laser Paint Stripping Machine

General Overview

This guide outlines the essential logistics and compliance considerations for the transportation, import/export, and operational use of a Laser Paint Stripping Machine. Adherence to international, national, and local regulations ensures safe handling, legal compliance, and smooth deployment.

Regulatory Classification & Documentation

Laser paint stripping machines are typically classified under specific industrial or optical equipment categories for customs and transportation purposes. Key steps include:

– HS Code Identification: Confirm the appropriate Harmonized System (HS) code (e.g., 8515.80 or 9013.20, depending on configuration) to determine import duties and restrictions.

– Product Compliance Certifications: Ensure the machine complies with IEC 60825 (laser safety), CE, FCC, or other relevant regional standards. Maintain copies of test reports and conformity declarations.

– Technical Specifications Dossier: Prepare a detailed technical document including power rating, laser class (typically Class 4), dimensions, weight, and safety features for customs and regulatory authorities.

International Shipping Requirements

Transporting laser equipment internationally requires careful planning:

– Dangerous Goods Classification: While lasers themselves are not hazardous materials, Class 4 lasers are often subject to special handling due to potential radiation risks. Consult IATA (air) or IMDG (sea) guidelines for packaging and labeling.

– Packaging Standards: Use shock-resistant, moisture-proof packaging with clear “Fragile” and “This Side Up” labels. Include internal immobilization to prevent movement during transit.

– Export Controls: Verify if the machine contains controlled components (e.g., high-power lasers) under export regulations such as the U.S. Export Administration Regulations (EAR) or EU Dual-Use Regulation. Licenses may be required.

Import Compliance & Duties

Upon arrival in the destination country:

– Customs Clearance: Submit commercial invoice, packing list, bill of lading/airway bill, certificate of origin, and compliance certificates.

– Duty & Tax Assessment: Pay applicable import duties, VAT, or GST based on declared value and HS code classification.

– Local Approvals: Some countries require pre-shipment inspection or approval from national radiation protection or industrial safety agencies.

On-Site Installation & Safety Compliance

After delivery, ensure operational compliance:

– Laser Safety Program: Implement a Laser Safety Officer (LSO)-led program per ANSI Z136.1 or equivalent standard.

– Controlled Access Zone: Establish a designated work area with interlocks, warning signs, and beam enclosures.

– Personal Protective Equipment (PPE): Provide appropriate laser safety goggles (wavelength-specific), protective clothing, and respiratory protection if fumes are generated.

– Ventilation & Fume Extraction: Install certified fume extraction systems to capture hazardous airborne particles released during stripping.

Environmental & Waste Management

Laser paint stripping may generate hazardous waste:

– Regulatory Compliance: Follow EPA (U.S.), REACH (EU), or local environmental regulations for handling ablated paint residues, especially if containing lead or chromates.

– Waste Disposal: Classify and dispose of waste through licensed hazardous waste handlers with proper documentation (e.g., waste manifests).

– Emissions Monitoring: Conduct periodic air quality checks to ensure workplace exposure limits (e.g., OSHA PELs) are not exceeded.

Training & Operational Documentation

Ensure all operators are fully trained:

– Operator Certification: Provide training on laser safety, machine operation, emergency shutdown, and maintenance. Maintain training records.

– Standard Operating Procedures (SOPs): Develop and enforce SOPs compliant with local occupational health and safety regulations.

– Maintenance Logs: Keep detailed records of inspections, calibrations, and repairs to demonstrate compliance during audits.

Incident Reporting & Liability

Prepare for potential incidents:

– Reporting Protocols: Establish procedures for reporting laser exposure, fires, or equipment malfunctions to relevant authorities (e.g., OSHA, HSE).

– Insurance Coverage: Ensure liability and equipment insurance covers laser operations and potential third-party damage.

– Product Liability: Retain compliance documentation to demonstrate due diligence in case of legal or regulatory challenges.

Summary

Successful logistics and compliance for a Laser Paint Stripping Machine require proactive planning across shipping, regulatory, safety, and environmental domains. Always consult local authorities and certified professionals to ensure full adherence to applicable laws and standards.

Conclusion: Sourcing a Laser Paint Stripping Machine

Sourcing a laser paint stripping machine represents a strategic investment in advanced, sustainable, and efficient surface preparation technology. As industries increasingly prioritize precision, environmental compliance, and operational safety, laser-based systems offer a compelling alternative to traditional methods such as sandblasting, chemical stripping, or mechanical abrasion.

After evaluating various suppliers, technologies, and cost-benefit factors, it is evident that laser paint stripping machines deliver superior results in terms of substrate preservation, reduced waste, and minimal environmental impact. Although the initial capital expenditure is higher than conventional methods, the long-term savings—derived from lower consumable costs, reduced labor, compliance with environmental regulations, and decreased downtime—justify the investment, particularly for high-value or sensitive components.

Key considerations in the sourcing decision include laser power, automation compatibility, scalability, after-sales support, and the supplier’s industry experience. Choosing a reputable provider with proven applications in your specific sector (e.g., aerospace, maritime, or automotive) ensures reliable performance and technical assistance.

In conclusion, adopting a laser paint stripping machine aligns with modern industrial trends toward cleaner, smarter manufacturing. It enhances operational efficiency, supports sustainability goals, and positions the organization at the forefront of technological innovation in surface treatment processes. Therefore, moving forward with procurement—selected through careful supplier evaluation and pilot testing—is a forward-thinking and commercially sound decision.