The global laser cutting machine market is experiencing robust growth, driven by rising demand for precision manufacturing across industries such as automotive, aerospace, and electronics. According to Mordor Intelligence, the market was valued at USD 4.85 billion in 2023 and is projected to reach USD 7.23 billion by 2029, growing at a CAGR of approximately 6.9% during the forecast period. Similarly, Grand View Research estimates strong expansion due to advancements in fiber laser technology and increasing automation in production processes. As competition intensifies, manufacturers are strategically positioning themselves to offer cost-effective, high-performance laser systems, making price a critical differentiator. This growing market landscape has led to a proliferation of suppliers offering diverse pricing models based on application, power, and automation level. Below, we analyze the top 10 laser machine manufacturers known for their competitive pricing, technological innovation, and market reach.

Top 10 Laser Machine Price Manufacturers (2026 Audit Report)

(Ranked by Factory Capability & Trust Score)

#1 LaserStar Technologies

Website: laserstar.net

Key Highlights: LaserStar Technologies is a US manufacturer of laser products and has engineered, designed, and built laser systems and solutions for use in high-precision ……

#2 Universal Laser Systems

Website: ulsinc.com

Key Highlights: Solve Material Processing Challenges. Overcome your most demanding and complex applications. ULS helps companies evaluate the feasibility of laser technology….

#3 Wattsan

Website: wattsan.com

Key Highlights: Wattsan is a manufacturer of laser and cnc milling machines of European quality at affordable prices with worldwide delivery….

#4 Full Spectrum Laser

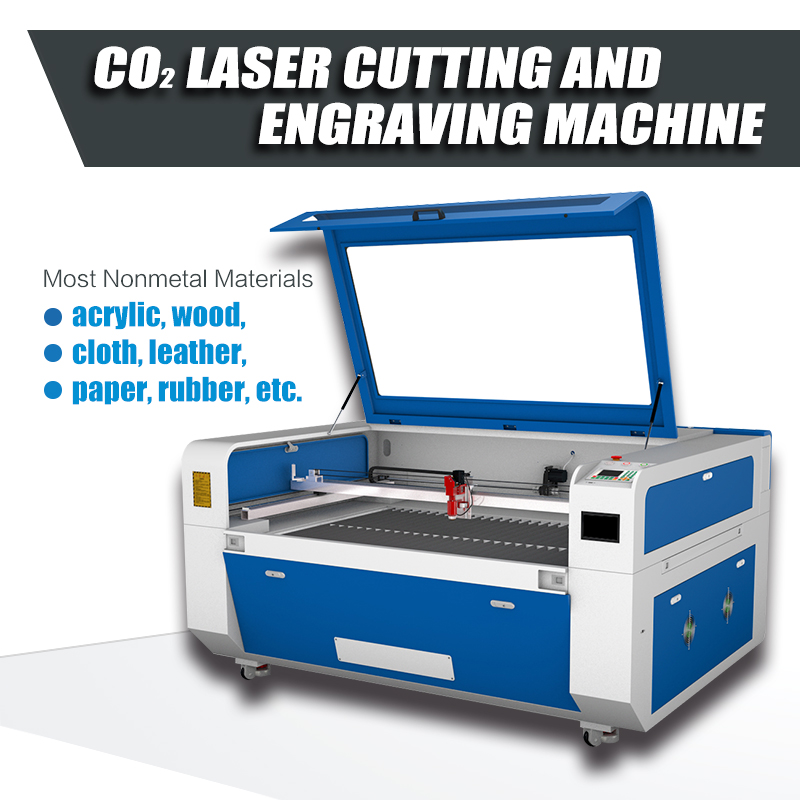

#5 CO2 Laser Cutters and Engravers, Fiber Lasers, and More

Website: omtech.com

Key Highlights: Free delivery · 30-day returnsBrowse our wide collection of laser cutters and engravers! From CO2 laser engravers and cutters to the best fiber laser engravers for metal marking, …

#6 Laser Cutting, Engraving & Marking Machines

Website: thunderlaser.com

Key Highlights: Thunder Laser is committed to providing high-quality laser solutions at competitive prices. We are all about bringing innovative laser systems and efficient ……

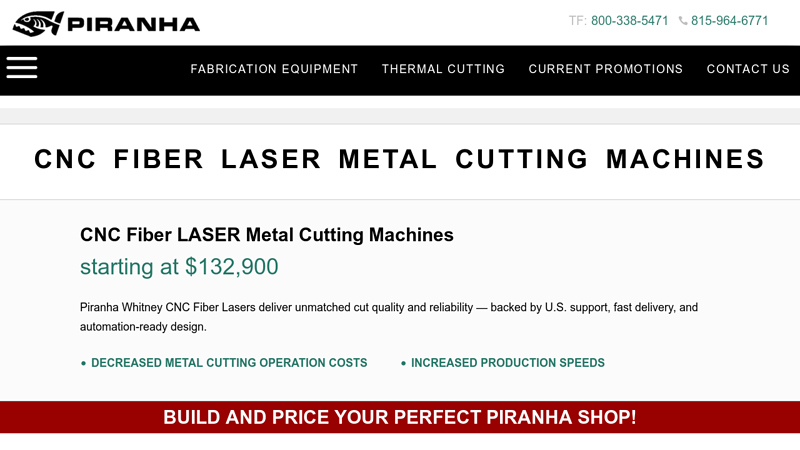

#7 CNC Fiber LASER Metal Cutting Machines

Website: piranhafab.com

Key Highlights: CNC Fiber LASER Metal Cutting Machines by Piranha Range From 1kW Fiber LASER to 20kW Fiber LASER: CNC LASER Steel Cutting Up To 525 IPM @ 1/4 Inch….

#8 Desktop Laser Engravers and Cutters for Any Budget

#9 Laser cutting and engraving machine

Website: troteclaser.com

Key Highlights: Fastest laser engraver on the market ✓ Engrave and cut acrylic, wood, leather etc. ✓ Work area of 1016 x 610 mm. Check it out now!…

#10 6 Best Laser Engraving Cutting Machines

Website: 1laser.com

Key Highlights: 4–6 day deliveryWe deliver the high quality laser engravers and cutters. From CO2 laser engravers to desktop laser engravers, find your best laser cutting machines today….

Expert Sourcing Insights for Laser Machine Price

H2: Analysis of 2026 Market Trends for Laser Machine Prices

As we approach 2026, the global market for laser machines is undergoing significant transformation driven by technological innovation, increasing automation across industries, and shifting supply chain dynamics. These factors are collectively influencing laser machine pricing trends, with both downward pressures from mass production and upward influences from advanced capabilities and demand in high-growth sectors.

1. Technological Advancements Driving Price Diversification

By 2026, fiber laser technology will dominate the industrial segment due to its superior efficiency, lower maintenance, and longer operational life compared to CO2 and crystal lasers. This widespread adoption has led to economies of scale, particularly in mid-power (1–6 kW) fiber lasers, resulting in a 10–15% decline in average prices over the past two years. However, high-power lasers (10 kW and above) used in heavy metal cutting and aerospace applications are seeing price stability or slight increases due to specialized components and R&D costs.

2. Rising Demand in Emerging Markets

Expansion in manufacturing hubs in Southeast Asia, India, and Eastern Europe is fueling demand for affordable and reliable laser cutting and welding machines. Local manufacturers in China and South Korea are capitalizing on this by offering competitively priced machines with improved quality. This has intensified price competition, especially in the entry-level and mid-range segments, where prices could drop by up to 20% from 2023 levels.

3. Integration of AI and Smart Manufacturing

Laser machines with AI-powered diagnostics, predictive maintenance, and IoT connectivity are becoming standard in Industry 4.0 environments. These “smart” systems command a premium of 15–25% over traditional models. As automation becomes essential in automotive, electronics, and medical device manufacturing, demand for intelligent laser systems will support higher price points despite overall market price erosion.

4. Supply Chain and Raw Material Costs

The availability and cost of key components—such as laser diodes, optical fibers, and rare-earth materials—remain volatile. Geopolitical tensions and export restrictions, particularly involving China and the U.S., may create supply bottlenecks. While automation in production is helping offset labor costs, potential increases in semiconductor and photonic component prices could limit further price reductions in 2026.

5. Sustainability and Regulatory Pressures

Environmental regulations in Europe and North America are pushing manufacturers toward energy-efficient and recyclable laser systems. Compliance with these standards adds to production costs but also differentiates premium products. As sustainability becomes a purchasing criterion, eco-certified laser machines may maintain or increase in price relative to non-compliant models.

Conclusion

In 2026, the laser machine market will experience a bifurcated pricing trend: commoditized, mid-range machines will see continued price declines due to competition and mass production, while high-end, intelligent, and application-specific systems will maintain or increase in value. Buyers can expect greater affordability in standard industrial models but will pay a premium for innovation, integration, and performance. Overall, average prices are projected to remain stable with a slight downward tilt (-3% to -5% annually), contingent on supply chain resilience and technological breakthroughs.

Common Pitfalls When Sourcing Laser Machine Prices (Quality, IP)

When sourcing laser machines, focusing solely on price can lead to significant long-term costs and risks. Two critical areas often overlooked are quality and intellectual property (IP). Falling into these pitfalls can compromise performance, safety, and legal compliance.

Overlooking Build Quality and Component Standards

Many suppliers offer attractively low prices by using substandard materials and components. Machines with inferior optics, weak mechanical frames, or low-grade electronics may fail prematurely or deliver inconsistent results. Buyers must verify the quality of core components like laser sources, motion systems, and cooling units—often by requesting detailed specifications and third-party certifications.

Ignoring Long-Term Maintenance and Support Costs

A low initial price can be misleading if maintenance is frequent or spare parts are expensive and hard to source. Some low-cost machines use proprietary parts or lack local service support, leading to extended downtime. Always assess the availability of technical support, service networks, and cost of consumables before purchasing.

Falling for Misrepresented Laser Power and Performance

Some suppliers exaggerate laser power or cutting/writing capabilities. A machine advertised as “100W” might deliver significantly less effective power due to poor design or component inefficiencies. Request real-world performance data, test cuts, or third-party validation to confirm advertised specifications.

Neglecting Intellectual Property (IP) Infringement Risks

Low-cost laser machines, especially from certain regions, may use cloned firmware, counterfeit control boards, or pirated software. Using such equipment exposes buyers to legal risks, including IP litigation, customs seizures, or forced shutdowns. Always verify software licenses and ensure the machine uses original, legally licensed components.

Skipping Proper Due Diligence on Suppliers

Relying on price alone often means choosing unknown or unverified suppliers. These vendors may disappear after sale or fail to honor warranties. Conduct background checks, review customer testimonials, and consider visiting the manufacturer. Reputable suppliers provide transparent documentation and stand behind their products.

Assuming All Certifications Are Genuine

Machines may claim compliance with safety or EMC standards (e.g., CE, FCC), but these certifications can be forged. Request copies of valid test reports and verify them when possible. Non-compliant machines pose safety hazards and may be rejected by regulators or insurers.

By addressing these pitfalls, buyers can make informed decisions that balance cost with quality, reliability, and legal safety—ensuring a better return on investment and operational peace of mind.

Logistics & Compliance Guide for Laser Machine Price

When evaluating the total cost of acquiring a laser machine, the listed price is only the starting point. Logistics and compliance factors significantly impact the final delivered cost and operational readiness. Understanding these elements ensures accurate budgeting and avoids delays or penalties.

Understanding the Total Cost of Ownership

The initial laser machine price often excludes critical logistics and compliance-related expenses. Buyers must consider shipping, insurance, import duties, taxes, customs clearance, and regulatory compliance to determine the true cost. Failing to account for these can lead to unexpected financial burdens and shipment delays.

Shipping and Transportation Costs

Freight method—air, sea, or land—greatly affects delivery time and cost. Large industrial laser machines are typically shipped via sea freight due to size and weight, which is cost-effective but slower. Air freight offers speed at a premium. Packaging must meet international standards, often requiring crating and shock protection. Include origin and destination handling fees, inland transportation, and port charges in your budget.

Import Duties and Taxes

Laser machines may be subject to import duties based on the Harmonized System (HS) code, which varies by country. Value Added Tax (VAT), Goods and Services Tax (GST), or other sales taxes are typically applied to the total landed cost (machine price + shipping + insurance + duties). Research your country’s tariff schedule and tax regulations to estimate these costs accurately.

Customs Clearance and Documentation

Smooth customs clearance requires proper documentation, including a commercial invoice, packing list, bill of lading or air waybill, and certificate of origin. Some countries require additional forms for high-value machinery. Delays occur if documentation is incomplete or inaccurate. Partnering with a licensed customs broker can streamline this process and ensure compliance.

Regulatory and Safety Compliance

Laser machines are subject to strict safety and technical regulations. Key compliance standards include:

– FDA/CDRH (U.S.): Requires laser product reporting and certification.

– CE Marking (EU): Mandates compliance with the Machinery Directive and EMF Directive.

– RoHS and REACH: Environmental and chemical restrictions applicable in many regions.

– Laser Safety Standards (IEC 60825): Defines classifications and safety requirements.

Non-compliant machines may be detained or rejected at customs. Verify that the manufacturer provides necessary certifications and technical files before purchase.

Installation and On-Site Compliance

After delivery, ensure the installation site meets electrical, ventilation, and safety requirements. Some jurisdictions require on-site inspections or permits for industrial laser operations. Training personnel according to OSHA (U.S.) or equivalent local safety standards is also essential for compliance.

Final Recommendation

Always request a detailed breakdown of the laser machine price that includes or estimates shipping, insurance, duties, and taxes. Work with suppliers experienced in international trade and confirm they provide all necessary compliance documentation. Proactive planning in logistics and compliance minimizes risks and ensures a seamless integration of your laser system.

Conclusion for Sourcing Laser Machine Price:

After thorough research and evaluation of various suppliers, models, and pricing structures, it is evident that the cost of a laser machine varies significantly based on factors such as laser type (CO2, fiber, or diode), power output, brand reputation, application (cutting, engraving, marking), precision requirements, and included software and support. While budget-friendly options are available, they often come with trade-offs in durability, accuracy, and post-purchase support.

For optimal value, it is recommended to balance initial investment with long-term operational efficiency, maintenance costs, and reliability. Sourcing from reputable suppliers—whether domestic or international—ensures better quality control and technical assistance. Additionally, obtaining multiple quotes, negotiating bulk pricing, and considering refurbished or certified pre-owned machines can lead to substantial cost savings without compromising performance.

Ultimately, the decision should align with specific production needs, scalability goals, and return on investment. Prioritizing total cost of ownership over upfront price will lead to a more sustainable and efficient acquisition of laser machining capabilities.