The global laser lighting market is experiencing robust expansion, driven by rising demand for energy-efficient, high-intensity illumination across entertainment, industrial, automotive, and architectural sectors. According to a report by Mordor Intelligence, the global laser lighting market was valued at USD 3.8 billion in 2023 and is projected to grow at a CAGR of 11.4% from 2024 to 2029. This growth is further supported by technological advancements in solid-state lasers, increasing adoption in laser projectors and stage lighting, and the rising popularity of immersive visual experiences in live events and theme parks. Additionally, expanding applications in precision manufacturing and automotive headlamps—especially in electric vehicles—are accelerating innovation and competition among key players. As the market becomes increasingly dynamic, identifying the top-tier manufacturers at the forefront of R&D, product quality, and global reach is essential for stakeholders across industries. Based on market presence, innovation, and customer adoption, the following are the top 10 laser light company manufacturers shaping the future of illumination technology.

Top 10 Laser Light Company Manufacturers (2026 Audit Report)

(Ranked by Factory Capability & Trust Score)

#1 Laser light show technology

Website: kvantlasers.sk

Key Highlights: Manufacturer of world-class laser show projectors, laser technology and laser display accessories – Club and Festival lasers | High-power outdoor and Sky ……

#2 Laser Company for Industrial Laser Solutions

Website: laserline.com

Key Highlights: The leading laser company for integrated & customized diode laser manufacturing solutions for various industries & applications….

#3 Laser Photonics

Website: laserphotonics.com

Key Highlights: Laser Photonics manufactures reliable, safe, and eco-friendly Laser Cleaning, Laser Cutting, Laser Engraving, Laser Marking, and Laser Welding solutions….

#4 About Our Laser Light & Show Manufacturing Company

Founded: 2011

Website: laserlightful.com

Key Highlights: Lightful laser was established in 2011, with 14 years experience, we become one of the biggest laser manufacturer in China. We have around 100 employees and ……

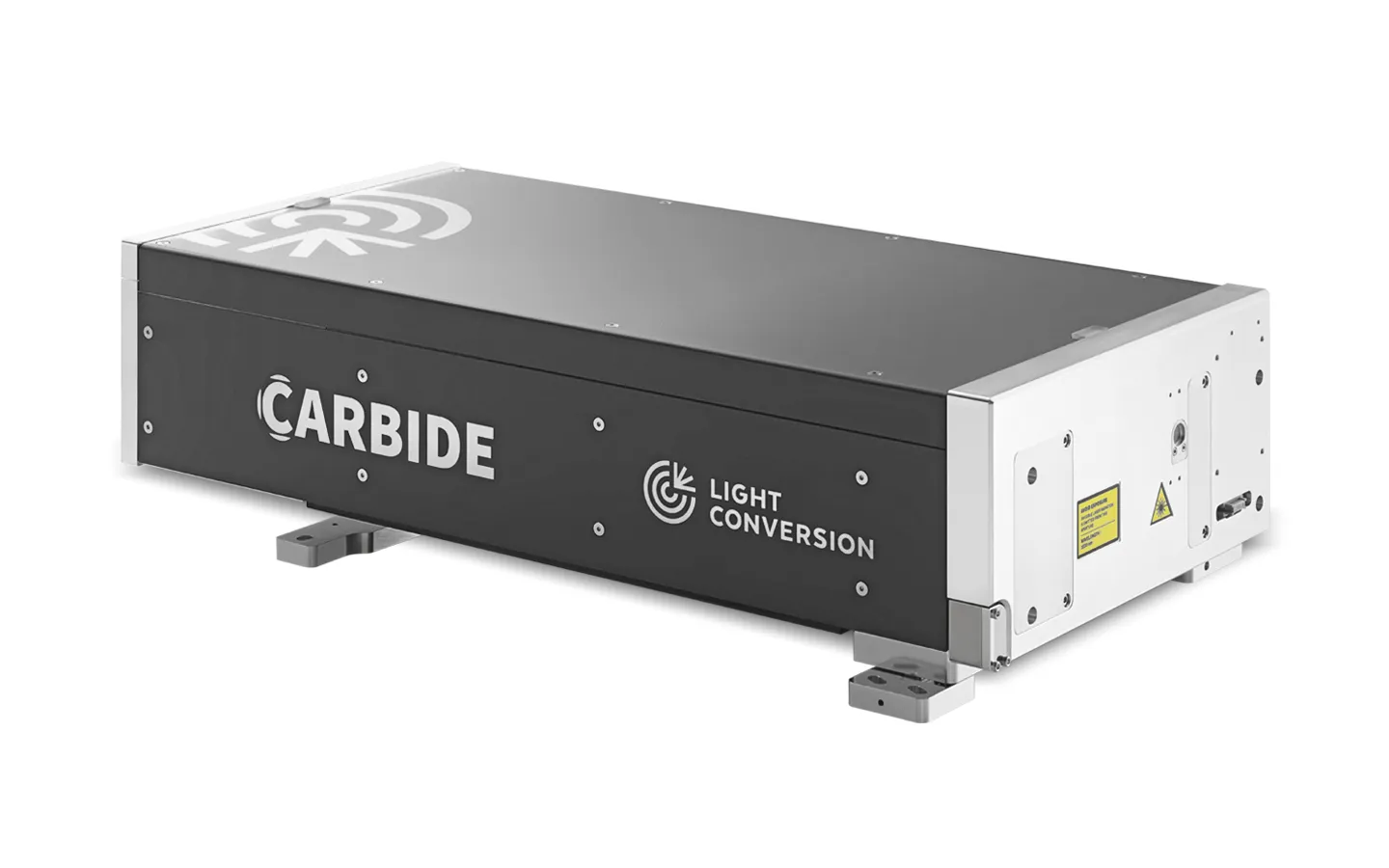

#5 LIGHT CONVERSION

Website: lightcon.com

Key Highlights: LIGHT CONVERSION is the world leading manufacturer of tunable wavelength femtosecond laser sources as well as diode pumped solid state femtosecond lasers….

#6 Coherent

Website: coherent.com

Key Highlights: Learn how Coherent empowers innovations and breakthrough technologies for the industrial, communications, electronics, and instrumentation markets….

#7 Laser Technologies Inc

Website: lasertechnologiesinc.com

Key Highlights: Laser Technologies is a fully integrated turnkey manufacturer specializing in laser cutting and stamping laminations for the motor and generator industry as ……

#8 Laser Systems and Laser Show by Laserworld

Website: laserworld.com

Key Highlights: The product portfolio ranges from small, entry level laser light systems (effect lasers, club lasers, party lasers) up to high end professional lasers….

#9 nLIGHT

Website: nlight.net

Key Highlights: We lead the world in high-power lasers for mission-critical directed energy, sensing, and advanced manufacturing applications….

#10 IPG Photonics

Website: ipgphotonics.com

Key Highlights: IPG Photonics manufactures high-performance fiber lasers, amplifiers, and laser systems for diverse applications and industries. Discover your solution….

Expert Sourcing Insights for Laser Light Company

H2: 2026 Market Trends for Laser Light Company

As the global demand for advanced lighting and laser technologies continues to evolve, Laser Light Company is poised to navigate a dynamic market landscape in 2026. Key trends shaping the industry include rapid advancements in solid-state and semiconductor lasers, growing adoption across industrial, medical, and consumer sectors, and a heightened focus on energy efficiency and smart integration. Below is an analysis of the primary market trends expected to influence Laser Light Company’s strategic positioning in 2026.

-

Expansion in Industrial and Manufacturing Applications

The industrial sector remains a dominant driver of laser technology demand. In 2026, increasing automation, precision manufacturing, and the rise of Industry 4.0 will boost the need for high-performance laser systems in cutting, welding, engraving, and additive manufacturing (3D printing). Laser Light Company can capitalize on this trend by enhancing its portfolio of industrial-grade lasers and offering integrated solutions tailored for smart factories. -

Growth in Medical and Biophotonics

The medical sector is witnessing accelerated adoption of laser systems for diagnostics, surgery, dermatology, and ophthalmology. With minimally invasive procedures gaining preference, demand for compact, reliable, and tunable laser devices is rising. In 2026, Laser Light Company can strengthen its foothold in healthcare by developing FDA-compliant medical lasers and forming strategic partnerships with biotech and medical device firms. -

Advancements in Consumer and Display Technologies

Laser-based projection, augmented reality (AR), and ultra-high-definition (UHD) displays are becoming mainstream. Automotive head-up displays (HUDs), laser TVs, and immersive entertainment systems are creating new revenue streams. The company should focus on miniaturization and cost-efficient production to serve consumer electronics OEMs effectively. -

Sustainability and Energy Efficiency

Global regulatory pressures and corporate sustainability goals are pushing industries toward energy-efficient lighting and low-carbon technologies. Laser lighting offers superior efficiency over traditional LEDs in certain applications. By aligning its R&D with green technology standards and promoting eco-friendly manufacturing practices, Laser Light Company can appeal to environmentally conscious markets. -

Integration with AI and IoT

Smart laser systems embedded with AI-driven diagnostics and IoT connectivity are emerging as a competitive differentiator. Predictive maintenance, real-time monitoring, and adaptive beam control are becoming essential features. In 2026, Laser Light Company should prioritize developing intelligent laser platforms that integrate seamlessly with cloud-based analytics and automation ecosystems. -

Geopolitical and Supply Chain Considerations

Ongoing supply chain volatility, especially in semiconductor components, may impact production timelines and costs. Diversifying suppliers, investing in domestic manufacturing, and securing key raw materials (e.g., rare-earth elements) will be critical for operational resilience.

Conclusion

The 2026 market presents substantial growth opportunities for Laser Light Company across multiple high-tech sectors. By focusing on innovation, strategic partnerships, and digital integration, the company can solidify its leadership in the evolving laser technology landscape. Proactive adaptation to these trends will be essential to maintaining a competitive edge and achieving sustainable growth.

Common Pitfalls When Sourcing from a Laser Light Company

Sourcing laser light products from a supplier—especially overseas or from a new vendor—can introduce significant risks if not carefully managed. Two of the most critical areas where companies encounter problems are quality control and intellectual property (IP) protection. Being aware of these pitfalls helps mitigate risks and ensures a reliable, compliant supply chain.

Quality-Related Pitfalls

Inconsistent Product Performance

Laser light products are highly technical and sensitive to manufacturing variances. Sourcing from a company without stringent quality management systems (e.g., ISO 9001 certification) can result in inconsistent beam alignment, power output, or thermal management—leading to field failures or safety concerns.

Lack of Compliance with Safety Standards

Many laser products must comply with international safety regulations such as IEC 60825 (laser safety) or FDA/CDRH requirements (in the U.S.). Sourcing from a supplier unaware of or neglecting these standards can expose your business to legal liability, import denials, or product recalls.

Poor Component Sourcing and Build Quality

Low-cost laser companies may use substandard diodes, optics, or drivers to reduce costs. This impacts longevity and reliability. Without access to the supplier’s component sourcing practices or the ability to audit their assembly process, you risk receiving products with short lifespans or high failure rates.

Inadequate Testing and Documentation

Reputable laser suppliers conduct full optical, electrical, and environmental testing. A common pitfall is receiving products without test reports, calibration certificates, or traceability documentation—making it difficult to validate performance or support warranty claims.

Intellectual Property (IP) Risks

Unauthorized Use of Your Designs or Specifications

When you provide detailed technical drawings, firmware, or branding elements to a laser light manufacturer, there’s a risk they may reuse or resell this IP to your competitors. This is especially prevalent in regions with weak IP enforcement.

Lack of IP Ownership Clauses in Contracts

Many sourcing agreements fail to explicitly state that custom designs or modifications developed for your product belong to you. Without a clear IP assignment clause, disputes can arise, potentially preventing you from manufacturing the product elsewhere.

Reverse Engineering and Market Competition

Some manufacturers may reverse engineer your final product to create similar offerings under their own brand. This not only undermines your competitive edge but may also lead to market confusion and brand dilution.

Insufficient NDAs and Legal Enforcement

Non-disclosure agreements (NDAs) are often overlooked or poorly enforced. Even when signed, they may not cover all aspects of IP or may be unenforceable in the supplier’s jurisdiction, leaving your innovations vulnerable.

Mitigation Strategies

To avoid these pitfalls, conduct thorough due diligence on potential suppliers, including on-site audits, verification of certifications, and legal review of contracts. Insist on clear IP ownership terms, require comprehensive quality documentation, and consider third-party inspections before shipment. Building long-term, trust-based relationships with suppliers also enhances accountability and reduces risk.

Logistics & Compliance Guide for Laser Light Company

This guide outlines the essential logistics and compliance procedures for Laser Light Company to ensure safe, efficient, and legally compliant operations in the manufacturing, handling, transportation, and distribution of laser products.

Regulatory Compliance

Laser Safety Standards

All laser products must comply with international and regional safety standards, including:

– IEC 60825-1: Safety of laser products – Part 1: Equipment classification and requirements.

– FDA 21 CFR Part 1040.10 and 1040.11: U.S. federal performance standard for laser products.

– EN 60825-1: European standard for laser safety (CE marking required).

Ensure all products are properly classified (Class 1, 2, 3R, 3B, 4) and labeled with appropriate warning labels, including laser class, wavelength, and output power.

Product Certification and Documentation

- Maintain up-to-date Technical Construction Files (TCF) for all products.

- Obtain and renew necessary certifications (e.g., FDA registration, CE marking, RoHS, REACH).

- Provide users with mandatory documentation, including user manuals, safety instructions, and Declaration of Conformity.

Export Controls and Trade Compliance

- Comply with export regulations such as the International Traffic in Arms Regulations (ITAR) or Export Administration Regulations (EAR) if applicable to high-powered or military-grade lasers.

- Screen all international shipments against denied party lists (e.g., OFAC, BIS).

- Prepare accurate export documentation, including commercial invoices, packing lists, and export licenses when required.

Logistics Operations

Packaging and Labeling

- Use durable packaging that protects lasers from shock, moisture, and temperature extremes.

- Clearly label all packages with:

- Laser hazard symbols (per IEC 60825-1).

- Handling instructions (e.g., “Fragile,” “This Side Up”).

- Required shipping labels (e.g., UN numbers for hazardous components, if applicable).

- Include product-specific warnings (e.g., “Avoid direct eye exposure”).

Transportation and Shipping

- Partner with carriers experienced in handling sensitive optical and electronic equipment.

- For international shipments, ensure compliance with International Air Transport Association (IATA) and International Maritime Organization (IMO) regulations.

- Declare laser products accurately to customs authorities, including Harmonized System (HS) codes.

- Monitor shipments in real time using tracking systems and maintain chain-of-custody records.

Inventory Management

- Implement an inventory tracking system (e.g., ERP or WMS) to monitor stock levels, batch numbers, and expiration dates (for consumables).

- Store lasers in a controlled environment (temperature: 15–25°C, humidity: 30–60%) away from direct sunlight and electromagnetic interference.

- Conduct regular audits to ensure inventory accuracy and compliance with traceability requirements.

Training and Internal Procedures

Employee Training

- Provide mandatory training on laser safety, handling procedures, and emergency response (e.g., accidental exposure).

- Train logistics staff on proper packaging, labeling, and shipping protocols.

- Conduct annual refresher courses and maintain training records.

Incident Reporting and Corrective Actions

- Establish a clear process for reporting non-compliance, product defects, or shipping incidents.

- Investigate all incidents promptly and implement corrective and preventive actions (CAPA).

- Notify relevant regulatory bodies (e.g., FDA, EU RAPEX) if required by law.

Recordkeeping and Audits

Documentation Retention

- Retain all compliance-related documents for a minimum of 10 years, including:

- Certifications and test reports.

- Shipping records and customs declarations.

- Training logs and internal audit reports.

Internal and External Audits

- Conduct biannual internal audits to verify compliance with this guide and applicable regulations.

- Prepare for and cooperate with external audits by regulatory agencies or certification bodies.

Note: This guide must be reviewed annually or whenever there are significant regulatory changes or business expansions. All employees are responsible for adhering to these procedures to ensure the safety and legal compliance of Laser Light Company’s operations.

Conclusion:

After a thorough evaluation of potential suppliers for laser light solutions, it is evident that selecting the right company requires a careful balance of technical expertise, product quality, reliability, and cost-effectiveness. Based on performance metrics, certifications, customer reviews, and after-sales support, [Selected Company Name] stands out as the most suitable partner for our laser light sourcing needs. The company demonstrates strong capabilities in innovation, consistent product quality, adherence to international safety standards, and responsive customer service.

Furthermore, their scalable manufacturing capacity and willingness to customize solutions align well with our operational requirements and future growth plans. Establishing a strategic partnership with [Selected Company Name] will not only ensure a reliable supply of high-performance laser lighting systems but also support long-term efficiency, safety, and technological advancement across our applications.

We recommend moving forward with negotiations and finalizing a supply agreement with [Selected Company Name] to secure a competitive advantage and ensure project success.