The global laser paint removal machine market is experiencing robust growth, driven by increasing demand for precision surface treatment in aerospace, automotive, and heritage restoration industries. According to a 2023 report by Mordor Intelligence, the industrial laser market is projected to grow at a CAGR of over 7.5% from 2023 to 2028, with laser ablation technologies—particularly for paint and coating removal—representing a rapidly expanding segment. This surge is fueled by the advantages of laser systems, including minimal substrate damage, reduced waste, and compliance with environmental regulations compared to traditional sandblasting or chemical methods. As industries prioritize efficiency and sustainability, investment in high-performance laser paint removal solutions is accelerating. In response, manufacturers are innovating to deliver scalable, cost-effective systems tailored to diverse industrial needs. Based on current market trends and pricing data, the following eight manufacturers stand out for their competitive pricing, technical capabilities, and market presence in the laser paint removal space.

Top 8 Laser Paint Removal Machine Price Manufacturers (2026 Audit Report)

(Ranked by Factory Capability & Trust Score)

#1 Laser Cleaning Machine Manufacturer

Website: hantencnc.com

Key Highlights: The advanced scanning system ensures precise cleaning control and superior beam quality. Our laser technology efficiently removes rust, paint, oil, and more….

#2 Laser cleaner machine prices

Website: pulsar-laser.com

Key Highlights: Laser cleaner machine prices and parameters, download our Catalogue….

#3 P-laser Industrial laser cleaning

Website: p-laser.com

Key Highlights: Specializing in the production of premium-quality, Belgian-made industrial laser cleaning equipment, we take great pride in our craftsmanship and innovative ……

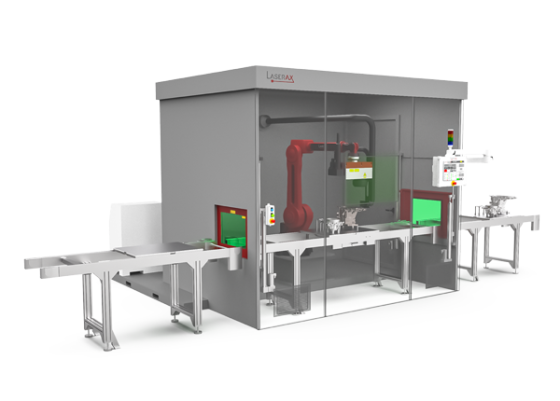

#4 Laserax

Website: laserax.com

Key Highlights: Laserax works with the world’s leading manufacturers to implement laser cleaning, welding, texturing, and marking solutions….

#5 Industrial 1500W 2000W CW Laser Cleaning Machine Rusty Remove

Website: xinglaser.com

Key Highlights: XING Laser (6am Life LLC, DBA XING Laser) specializes in the development and manufacture of high-performance handheld laser cleaning and rust removal equipment….

#6 Argento Lux

Website: argentolux.com

Key Highlights: Laser cleaning removes paint, contaminants, rust, and residues with a high-energy laser beam which leaves the substrate untouched. Our Laser Ablation is the ……

#7 Laser Cleaning and Laser Ablation Systems

Website: laserphotonics.com

Key Highlights: Utilize this laser cleaning machine for rust removal and coating removal, decontamination, degreasing, pre- and post-weld surface preparation, and texturing….

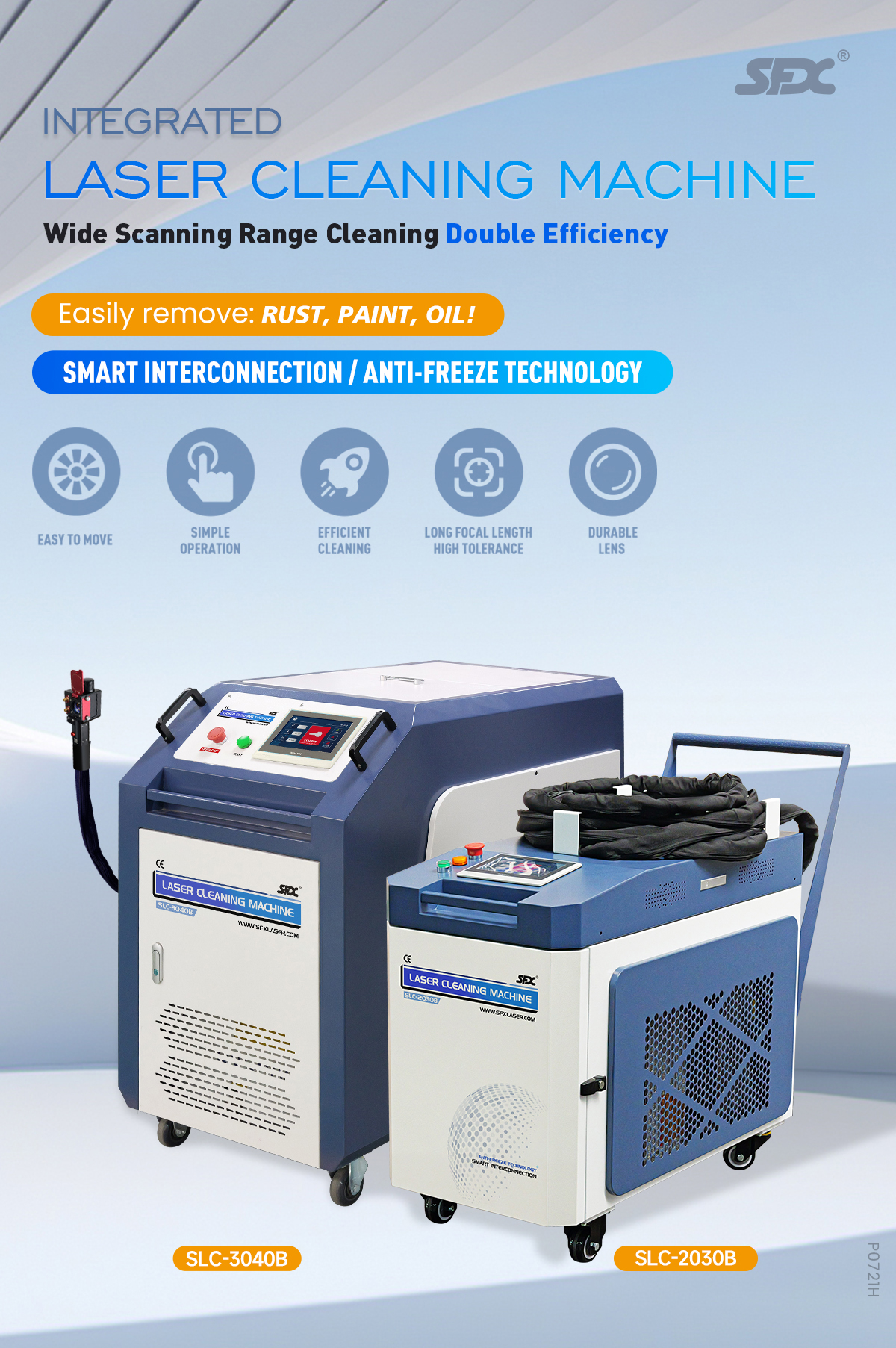

#8 500W 1000W Pulse Laser Cleaning Machine Laser Metal Rust Oil …

Website: sfxlaser.com

Key Highlights: In stock Free deliverySFX 500w 1000w pulse laser cleaning machine is suitable for rust, oil, paint, coating, mold cleaning, adhesive layer removal, cultural relic restoration, etc….

Expert Sourcing Insights for Laser Paint Removal Machine Price

H2: 2026 Market Trends for Laser Paint Removal Machine Price

The global market for laser paint removal machines is poised for significant transformation by 2026, driven by technological innovation, growing environmental regulations, and increasing adoption across aerospace, automotive, and heritage restoration industries. As demand rises, price trends for laser paint removal systems are expected to reflect a complex interplay of cost reduction from technological advancements and upward pressure from demand and material inputs.

1. Technological Advancements Driving Efficiency and Cost Optimization

By 2026, continued improvements in fiber laser technology, automation, and user interface integration are expected to enhance the efficiency and reliability of laser paint removal machines. These advancements may lead to economies of scale in manufacturing, potentially lowering unit costs over time. However, high-end models featuring AI-powered surface detection, real-time monitoring, and robotic integration will command premium pricing, creating a segmented market with a wide price range.

2. Rising Demand Across Key Industries

The aerospace and defense sectors are major adopters due to the need for non-abrasive, precision coating removal on aircraft components. Similarly, the automotive industry is increasingly using laser systems for eco-friendly refurbishment and EV component maintenance. This expanding demand is likely to sustain or increase machine prices in the short to medium term, especially for industrial-grade systems.

3. Environmental and Regulatory Influences

Growing global emphasis on sustainable manufacturing and restrictions on chemical-based paint stripping (e.g., under REACH and EPA guidelines) are accelerating the transition to laser alternatives. As compliance becomes mandatory, companies may be willing to invest in higher-priced laser systems despite upfront costs, supporting stable or rising price levels through 2026.

4. Regional Price Variations and Supply Chain Dynamics

North America and Europe are expected to lead in adoption, with higher average machine prices due to stringent safety standards and advanced feature integration. In contrast, Asia-Pacific markets may see more competitive pricing due to local manufacturing and lower operational costs. Supply chain resilience, particularly for rare earth elements used in laser components, could also influence pricing volatility.

5. Price Range Projections for 2026

By 2026, the average price for industrial laser paint removal machines is projected to range between $80,000 and $250,000, depending on power output, automation level, and portability. Entry-level and handheld systems may be available for $20,000–$50,000, catering to small businesses and restoration specialists. Despite gradual cost reductions in components, the overall market price is expected to remain stable or increase slightly due to added functionality and regulatory tailwinds.

In conclusion, the 2026 market for laser paint removal machine prices will be shaped by innovation, regulatory support, and sector-specific demand. While competition and technology may moderate prices for basic models, the trend toward智能化 (smart automation) and compliance-driven adoption will sustain value and pricing power for advanced systems.

Common Pitfalls When Sourcing Laser Paint Removal Machine Price (Quality, IP)

Sourcing a laser paint removal machine involves more than just comparing prices—overlooking critical factors related to quality and intellectual property (IP) can lead to significant setbacks. Here are key pitfalls to avoid:

Overlooking Build Quality and Component Standards

Many suppliers offer lower-priced machines that use inferior materials, substandard optics, or underpowered lasers. These systems may fail prematurely, require frequent maintenance, or deliver inconsistent results. Always verify the quality of core components like laser sources (e.g., fiber laser brand), cooling systems, motion control, and protective enclosures. Request third-party certifications (e.g., CE, ISO) and conduct factory audits if possible.

Ignoring Intellectual Property (IP) Risks

Purchasing from manufacturers that infringe on patented technology can expose your business to legal liability. Some low-cost suppliers reverse-engineer branded machines without proper licensing. Ensure the supplier holds legitimate IP rights or partnerships with recognized laser technology developers. Request documentation on IP ownership and verify compliance with international patent laws.

Focusing Solely on Upfront Cost

The cheapest machine often has the highest total cost of ownership due to downtime, repairs, and inefficient performance. Evaluate long-term costs like energy consumption, consumables, service contracts, and expected lifespan. A higher initial investment in a reliable, IP-compliant machine typically delivers better ROI.

Lack of Technical Support and Spare Parts Availability

Low-cost suppliers, especially from regions with weak after-sales infrastructure, may not offer timely technical support or spare parts. Confirm the availability of local service teams, response times, and spare parts inventory before purchasing. Poor support can halt operations and increase downtime costs.

Inadequate Safety and Compliance Features

Budget machines may lack essential safety certifications (e.g., FDA, IEC) or proper safety interlocks, fume extraction, and beam shielding. Non-compliant systems pose risks to operators and may fail regulatory inspections, leading to fines or shutdowns.

Misalignment with Application Requirements

Not all laser paint removal systems are suited for every substrate or coating type. Some low-cost models have limited power adjustability, spot size control, or scanning speed. Ensure the machine’s specifications match your specific use case—such as aerospace composites, automotive restoration, or marine hull cleaning.

Hidden Costs in Installation and Integration

Price quotes may exclude installation, training, software licensing, or integration with existing production lines. Clarify what’s included and budget for auxiliary systems like dust extraction, power upgrades, or robotic arms if needed.

By thoroughly evaluating quality, verifying IP legitimacy, and looking beyond the sticker price, buyers can avoid costly mistakes and select a laser paint removal machine that delivers safe, effective, and legally compliant performance.

Logistics & Compliance Guide for Laser Paint Removal Machine Price

When evaluating the price of a laser paint removal machine, it’s essential to consider not only the upfront cost but also the logistics and compliance factors that can significantly impact total expenses. Understanding these elements ensures accurate budgeting, avoids unexpected delays, and ensures legal and safe operation.

Equipment Sourcing and Shipping Logistics

The origin of the laser paint removal machine—whether domestic or international—plays a major role in final pricing. Importing from overseas suppliers may offer lower base prices but adds shipping, customs, and handling costs. Air freight is faster but considerably more expensive than sea freight, which is more economical for heavy industrial equipment but slower. Proper packaging and use of certified freight forwarders experienced in handling sensitive laser systems are critical to prevent damage and ensure timely delivery.

Import Duties and Taxes

Purchasing a laser machine from outside your country typically incurs import duties, value-added tax (VAT), and other local surcharges. These fees vary by country and product classification (e.g., under HS Code 8543 for electrical apparatus). Failure to account for these can lead to price surprises. Consult with customs brokers to determine applicable rates and ensure accurate declaration to avoid penalties.

Regulatory Compliance and Safety Certification

Laser paint removal machines are subject to strict safety and environmental regulations. Ensure the machine complies with standards such as:

- IEC 60825-1 (laser safety)

- OSHA (Occupational Safety and Health Administration) guidelines in the U.S.

- CE marking for the EU (covering Machinery Directive and EMC Directive)

- FDA/CDRH registration in the U.S. for laser products

Non-compliant machines may be blocked at customs or result in operational fines. Compliance often affects price—certified machines may cost more but reduce long-term risks.

Hazardous Material and Fume Extraction Requirements

Laser ablation of paint can release hazardous fumes, especially when removing lead-based or chemically treated coatings. Regulatory frameworks such as EPA NESHAP (National Emission Standards for Hazardous Air Pollutants) in the U.S. or REACH in the EU may require integrated fume extraction and filtration systems. Machines equipped with compliant extraction add to the initial cost but are essential for legal operation and worker safety.

Installation, Training, and After-Sales Support

Total cost of ownership includes installation, operator training, and ongoing technical support. Machines from reputable suppliers often include on-site setup and safety training, which impacts pricing. Consider whether remote or local service support is available, especially for warranty and maintenance. Machines with poor support may lead to downtime and increased operational costs.

Environmental and Disposal Regulations

Spent filters and removed paint residue may be classified as hazardous waste. Compliance with local waste disposal laws (e.g., RCRA in the U.S.) affects operating costs. Factor in the cost of proper disposal systems and documentation when comparing machine prices.

Conclusion

The listed price of a laser paint removal machine is only the starting point. Logistics costs, import fees, compliance certifications, safety systems, and regulatory adherence all contribute to the total investment. Always request a detailed breakdown of all associated costs and confirm that the equipment meets regional legal and safety requirements before purchase.

In conclusion, sourcing a laser paint removal machine requires a comprehensive evaluation of several factors beyond just the initial price. While cost is an important consideration, it is essential to assess the machine’s performance, power, portability, safety features, durability, and after-sales support. Prices can vary significantly depending on the technology, brand reputation, automation level, and intended application—whether for industrial, aerospace, automotive, or restoration use. Investing in a high-quality laser paint removal system may involve a higher upfront cost but can lead to long-term savings through increased efficiency, reduced labor and waste disposal costs, and minimal substrate damage. It is advisable to obtain quotes from multiple reputable suppliers, request live demonstrations or trials, and consider total cost of ownership when making a decision. Ultimately, choosing the right laser paint removal machine at a competitive price involves balancing affordability with performance, reliability, and return on investment.