The global laser marking machine market is experiencing robust growth, driven by rising demand for permanent, high-precision marking solutions across industries such as automotive, electronics, medical devices, and aerospace. According to a 2023 report by Mordor Intelligence, the market was valued at USD 1.57 billion in 2022 and is projected to grow at a CAGR of 7.8% from 2023 to 2028. This expansion is largely fueled by the increasing adoption of 3D laser marking technology, which enables intricate engraving on complex and curved surfaces—capabilities that traditional 2D systems cannot achieve. Grand View Research also highlights the growing integration of automation and fiber laser systems as key drivers, with industries prioritizing efficiency, traceability, and compliance with regulatory standards. As demand for advanced 3D marking solutions intensifies, a select group of manufacturers have emerged as leaders, combining innovation, precision engineering, and global reach to dominate the space.

Top 10 Laser Marking Machine 3D Manufacturers (2026 Audit Report)

(Ranked by Factory Capability & Trust Score)

#1 Industrial Laser Markers

Website: telesis.com

Key Highlights: Laser marking systems are ideal for manufacturers looking to mark serial numbers, codes, logos and more on their products. Learn more today!…

#2 Focus on laser

Website: hanslaser.net

Key Highlights: Laser marking machines Laser cutting machines Laser welding machines Automation Laser generator Semiconductor packaging equipment 3D printers Motor….

#3 Laser Marking for All Industries

Website: lasermarktech.com

Key Highlights: Discover innovative laser marking solutions tailored for various industries. Explore our cutting-edge technology as leaders in laser marking and engraving….

#4 HGLASER

Website: hglaserglobal.com

Key Highlights: HGLASER is a leading provider of laser cutting machine, laser marking mahcine and laser cleaning machine.Email:[email protected]….

#5 3D Scanhead For Laser Marking Machine Manufactures and Suppliers

Website: cklasermachine.com

Key Highlights: CKLASER is one of the leading manufacturers and suppliers of 3d scanhead for laser marking machine. Top quality, great selection and expert advice are our ……

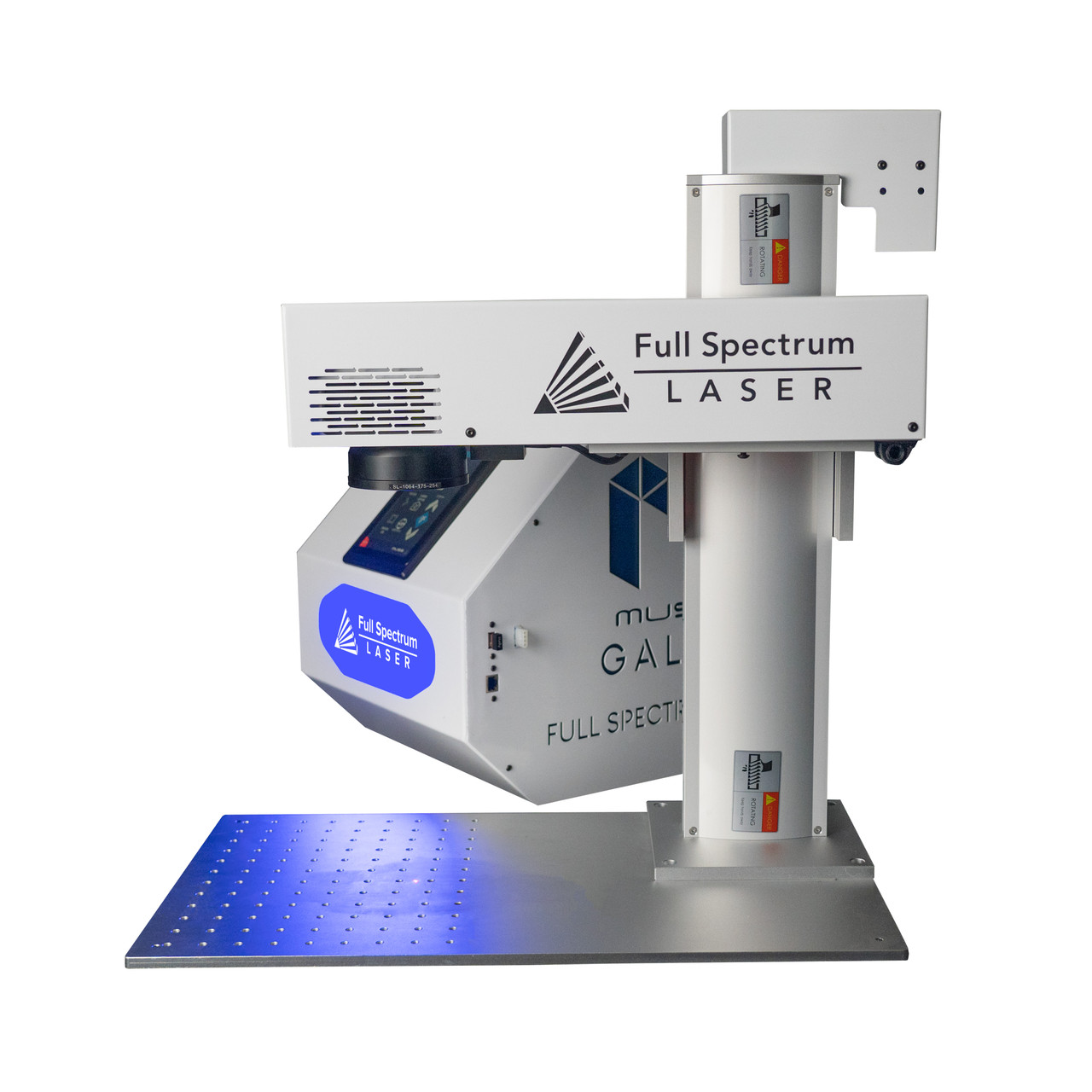

#6 Full Spectrum Laser

#7 Laser Equipment Supplier

Website: radianlaser.com

Key Highlights: Radian Laser Systems designs and manufactures high-end 2D and 3D (3-axis) fiber, CO2, and UV galvanometer-based laser and marking solutions….

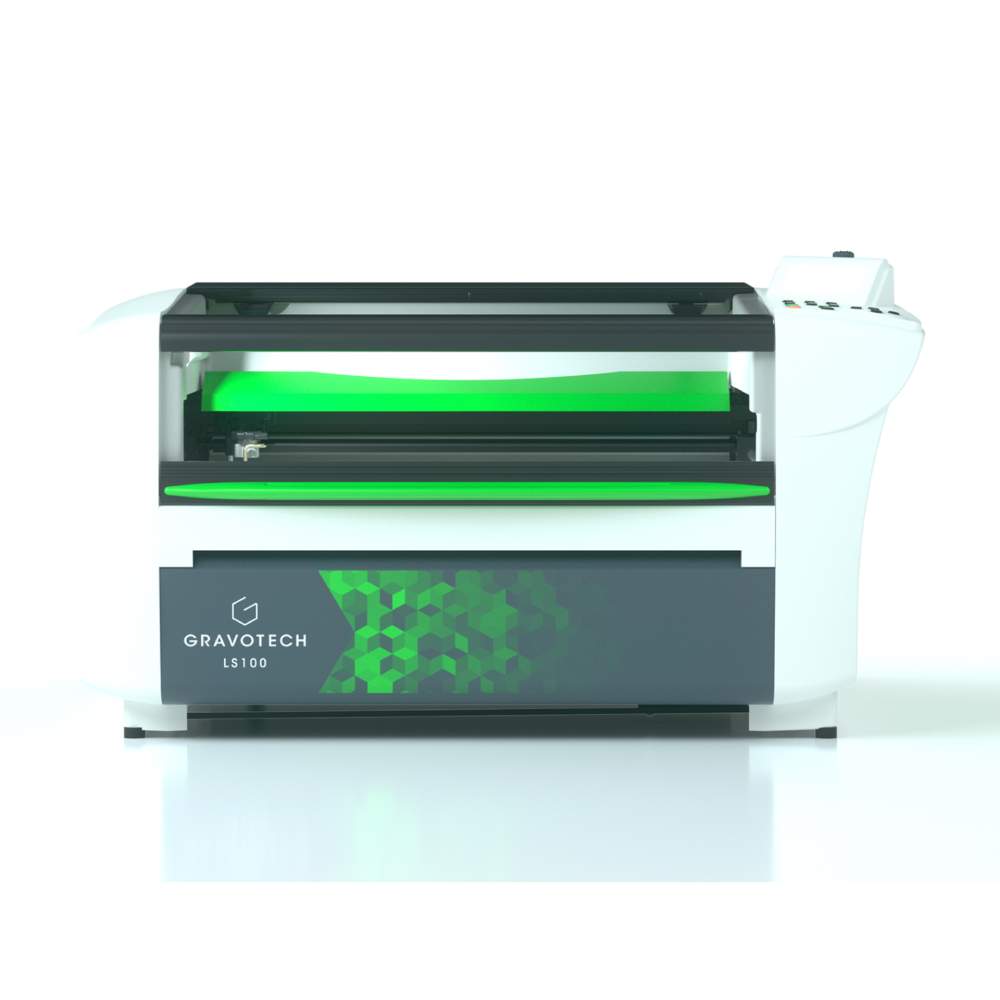

#8 Gravotech

Website: gravotech.us

Key Highlights: Gravotech designs, manufactures, and distributes innovative engraving, marking, and cutting solutions….

#9 Snapmaker US: Snapmaker Online Store

#10 Laser Marking and Engraving Machines

Website: coherent.com

Key Highlights: Choose from a wide range of laser marking and engraving machines, from self-contained table-top systems to fully automated machines with robotic parts ……

Expert Sourcing Insights for Laser Marking Machine 3D

H2: 2026 Market Trends for 3D Laser Marking Machines

The global market for 3D laser marking machines is poised for significant transformation by 2026, driven by technological advancements, expanding industrial automation, and growing demand for precision marking across high-value sectors. This analysis examines key trends shaping the 3D laser marking machine market in 2026 under the H2 framework—highlighting Hybrid Technologies, High-Precision Demands, Industrial 4.0 Integration, and Health & Sustainability considerations.

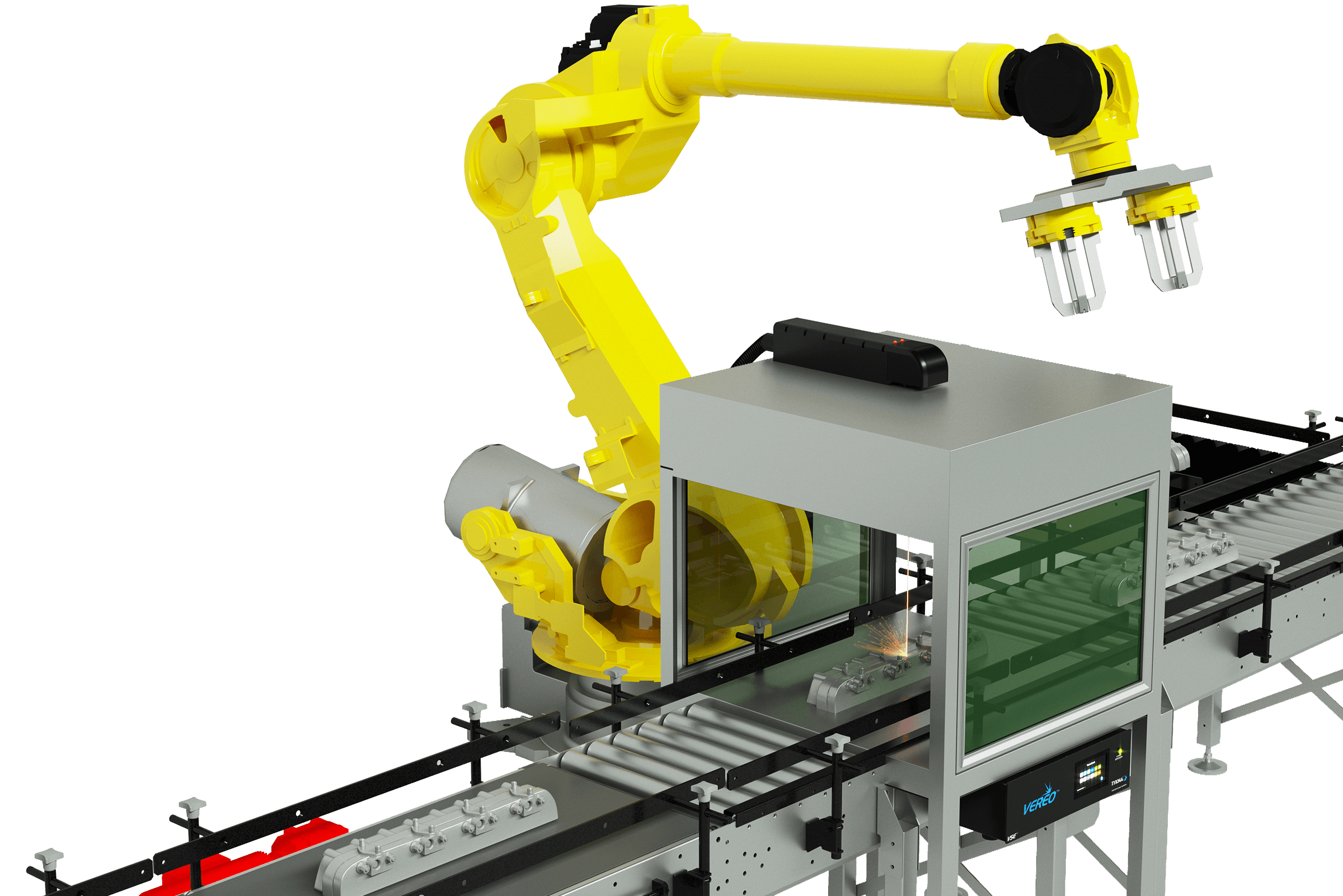

1. Hybrid Technologies: Convergence of 3D Laser with Additive and Smart Manufacturing

By 2026, hybrid systems that combine 3D laser marking with additive manufacturing (3D printing) and multi-axis robotics are expected to dominate advanced production lines. Manufacturers are increasingly adopting integrated solutions where laser marking is applied in situ during or immediately after fabrication, ensuring traceability and reducing handling. Fiber lasers with dynamic focus and galvanometer scanning systems are being enhanced with AI-driven path optimization, enabling real-time adaptation to complex 3D surfaces. This fusion supports custom, on-demand production—especially in aerospace, medical devices, and automotive sectors—where part serialization, anti-counterfeiting, and regulatory compliance are critical.

2. High-Precision Demands: Miniaturization and Micro-Marking Capabilities

The push toward miniaturization in electronics, medical implants, and semiconductors is driving demand for ultra-high precision 3D laser marking. By 2026, ultrafast lasers (e.g., picosecond and femtosecond) are expected to gain market share due to their ability to mark intricate patterns without thermal damage on sensitive materials. These systems support micron-level accuracy and are essential for marking serial numbers, QR codes, and data matrices on curved or irregular 3D geometries. Market leaders are investing in software algorithms that allow sub-micron positioning, improving readability and durability of marks on challenging substrates such as ceramics, polymers, and coated metals.

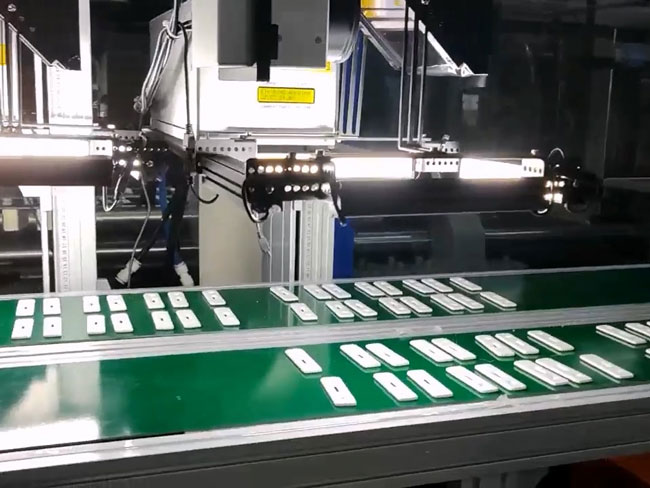

3. Industrial 4.0 Integration: Smart, Connected, and Data-Driven Marking Systems

The integration of 3D laser marking machines into smart factories is accelerating. By 2026, most industrial-grade systems will feature IoT connectivity, cloud-based monitoring, and compatibility with Manufacturing Execution Systems (MES) and Product Lifecycle Management (PLM) platforms. Real-time data collection enables predictive maintenance, quality assurance, and full traceability across the production chain. Embedded vision systems with machine learning capabilities allow for automatic surface recognition and mark verification, reducing human intervention and errors. This trend is particularly strong in regulated industries such as pharmaceuticals and automotive, where audit trails and part genealogy are mandatory.

4. Health & Sustainability: Eco-Friendly Operations and Worker Safety

Environmental and occupational health concerns are influencing the design and operation of 3D laser systems. By 2026, manufacturers are expected to prioritize energy-efficient lasers, recyclable components, and closed-loop fume extraction systems to meet stricter global environmental regulations (e.g., EU RoHS, REACH). The adoption of green lasers (532 nm) and UV lasers for marking sensitive materials reduces heat-affected zones and hazardous emissions. Additionally, improved enclosure designs and automated safety interlocks enhance operator protection, aligning with ISO 13849 and IEC 60825 standards. Sustainability is becoming a competitive differentiator, with customers favoring suppliers offering low-carbon footprint solutions.

Conclusion

The 3D laser marking machine market in 2026 will be defined by intelligent, integrated, and sustainable systems that meet the evolving needs of advanced manufacturing. Companies that leverage hybrid technologies, deliver micron-level precision, enable Industry 4.0 connectivity, and adhere to health and environmental standards will lead the market. As global supply chains demand greater transparency and customization, 3D laser marking will transition from a simple identification tool to a core component of smart, agile production ecosystems.

Common Pitfalls When Sourcing a 3D Laser Marking Machine (Quality & IP)

Sourcing a 3D laser marking machine involves significant investment and technical considerations. Overlooking key aspects related to quality and intellectual property (IP) can lead to operational failures, legal risks, and financial losses. Below are common pitfalls to avoid:

Poor Build Quality and Component Selection

Many suppliers, especially low-cost manufacturers, use substandard materials and components to reduce prices. This includes low-grade optics, unreliable galvanometers, and insufficient cooling systems. Such machines suffer from poor beam quality, inconsistent marking depth, frequent breakdowns, and shortened lifespans. Always verify the origin and specifications of core components like the laser source (e.g., IPG, Raycus), scanning heads, and control systems.

Inadequate 3D Marking Capabilities

Some machines marketed as “3D laser markers” lack true dynamic focus or advanced motion control systems needed for complex curved or uneven surfaces. Buyers may end up with a system that only simulates 3D marking through software tricks, resulting in blurry or distorted engravings. Ensure the machine supports real-time Z-axis control (e.g., via linear motors or servo-driven autofocus) and compatible 3D modeling software.

Lack of IP Protection and Risk of Infringement

Using a laser machine that incorporates unauthorized or pirated software—such as unlicensed versions of EZCAD, LaserMark, or CAD/CAM tools—exposes your business to legal liability. Additionally, some manufacturers copy patented optical designs or motion control algorithms. Sourcing from such suppliers may lead to IP infringement claims, especially in regulated markets like the EU or North America. Always request proof of software licensing and verify the OEM’s R&D credentials.

Insufficient After-Sales Support and Technical Documentation

Low-cost suppliers often lack robust technical support or spare parts availability. Poor documentation—missing calibration procedures, error codes, or maintenance guides—hampers troubleshooting and increases downtime. This is particularly critical for 3D systems, which require precise alignment and periodic recalibration. Confirm that the supplier provides detailed manuals, training, and accessible service engineers.

Hidden Costs from Non-Standard Interfaces and Integration Challenges

Some machines use proprietary communication protocols or software APIs that complicate integration with existing production lines or MES systems. This can lead to expensive custom development or delays in automation. Ensure the machine offers open communication standards (e.g., TCP/IP, Modbus) and SDKs for seamless factory integration.

Overlooking Compliance and Safety Certifications

Machines without proper safety certifications (e.g., CE, FDA, IEC 60825) may fail regulatory inspections, especially in medical or aerospace applications. Non-compliant systems can also pose health risks due to inadequate laser shielding or interlock systems. Always request valid certification documents and verify their authenticity.

By addressing these pitfalls early—through thorough supplier vetting, technical validation, and legal due diligence—buyers can ensure a reliable, compliant, and IP-safe 3D laser marking solution.

Logistics & Compliance Guide for Laser Marking Machine 3D

Overview

This guide outlines the essential logistics and compliance considerations for importing, transporting, installing, and operating a 3D Laser Marking Machine. Adherence to these guidelines ensures regulatory compliance, operational safety, and smooth supply chain processes.

Regulatory Compliance

Laser Safety Standards

Ensure the 3D laser marking machine complies with international and local laser safety regulations, including:

– IEC 60825-1: Safety of laser products – Equipment classification and requirements.

– FDA 21 CFR Part 1040.10 (U.S.): Performance standards for laser products; requires compliance certification and proper labeling.

– CE Marking (EU): Compliance with the Machinery Directive (2006/42/EC), Electromagnetic Compatibility (EMC) Directive (2014/30/EU), and the Low Voltage Directive (2014/35/EU).

– LVD and EMC Directives: Confirm machine conformity with safety and electromagnetic emission standards in target regions.

Equipment Certification and Documentation

- Obtain and maintain a Declaration of Conformity (DoC) from the manufacturer.

- Ensure the machine has a CE, FDA, or equivalent certification depending on the destination country.

- Include technical files, user manuals, and safety instructions in the local language(s) of the destination market.

Environmental and Chemical Compliance

- Verify compliance with RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) if applicable.

- Confirm that any auxiliary materials (e.g., marking coatings or cleaning agents) meet local environmental regulations.

Import and Export Requirements

Export Documentation

Prepare the following documentation for international shipments:

– Commercial Invoice

– Packing List

– Bill of Lading or Air Waybill

– Certificate of Origin

– Export License (if required by the exporting country for laser technology)

– Technical specifications and HS (Harmonized System) code (typically 8456.30 for laser cutting/marking machines)

Import Regulations

- Research import duties, taxes, and customs clearance procedures in the destination country.

- Confirm if the laser machine requires an import permit or special license (e.g., from customs or a national radiation safety authority).

- Be aware of restrictions on high-power lasers in certain jurisdictions.

Packaging and Transportation

Secure Packaging

- Use robust, shock-resistant packaging with anti-static protection.

- Include foam inserts or custom crating to prevent movement during transit.

- Clearly label packages with “Fragile,” “This Side Up,” and “Protect from Moisture.”

Shipping Methods

- Choose air freight for urgent deliveries or sea freight for cost-effective bulk transport.

- Use freight forwarders experienced in handling industrial machinery and hazardous/laser equipment.

- Ensure temperature and humidity controls during transport if required.

Handling and Delivery

- Confirm receiving site is accessible for delivery vehicles and has adequate space and equipment (e.g., forklifts) for unloading.

- Inspect the machine upon delivery for any visible damage; document and report issues immediately to the carrier and supplier.

Installation and Operational Compliance

Site Preparation

- Ensure the installation site meets electrical requirements (voltage, grounding, phase).

- Provide proper ventilation if fumes are generated during laser marking.

- Install the machine on a stable, vibration-free surface.

Safety Measures

- Install interlocks, emergency stop buttons, and protective enclosures per safety standards.

- Provide proper laser safety signage (e.g., warning labels, beam hazard indicators).

- Equip operators with appropriate personal protective equipment (PPE), including laser safety goggles rated for the machine’s wavelength.

Training and Maintenance

- Train operators on safe use, emergency procedures, and maintenance protocols.

- Maintain a log for regular servicing and safety inspections.

- Keep software updated and ensure compliance with cybersecurity standards if the machine is network-connected.

Recordkeeping and Audits

- Maintain logs of compliance certifications, maintenance, safety training, and incident reports.

- Prepare for periodic audits by regulatory bodies or internal compliance teams.

- Retain documentation for a minimum of 5–10 years, depending on local regulations.

Conclusion

Proper logistics planning and regulatory compliance are critical for the safe and legal deployment of 3D laser marking machines. By following this guide, businesses can mitigate risks, avoid delays, and ensure long-term operational success. Always consult with local authorities and compliance experts to address region-specific requirements.

Conclusion for Sourcing a 3D Laser Marking Machine

Sourcing a 3D laser marking machine is a strategic investment that significantly enhances production capabilities, especially for applications requiring precision, durability, and customization on complex or curved surfaces. These advanced systems offer superior flexibility compared to traditional 2D machines, enabling high-contrast, permanent marks on three-dimensional components used across industries such as automotive, aerospace, medical devices, and electronics.

When selecting a 3D laser marking machine, key considerations include laser type (fiber, UV, or CO₂), optical control systems (3D galvo scanners), software compatibility, working area, and integration capability with existing production lines. Additionally, evaluating vendor reputation, after-sales support, training, and cost of ownership ensures long-term reliability and performance.

Ultimately, the right 3D laser marking solution improves marking quality, boosts operational efficiency, and supports compliance with traceability and branding requirements. By carefully assessing technical specifications and aligning them with application needs, businesses can achieve a strong return on investment and maintain a competitive edge in high-precision manufacturing environments.