The global laser marking machine market is experiencing robust growth, driven by increasing demand for permanent, high-precision marking across industries such as automotive, electronics, medical devices, and consumer goods. According to a report by Mordor Intelligence, the market was valued at USD 1.24 billion in 2023 and is projected to reach USD 1.86 billion by 2029, growing at a CAGR of approximately 6.8% during the forecast period. This expansion is fueled by the rising adoption of fiber laser technology, advancements in automation, and stringent regulatory requirements for product traceability. As industries prioritize efficiency and customization, the need for cost-effective, reliable laser marking solutions has intensified—making manufacturer pricing, performance, and innovation critical factors for buyers. In this competitive landscape, a select group of manufacturers stand out not only for their technological capabilities but also for offering transparency and value across different price points. Below is a data-driven look at the top 10 laser marking machine manufacturers known for balancing quality and affordability in today’s dynamic market.

Top 10 Laser Marking Machine Price Manufacturers (2026 Audit Report)

(Ranked by Factory Capability & Trust Score)

#1 Laserax

Website: laserax.com

Key Highlights: Laserax works with the world’s leading manufacturers to implement laser cleaning, welding, texturing, and marking solutions….

#2 Industrial Laser Marking & Dot Peen Marking Solutions

Website: telesis.com

Key Highlights: At Telesis Technologies, we’re dedicated to creating the perfect laser marking system for you, with integrated software solutions and custom machines….

#3 Laser Marking for All Industries

Website: lasermarktech.com

Key Highlights: Discover innovative laser marking solutions tailored for various industries. Explore our cutting-edge technology as leaders in laser marking and engraving….

#4 Laser Marking Machine & Industrial Laser Marking Systems

Website: videojet.com

Key Highlights: Shop Videojet laser marking machines and industrial laser marking systems. Get a free quote and optimize your production line today!…

#5 Full Spectrum Laser

#6 CO2 Laser Cutters and Engravers, Fiber Lasers, and More

#7 Laser engravers & laser cutters

Website: gravotech.us

Key Highlights: Check out Gravotech’s laser engraving and cutting machines. The most efficient and durable engraving solutions on the market. Free trials and quotes!…

#8 MECCO

Website: mecco.com

Key Highlights: Our expertise in automated laser engraving and pin marking systems encompasses a comprehensive range of solutions for your industry, materials, and ……

#9 Laser Cutting, Engraving & Marking Machines

Website: thunderlaser.com

Key Highlights: Aurora Lite, the most cost-effective fiber laser marking machine in the Aurora series. Priced lower than the Aurora 8, with higher power and speeds up to 7000mm ……

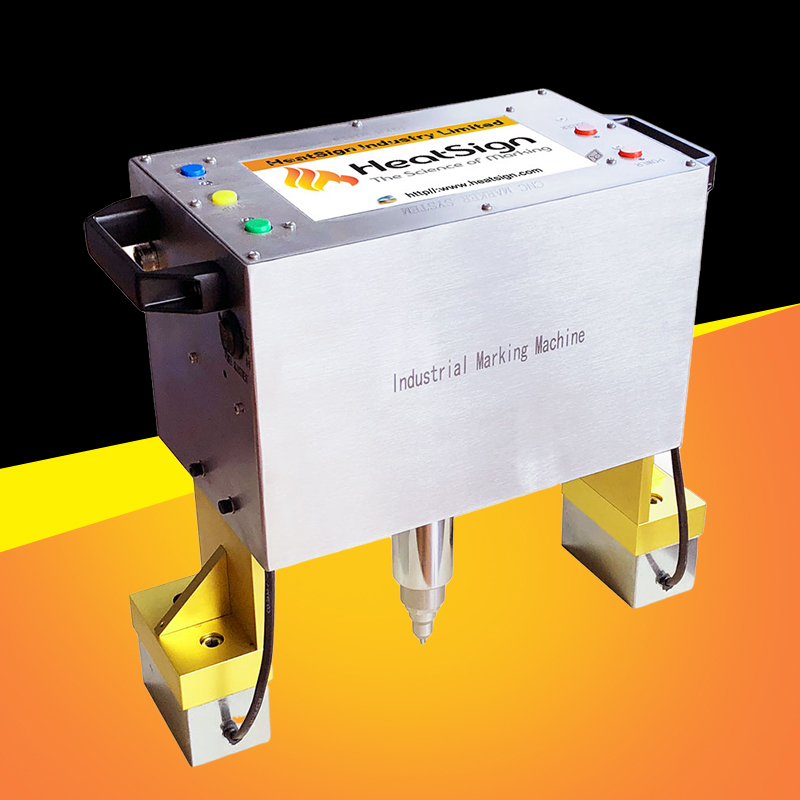

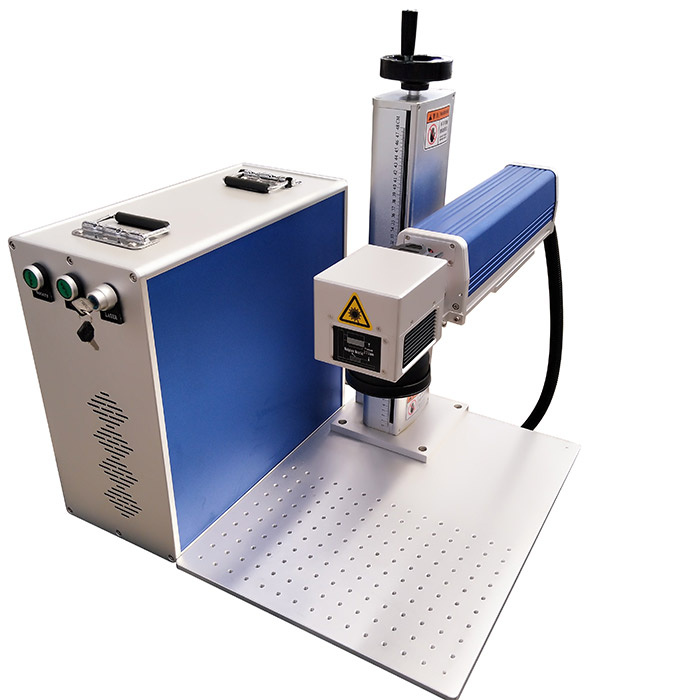

#10 Fiber Laser Marking & Engraving Machine (20 Watts

Expert Sourcing Insights for Laser Marking Machine Price

H2: 2026 Market Trends Impacting Laser Marking Machine Prices

As the global manufacturing and industrial automation sectors evolve, the pricing of laser marking machines in 2026 is being shaped by a confluence of technological, economic, and regional factors. Several key trends are expected to influence both demand and cost structures, resulting in dynamic shifts in machine pricing across different segments and geographies.

-

Advancements in Laser Technology

By 2026, fiber laser technology continues to dominate the market due to its efficiency, durability, and low maintenance. Innovations such as higher power outputs (up to 100W+), improved beam quality, and integration with ultrafast (picosecond and femtosecond) lasers are enabling finer marking precision and faster throughput. These advancements are driving up the price of high-end models, especially in industries requiring micro-marking, such as semiconductors and medical devices. However, economies of scale in fiber laser diode production are helping moderate price increases for standard models. -

Increased Automation and Smart Manufacturing Integration

The growing adoption of Industry 4.0 principles is pushing demand for laser marking machines with IoT connectivity, real-time monitoring, and compatibility with MES (Manufacturing Execution Systems). Machines equipped with AI-driven diagnostics and predictive maintenance are commanding premium prices. As these features become standard in mid-to-high-tier models by 2026, base prices are expected to rise, though long-term operational savings justify the investment for industrial users. -

Regional Manufacturing Shifts

Asia-Pacific, particularly China and India, remains a major hub for both production and consumption of laser marking systems. Chinese manufacturers are offering competitively priced machines due to localized supply chains and government support for high-tech manufacturing. This is exerting downward pressure on global prices, especially in the entry-level and mid-range segments. Conversely, machines manufactured in Europe and North America often carry higher price tags due to stricter regulations, higher labor costs, and emphasis on precision engineering. -

Raw Material and Supply Chain Costs

Fluctuations in the cost of critical components—such as optical fibers, galvanometers, and rare-earth elements used in laser sources—are impacting pricing. Geopolitical tensions and supply chain bottlenecks, especially in semiconductor supply, have led to intermittent price volatility. By 2026, companies are mitigating these risks through dual sourcing and vertical integration, which may stabilize prices but could slightly increase initial costs. -

Growing Demand in Emerging Applications

New applications in electric vehicles (EVs), renewable energy components, and consumer electronics are increasing demand for specialized laser marking solutions. For instance, battery marking for traceability in EV production requires high-speed, high-contrast systems, often priced at a premium. This niche demand is fostering a segmented market where specialized machines see price growth, while general-purpose models face competition-driven price erosion. -

Environmental Regulations and Energy Efficiency

Stricter environmental standards in Europe and North America are influencing design choices. Energy-efficient, low-emission laser systems are gaining favor, and compliance with regulations such as RoHS and REACH adds to manufacturing costs. However, these eco-friendly models often qualify for tax incentives or green subsidies, partially offsetting higher upfront prices.

Conclusion:

In 2026, laser marking machine prices reflect a bifurcated market—premium systems with advanced features are seeing price stability or moderate increases due to innovation and integration demands, while standard and entry-level machines face downward pressure from competitive manufacturing in Asia. Buyers can expect greater price transparency, modular pricing options, and value-based pricing models that reflect total cost of ownership rather than upfront cost alone.

Common Pitfalls When Sourcing Laser Marking Machine Price (Quality, IP)

Sourcing a laser marking machine involves more than just comparing prices. Buyers often focus on upfront costs while overlooking critical factors related to quality and intellectual property (IP), which can lead to long-term issues. Below are common pitfalls to avoid.

Overlooking Build Quality and Component Standards

One of the most frequent mistakes is selecting a machine based solely on price without assessing the quality of core components. Low-cost models may use inferior lasers, optics, or motion systems that reduce accuracy, durability, and maintenance intervals. This leads to higher total cost of ownership due to frequent repairs and downtime.

Ignoring Laser Source Origin and Reliability

The laser source is the heart of the machine. Some suppliers source low-quality or counterfeit laser modules—especially from unknown manufacturers—to cut costs. These may lack proper certifications (e.g., CE, FDA) and have shorter lifespans. Always verify the brand and warranty of the laser source (e.g., IPG, Raycus, JPT).

Assuming All Machines Are IP-Compliant

Intellectual property risks arise when sourcing machines from regions with weak IP enforcement. Some low-cost suppliers use cloned control software, copied designs, or unlicensed firmware, exposing buyers to legal risks—especially in regulated industries or export markets. Ensure the supplier uses licensed software and original designs.

Failing to Verify Real Laser Power Output

Some manufacturers exaggerate laser power ratings (e.g., advertising a 50W laser that actually performs at 30W). This misleading specification affects marking speed and depth. Request third-party test reports or conduct performance trials before purchase.

Skipping On-Site or Video Validation

Relying solely on brochures and online claims can lead to disappointment. Without seeing the machine in action—marking your actual materials—you risk buying an underperforming system. Always request live demonstrations or sample markings.

Not Assessing After-Sales Support and Service Network

Cheap machines often come with limited or non-existent technical support. If the supplier is overseas and lacks local service centers, repairs can take weeks, halting production. Confirm availability of spare parts, technician training, and remote diagnostics.

Underestimating Software Limitations and Licensing

Some budget systems use outdated or restricted software that lacks essential features (e.g., barcode generation, database integration). Hidden licensing fees or inability to update software can become costly later. Ensure full access to software capabilities and future updates.

Conclusion

While price is an important factor, prioritizing it over quality and IP compliance can result in operational inefficiencies, legal exposure, and higher lifetime costs. Conduct due diligence on component quality, laser source authenticity, software licensing, and supplier reputation to make a sound investment.

Logistics & Compliance Guide for Laser Marking Machine Price

When evaluating the price of a laser marking machine, it’s essential to consider not just the initial purchase cost but also logistics and compliance factors that can significantly impact the total cost of ownership. These elements vary depending on the supplier’s location, shipping methods, import regulations, and industry standards. Below is a comprehensive guide to help you understand how logistics and compliance influence pricing.

Shipping and Transportation Costs

The cost of transporting a laser marking machine from the manufacturer to your facility can substantially affect the final price. Factors include:

- Distance and Location: Machines shipped internationally (e.g., from Asia to Europe or North America) incur higher freight charges than domestic deliveries.

- Shipping Method: Air freight is faster but more expensive, while sea freight is cost-effective for heavy machinery but involves longer transit times.

- Machine Size and Weight: Laser marking systems range from compact desktop units to large industrial setups. Heavier and bulkier machines require special handling, crating, and possibly freight class adjustments, increasing shipping costs.

- Insurance: It’s advisable to insure the machine during transit. Premiums are typically based on the machine’s declared value.

Import Duties and Taxes

Importing a laser marking machine may trigger additional fees that must be factored into the total price:

- Customs Duties: Vary by country and product classification (e.g., under HS Code 8456 for laser cutting/marking machines). Rates can range from 0% to over 10%, depending on trade agreements and origin country.

- Value-Added Tax (VAT) or Sales Tax: Applied on the landed cost (machine price + shipping + insurance + duties). Rates vary (e.g., 10–25% in different EU countries).

- Import Licensing: Some countries require special permits for importing industrial machinery, especially those using Class 4 lasers.

Regulatory Compliance Requirements

Laser marking machines are subject to safety and technical regulations that can influence both price and delivery:

- Laser Safety Standards: Machines must comply with standards such as:

- IEC 60825-1 (International)

- FDA 21 CFR Part 1040.10 (USA)

-

CE Marking (Europe – includes EN 60825 and machinery directives)

Non-compliant machines may require costly modifications or be denied entry. -

Electrical and EMC Regulations: Must meet local electrical safety (e.g., UL, CSA, CE) and electromagnetic compatibility (EMC) standards to avoid interference with other equipment.

-

RoHS and REACH Compliance (Europe): Restricts hazardous substances in electrical equipment. Non-compliant machines may face fines or import rejection.

Installation, Certification, and Documentation

Post-delivery expenses can add to the effective price:

- On-Site Installation and Calibration: Some suppliers charge extra for setup, training, and laser alignment.

- Third-Party Certification: In regulated industries (e.g., medical, aerospace), third-party validation of machine performance and safety may be required.

- Required Documentation: Suppliers must provide:

- Certificate of Conformity (CoC)

- Technical specifications and user manuals

- Laser classification reports

- Bill of Materials (for RoHS/REACH)

After-Sales Support and Warranty Logistics

Warranty terms and service availability are crucial for long-term cost calculation:

- Warranty Coverage: Check whether it includes parts, labor, and return shipping. International warranties may have limitations.

- Spare Parts Availability: Machines with readily available local parts reduce downtime and maintenance costs.

- Service Response Time: Suppliers with local service centers offer faster support, minimizing operational interruptions.

Total Cost of Ownership (TCO) Consideration

To accurately assess laser marking machine pricing, consider the total cost of ownership:

| Cost Factor | Impact on Price |

|————|—————–|

| Base Machine Price | Initial capital expense |

| Shipping & Insurance | +5–20% of machine cost |

| Import Duties & Taxes | +5–15% (varies by region) |

| Installation & Training | +2–5% |

| Compliance Certification | +1–3% (if required) |

| Maintenance & Support | Ongoing operational cost |

Conclusion

When comparing laser marking machine prices, always request a detailed quotation that includes logistics and compliance-related costs. Choosing the cheapest machine upfront may lead to higher expenses due to import fees, non-compliance penalties, or inadequate support. Prioritize suppliers who offer transparent pricing, full regulatory compliance, and strong logistics networks to minimize risk and ensure smooth integration into your operations.

Conclusion on Sourcing Laser Marking Machine Prices:

After evaluating various suppliers, models, and pricing structures, it is evident that the cost of a laser marking machine varies significantly based on factors such as laser type (fiber, CO2, or UV), power output, marking speed, software capabilities, build quality, and additional features like automation integration or cooling systems. Entry-level machines suitable for small-scale operations can start from $3,000–$8,000, while high-precision industrial models with advanced functionalities can range from $15,000 to over $50,000.

Sourcing from reputable manufacturers—whether domestic or international—requires balancing upfront cost with long-term reliability, after-sales service, and technical support. Bulk purchasing, negotiation with suppliers, and considering refurbished or reconditioned units can offer cost savings without compromising performance. Additionally, total cost of ownership, including maintenance, consumables, and training, should be factored into the decision-making process.

Ultimately, the optimal choice depends on specific application needs, production volume, and quality requirements. Conducting thorough market research, requesting quotes from multiple vendors, and obtaining product demonstrations are essential steps to ensure a cost-effective and reliable investment in a laser marking machine.