The global laser marking machine market is experiencing robust growth, driven by increasing demand for permanent, high-precision marking solutions across industries such as automotive, electronics, medical devices, and consumer goods. According to a report by Mordor Intelligence, the global laser marking systems market was valued at USD 3.5 billion in 2023 and is projected to grow at a CAGR of over 7.5% from 2024 to 2029. A key contributor to this expansion is the rising adoption of portable laser marking machines, which offer flexibility, ease of integration, and on-site traceability—critical for maintenance, asset tracking, and field-based manufacturing.

Lightweight, hand-held designs, combined with advancements in fiber laser technology, have improved portability without sacrificing marking quality or durability. Additionally, Grand View Research highlights the influence of Industry 4.0 and the need for digital traceability, pushing manufacturers to adopt portable systems that support real-time data marking and integration with enterprise software.

As demand surges, a growing number of manufacturers are specializing in portable laser marking solutions, delivering innovations in power efficiency, battery life, software controls, and material compatibility. Below, we examine the top nine manufacturers leading this niche with strong product portfolios, global distribution, and demonstrated technological expertise.

Top 9 Laser Marking Machine Portable Manufacturers (2026 Audit Report)

(Ranked by Factory Capability & Trust Score)

#1 Automator Marking Systems

Founded: 1940

Website: automator.com

Key Highlights: Since 1940, Automator Marking Systems has been a world leader in industrial marking solutions, with an unwavering commitment to customer-centric innovation….

#2 Industrial Laser Marking & Dot Peen Marking Solutions

Website: telesis.com

Key Highlights: At Telesis Technologies, we’re dedicated to creating the perfect laser marking system for you, with integrated software solutions and custom machines….

#3 Technomark North America

Website: technomark-inc.com

Key Highlights: Technomark’s industrial laser marking systems provide permanent, high-contrast marks on metal, plastic, and composites. From compact units to high-speed, ……

#4 MECCO

Website: mecco.com

Key Highlights: Our expertise in automated laser engraving and pin marking systems encompasses a comprehensive range of solutions for your industry, materials, and ……

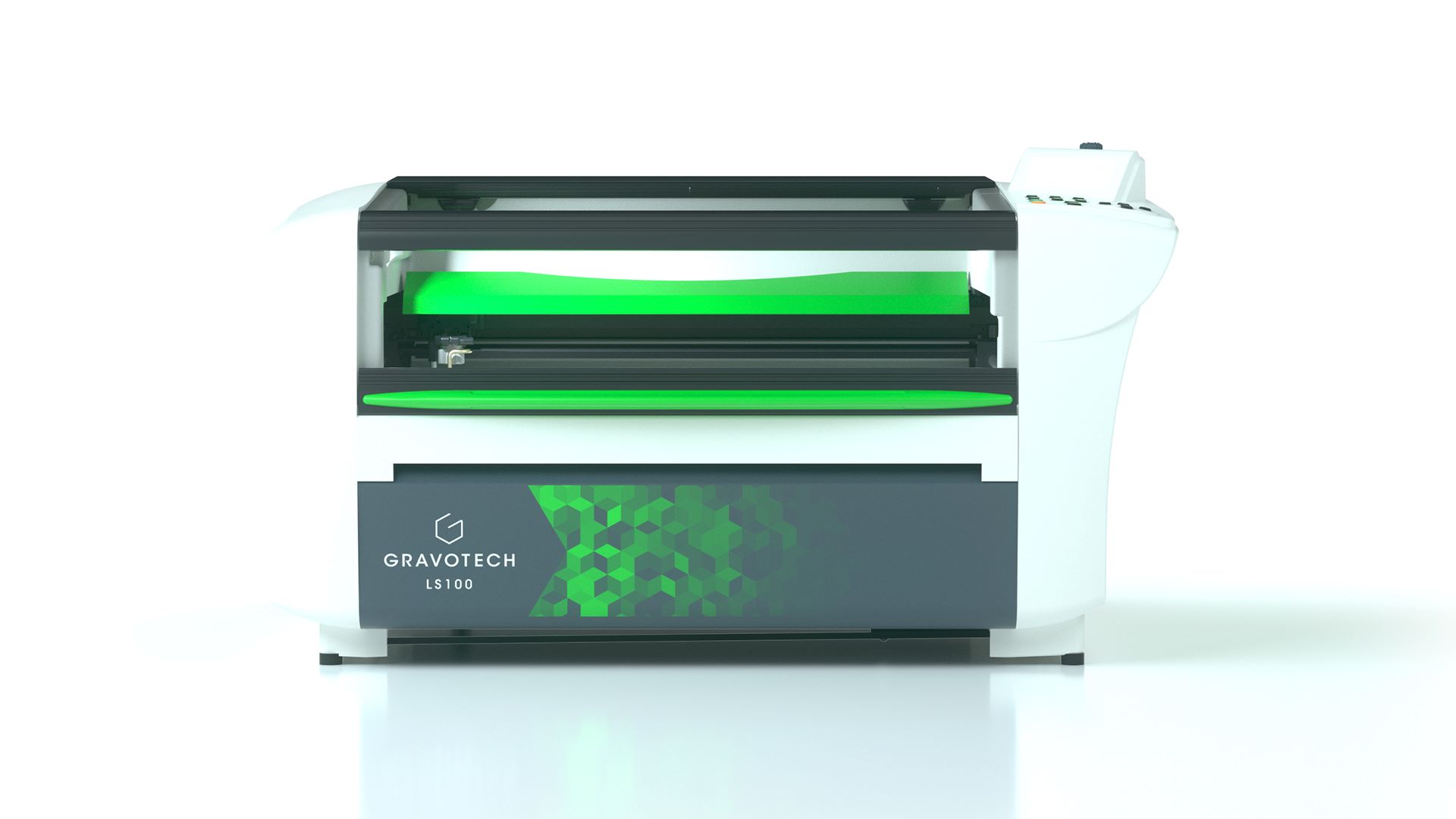

#5 Gravotech

Website: gravotech.us

Key Highlights: Small and portable engraving machine for jewelry. Marking area: 100 x 100 mm. Diameter: 12,5 to 27 mm. Materials: Plastics, metals and organic materials (glass, ……

#6 Lase

Website: permanentmarking.com

Key Highlights: The LaseNGo is a portable, handheld class 1 MOPA laser engraver on wheels, offering the flexibility for marking large objects like pipes, large containers, ……

#7 Handheld Laser Marking Systems

Website: laserphotonics.com

Key Highlights: The MarkStar Handheld Pro+ Marking Laser 1030 is our most powerful handheld tool for accelerated permanent marking. Delivering 30% more power than other ……

#8 20W Portable Handheld Fiber Laser Marker & Marking Machine

Website: us.hanslaser.net

Key Highlights: 20W portable laser marking machine is equipped with a high-precision 2D scanning head. With laser etching completed within 20s, it achieves fast marking….

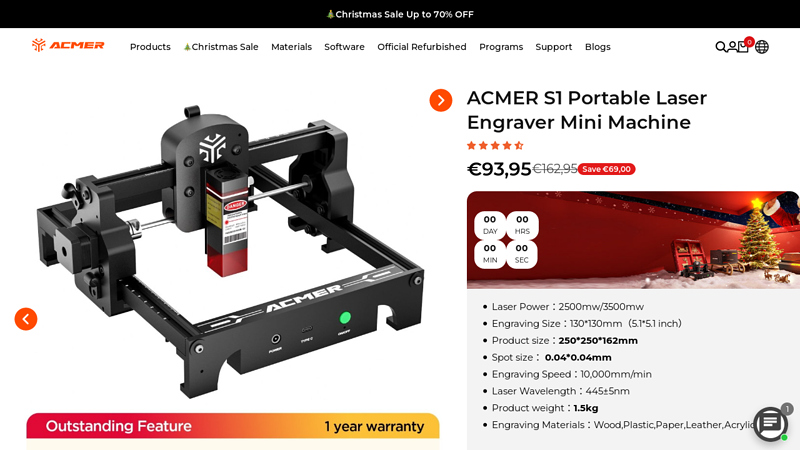

#9 ACMER S1 Portable Laser Engraver Mini Machine

Website: acmerlaser.com

Key Highlights: Free delivery 30-day returnsCompact ACMER S1 Portable Laser Engraver with 10000mm/min speed, 130×130mm area, and 0.04mm precision. Perfect mini laser engraver for DIY projects….

Expert Sourcing Insights for Laser Marking Machine Portable

H2: 2026 Market Trends for Portable Laser Marking Machines

The global market for portable laser marking machines is poised for significant transformation by 2026, driven by technological advancements, expanding industrial applications, and growing demand for on-site precision marking solutions. Key trends shaping this market include:

-

Increased Demand Across Industries

By 2026, industries such as automotive, aerospace, electronics, medical devices, and energy are expected to increase their adoption of portable laser marking systems. These machines offer flexibility for on-the-go part identification, serial numbering, and traceability compliance—critical for quality assurance and regulatory requirements. -

Advancements in Laser Technology

Fiber and UV laser technologies are becoming more compact, energy-efficient, and powerful. The integration of high-performance diodes and improved beam quality enables clearer, deeper, and faster marking—even on challenging materials like stainless steel, aluminum, and engineered plastics—making portable units more versatile and effective. -

Growth in On-Site and Field Service Applications

The mobility and ease of use of portable laser markers are driving their deployment in remote and field environments. Sectors like oil & gas, power generation, and infrastructure maintenance increasingly rely on these systems for asset identification, repair verification, and compliance marking without requiring parts to be transported to fixed facilities. -

Integration with Industry 4.0 and Smart Manufacturing

Portable laser marking machines are being integrated with digital workflows, cloud-based data management, and IoT platforms. By 2026, many models will support wireless connectivity, barcode/QR code generation, and real-time data logging, aligning with the broader trend toward smart factories and digital traceability systems. -

Emphasis on User-Friendly Design and Safety

Manufacturers are focusing on ergonomic design, intuitive software interfaces, and enhanced safety features (e.g., enclosed marking zones, beam shutters, and real-time monitoring) to improve operator experience and comply with international safety standards such as IEC 60825. -

Rising Adoption in Small and Medium Enterprises (SMEs)

Decreasing costs, modular configurations, and flexible financing options are making portable laser marking machines more accessible to SMEs. These businesses benefit from in-house marking capabilities without investing in large, fixed installations. -

Expansion in Emerging Markets

Asia-Pacific, Latin America, and Africa are expected to witness strong growth due to industrialization, rising manufacturing output, and government initiatives promoting digitalization and product traceability. China, India, and Southeast Asian countries will be key contributors to market expansion. -

Sustainability and Eco-Friendly Operations

As environmental regulations tighten, the non-contact, chemical-free nature of laser marking is gaining favor over traditional ink-based methods. Portable systems further reduce waste and energy use, supporting corporate sustainability goals.

In conclusion, the portable laser marking machine market in 2026 will be defined by mobility, intelligence, and adaptability. As industries demand greater flexibility and traceability, these compact systems will play a crucial role in modern manufacturing and maintenance ecosystems worldwide.

Common Pitfalls When Sourcing a Portable Laser Marking Machine (Quality & IP)

Sourcing a portable laser marking machine requires careful evaluation to avoid compromising on quality and intellectual property (IP) protection. Overlooking key factors can lead to poor performance, legal risks, and long-term cost inefficiencies. Below are common pitfalls to watch out for:

Poor Build Quality and Component Selection

Many low-cost suppliers use substandard materials and unreliable components to cut costs. This includes weak housings, low-grade optics, and unstable laser sources that degrade quickly. As a result, machines may suffer from inconsistent marking quality, frequent breakdowns, and short lifespans—undermining productivity and increasing maintenance costs.

Inaccurate or Overstated Technical Specifications

Some suppliers exaggerate laser power, marking speed, or depth capabilities. For instance, a machine advertised as 20W may deliver significantly less actual output due to inefficient cooling or poor diode quality. Always verify specs with independent test reports or request live demonstrations under real-world conditions.

Lack of IP Protection and Risk of Counterfeit Technology

Purchasing from manufacturers without legitimate intellectual property rights can expose your business to legal liability. Cloned or reverse-engineered laser systems may infringe on patents or trademarks. Ensure the supplier holds valid IP rights or proper licensing for their technology—especially critical if you operate in regulated industries or export markets.

Inadequate Software and Firmware Compliance

Proprietary software bundled with the machine may use unlicensed code or lack encryption, posing security and IP risks. Additionally, non-compliant firmware can prevent integration with existing production systems or fail to meet industry standards (e.g., GDPR, ISO). Confirm software authenticity and check for open-source compliance if needed.

Insufficient After-Sales Support and Spare Parts Availability

Portable units are often used in remote or field environments where reliability is crucial. Suppliers based overseas may lack local service networks, leading to prolonged downtimes. Verify access to technical support, firmware updates, and genuine spare parts before making a purchase.

Non-Compliance with International Safety and Export Standards

Cheaply made machines may not meet essential safety certifications (e.g., FDA, CE, RoHS), creating hazards and import barriers. Laser classification (e.g., Class 1 vs. Class 4) must be accurate—mislabeling can result in regulatory penalties and operational disruptions.

Hidden Costs from Poor Integration and Training

While the initial price may seem attractive, poor documentation, lack of training, and incompatible interfaces can increase total cost of ownership. Ensure the supplier provides comprehensive onboarding, API access (if needed), and compatibility with common design software (e.g., CorelDraw, AutoCAD).

By addressing these pitfalls proactively, buyers can secure a high-quality, legally compliant portable laser marking solution that delivers reliable performance and protects long-term business interests.

Logistics & Compliance Guide for Portable Laser Marking Machine

This guide outlines essential considerations for the safe, efficient, and compliant logistics and handling of portable laser marking machines, covering transportation, documentation, safety, and regulatory requirements.

Shipping & Transportation

Ensure the portable laser marking machine is securely packaged in its original container or a suitable protective case with ample cushioning to prevent damage during transit. Use shock-absorbing materials and secure internal components to avoid movement. Clearly label the package as “Fragile” and “This Side Up.” When shipping via air, ground, or sea, comply with carrier-specific regulations for electronic equipment and lithium batteries (if included in the power supply or handheld unit). Confirm whether the shipment requires a Material Safety Data Sheet (MSDS) or Safety Data Sheet (SDS), particularly if the machine contains batteries or hazardous materials.

Import/Export Regulations

Verify compliance with import and export control regulations in both the origin and destination countries. Portable laser devices may be subject to export controls under frameworks such as the International Traffic in Arms Regulations (ITAR) or the Export Administration Regulations (EAR) in the U.S., depending on power output and technical specifications. Classify the machine using the appropriate Harmonized System (HS) code (e.g., 8456.11 or 8515.21) to determine duties and restrictions. Obtain required export licenses or authorizations where applicable, and ensure all documentation—including commercial invoice, packing list, and certificate of origin—is accurate and complete.

Safety Compliance & Certification

Ensure the portable laser marking machine meets relevant safety standards before shipment or operation. In the U.S., compliance with the FDA/CDRH (Code of Federal Regulations 21 CFR Part 1040.10) for laser products is mandatory. In the European Union, the machine must carry the CE marking and conform to the Laser Products Safety Standard (EN 60825-1) and the Machinery Directive (2006/42/EC) or Electromagnetic Compatibility (EMC) Directive (2014/30/EU) as applicable. Other regions may require PSE (Japan), RCM (Australia/New Zealand), or KC (South Korea) certification. Maintain documentation of conformity assessments, test reports, and technical files.

Laser Safety & User Training

The portable laser marking machine must be operated in accordance with local occupational health and safety regulations. Users must be trained on laser safety protocols, including proper use of personal protective equipment (PPE) such as laser safety goggles rated for the specific wavelength and power of the laser. Implement engineering controls (e.g., beam enclosures where possible) and administrative controls (e.g., restricted access zones) during operation. Provide a user manual that includes safety warnings, maintenance instructions, and emergency procedures. Comply with standards such as ANSI Z136.1 (U.S.) or IEC 60825 internationally.

Battery & Electrical Compliance (if applicable)

If the portable unit includes a built-in or external rechargeable battery (e.g., lithium-ion), ensure compliance with transportation regulations for lithium batteries (e.g., IATA Dangerous Goods Regulations for air transport). Batteries must be properly installed, protected from short circuits, and shipped at a state of charge not exceeding 30% when required. Electrical components should meet regional standards such as UL (U.S.), CSA (Canada), or CE (EU) for electrical safety, ensuring protection against overcurrent, overheating, and electric shock.

Documentation & Recordkeeping

Maintain comprehensive documentation throughout the product lifecycle, including:

– Certificate of Conformity (CoC)

– Technical construction file

– Risk assessment report

– User manual with multilingual warnings

– Calibration and maintenance logs

– Export control classification number (ECCN) or licensing documents

Retain records for a minimum of five years or as required by local regulations to support audits and compliance verification.

End-of-Life & Environmental Compliance

Dispose of the portable laser marking machine in accordance with environmental regulations such as WEEE (Waste Electrical and Electronic Equipment Directive) in the EU or equivalent local e-waste laws. Do not discard batteries in regular trash; recycle them through approved channels. Provide end-users with information on proper disposal and recycling options to ensure compliance with environmental standards.

Conclusion: Sourcing a Portable Laser Marking Machine

Sourcing a portable laser marking machine is a strategic investment that offers significant advantages in flexibility, efficiency, and cost-effectiveness for businesses across various industries such as manufacturing, automotive, aerospace, and metal fabrication. These compact and mobile systems enable on-site marking of serial numbers, barcodes, logos, and other identifiers directly on large or immovable components, reducing downtime and eliminating the need to transport parts to fixed workstations.

When selecting a portable laser marking machine, key factors to consider include laser type (fiber, CO2, or UV), marking speed, precision, durability, ease of use, compatibility with different materials, and after-sales support. It is crucial to evaluate suppliers based on reputation, technical expertise, and service offerings to ensure long-term reliability and performance.

In conclusion, a well-chosen portable laser marking solution enhances operational agility, improves traceability, and supports compliance with industry standards. By carefully assessing technical specifications and supplier capabilities, businesses can identify a system that meets their specific needs and delivers a strong return on investment.