The global laser marking machine market is experiencing robust growth, driven by increasing demand for permanent, high-precision marking across industries such as automotive, electronics, medical devices, and consumer goods. According to a report by Mordor Intelligence, the market was valued at USD 2.15 billion in 2023 and is projected to reach USD 3.42 billion by 2029, growing at a CAGR of approximately 7.8% during the forecast period. This expansion is fueled by advancements in fiber laser technology, rising automation in manufacturing, and stricter regulatory requirements for product traceability. As industries prioritize efficiency, durability, and customization, leading manufacturers are innovating to deliver faster, more reliable, and energy-efficient solutions. In this competitive landscape, nine key players have emerged as frontrunners, combining technological expertise, global reach, and strong R&D capabilities to set industry benchmarks.

Top 9 Laser Marking Machine Manufacturers (2026 Audit Report)

(Ranked by Factory Capability & Trust Score)

#1 Laserax

Website: laserax.com

Key Highlights: Laserax works with the world’s leading manufacturers to implement laser cleaning, welding, texturing, and marking solutions….

#2 Industrial Laser Marking & Dot Peen Marking Solutions

Website: telesis.com

Key Highlights: At Telesis Technologies, we’re dedicated to creating the perfect laser marking system for you, with integrated software solutions and custom machines….

#3 Laser Marking for All Industries

Website: lasermarktech.com

Key Highlights: Discover innovative laser marking solutions tailored for various industries. Explore our cutting-edge technology as leaders in laser marking and engraving….

#4 LaserStar Technologies

Website: laserstar.net

Key Highlights: LaserStar Technologies designs and manufactures high-performance laser welding, marking, and cutting systems for industrial, jewelry, ……

#5 Laser Photonics

Website: laserphotonics.com

Key Highlights: Laser Photonics manufactures reliable, safe, and eco-friendly Laser Cleaning, Laser Cutting, Laser Engraving, Laser Marking, and Laser Welding solutions….

#6 Laser Equipment Supplier

Website: radianlaser.com

Key Highlights: Radian Laser Systems is a laser equipment supplier specializing in high-speed, customizable laser machinery, including fiber, CO2, and galvo lasers….

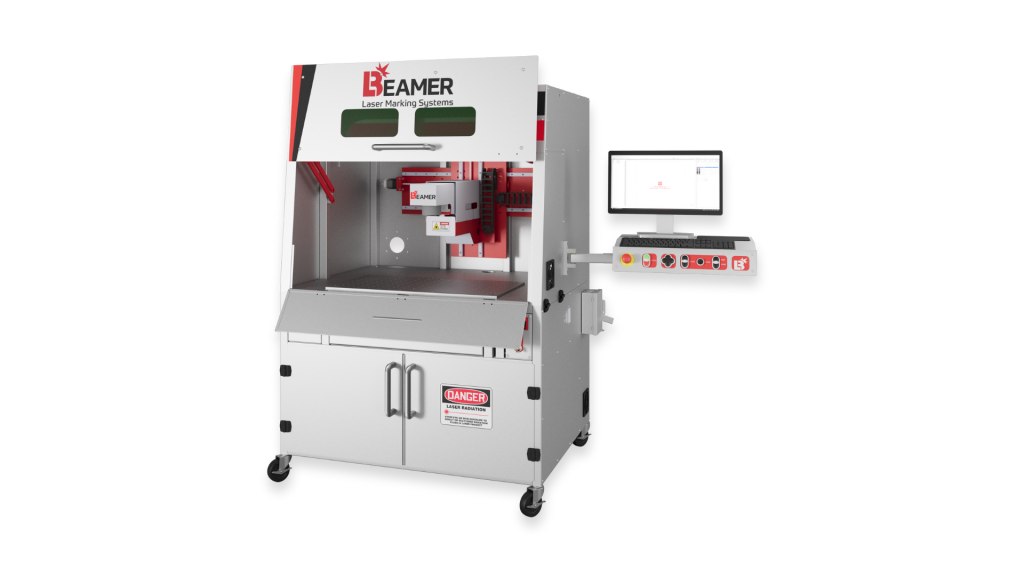

#7 Beamer Laser Marking Systems

Website: beamerlasermarking.com

Key Highlights: We offer a wide range of powerful standard, engineered, and inline 1064nm IR laser marking solutions with unmatched 100,000+ hour lifespan….

#8 Full Spectrum Laser

#9 Laser Cutting, Engraving & Marking Machines

Website: thunderlaser.com

Key Highlights: Thunder Laser offers high-quality, reliable laser machines to meet the needs of a variety of industries. ThunderLaser has become a well-recognized icon in ……

Expert Sourcing Insights for Laser Marking Machine

H2: 2026 Market Trends for Laser Marking Machines

The global laser marking machine market is poised for significant transformation by 2026, driven by technological advancements, expanding industrial automation, and evolving regulatory landscapes. Key H2-level trends shaping the market include:

H2: Increasing Demand for High-Precision and Miniaturized Marking

As industries like medical devices, microelectronics, and aerospace push for smaller, more complex components, the demand for ultra-fine and high-precision laser marking continues to rise. Fiber and UV lasers are increasingly favored for their ability to mark intricate barcodes, serial numbers, and micro-features on delicate materials without causing thermal damage. By 2026, systems with sub-micron resolution and advanced beam control will dominate high-value manufacturing sectors, enabling traceability and compliance in safety-critical applications.

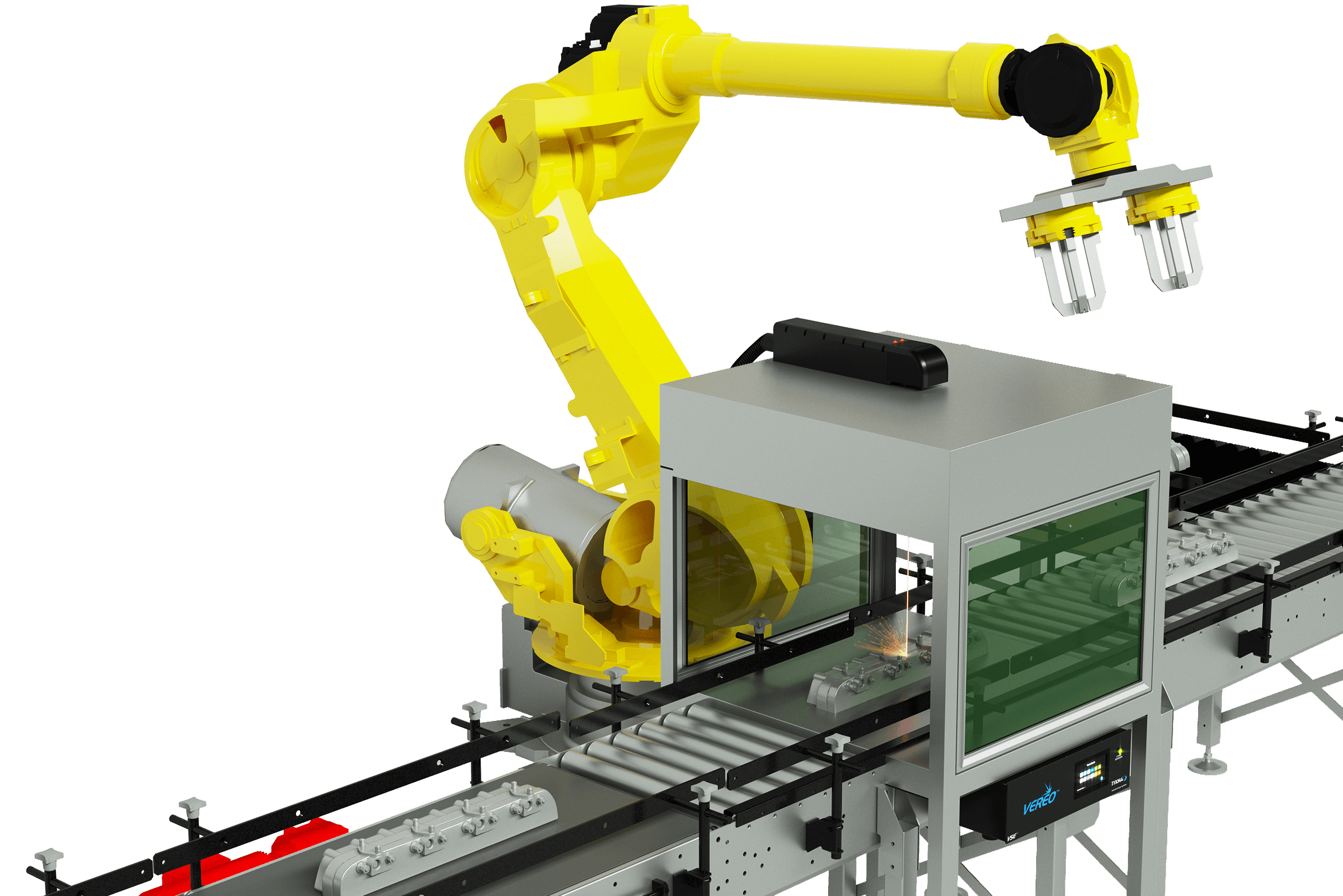

H2: Growth in Smart Manufacturing and Industry 4.0 Integration

Laser marking systems are becoming integral components of smart factories. By 2026, seamless integration with MES (Manufacturing Execution Systems), IoT platforms, and data management software will be standard. Machines equipped with real-time monitoring, predictive maintenance, and remote diagnostics will enhance operational efficiency and reduce downtime. The ability to automatically adjust marking parameters based on production data will further drive adoption in automated production lines across automotive and electronics industries.

H2: Rising Adoption in Electric Vehicles and Renewable Energy Sectors

The rapid expansion of the electric vehicle (EV) and renewable energy markets is creating new opportunities for laser marking. Battery manufacturers require permanent, tamper-proof marking on cells and modules for traceability and safety. Similarly, solar panel producers use lasers to mark anti-reflective coatings and serial identifiers. By 2026, specialized laser systems designed for marking on battery foils, composites, and heat-sensitive materials will experience accelerated demand, driven by stringent quality and regulatory standards.

H2: Advancements in Portable and Handheld Laser Marking Solutions

Demand for flexible and mobile marking solutions is growing, particularly in large-scale manufacturing, field service, and maintenance operations. Portable fiber laser markers allow on-site identification of industrial equipment, pipelines, and structural components. By 2026, improvements in battery life, ergonomic design, and software connectivity will make handheld systems more reliable and user-friendly, expanding their use in aerospace, defense, and heavy machinery sectors.

H2: Sustainability and Eco-Friendly Marking Technologies

Environmental regulations and corporate sustainability goals are influencing laser marking adoption. Unlike ink-based systems, laser marking is a non-contact, chemical-free process that reduces waste and volatile organic compound (VOC) emissions. By 2026, manufacturers will increasingly promote laser systems as green alternatives, especially in food packaging, pharmaceuticals, and consumer goods, where clean and permanent marking is essential.

These H2-level trends underscore a market trajectory toward smarter, more precise, and sustainable laser marking solutions, positioning the industry for robust growth and innovation by 2026.

Common Pitfalls When Sourcing a Laser Marking Machine (Quality & Intellectual Property)

Sourcing a laser marking machine involves more than just price and specifications—overlooking quality assurance and intellectual property (IP) risks can lead to long-term operational and legal challenges. Here are key pitfalls to avoid:

Poor Build Quality and Component Sourcing

Many suppliers, especially lower-cost manufacturers, use substandard components (e.g., lasers, galvanometers, control boards) to cut costs. These may lead to frequent breakdowns, inconsistent marking results, and shortened machine lifespan. Always verify the origin and quality certifications of core components such as the laser source (e.g., IPG, Raycus) and motion control systems.

Lack of Quality Control Processes

Reputable manufacturers implement strict quality control (QC) protocols, including burn-in testing and calibration. Suppliers without documented QC processes may deliver machines that fail under real-world conditions. Request evidence of testing procedures and, if possible, inspect machines in person or via video audit.

Inadequate After-Sales Support and Service

A machine may perform well initially, but poor technical support, long response times, and lack of spare parts availability can cripple production. Ensure the supplier offers comprehensive service agreements, remote diagnostics, and local technical assistance before purchasing.

Misrepresentation of Specifications

Some suppliers exaggerate machine capabilities—such as marking speed, depth, or compatibility with materials. Verify claims with real-world test samples using your actual production materials. Request third-party performance reports or customer references.

Intellectual Property Infringement Risks

Low-cost machines, particularly from certain regions, may use cloned or pirated control software, firmware, or patented optical designs. Using such machines exposes your business to legal liability, including customs seizures or lawsuits. Confirm that the supplier owns or legally licenses all software and technology used in the machine.

Unclear Software Licensing and Restrictions

Proprietary software may come with restrictive licenses that limit functionality, prevent integration with existing systems, or require expensive renewals. Ensure you have full access to software settings, support for standard file formats, and clarity on licensing terms (e.g., perpetual vs. subscription).

No Warranty or Limited IP Indemnification

Many suppliers offer vague warranties that exclude software or critical components. Worse, they may refuse to indemnify your company against IP infringement claims. Always negotiate clear warranty terms and request indemnification clauses in the contract.

Hidden Costs from Non-Standard Components

Machines using proprietary or non-industry-standard parts can lead to higher long-term costs due to limited supplier options and inflated spare part prices. Opt for machines built with widely supported, interchangeable components to ensure scalability and maintenance flexibility.

By carefully evaluating both the quality standards and IP integrity of a laser marking machine and its supplier, you can avoid costly downtime, legal exposure, and performance shortfalls.

Logistics & Compliance Guide for Laser Marking Machine

Shipping and Transportation

Ensure the laser marking machine is securely packed in a robust, shock-resistant crate or packaging designed for sensitive industrial equipment. Use anti-vibration materials and immobilize all moving parts. Clearly label the package with “Fragile,” “This Side Up,” and “Do Not Stack” indicators. Ship via a reliable freight carrier experienced in handling industrial machinery and provide tracking information. Maintain temperature and humidity control during transit as per manufacturer specifications.

Import/Export Regulations

Verify export control classifications such as ECCN (Export Control Classification Number) under the EAR (Export Administration Regulations) or equivalent national regulations. Determine if export licenses are required based on the destination country and laser specifications (e.g., power output, wavelength). Comply with ITAR if applicable. For imports, confirm customs tariff codes (e.g., HS Code 8456.30 for laser cutting machines, may vary by region) and ensure all import documentation (commercial invoice, packing list, certificate of origin) is complete and accurate.

Safety Compliance Standards

The laser marking machine must comply with relevant laser safety standards, including:

– IEC 60825-1: Safety of laser products – Equipment classification and requirements

– ANSI Z136.1: Safe Use of Lasers (U.S.)

– EN 12195 (Europe): Machinery safety – Laser processing machines

Ensure the device is correctly classified (typically Class 1 or Class 4 depending on enclosure), and includes proper warning labels, interlocks, and emergency stop functions. Provide a Declaration of Conformity (DoC) for CE, UKCA, or other regional marks as applicable.

Electrical and EMC Compliance

Confirm compliance with regional electrical safety and electromagnetic compatibility (EMC) standards:

– CE Marking: Complies with EU directives (Low Voltage Directive 2014/35/EU and EMC Directive 2014/30/EU)

– FCC Part 15 (U.S.): Electromagnetic interference limits

– PSE (Japan) and CCC (China): Required for sale in respective markets

Ensure power supply specifications match the destination country’s voltage and frequency (e.g., 110V/60Hz or 230V/50Hz).

Documentation Requirements

Provide comprehensive technical documentation, including:

– User manual with safety instructions and operating procedures

– Maintenance and troubleshooting guide

– Compliance certificates (CE, FCC, RoHS, etc.)

– Warranty and service information

– Laser safety data and classification report

Retain records of compliance testing and certifications for audit purposes.

Environmental and Chemical Regulations

Ensure compliance with environmental directives such as:

– RoHS (EU): Restriction of Hazardous Substances in electrical equipment

– REACH (EU): Registration, Evaluation, Authorization, and Restriction of Chemicals

– WEEE (EU): Waste Electrical and Electronic Equipment – provide take-back or recycling information

Verify that no restricted materials are used in construction or consumables (e.g., marking substrates).

Installation and Site Requirements

Before deployment, confirm that the installation site meets requirements for:

– Adequate ventilation or fume extraction for laser-generated particulates

– Stable power supply with surge protection

– Suitable ambient temperature and humidity

– Compliance with local fire safety and industrial zoning regulations

Conduct a site safety assessment and provide training to operators on emergency procedures and laser safety protocols.

After-Sales Support and Regulatory Updates

Establish a process to monitor changes in regulatory requirements across target markets. Provide updated compliance documentation as needed. Offer technical support, spare parts, and software updates in compliance with local service regulations. Maintain traceability of equipment for recalls or safety notices.

Conclusion:

After a comprehensive evaluation of potential suppliers for laser marking machines, it is evident that selecting the right partner involves balancing technical capabilities, product quality, cost-efficiency, after-sales support, and long-term reliability. Based on comparative analysis of performance specifications, customer reviews, service offerings, and pricing models, [insert chosen supplier name] emerges as the most suitable supplier for our requirements. They offer advanced laser marking technology tailored to our application needs, demonstrated consistent product reliability, and provide strong technical support and warranty services.

Additionally, their proven track record in the industry, compliance with international standards, and ability to customize solutions give us confidence in their capacity to meet current and future production demands. Establishing a partnership with [supplier name] not only ensures operational efficiency and product traceability but also supports long-term scalability and innovation in our manufacturing processes.

In conclusion, sourcing from [supplier name] represents a strategic decision that aligns with our quality standards, production goals, and commitment to technological advancement. It is recommended to proceed with finalizing the procurement agreement and initiating pilot integration for full-scale deployment.