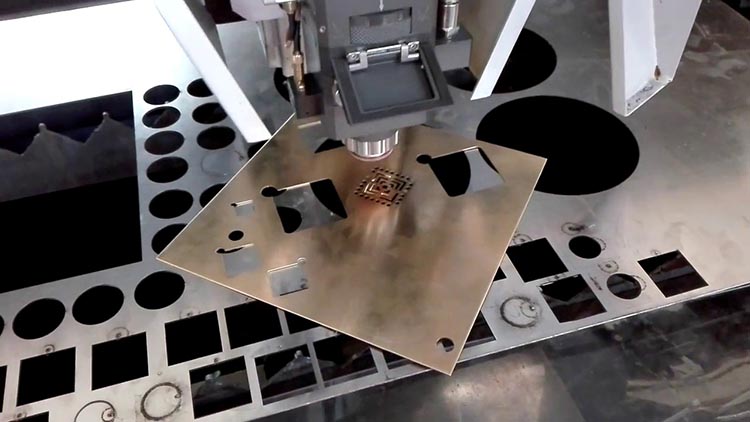

The global jewelry manufacturing industry is undergoing a technological transformation, driven by rising consumer demand for intricate, customized designs and the need for precision, efficiency, and scalability in production. According to a 2023 report by Mordor Intelligence, the global laser processing equipment market—critical to modern jewelry fabrication—is projected to grow at a CAGR of 7.8% from 2023 to 2028, fueled by increased adoption of laser marking, engraving, welding, and cutting systems in high-precision sectors like luxury goods and fine jewelry. Similarly, Grand View Research estimates that the laser system market for industrial manufacturing will expand at a CAGR of over 7.2% through 2030, with advancements in fiber and UV laser technologies enabling micron-level accuracy essential for delicate jewelry components. As manufacturers seek to reduce waste, improve repeatability, and streamline workflows, investment in advanced laser machines has become a strategic priority. In this evolving landscape, selecting the right laser system is no longer just about automation—it’s about unlocking new design capabilities and maintaining a competitive edge. Below, we evaluate the top 10 laser machines transforming jewelry manufacturing today based on precision, versatility, throughput, and integration with digital design ecosystems.

Top 10 Laser Machine For Jewelry Manufacturers (2026 Audit Report)

(Ranked by Factory Capability & Trust Score)

#1 ACMER

Website: acmerlaser.com

Key Highlights: Free delivery 30-day returnsACMER is committed to top laser technology, it is equipped with the world’s first corexy laser engraving machine and the world’s first Gantry dual laser…

#2 LaserStar Technologies

Website: laserstar.net

Key Highlights: LaserStar Technologies designs and manufactures high-performance laser welding, marking, and cutting systems for industrial, jewelry, ……

#3 Laser engravers & laser cutters

Website: gravotech.us

Key Highlights: Our laser tables are designed to engrave, mark and cut on a wide variety of materials (plastic, wood, metal, leather, glass, paper, stone) and shapes….

#4 Laser Cutting, Engraving & Marking Machines

Website: thunderlaser.com

Key Highlights: Thunder Laser offers high-quality, reliable laser machines to meet the needs of a variety of industries. ThunderLaser has become a well-recognized icon in ……

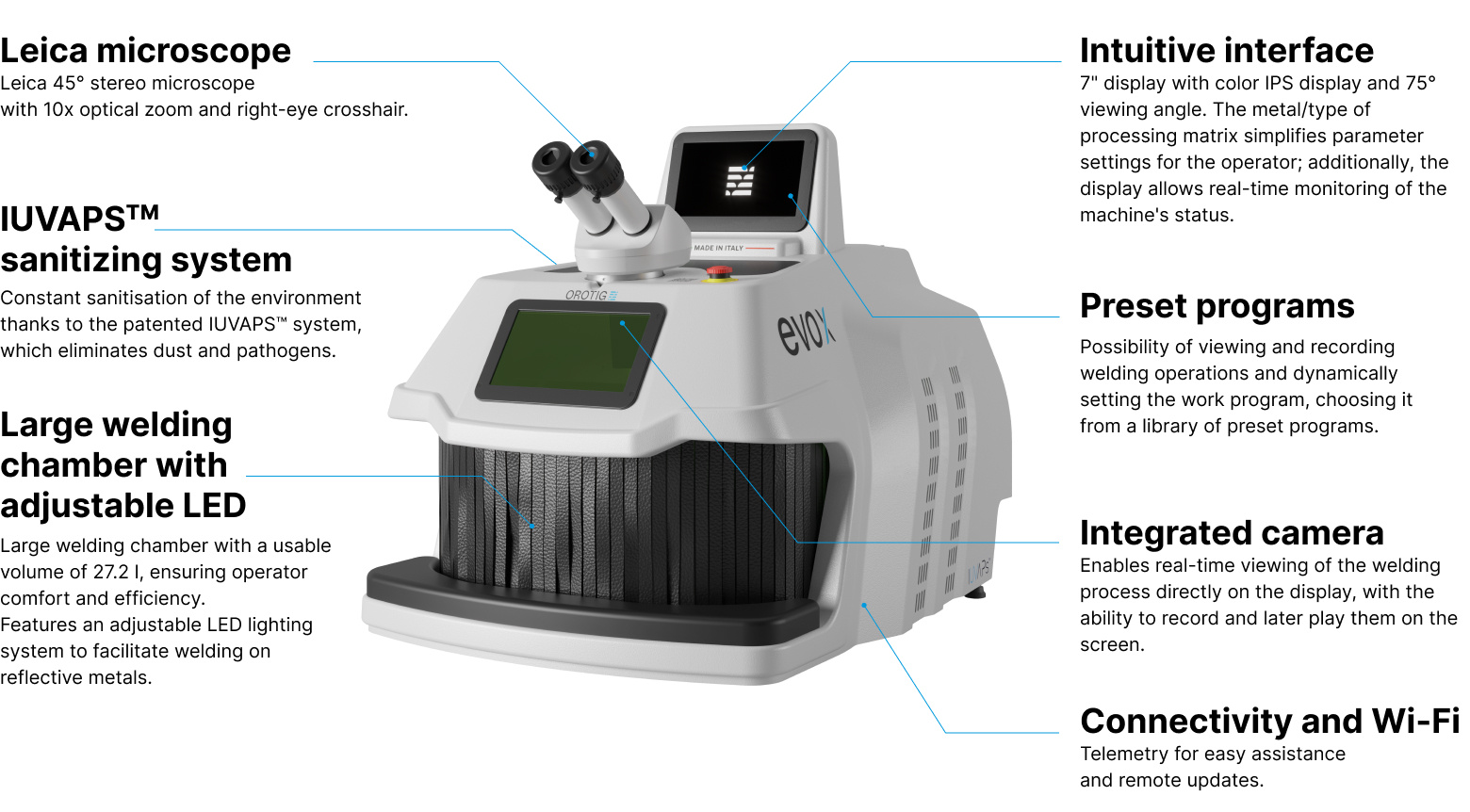

#5 Orotig: Laser Machinery

Website: orotig.com

Key Highlights: We specialise in engineering and manufacturing laser solutions for welding, engraving, casting and cutting precious and non-precious metals in the jewellery, ……

#6 Laser Equipment Supplier

Website: radianlaser.com

Key Highlights: Radian Laser Systems is a laser equipment supplier specializing in high-speed, customizable laser machinery, including fiber, CO2, and galvo lasers….

#7 Desktop Laser Engravers and Cutters for Any Budget

Website: xtool.com

Key Highlights: Free delivery over $89xTool laser engraver and cutter machines can cut or engrave hundreds of types of materials, including but not limited to wood, metal, and acrylic, fabric, ……

#8 Machinery and laser systems

Website: sisma.com

Key Highlights: More than 130 machine models for the automatic production of gold chains · Laser systems for marking, welding, cutting and engraving. · Laser systems for welding….

#9 Laser cutting and engraving machine

Website: troteclaser.com

Key Highlights: Fastest laser engraver on the market ✓ Engrave and cut acrylic, wood, leather etc. ✓ Work area of 1016 x 610 mm. Check it out now!…

#10 Best Laser Engraving Machine for Jewelry Making

Website: wecreat.com

Key Highlights: Create stunning custom jewelry with WeCreat Laser Machines. Featuring 0.00199mm ultra-fine precision, IR laser for metal engraving, and blazing speed for ……

Expert Sourcing Insights for Laser Machine For Jewelry

2026 Market Trends for Laser Machines in the Jewelry Industry

The laser machine market for jewelry manufacturing is poised for significant transformation by 2026, driven by technological innovation, shifting consumer preferences, and evolving production demands. Key trends shaping the landscape include:

Advancements in Precision and Miniaturization

Laser technology will continue to push the boundaries of precision, enabling jewelers to create intricate designs and micro-detailed engravings on increasingly smaller components. Ultra-short pulse (USP) and femtosecond lasers are expected to gain traction for high-accuracy tasks such as setting micro-pave stones or engraving serial numbers and hallmarks without material deformation. This precision supports the growing demand for personalized and bespoke jewelry.

Integration of AI and Smart Manufacturing

By 2026, artificial intelligence (AI) and machine learning will play a larger role in laser systems, optimizing parameters like power, speed, and focus in real time for different materials and designs. Integrated CAD/CAM software with AI-driven design suggestions and automated job preparation will streamline workflows, reduce errors, and enhance consistency—especially valuable for small-batch and custom production.

Growth in Sustainable and On-Demand Production

As sustainability becomes a priority, laser machines will support eco-friendly manufacturing by minimizing material waste through precise cutting and welding. The rise of direct-to-consumer (DTC) jewelry brands will further fuel demand for on-demand, localized production. Compact, desktop laser systems will empower jewelers and designers to produce small runs or one-of-a-kind pieces efficiently, reducing overproduction and carbon footprint.

Rising Demand for Multi-Function Laser Systems

Jewelers are increasingly seeking all-in-one laser platforms capable of cutting, welding, engraving, and marking various metals—gold, silver, platinum, and even titanium. These multi-functional systems improve cost-efficiency and space utilization, making them ideal for artisanal workshops and mid-sized manufacturers aiming to scale without expanding facilities.

Expansion in Emerging Markets

Asia-Pacific, particularly India and China, will remain key growth regions due to rising disposable income, expanding middle classes, and a strong tradition in jewelry craftsmanship. Local adoption of laser technology will accelerate as manufacturers modernize production to meet both domestic and export demand. Government initiatives promoting advanced manufacturing will further support market penetration.

Increased Focus on User-Friendly Interfaces and Training

As laser systems become more sophisticated, ease of use will be a competitive differentiator. Manufacturers will prioritize intuitive touchscreens, automated calibration, and remote diagnostics. Additionally, expanded training programs and online support will help smaller jewelers adopt laser technology with confidence, reducing the learning curve and operational downtime.

Conclusion

By 2026, laser machines will be central to the modernization of the jewelry industry, enabling greater creativity, efficiency, and sustainability. Companies investing in advanced, flexible, and intelligent laser solutions will be best positioned to capitalize on evolving market dynamics and meet the growing consumer appetite for personalized, high-quality jewelry.

Common Pitfalls When Sourcing Laser Machines for Jewelry Making

Sourcing a laser machine for jewelry production involves balancing precision, durability, and intellectual property (IP) protection. Overlooking key factors can lead to subpar results, costly downtime, or even legal issues. Below are common pitfalls to avoid.

Quality-Related Pitfalls

Inadequate Precision and Resolution

Jewelry often requires micrometer-level accuracy for engraving fine details or cutting delicate components. Choosing a machine with insufficient resolution or poor beam quality can result in blurry engravings, rough edges, or material warping—especially on precious metals or gemstone settings.

Poor Build Quality and Material Compatibility

Low-cost machines may use inferior components (e.g., unstable galvanometers, weak cooling systems) that degrade quickly under continuous use. Additionally, not all lasers handle jewelry materials effectively—fiber lasers are ideal for metals, while CO₂ lasers struggle with conductivity. Selecting the wrong laser type can damage materials or reduce lifespan.

Lack of Reputable After-Sales Support

Many suppliers, especially from emerging markets, offer attractive prices but provide minimal technical support or spare parts. Downtime for repairs can halt production, and inaccessible firmware updates may leave the machine obsolete.

Overlooking Calibration and Consistency

Inconsistent beam focus, misaligned optics, or poor software integration can cause variations between identical pieces. Without proper calibration tools and quality control protocols, batch production becomes unreliable.

Intellectual Property (IP)-Related Pitfalls

Risk of Design Theft During Prototyping or Service

Sending digital jewelry designs to third-party manufacturers or service bureaus for laser processing exposes IP to unauthorized copying. Some suppliers may lack strict data policies or cybersecurity measures, increasing the risk of leaks or misuse.

Use of Machines with Embedded Monitoring or Data Collection

Certain laser systems—especially budget models—may include software that collects or transmits design files to external servers for “analytics” or remote diagnostics. This poses a serious IP risk if sensitive designs are unintentionally shared.

Inadequate Software Licensing and Restrictions

Proprietary laser software may limit design import formats, restrict file editing, or watermark outputs. Some systems lock users into specific ecosystems, preventing integration with CAD/CAM tools commonly used in jewelry design and risking compliance issues.

Counterfeit or Clone Machines with Hidden Vulnerabilities

Illegitimate copies of branded laser systems may appear cost-effective but often lack proper firmware security, making them susceptible to hacking or unauthorized access. These machines may also infringe on patents, exposing buyers to legal liability.

Conclusion

To avoid these pitfalls, conduct thorough due diligence: verify machine specifications with sample testing, choose reputable suppliers with strong service networks, ensure data privacy agreements are in place, and confirm software and hardware compliance with IP protection standards. Investing in quality and security upfront protects both craftsmanship and intellectual assets in the competitive jewelry market.

Logistics & Compliance Guide for Laser Machine For Jewelry

Overview of Laser Machines in Jewelry Manufacturing

Laser machines are widely used in the jewelry industry for precision cutting, engraving, welding, and marking precious metals and gemstones. These machines require careful handling during shipping and strict adherence to international regulations due to their optical, electrical, and mechanical components.

International Shipping Considerations

Laser machines are classified as high-value, sensitive equipment and must be shipped using appropriate methods:

– Packaging: Use custom wooden crates with internal foam or shock-absorbing materials to protect delicate optics and electronics.

– Transport Mode: Air freight is preferred for speed and reduced handling; sea freight may be used for cost efficiency with proper moisture and impact protection.

– Labeling: Clearly mark crates with “Fragile,” “This Side Up,” and “Do Not Stack” labels. Include handling instructions for laser safety.

Export Compliance and Documentation

Ensure compliance with export regulations in the country of origin:

– Export License: Verify if the laser machine requires an export license based on power output and technology classification (e.g., under the U.S. Commerce Control List or EU Dual-Use Regulations).

– Commercial Invoice: Include detailed specifications such as laser type (fiber, CO₂, etc.), wavelength, power (in watts), and intended use.

– Packing List: List all components (laser source, chiller, control software, accessories) with weights and dimensions.

– Certificate of Origin: Required by many countries for customs clearance and tariff determination.

Laser Safety and Regulatory Standards

Laser machines must meet international safety standards to be legally imported and operated:

– FDA Compliance (USA): All laser products exported to the U.S. must comply with 21 CFR 1040.10 and 1040.11. A Laser Notice and Certification Report must be submitted to the FDA, and the machine must bear a compliant laser radiation label.

– IEC 60825-1: International standard for laser product safety. Required in the EU, UK, Canada, Australia, and many other countries.

– CE Marking (EU/UK): Mandatory for placing laser equipment on the market. Requires conformity assessment, technical documentation, and a Declaration of Conformity.

– RoHS & REACH (EU): Ensure materials used in the machine comply with restrictions on hazardous substances.

Import Regulations by Major Markets

Different countries have specific import requirements:

– United States: FDA pre-market notification, CBP entry filing, Harmonized Tariff Schedule (HTS) code (e.g., 8515.21 for laser welding machines).

– European Union: CE certification, customs declaration (via Import Control System), and VAT registration. HTS code under 8515.

– China: Requires CCC certification if applicable, import license, and customs clearance through China Customs.

– India: BIS certification may be required; check latest DGFT guidelines and import duty structure under HS Code 8515.

– UAE/Saudi Arabia: SASO certification (Saudi) or Emirates Conformity Assessment Scheme (ECAS) may apply.

Software and Technology Transfer Compliance

Laser control software may be subject to export controls:

– Confirm whether software contains encryption or proprietary algorithms that fall under export-restricted categories (e.g., ECCN 5D002).

– Avoid shipping software on physical media with the machine unless properly licensed; provide secure download links instead.

After-Sales Support and Warranty Logistics

Plan for compliance in service and maintenance:

– Spare parts shipments must follow the same export/import rules as the main machine.

– Remote diagnostics and software updates should comply with data privacy laws (e.g., GDPR in Europe).

– On-site technician visits may require work visas and temporary import permits for tools.

Best Practices for Smooth Clearance

- Work with experienced freight forwarders familiar with laser equipment.

- Provide complete, accurate documentation to avoid customs delays.

- Pre-notify consignees of required local certifications and installation support.

- Maintain records of compliance for at least 5 years for audit purposes.

By following this guide, businesses can ensure safe, legal, and efficient global distribution of laser machines for jewelry manufacturing.

Conclusion: Sourcing a Laser Machine for Jewelry Manufacturing

Sourcing a laser machine for jewelry production is a strategic investment that can significantly enhance precision, efficiency, and design capabilities. Laser technologies—such as laser welding, engraving, marking, and cutting—offer unparalleled accuracy and control, making them ideal for working with delicate materials and intricate designs commonly used in fine jewelry.

When selecting the appropriate laser machine, key considerations include the type of application (e.g., welding repairs, stone setting, custom engraving), material compatibility (gold, silver, platinum, etc.), power requirements, ease of use, automation features, and after-sales support. Fiber lasers are typically preferred for metal marking and engraving, while pulsed Nd:YAG or fiber lasers are ideal for precision welding.

It is essential to evaluate suppliers based on reputation, technical expertise, training offerings, and service reliability. Machines should comply with safety standards and offer scalability for future production needs. While initial costs can be significant, the long-term benefits—such as reduced material waste, shorter production times, and the ability to offer customized designs—often justify the investment.

In conclusion, sourcing the right laser machine empowers jewelry makers to meet evolving market demands, improve craftsmanship, and stay competitive in a high-precision industry. A well-informed selection process tailored to specific business needs ensures optimal performance, return on investment, and sustainable growth.