The global laser machining market is experiencing robust growth, driven by increasing demand for high-precision manufacturing across industries such as automotive, aerospace, electronics, and medical devices. According to a report by Mordor Intelligence, the laser marking, engraving, and cutting machines market was valued at USD 6.94 billion in 2023 and is projected to reach USD 10.43 billion by 2029, growing at a CAGR of approximately 6.9% during the forecast period. Similarly, Grand View Research estimates that the global industrial lasers market size was valued at USD 7.1 billion in 2022 and is expected to expand at a CAGR of 7.4% from 2023 to 2030. This sustained growth is fueled by the rising adoption of fiber lasers, automation integration, and advancements in laser technology that enhance efficiency and accuracy. As competition intensifies and innovation accelerates, a select group of manufacturers are leading the charge in delivering cutting-edge laser solutions. Here’s a data-informed look at the top 10 laser machine manufacturers shaping the future of industrial manufacturing.

Top 10 Laser Machine Manufacturers (2026 Audit Report)

(Ranked by Factory Capability & Trust Score)

#1 Focus on laser

Founded: 1996

Website: hanslaser.net

Key Highlights: Han’s Laser Technology Industry Group Co., Ltd, a public company which was established in 1996, has now became the flagship of Chinese national laser industry ……

#2 Laserax

Website: laserax.com

Key Highlights: Laserax works with the world’s leading manufacturers to implement laser cleaning, welding, texturing, and marking solutions….

#3 LaserStar Technologies

Website: laserstar.net

Key Highlights: LaserStar Technologies is a US manufacturer of laser products and has engineered, designed, and built laser systems and solutions for use in high-precision ……

#4 Laser Photonics

Website: laserphotonics.com

Key Highlights: Laser Photonics manufactures reliable, safe, and eco-friendly Laser Cleaning, Laser Cutting, Laser Engraving, Laser Marking, and Laser Welding solutions….

#5 Universal Laser Systems

Website: ulsinc.com

Key Highlights: Solve Material Processing Challenges. Overcome your most demanding and complex applications. ULS helps companies evaluate the feasibility of laser technology….

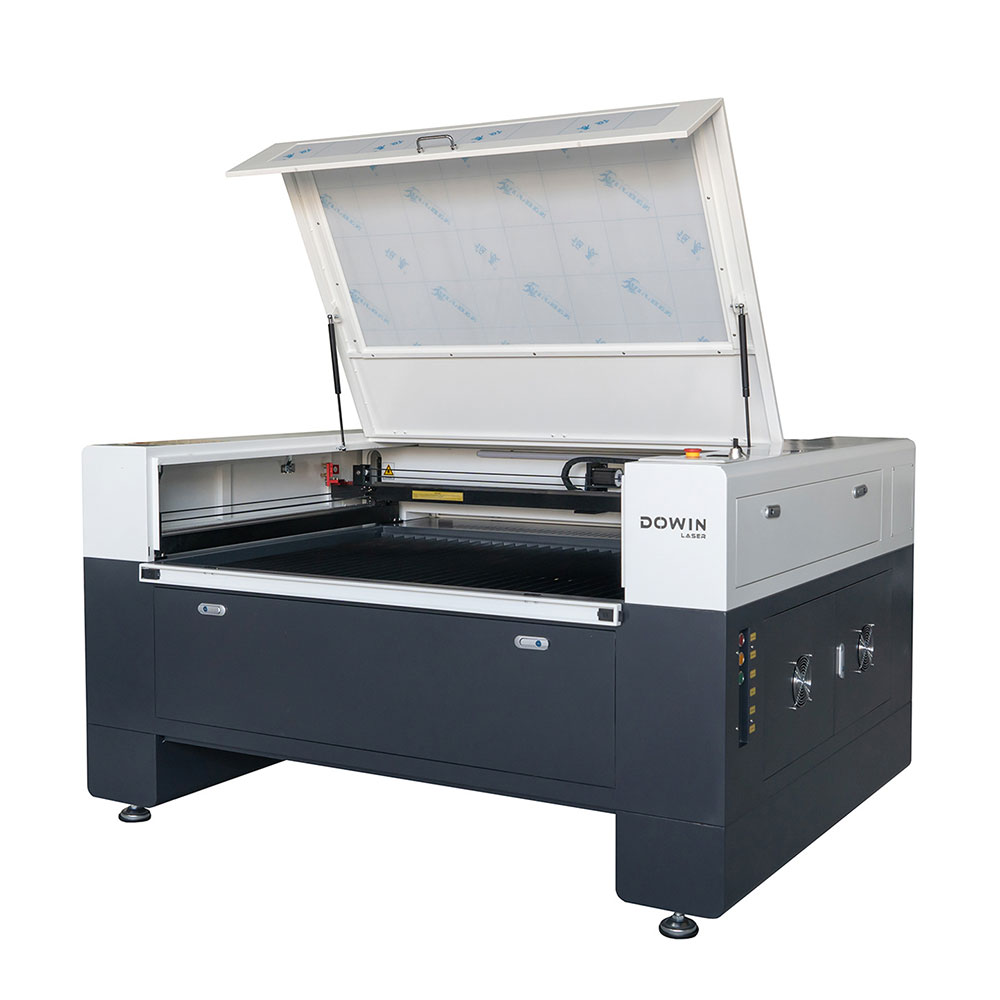

#6 Fiber Laser Cutting Machine and CO2 Laser Cutter Manufacturer …

Website: gwklaser.com

Key Highlights: Leading manufacturer of laser cutting machine, CO2 laser cutter, laser welding machine, laser bending machine and laser cleaning machine, etc….

#7 Full Spectrum Laser

#8 IPG Photonics

Website: ipgphotonics.com

Key Highlights: IPG Photonics manufactures high-performance fiber lasers, amplifiers, and laser systems for diverse applications and industries. Discover your solution….

#9 Laser Equipment Supplier

Website: radianlaser.com

Key Highlights: Radian Laser Systems is a laser equipment supplier specializing in high-speed, customizable laser machinery, including fiber, CO2, and galvo lasers….

#10 Laser Cutting, Engraving & Marking Machines

Website: thunderlaser.com

Key Highlights: Thunder Laser Machine Range The best home desktop laser engraving machine. Up to 1500mm/s speed and a design so small that just two people can easily lift it….

Expert Sourcing Insights for Laser Machine

H2: 2026 Market Trends for Laser Machines

The global laser machine market is poised for robust expansion by 2026, driven by technological advancements, increasing automation, and growing demand across diverse industrial and non-industrial sectors. Here’s a detailed analysis of the key trends shaping the market in 2026:

1. Increased Industrial Automation and Smart Manufacturing

By 2026, laser machines will be deeply integrated into Industry 4.0 ecosystems. Smart factories will increasingly adopt laser systems equipped with IoT connectivity, real-time monitoring, and predictive maintenance capabilities. This integration enhances precision, reduces downtime, and improves overall production efficiency, especially in automotive, aerospace, and electronics manufacturing.

2. Rise of Fiber Lasers and High-Power Applications

Fiber laser technology will dominate the market due to its superior efficiency, reliability, and lower maintenance costs compared to CO₂ and crystal lasers. By 2026, high-power fiber lasers (10kW and above) will see rising adoption for heavy-duty cutting and welding in shipbuilding, construction, and energy infrastructure, enabling faster processing of thick metals.

3. Expansion in EV and Battery Manufacturing

The booming electric vehicle (EV) industry will significantly drive demand for precision laser systems. Laser welding, cutting, and structuring are critical in battery cell production, battery pack assembly, and lightweight component manufacturing. In 2026, specialized laser solutions for lithium-ion battery processing—such as tab cutting, sealing, and electrode structuring—will represent a high-growth segment.

4. Growth in Microprocessing and Ultrafast Lasers

Ultrafast lasers (picosecond and femtosecond) will gain traction in high-precision applications requiring minimal thermal damage. These include medical device manufacturing, semiconductor processing, and consumer electronics (e.g., smartphone glass cutting, display patterning). As demand for miniaturization grows, ultrafast lasers will become essential tools in advanced manufacturing.

5. Sustainability and Energy Efficiency

Environmental regulations and corporate sustainability goals will push manufacturers toward energy-efficient laser systems. Fiber lasers, with their higher wall-plug efficiency, will be favored over traditional options. Additionally, closed-loop cooling systems, recyclable components, and reduced consumable usage will be key differentiators for laser machine vendors.

6. Adoption in Emerging Markets and SMEs

Emerging economies in Asia-Pacific (especially India, Vietnam, and Indonesia) will witness increased laser machine adoption due to industrialization and government support for manufacturing. Simultaneously, cost reductions and the availability of compact, user-friendly desktop laser systems will enable small and medium enterprises (SMEs) to adopt laser technology for prototyping, signage, and custom fabrication.

7. Advancements in Software and AI Integration

Laser machine performance will be enhanced through AI-powered software for path optimization, defect detection, and adaptive control. In 2026, intuitive CAD/CAM interfaces and cloud-based platforms will streamline workflows, reduce setup time, and enable remote operation—making laser systems more accessible and efficient.

8. Diversification into New Applications

Beyond traditional cutting and welding, laser applications will expand into additive manufacturing (3D metal printing), surface texturing, and medical aesthetics. In healthcare, laser systems will be used for surgical devices and personalized implants, while in consumer goods, customization via laser engraving and marking will grow in popularity.

9. Supply Chain Localization and Geopolitical Shifts

Ongoing geopolitical tensions and supply chain disruptions will encourage regional manufacturing and localization of laser component production. This trend will benefit domestic laser manufacturers in North America and Europe, fostering innovation and reducing dependency on global suppliers.

10. Consolidation and Strategic Partnerships

The competitive landscape will see increased mergers, acquisitions, and partnerships among laser technology providers, system integrators, and automation companies. These collaborations will drive innovation and expand market reach, particularly in high-growth verticals like renewable energy and advanced electronics.

Conclusion:

By 2026, the laser machine market will be characterized by smarter, faster, and more efficient systems serving a broadening array of industries. Technological innovation, coupled with global manufacturing trends and sustainability imperatives, will fuel market growth, positioning laser technology as a cornerstone of next-generation industrial production.

Common Pitfalls When Sourcing Laser Machines: Quality and Intellectual Property Risks

Sourcing laser machines, especially from international suppliers, can present significant challenges related to product quality and intellectual property (IP) protection. Being aware of these pitfalls is crucial to making informed purchasing decisions and safeguarding your business interests.

Quality-Related Pitfalls

Inconsistent Build and Performance Standards

Many suppliers, particularly in competitive low-cost markets, may use substandard components (e.g., laser tubes, cooling systems, motion systems) to reduce prices. This often results in inconsistent machine performance, frequent breakdowns, and shorter operational lifespans. Machines may not meet advertised specifications such as cutting accuracy, speed, or power output.

Lack of Certification and Compliance

Some sourced laser machines lack necessary safety certifications (e.g., CE, FDA, IEC standards), posing hazards to operators and potential legal issues. Non-compliant machines may fail workplace safety inspections or be denied entry at customs, causing costly delays.

Insufficient After-Sales Support and Spare Parts Availability

Low-cost suppliers often provide limited technical support, training, or access to replacement parts. When maintenance is needed, long lead times for spare parts or unresponsive service teams can lead to significant downtime, reducing overall productivity and return on investment.

Misrepresentation of Capabilities

Suppliers may exaggerate machine capabilities—such as material compatibility, precision, or software features—through misleading marketing materials or doctored demonstration videos. Buyers may discover too late that the machine cannot perform required tasks effectively.

Intellectual Property (IP) Pitfalls

Risk of Infringing on Patented Technologies

Some laser machines, especially lower-cost models, may incorporate components or software that infringe on existing patents. Purchasing such equipment exposes your business to legal risks, including lawsuits, import bans, or forced equipment seizure, particularly in markets with strong IP enforcement.

Proprietary Software and Licensing Issues

Machines may come with embedded software that lacks proper licensing or contains unauthorized code. This can limit your ability to modify, integrate, or scale operations and may lead to legal action if the software is found to be pirated or reverse-engineered.

Lack of IP Ownership Clarity in Custom Solutions

When working with suppliers on customized laser systems, contracts often fail to specify who owns the resulting designs, software modifications, or process innovations. This ambiguity can lead to disputes over future use, resale, or further development of the technology.

Counterfeit or Clone Equipment

Some suppliers sell machines that are outright clones of branded models. These counterfeit units not only undermine innovation but also carry hidden defects and lack warranty protection. Using such machines may inadvertently associate your business with IP theft and damage your reputation.

Mitigation Strategies

To avoid these pitfalls, conduct thorough due diligence: verify supplier credentials, request third-party testing reports, inspect machines in person if possible, and consult legal experts to review contracts and IP clauses. Prioritize suppliers with transparent manufacturing practices, strong warranties, and a clear commitment to compliance and IP integrity.

Logistics & Compliance Guide for Laser Machine

Overview

Transporting and operating a laser machine requires strict adherence to logistics protocols and regulatory compliance standards. This guide outlines key considerations for safe, legal, and efficient handling of laser machines during shipping, import/export, installation, and operation.

International Shipping & Transportation

- Packaging Requirements: Use robust, shock-resistant packaging with internal cushioning to protect sensitive optics and electronics. Include moisture barriers if shipping to humid climates.

- Labeling: Clearly mark packages with “Fragile,” “This Side Up,” and “Protect from Moisture” labels. Include handling instructions and the manufacturer’s contact information.

- Hazard Classification: Most industrial laser machines are not classified as hazardous goods under IATA/IMDG unless they contain batteries (e.g., lithium-ion for portable units). Confirm if batteries require UN38.3 certification and appropriate labeling.

- Mode of Transport: Air freight may require additional documentation and restrictions, especially for Class 3B or Class 4 lasers. Sea freight is typically preferred for heavy machinery due to cost and stability.

Import/Export Regulations

- HS Code Classification: Identify the correct Harmonized System (HS) code (e.g., 8456.11 or 8456.12 for laser-cutting machines) to determine tariffs and import restrictions.

- Export Controls: Check if the laser machine is subject to export control regulations such as:

- EAR (Export Administration Regulations, USA) – May apply if the laser exceeds power thresholds or has military applications.

- Wassenaar Arrangement – Controls dual-use technologies, including high-power lasers.

- Required Documentation:

- Commercial Invoice

- Packing List

- Bill of Lading or Air Waybill

- Certificate of Origin

- Export License (if applicable)

- Technical specifications (laser class, wavelength, power output)

Laser Safety Compliance

- Laser Classification: Ensure the machine complies with IEC 60825-1 / FDA 21 CFR 1040.10 standards. Clearly label the device with its laser class (e.g., Class 1, Class 4).

- Safety Features: Verify the presence of:

- Interlock systems

- Emergency stop buttons

- Protective enclosures

- Beam shutters

- Key-controlled operation

- User Training: Operators must be trained in laser safety (e.g., ANSI Z136.1 in the U.S. or EN 60825 in Europe).

Electrical & Environmental Standards

- Voltage & Frequency: Confirm compatibility with local power supply (e.g., 110V/60Hz vs. 230V/50Hz). Use transformers if necessary.

- Certifications: Ensure the machine has required regional certifications:

- CE Marking (Europe): Includes compliance with Machinery Directive, EMC Directive, and LVD.

- UKCA Marking (UK): Required post-Brexit.

- FCC Certification (USA): For electromagnetic compatibility.

- EAC Certification (Eurasian Economic Union).

- Cooling & Ventilation: Plan for adequate air circulation, fume extraction, and coolant systems to meet environmental and operational safety standards.

Installation & Site Preparation

- Space Requirements: Allow sufficient clearance around the machine for maintenance, ventilation, and emergency access.

- Floor Load Capacity: Confirm the floor can support the machine’s weight (especially for large industrial lasers).

- Utilities: Ensure access to required power, compressed air, cooling water, and exhaust systems.

- Fume Extraction: Install a compliant exhaust system with filtration to capture particulate matter and hazardous gases (e.g., ozone, metal fumes).

Regulatory Documentation & Record Keeping

- Maintain records of:

- Factory acceptance test (FAT) reports

- Calibration certificates

- Laser safety audits

- Operator training logs

- Import/export licenses

- Provide end-users with:

- User manuals in local language

- Safety instructions

- Warranty and service information

Maintenance & Decommissioning

- Regular Servicing: Follow manufacturer-recommended maintenance schedules to ensure compliance and performance.

- Waste Disposal: Dispose of laser components (e.g., tubes, filters, coolant) according to local environmental regulations. Some parts may be classified as electronic or hazardous waste.

- End-of-Life Recycling: Partner with certified e-waste recyclers for responsible decommissioning.

Summary

Complying with logistics and regulatory requirements for laser machines is essential for legal operation, user safety, and smooth international trade. Always consult with regulatory experts and freight forwarders experienced in high-tech equipment to ensure full compliance.

Conclusion: Sourcing a Laser Machine Manufacturer

After a comprehensive evaluation of potential laser machine manufacturers, it is clear that selecting the right partner requires a balanced consideration of technology, quality, cost, service, and scalability. Key factors such as machine precision, build quality, after-sales support, technical expertise, and compliance with international standards play a crucial role in ensuring long-term operational efficiency and return on investment.

Manufacturers based in regions with strong engineering infrastructure—such as Germany, Japan, China, and the United States—offer varying advantages in terms of innovation, pricing, and customization capabilities. While European and Japanese brands often lead in precision and reliability, Chinese manufacturers have significantly improved in quality and offer competitive pricing, making them attractive for cost-conscious buyers seeking value.

Ultimately, the ideal supplier should not only meet current production needs but also support future growth through scalable solutions and responsive technical support. Conducting factory audits, reviewing customer testimonials, and testing sample machines are essential final steps before making a commitment.

In conclusion, a strategic and due-diligent approach to sourcing a laser machine manufacturer ensures the acquisition of a reliable, high-performance system that enhances productivity, maintains product quality, and strengthens competitive advantage in the marketplace.