The global laser paint removal market is poised for substantial growth, driven by increasing demand for precision surface treatment in aerospace, automotive, and cultural heritage restoration industries. According to Mordor Intelligence, the market is projected to grow at a CAGR of approximately 7.3% from 2023 to 2028, fueled by advancements in fiber laser technology and rising adoption of eco-friendly, non-abrasive cleaning methods. As industries shift away from chemical and mechanical stripping techniques, laser-based solutions offer superior control, reduced substrate damage, and compliance with environmental regulations. This accelerating trend has spurred the expansion of innovative manufacturers specializing in laser paint removal guns. Based on technical capabilities, global reach, and product innovation, the following eight companies have emerged as leading manufacturers shaping the future of laser surface preparation.

Top 8 Laser Paint Removal Gun Manufacturers (2026 Audit Report)

(Ranked by Factory Capability & Trust Score)

#1 P-laser Industrial laser cleaning

Website: p-laser.com

Key Highlights: we engineer and manufacture the most advanced—and most powerful—pulsed industrial laser cleaning systems on the market, built for both manual and automated ……

#2 Laserax

Website: laserax.com

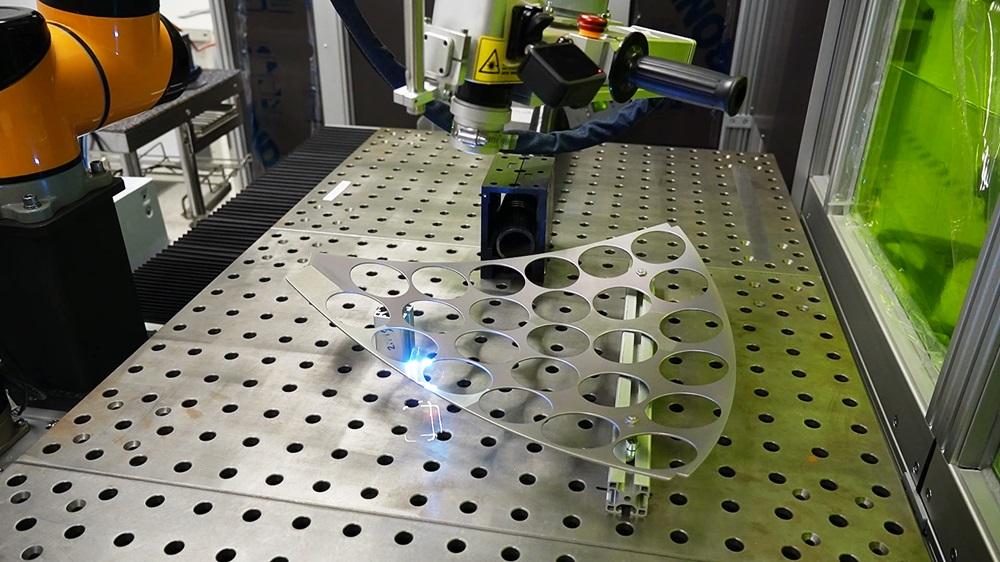

Key Highlights: Laserax works with the world’s leading manufacturers to implement laser cleaning, welding, texturing, and marking solutions….

#3 SHARK P CL Industrial Laser Cleaning Machines (100

Website: pulsar-laser.com

Key Highlights: SHARK P CL is an industrial pulsed laser cleaning machine series by PULSAR Laser with outputs from 100 W to 1000 W, air-cooled up to 500 W….

#4 Laser Photonics

Website: laserphotonics.com

Key Highlights: Laser Photonics manufactures reliable, safe, and eco-friendly Laser Cleaning, Laser Cutting, Laser Engraving, Laser Marking, and Laser Welding solutions….

#5 Argento Lux

Website: argentolux.com

Key Highlights: Our Laser Ablation is the most cost-effective, efficient, and safest method of industrial cleaning, rust removal, paint removal, and surface preparation….

#6 SFX Laser

Website: sfxlaser.com

Key Highlights: SFX Laser is a 20+ years professional laser equipment manufacturer including laser cleaning machine, laser welding machine, fiber laser engraver, ……

#7 Clean Laser Systems

Website: cleanlaser.de

Key Highlights: IPG | cleanLASER has been developing and producing high-precision laser systems for cleaning and industrial surface treatment for more than 20 years….

#8 Laser cleaning

Website: p-laserusa.com

Key Highlights: Our laser machines are mainly used to remove the following contaminants: Rust – Paint – Coatings – Release Agents – Grease, Oils – Soot – Rubber- Organic ……

Expert Sourcing Insights for Laser Paint Removal Gun

2026 Market Trends for Laser Paint Removal Gun

The global market for laser paint removal guns is poised for significant transformation by 2026, driven by technological advancements, increasing environmental regulations, and growing demand across key industries such as aerospace, automotive, and maritime. This analysis explores the major trends shaping the adoption and development of laser paint removal guns in the coming years.

Rising Demand for Eco-Friendly Surface Preparation Technologies

One of the most influential drivers of the laser paint removal gun market by 2026 is the shift toward environmentally sustainable practices. Traditional paint removal methods—such as sandblasting, chemical stripping, and high-pressure water jetting—generate hazardous waste, airborne pollutants, and require extensive containment. In contrast, laser paint removal is a clean, precise, and waste-minimizing alternative. As environmental regulations tighten globally, particularly under frameworks like the EU Green Deal and U.S. EPA guidelines, industries are increasingly adopting laser systems to reduce their environmental footprint. This regulatory push is expected to accelerate laser paint removal gun adoption, especially in regions with strict emissions and waste disposal standards.

Technological Advancements Enhancing Efficiency and Accessibility

By 2026, laser paint removal technology is expected to become more efficient, compact, and user-friendly. Innovations in fiber laser sources, real-time monitoring systems, and automated beam control are improving removal speed and precision while reducing energy consumption. Portable and handheld laser paint removal guns are becoming more prevalent, allowing for on-site applications in field maintenance and restoration. Moreover, integration with AI-driven diagnostics and IoT-enabled performance tracking will enable predictive maintenance and optimize operational efficiency. These advancements are lowering the total cost of ownership and making the technology more accessible to small and medium-sized enterprises (SMEs).

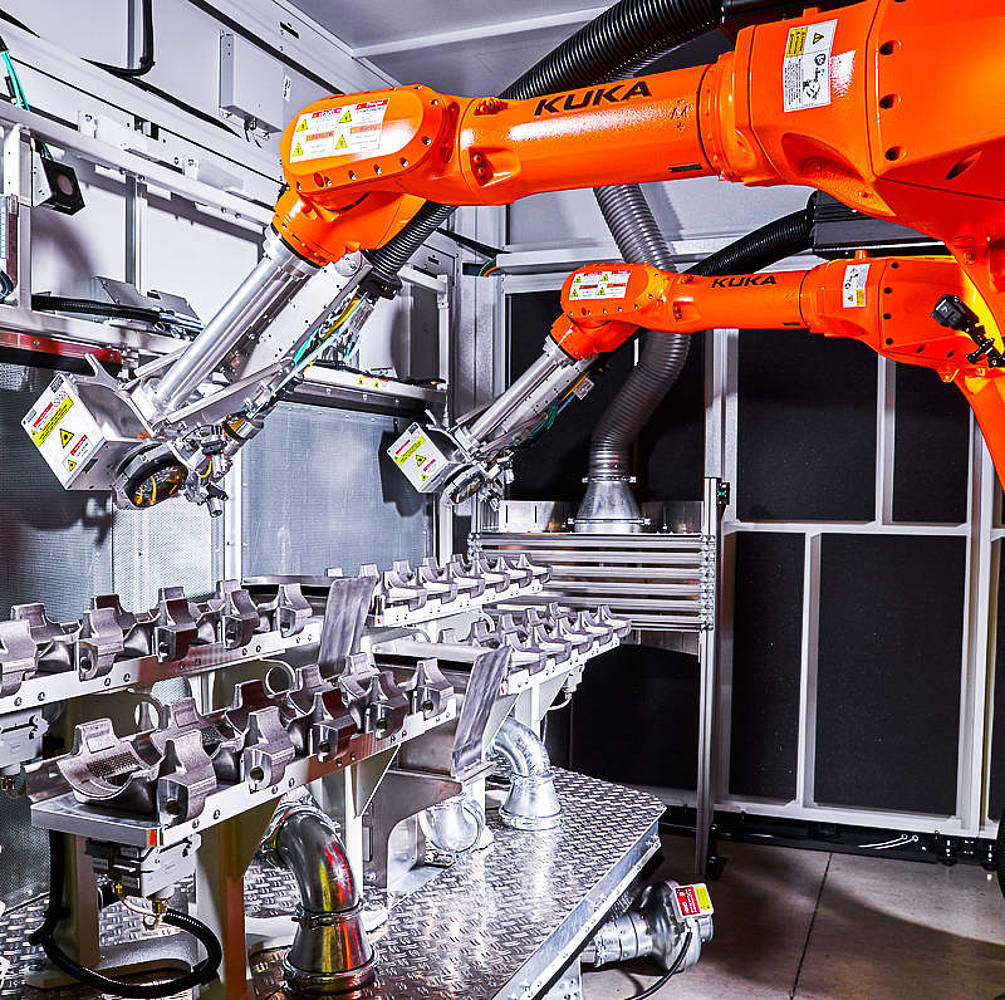

Expansion in Aerospace and Defense Applications

The aerospace and defense sector remains a primary adopter of laser paint removal guns due to the need for non-destructive surface treatment on sensitive materials like composites and aluminum alloys. By 2026, increasing aircraft fleet sizes, coupled with stringent maintenance, repair, and overhaul (MRO) requirements, will drive demand for reliable and repeatable paint stripping solutions. Laser systems offer selective material ablation without damaging underlying substrates—critical for maintaining aircraft structural integrity. Defense contractors are also investing in mobile laser units for field-deployable maintenance, further expanding the use cases for handheld laser paint removal guns.

Growth in Automotive and Restoration Markets

The automotive industry, particularly in luxury and vintage vehicle restoration, is emerging as a high-potential market for laser paint removal guns. These tools allow for precise stripping of paint without harming delicate body panels or original finishes. As the classic car restoration market grows, especially in North America and Europe, demand for non-abrasive, high-precision tools is rising. Additionally, electric vehicle (EV) manufacturers are exploring laser cleaning for battery and component preparation, opening new applications beyond paint removal.

Competitive Landscape and Regional Market Dynamics

The laser paint removal gun market is becoming increasingly competitive, with key players such as Cleanlas, Laser Photonics, and P-Laser expanding their product portfolios and geographic reach. North America and Europe are expected to lead in market adoption due to strong regulatory support and high industrial automation rates. Meanwhile, the Asia-Pacific region—particularly China and India—is witnessing rapid growth due to expanding manufacturing bases and increasing investments in advanced surface treatment technologies. Strategic partnerships, R&D investments, and government grants are expected to fuel innovation and market penetration through 2026.

Challenges and Future Outlook

Despite the positive outlook, challenges remain, including high initial equipment costs, the need for operator training, and safety concerns related to laser radiation. However, as technology matures and economies of scale are achieved, prices are expected to decline, broadening market access. By 2026, the global laser paint removal gun market is projected to experience a compound annual growth rate (CAGR) of over 12%, driven by sustainability mandates, technological innovation, and expanding industrial applications. The laser paint removal gun is set to become a standard tool in modern surface preparation, marking a pivotal shift from conventional to smart, clean manufacturing practices.

Common Pitfalls When Sourcing a Laser Paint Removal Gun (Quality, IP)

Sourcing a laser paint removal gun involves several potential pitfalls, especially concerning product quality and intellectual property (IP) rights. Being aware of these challenges can help avoid costly mistakes and legal complications.

Poor Build Quality and Performance Inconsistencies

Many suppliers, particularly from regions with less stringent manufacturing standards, offer laser paint removal guns that appear cost-effective but often lack durability and precision. Common issues include inconsistent laser output, overheating, and premature component failure. Lower-quality optics and cooling systems reduce efficiency and increase maintenance costs over time.

Misleading Power and Safety Specifications

Some manufacturers exaggerate the laser’s power output (measured in watts) or omit critical safety certifications (such as FDA, CE, or IEC 60825). This can result in underperforming equipment or non-compliance with workplace safety regulations, posing risks to operators and leading to liability issues.

Lack of IP Compliance and Risk of Infringement

Purchasing laser systems from unverified suppliers may expose buyers to intellectual property violations. Some low-cost providers replicate patented technologies without authorization. Using such equipment could lead to legal action, product seizures, or reputational damage, especially in regulated industries like aerospace or automotive restoration.

Inadequate Technical Support and Spare Parts Availability

Even if a laser paint removal gun performs well initially, poor after-sales support can render it useless over time. Many third-party suppliers fail to provide firmware updates, user training, or access to replacement parts. This lack of support increases downtime and total cost of ownership.

Absence of IP Protection in Supplier Contracts

When developing or customizing laser systems, failing to secure IP rights through clear contractual agreements is a major oversight. Suppliers may retain rights to design improvements or software algorithms, limiting your ability to innovate or scale operations independently.

To mitigate these risks, conduct thorough due diligence on suppliers, verify certifications, audit manufacturing processes, and consult legal experts to ensure IP compliance and protection.

Logistics & Compliance Guide for Laser Paint Removal Gun

Product Classification and Documentation

Ensure accurate classification of the laser paint removal gun under the appropriate Harmonized System (HS) Code for international shipping. Typical classifications may fall under 8543.70 (Electrical machines and apparatus, having individual functions, not specified elsewhere) or 9013.20 (Lasers, other than laser diodes). Confirm with local customs authorities. Maintain comprehensive technical documentation including user manuals, safety data sheets (if applicable), CE/UKCA marking certificates, FDA registration (if applicable in the U.S.), and a Declaration of Conformity.

Regulatory Compliance

Comply with international and regional regulations governing laser devices. Key requirements include:

– IEC 60825-1: Ensure the product meets laser safety standards for classification (typically Class 1, 1M, or 4 with safety interlocks).

– CE Marking (EU): Adhere to the Machinery Directive (2006/42/EC), Electromagnetic Compatibility (EMC) Directive (2014/30/EU), and Radio Equipment Directive (if wireless functions exist).

– FDA/CDRH (USA): Register the product with the FDA’s Center for Devices and Radiological Health and comply with 21 CFR Part 1040.10 for laser products.

– UKCA Marking (UK): Follow equivalent UK regulations post-Brexit.

– RoHS & REACH (EU): Confirm compliance with restrictions on hazardous substances and chemical registration.

Packaging and Labeling

Package the laser paint removal gun using shock-resistant, anti-static materials to prevent damage during transit. Clearly label each unit and shipping container with:

– Product name and model number

– Laser classification (e.g., “Laser Class 4 – Avoid direct exposure to beam”)

– CE, UKCA, FDA, or other relevant certification marks

– Manufacturer/importer contact information

– Handling symbols (e.g., fragile, do not stack)

– Safety warnings in the language(s) of the destination country

Shipping and Transportation

Use certified carriers experienced in handling industrial equipment and laser devices. Classify the shipment correctly under IATA (air), IMDG (sea), or ADR (road) regulations if batteries or hazardous components are included. For lithium-ion batteries (if used in portable models), follow IATA Dangerous Goods Regulations (DGR) for packaging, labeling, and documentation. Provide a commercial invoice, packing list, bill of lading/air waybill, and any required export licenses.

Import/Export Controls

Verify export eligibility under national regulations such as:

– U.S. Commerce Control List (CCL): Check ECCN (Export Control Classification Number) – potentially 6A003.b.4 for high-powered lasers.

– Wassenaar Arrangement: Confirm the device does not fall under dual-use technology controls.

Obtain necessary export licenses from relevant authorities (e.g., BIS in the U.S.) if required. For import, ensure the destination country does not restrict laser devices above certain power thresholds.

End-User Compliance and Training

Provide end-users with mandatory safety training materials and operational guidelines. Emphasize:

– Use of appropriate personal protective equipment (PPE), including laser safety goggles

– Controlled operational environments (e.g., restricted access zones)

– Proper disposal of ablated paint particles (potentially hazardous waste)

– Maintenance protocols to ensure continued compliance

Record Keeping and Audits

Maintain records of compliance documentation, shipment details, customer certifications, and training logs for a minimum of 5–10 years, depending on jurisdiction. Conduct annual internal audits to verify adherence to logistics and regulatory standards, and update documentation as regulations evolve.

Environmental and Disposal Compliance

Inform customers of proper disposal procedures in accordance with local environmental laws (e.g., WEEE in the EU). Recommend recycling programs for electronic components and safe handling of contaminated waste from paint removal operations.

Conclusion for Sourcing a Laser Paint Removal Gun

After thorough evaluation of available technologies, market options, and operational requirements, sourcing a laser paint removal gun presents a promising and forward-thinking solution for precision surface preparation. Laser ablation technology offers significant advantages over traditional methods such as sandblasting or chemical stripping, including minimized substrate damage, reduced waste generation, improved operator safety, and compliance with environmental regulations.

When sourcing the appropriate laser paint removal system, key factors to consider include laser power and wavelength, portability, ease of use, maintenance requirements, and total cost of ownership. Systems utilizing fiber laser technology with pulse modulation capabilities have proven effective for selective paint removal on sensitive materials like aerospace composites and metal alloys.

Suppliers should be vetted based on technical support, training availability, and proven track record in relevant industries such as aviation, automotive restoration, or cultural heritage preservation. While the initial investment is higher than conventional tools, the long-term benefits—such as lower operational costs, reduced downtime, and sustainability—justify the expenditure.

In conclusion, sourcing a laser paint removal gun is a strategic decision aligned with modern demands for efficiency, safety, and environmental responsibility. With careful selection and implementation, this advanced technology can significantly enhance surface maintenance operations and position organizations at the forefront of innovation.