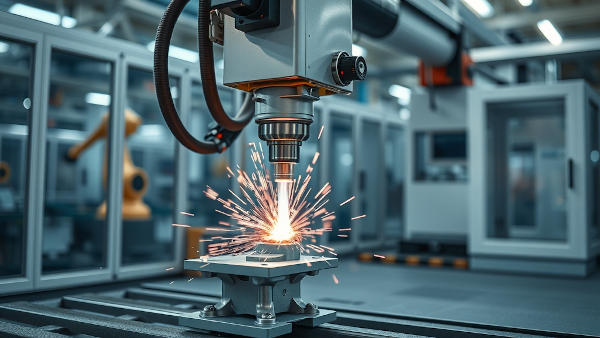

The global laser micro welding market is experiencing robust growth, driven by increasing demand for precision manufacturing across industries such as electronics, medical devices, and automotive. According to Grand View Research, the global laser welding market size was valued at USD 4.7 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 7.8% from 2023 to 2030, with micro welding applications playing a significant role in this expansion. Advancements in fiber laser technology, coupled with the rising need for non-contact, high-accuracy joining solutions, have intensified competition among equipment manufacturers. As automation and miniaturization trends accelerate, particularly in the production of wearable devices and implantable medical components, the demand for reliable and scalable laser micro welding systems continues to rise. This growing landscape has positioned several key players at the forefront of innovation, setting the stage for the following overview of the top 10 laser micro welder manufacturers shaping the future of precision manufacturing.

Top 10 Laser Micro Welder Manufacturers (2026 Audit Report)

(Ranked by Factory Capability & Trust Score)

#1 Micro Tig Welding Company & Micro Welding Services

Website: microweldinc.com

Key Highlights: Micro Weld, Inc. provides expert micro welding services nationwide, specializing in micro TIG and laser welding for medical devices, molds, and industrial ……

#2 Micro Arc Welding, Inc.

Website: microarcwelding.com

Key Highlights: Micro TIG and Laser Welding We’re the company you call when other companies won’t even quote your job. Specialty jobs are our specialty….

#3 Equipment & Systems

Website: amadaweldtech.com

Key Highlights: Manufacturer of equipment and systems for welding, cutting, marking, micromachining, sealing, and bonding. Resistance welding. Laser….

#4 Ultra

Website: laserphotonics.com

Key Highlights: Laser welding is a non-contact, highly precise process that enables manufacturers of miniature components to create strong, high-quality ……

#5 Laser Technology & Laser Machines from ALPHA LASER

Website: alphalaser.eu

Key Highlights: As a pioneer in the field of mobile laser welding, ALPHA LASER GmbH offers a wide range of high-quality laser welding devices. This includes laser welding ……

#6 Laser Micro Welding

Website: ebindustries.com

Key Highlights: We utilize different types of lasers to weld parts and electronic packages. Pulsed lasers apply a minimal amount of heat, which can greatly reduce, if not ……

#7 Sunstone Welders

Website: sunstonewelders.com

Key Highlights: Sunstone designs and manufactures high-tech micro welding and engraving solutions for many different industries. In short, wherever a very small spot weld ……

#8 Laser Welding

Website: ipgphotonics.com

Key Highlights: Discover Your Laser Welding Solution IPG is a partner for every stage of production from research and development to full-scale manufacturing….

#9 Microtech Welding Corp.

Website: microtechwelding.com

Key Highlights: Quality Precision Welding. Your reliable partner for American-made welding solutions with unmatched speed, service, and proven expertise….

#10 Laser Welding Machine

Website: baikeopto.com

Key Highlights: Model:200W YAG laser jewelry welding machine BK-JW200X Pro Voltage:110V/220V Laser Type:1064nm YAG Laser Small size Low weight Easy to operate ……

Expert Sourcing Insights for Laser Micro Welder

2026 Market Trends for Laser Micro Welders

H2: Rising Demand in Precision Industries Drives Laser Micro Welding Growth

The global laser micro welding market is poised for significant expansion by 2026, primarily fueled by escalating demand for ultra-precise, high-integrity joining solutions across advanced manufacturing sectors. Key trends shaping the market include:

-

Electronics & Semiconductor Dominance: The relentless miniaturization of electronic components, wearables, and advanced semiconductors necessitates non-contact, heat-precise welding. Laser micro welding enables reliable connections in micro-motors, sensors, battery tabs (especially for EVs and consumer electronics), and delicate circuitry without damaging surrounding materials, making it indispensable.

-

Medical Device Manufacturing Surge: Stringent requirements for biocompatibility, hermeticity, and minimal thermal impact in medical devices (implants, surgical tools, diagnostic equipment, drug delivery systems) are driving adoption. Fiber and pulsed lasers offer the precision needed for welding dissimilar metals and thin-walled components critical in this sector.

-

Automotive Electrification Acceleration: The shift towards electric vehicles (EVs) creates massive demand for high-precision battery manufacturing. Laser micro welding is crucial for joining battery cell tabs, busbars, and sensor components within battery packs, ensuring low resistance, high reliability, and safety. This application is a major growth engine.

-

Advancements in Laser Technology: Developments in ultra-short pulse (USP) lasers (picosecond, femtosecond), higher-power fiber lasers, and improved beam delivery systems enable finer control, reduced heat-affected zones (HAZ), and welding of previously challenging materials (e.g., dissimilar metals, transparent materials). Integrated sensors and real-time process monitoring enhance quality control and yield.

-

Automation & Integration: Laser micro welding systems are increasingly integrated into fully automated production lines with robotics and vision systems. This improves throughput, consistency, and enables complex 3D welding paths, meeting the demands of high-volume manufacturing in electronics and automotive.

-

Material Diversification: The need to weld dissimilar materials (e.g., copper to aluminum in batteries, metals to ceramics) and advanced alloys pushes innovation in laser parameters and process development, expanding the application scope of micro welding.

-

Focus on Sustainability & Efficiency: Laser micro welding is inherently a low-waste, energy-efficient process compared to traditional methods. This aligns with growing industrial sustainability goals, further boosting its appeal.

In conclusion, by 2026, the laser micro welder market will be characterized by robust growth, driven by technological innovation and fundamental shifts in core industries like electronics, medical devices, and electric vehicles, demanding unprecedented levels of precision and reliability in joining processes.

Common Pitfalls When Sourcing a Laser Micro Welder: Quality and Intellectual Property Risks

Sourcing a laser micro welder involves significant investment and technical complexity. Overlooking critical aspects related to quality and intellectual property (IP) can lead to costly setbacks, production delays, and legal exposure. Below are key pitfalls to avoid:

Quality-Related Pitfalls

Inadequate Process Validation and Repeatability

A major risk is selecting a system without thorough validation of its welding consistency and precision. Low-quality or poorly calibrated laser micro welders may produce inconsistent welds, especially on delicate or heat-sensitive materials. Always demand documented process capability studies (e.g., Cp/Cpk data), sample welds on your actual components, and verification of beam focus stability and positional accuracy.

Substandard Component Quality and Build Integrity

Some suppliers cut costs by using inferior optics, motion stages, or cooling systems. These components directly impact beam quality, system longevity, and maintenance needs. Poorly sourced galvanometers or laser sources may degrade rapidly, increasing downtime. Insist on transparency about component brands and specifications, and verify build quality through factory audits or third-party inspections.

Insufficient After-Sales Support and Calibration Services

High-precision systems require regular recalibration and technical support. Sourcing from suppliers without local service teams or clear service level agreements (SLAs) can result in extended downtimes. Ensure the supplier provides documented maintenance plans, accessible spare parts, and trained field engineers.

Intellectual Property-Related Pitfalls

Ambiguous IP Ownership in Customized Systems

When a laser micro welder is customized for a unique application, unresolved IP rights can create legal disputes. Suppliers may retain ownership of software algorithms, control logic, or process parameters developed during integration. Clearly define IP ownership in contracts—specify which elements (e.g., firmware, process recipes) are licensed vs. transferred, and ensure your proprietary processes remain protected.

Risk of IP Leakage During Technology Transfer

During setup and training, sensitive manufacturing know-how may be exposed to supplier personnel. Without strong non-disclosure agreements (NDAs) and data security protocols, there’s a risk of trade secret exposure, particularly when working with offshore vendors. Conduct due diligence on the supplier’s data handling practices and enforce strict access controls.

Using Counterfeit or Unauthorized Software/Firmware

Some lower-cost systems may incorporate pirated control software or unlicensed libraries, exposing the buyer to legal liability and cybersecurity risks. Confirm software authenticity, request licensing documentation, and verify compliance with relevant standards (e.g., CE, FDA, if applicable).

By proactively addressing these quality and IP concerns during the sourcing process, organizations can mitigate risks, ensure long-term performance, and protect their competitive advantages.

Logistics & Compliance Guide for Laser Micro Welder

Shipping & Handling

Ensure the Laser Micro Welder is properly packaged in its original, manufacturer-approved container with sufficient cushioning to prevent internal movement during transit. Use only carriers experienced in transporting precision industrial equipment. Clearly label the package as “Fragile,” “This Side Up,” and “Sensitive Equipment.” Maintain a stable temperature-controlled environment during shipping (typically 10°C to 40°C) to protect optical and electronic components. Avoid exposure to excessive humidity, dust, or vibration.

Import/Export Regulations

Verify export control classifications such as ECCN (Export Control Classification Number) under the U.S. Commerce Control List (CCL) or equivalent in your jurisdiction. Laser micro welders may be subject to regulations due to laser power, wavelength, or precision capabilities. Obtain required export licenses if shipping internationally, particularly to restricted destinations. Comply with International Traffic in Arms Regulations (ITAR) if applicable. For imports, ensure proper customs documentation including commercial invoice, packing list, and certificate of origin. Consult local customs authorities to confirm tariff codes (HS Code) and any import restrictions.

Laser Safety Compliance

Ensure the Laser Micro Welder meets relevant laser safety standards such as IEC 60825-1 (Safety of Laser Equipment) and FDA 21 CFR Part 1040.10 (U.S. laser product requirements). Confirm the device is properly classified (typically Class 1, 4, or embedded Class 1 with interlocks). Provide required safety labels, including laser warning signs, aperture labels, and emergency shutdown instructions. Implement engineering controls such as interlocks, beam enclosures, and key-controlled operation. Supply users with a Laser Safety Officer (LSO)-compatible operation manual and risk assessment documentation.

Electrical & Environmental Standards

Verify the equipment complies with regional electrical safety standards such as CE (EU), UL (USA), or CCC (China). Ensure grounding, voltage input (e.g., 200–240 VAC, 50/60 Hz), and power requirements match the destination’s infrastructure. Operate the system within specified environmental conditions: temperature (15°C to 35°C), humidity (30% to 70% non-condensing), and clean, low-particulate air. Avoid installation in explosive or corrosive atmospheres unless explicitly rated for such use.

Installation & Operational Training

Installation must be performed by qualified technicians following the manufacturer’s guidelines. Conduct a site survey to verify power stability, cooling requirements, compressed air (if applicable), and workspace clearance. Provide comprehensive operator and maintenance training covering startup procedures, emergency stops, routine maintenance, and hazard awareness. Maintain training records for compliance audits. Document all installation and commissioning steps for traceability.

Maintenance & Documentation

Adhere to the manufacturer’s preventive maintenance schedule, including calibration of optical components, inspection of cooling systems, and cleaning of laser delivery paths. Keep a service log with dates, performed actions, and technician details. Retain all compliance certificates (e.g., CE, FDA, laser safety), user manuals, and software version records. Update documentation promptly for any modifications or repairs to ensure ongoing regulatory compliance.

Conclusion for Sourcing a Laser Micro Welder

After a thorough evaluation of technical requirements, budget considerations, and production needs, sourcing a laser micro welder is a strategic investment that enhances precision, repeatability, and productivity in high-detail welding applications. The selected system balances advanced laser technology—such as pulsed fiber or YAG lasers—with automation capabilities and user-friendly controls to meet stringent quality standards in industries like medical device manufacturing, electronics, and aerospace.

Key factors driving the sourcing decision include beam accuracy, minimal heat-affected zones, compatibility with a range of materials (including dissimilar and sensitive metals), and long-term service support from the supplier. Additionally, lifecycle costs, training, and integration with existing production lines were critical in selecting a reliable and scalable solution.

By partnering with a reputable supplier offering proven technology, comprehensive technical support, and warranty coverage, the organization ensures sustained operational efficiency and a strong return on investment. The acquisition of a laser micro welder positions the company to meet current and future demands for high-precision joining processes, reinforcing its competitiveness in advanced manufacturing.