The global laser cleaning equipment market is experiencing robust growth, driven by increasing demand for eco-friendly, precision cleaning solutions across industries such as automotive, aerospace, energy, and heritage conservation. According to a report by Mordor Intelligence, the laser cleaning market was valued at USD 320 million in 2023 and is projected to grow at a compound annual growth rate (CAGR) of over 18.5% from 2024 to 2029. This expansion is fueled by stringent environmental regulations, the rising cost of traditional cleaning methods like sandblasting and chemical treatments, and the superior accuracy and automation compatibility of laser systems. Grand View Research further supports this trajectory, noting a growing adoption of fiber laser technologies due to their reliability, lower maintenance, and ability to remove contaminants without damaging substrates. Against this backdrop of rapid technological adoption and market expansion, identifying the leading manufacturers of laser light cleaning systems becomes critical for industrial decision-makers looking to leverage cutting-edge, sustainable surface treatment solutions.

Top 10 Laser Light Cleaning System Manufacturers (2026 Audit Report)

(Ranked by Factory Capability & Trust Score)

#1 Laser Machine – Laser Equipment Manufacturer

Website: dplaser.com

Key Highlights: DPLASER is a leading manufacturer & factory of industrial laser welding, laser cutting, laser marking and laser cleaning machines….

#2 P-laser Industrial laser cleaning

Website: p-laser.com

Key Highlights: we engineer and manufacture the most advanced—and most powerful—pulsed industrial laser cleaning systems on the market, built for both manual and automated ……

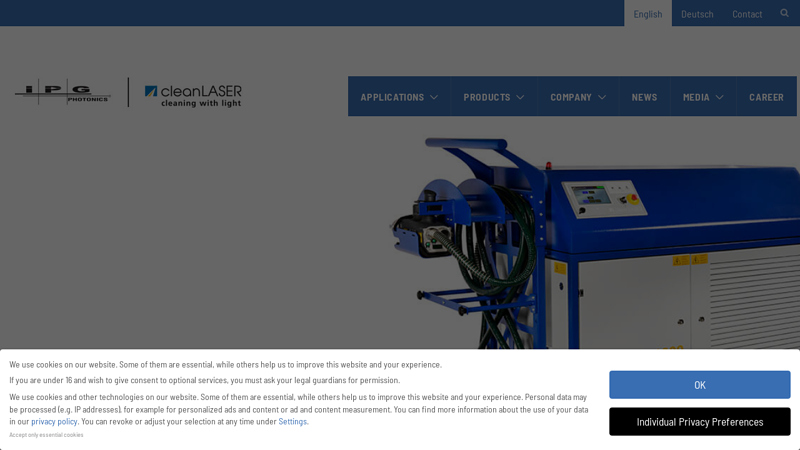

#3 Clean Laser Systems

Website: cleanlaser.de

Key Highlights: IPG | cleanLASER has been developing and producing high-precision laser systems for cleaning and industrial surface treatment for more than 20 years….

#4 SHARK P CL Industrial Laser Cleaning Machines (100

Website: pulsar-laser.com

Key Highlights: SHARK P CL is an industrial pulsed laser cleaning machine series by PULSAR Laser with outputs from 100 W to 1000 W, air-cooled up to 500 W….

#5 Laser Cleaning

Website: keyence.com

Key Highlights: Industrial laser cleaning is a laser light process that uses ablation to remove coatings or contaminates from a surface. The laser ablation process is a non- ……

#6 Laser Cleaning and Laser Ablation Systems

Website: laserphotonics.com

Key Highlights: Remove rust and surface contaminants with our laser cleaning & laser ablation systems. Experience superior cleaning tech, automation, and eco-friendly ……

#7 Handheld Laser Cleaning Machines

Website: ipgphotonics.com

Key Highlights: Handheld and portable laser cleaning machines designed for manual applications including rust removal, paint stripping, restoration, and more….

#8 Laser Cleaning Machine

Website: strlaser-en.com

Key Highlights: Laser cleaning offers precise, controllable, and standardized operation, replacing manual labor to boost efficiency, enhance work quality….

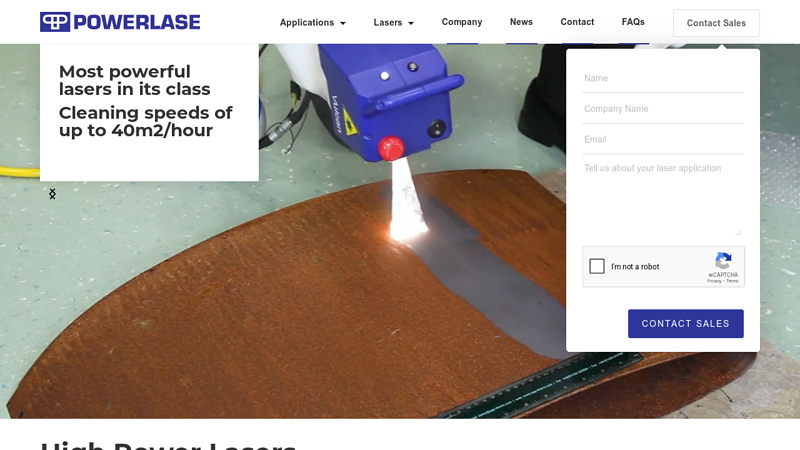

#9 Powerlase Limited

Website: powerlase-limited.com

Key Highlights: We are innovators in the high power laser industry and offer the fastest and lowest cost laser cleaning and surface preparation systems on the market….

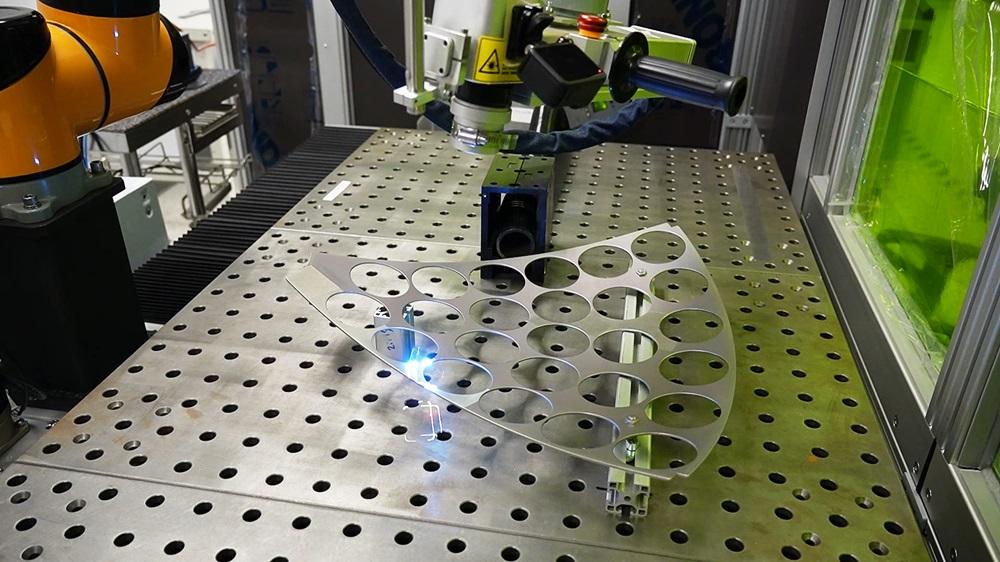

#10 Manual & Automated Laser Cleaning Machines

Website: laserax.com

Key Highlights: Our laser cleaning machines range from manually loaded to fully automated solutions to meet the needs of various applications….

Expert Sourcing Insights for Laser Light Cleaning System

2026 Market Trends for Laser Light Cleaning Systems

Rising Industrial Demand for Precision and Eco-Friendly Cleaning

By 2026, the global market for laser light cleaning systems is projected to experience robust growth, primarily driven by increasing demand across precision-oriented industries such as aerospace, automotive, and electronics manufacturing. As companies prioritize non-contact, residue-free cleaning methods, laser technology offers a compelling alternative to traditional solvents and abrasive techniques. Environmental regulations restricting chemical usage—especially in Europe and North America—are accelerating adoption, making laser cleaning a sustainable solution aligned with ESG (Environmental, Social, and Governance) goals.

Advancements in Fiber Laser Technology and System Automation

Core technological advancements, particularly in high-power fiber lasers, are enhancing cleaning efficiency, speed, and material compatibility. By 2026, expect wider availability of compact, portable, and fully automated laser cleaning systems integrated with robotics and AI-driven control software. These innovations will lower operational costs, reduce the skill barrier for operators, and enable integration into smart manufacturing environments (Industry 4.0), further boosting deployment in production lines for tasks like paint stripping, rust removal, and mold decontamination.

Expansion into New Applications and Geographic Markets

While historically used in niche industrial maintenance, laser cleaning is expanding into emerging applications such as cultural heritage restoration, nuclear decontamination, and medical device sterilization. Additionally, growing industrialization in Asia-Pacific—especially in China, India, and South Korea—is fueling regional market expansion. Government incentives promoting green manufacturing and digital transformation are expected to contribute significantly to the Asia-Pacific share of the global laser cleaning market by 2026.

Competitive Landscape and Cost Reduction Trajectory

The market is becoming increasingly competitive, with both established laser manufacturers and new entrants offering differentiated solutions. Intensifying competition is driving down equipment costs, making laser cleaning more accessible to small and medium-sized enterprises (SMEs). By 2026, declining prices for key components like laser diodes and improved total cost of ownership (TCO) models are expected to broaden market penetration beyond high-end industrial users.

Challenges: Safety Standards and Skills Gap

Despite positive momentum, challenges remain. Strict safety protocols for high-intensity laser operations require comprehensive training and protective measures, creating a skills gap in the workforce. Standardization of safety and performance guidelines across regions is still evolving. Addressing these issues through improved user interfaces, automated safety features, and industry-wide certification programs will be critical to sustaining growth through 2026 and beyond.

Common Pitfalls When Sourcing Laser Light Cleaning Systems: Quality and Intellectual Property (IP) Risks

Sourcing a Laser Light Cleaning System (LLCS) offers transformative benefits for industrial cleaning, but buyers must navigate significant quality and intellectual property (IP) pitfalls to ensure a successful, secure investment. Overlooking these aspects can lead to performance failures, safety hazards, legal disputes, and financial losses.

Quality-Related Pitfalls

-

Inadequate Power and Performance Verification:

Suppliers may exaggerate laser power (e.g., peak vs. average power) or cleaning speed claims. Buyers risk acquiring underperforming systems that fail to meet production demands. Always demand independent test reports or conduct on-site demonstrations with samples representative of your actual contaminants and substrates. -

Poor Beam Quality and Stability:

Low-quality lasers often suffer from inconsistent beam profiles (M² factor) and power fluctuations. This leads to uneven cleaning, potential substrate damage, and unreliable process repeatability. Verify beam quality specifications and inquire about long-term stability testing data. -

Substandard Optics and Scanning Systems:

Inferior lenses, mirrors, or galvanometer scanners degrade quickly, scatter laser light, reduce focus accuracy, and increase maintenance costs. Ensure optics are specified for the laser wavelength and power, and check the durability claims of scanning components. -

Insufficient Safety Features and Compliance:

Compromised systems may lack essential safety interlocks, proper beam enclosures, or fail to meet regional safety standards (e.g., IEC 60825). This poses severe risks to operators and can result in non-compliance with workplace regulations. Verify full certification documentation and conduct thorough safety audits. -

Lack of Robust System Integration and Control:

Poorly engineered control software, inadequate cooling systems, or unreliable motion integration can cause frequent downtime and inconsistent results. Evaluate the user interface, cooling efficiency, and compatibility with existing automation systems before purchase.

Intellectual Property (IP) Risks

-

Risk of Sourcing Counterfeit or Clone Systems:

The market includes suppliers offering systems that copy patented designs or use unauthorized laser sources. Purchasing such systems exposes the buyer to potential IP infringement lawsuits, even if unintentional. Conduct due diligence on the supplier’s reputation and request proof of IP ownership or licensing. -

Unclear Ownership of Process-Specific IP:

When co-developing cleaning processes with a supplier, ambiguity in contracts about who owns the resulting process parameters or optimizations can lead to disputes. Clearly define IP ownership in service and development agreements from the outset. -

Use of Unlicensed Core Technologies:

Some suppliers use laser diodes, software algorithms, or scanning technologies protected by patents without proper licensing. Buyers may face supply chain disruptions or liability if the original IP owner enforces its rights. Ask for documentation of third-party technology licenses. -

Inadequate Protection of Buyer’s Operational Data:

Connected LLCS may collect operational data. Without clear data ownership and confidentiality clauses, sensitive process information could be exploited or shared by the supplier. Ensure contractual safeguards for data privacy and IP protection. -

Weak Warranty and Support Tied to IP Violations:

If a system is found to infringe IP, suppliers may discontinue support or parts supply to avoid liability. This leaves the buyer with an unsupported, potentially unusable asset. Choose reputable suppliers with strong legal standing and comprehensive service agreements.

By proactively addressing these quality and IP pitfalls, organizations can make informed decisions, mitigate risks, and fully realize the advantages of laser cleaning technology.

H2: Logistics & Compliance Guide for Laser Light Cleaning System

This guide outlines key logistics considerations and compliance requirements for the safe and legal transportation, handling, installation, and operation of Laser Light Cleaning Systems.

H2: Logistics Considerations

-

Transportation & Packaging:

- Secure Packaging: Ensure the system is shipped in robust, manufacturer-approved packaging with adequate cushioning to prevent damage during transit (vibration, shock, moisture).

- Fragile Handling: Clearly label crates/containers as “FRAGILE,” “THIS SIDE UP,” and “LASER EQUIPMENT” to ensure proper handling.

- Environmental Protection: Protect components from extreme temperatures, humidity, and condensation during transport and storage. Avoid direct sunlight.

- Weight & Dimensions: Verify the system’s weight and dimensions match transport vehicle capacity and access requirements (doorways, elevators, crane lifts). Plan the delivery route accordingly.

- Documentation: Include all necessary shipping documents (packing list, commercial invoice, bill of lading/air waybill) and ensure they accurately describe the equipment.

-

Storage:

- Environment: Store the system in a clean, dry, temperature-controlled indoor environment (typically 10°C to 40°C / 50°F to 104°F, 20-80% non-condensing RH unless specified otherwise by the OEM).

- Security: Store in a secure location to prevent unauthorized access or tampering.

- Positioning: Store the main unit and handheld/cleaning head in their designated protective cases or on stable, level surfaces as per OEM instructions. Avoid stacking heavy items on top.

- Duration: Minimize long-term storage. If storage exceeds the OEM’s recommended period, consult them for specific preservation steps.

-

Installation & Site Preparation:

- Space Requirements: Ensure adequate floor space for the main unit, operator workspace, and the required safety perimeter (Nominal Ocular Hazard Distance – NOHD).

- Power Supply: Verify the electrical supply (voltage, phase, frequency, amperage, grounding) matches the system requirements. Use dedicated circuits if recommended. Ensure stable power quality.

- Ventilation & Fume Extraction: Install appropriate local exhaust ventilation (LEV) or fume extraction systems before operation, especially for applications generating particulates or fumes (e.g., rust, paint removal). Ensure exhaust ducts are correctly sized and routed.

- Floor & Environment: Provide a stable, level, non-slip floor. Ensure the environment is free from excessive dust, moisture, flammable materials, or strong electromagnetic interference.

- Utilities: Confirm availability of compressed air (if required) and cooling water (if required, with specified pressure, flow, and quality).

-

Handling:

- Manual Handling: Use appropriate lifting equipment (e.g., forklift, pallet jack, team lift) according to weight. Never lift solely by handles if the unit is heavy. Follow ergonomic principles.

- Cable Management: Carefully manage power, data, and fiber optic cables to prevent tripping hazards, damage, or strain on connectors.

- Fiber Optic Cables: Handle fiber optic delivery cables with extreme care. Avoid sharp bends (respect minimum bend radius), kinks, crushing, or pulling on the connector ferrules.

H2: Compliance Requirements

-

Laser Safety (Core Compliance):

- Classification: Confirm the laser system’s classification (typically Class 4). This dictates the highest level of safety controls.

- Regulatory Standards: Comply with all applicable national and international laser safety standards (e.g., IEC 60825-1, ANSI Z136.1, national regulations like FDA/CDRH in the US, Health Canada, EU directives).

- Laser Safety Officer (LSO): Appoint a qualified LSO responsible for the laser safety program.

- Controlled Area: Establish a clearly demarcated and controlled Laser Controlled Area (LCA) with appropriate warning signs (“Laser Radiation Avoid Eye or Skin Exposure,” “Danger – Class 4 Laser,” “Authorized Personnel Only”).

- Interlocks & Barriers: Ensure safety interlocks on access doors and emergency stop functions are operational. Use fixed or temporary barriers (curtains, walls) to contain beam reflections within the LCA where possible.

- Laser Protective Eyewear (LPE): Provide and mandate the use of LPE specifically rated for the laser’s wavelength(s) and power/energy levels (Optical Density – OD) for all personnel within the LCA during operation. Ensure proper fit and condition.

- Training: Conduct comprehensive laser safety training for all personnel accessing the LCA, covering hazards, controls, emergency procedures, and LPE use. Maintain training records.

- Procedures: Develop and enforce Standard Operating Procedures (SOPs) including startup, operation, shutdown, alignment, and maintenance.

- Maintenance: Perform maintenance only by qualified personnel following OEM procedures and LSO approval. Ensure LPE is worn during maintenance involving beam access.

-

Electrical Safety:

- Standards: Comply with relevant electrical safety standards (e.g., IEC/EN 61010-1, UL 61010-1, local electrical codes).

- Installation: Ensure installation is performed by qualified electricians.

- Grounding: Verify proper grounding of the equipment chassis.

- Inspection: Regularly inspect power cords, plugs, and connectors for damage.

-

Fume & Particulate Extraction:

- Hazard Assessment: Conduct a risk assessment for generated airborne contaminants (metal fumes, dust, paint particles, ozone).

- LEV Performance: Ensure LEV systems are designed, installed, commissioned, and maintained according to standards (e.g., ASHRAE, EN 14175). Perform regular face velocity tests.

- Filtration: Use appropriate filters (e.g., HEPA for particulates, activated carbon for ozone/organics) and change them regularly.

- Exhaust Disposal: Ensure exhaust is discharged safely to the outside, complying with local air quality regulations. Monitor for hazardous substances if required.

- Respiratory Protection: If LEV is insufficient or during maintenance, provide and mandate appropriate respiratory protection (e.g., N95/P2 for dust, specific cartridges for fumes) based on the hazard assessment.

-

General Workplace Safety:

- Hazard Communication (HazCom/GHS): Provide Safety Data Sheets (SDS) for any consumables (e.g., cleaning fluids for optics) and ensure proper labeling.

- Fire Safety: Have appropriate fire extinguishers (Class C for electrical) readily available. Remove flammable materials from the work area. Be aware some materials can ignite under the laser beam.

- Noise: Assess noise levels; provide hearing protection if required.

- Ergonomics: Design the workstation to minimize operator strain (e.g., adjustable height, proper posture).

-

Environmental Regulations:

- Waste Disposal: Classify and dispose of waste generated (contaminated filters, wipes, removed materials like rust/paint sludge) according to local, state/provincial, and federal hazardous waste regulations. Do not dispose of in regular trash.

- Releases: Ensure fume extraction prevents unauthorized releases to the environment.

-

Documentation & Records:

- Maintain comprehensive records including: System manual, LSO file, training records, LPE issue/inspection records, LEV inspection/test records, maintenance logs, waste disposal manifests, risk assessments, and incident reports.

Critical Reminder: This guide provides a framework. Always consult and strictly adhere to the specific manufacturer’s operating, installation, maintenance, and safety manuals for your laser system. Regulations vary significantly by country and region; consult local authorities and safety professionals to ensure full compliance. Safety is paramount when operating Class 4 lasers.

Conclusion: Sourcing a Laser Light Cleaning System

Sourcing a laser light cleaning system represents a strategic investment in advanced, sustainable, and efficient industrial cleaning technology. As industries increasingly prioritize precision, environmental responsibility, and operational safety, laser cleaning emerges as a superior alternative to traditional methods such as sandblasting, chemical cleaning, or dry ice blasting.

The evaluation of available systems highlights several key advantages: non-abrasive and non-contact cleaning, minimal maintenance, reduced waste generation, and compatibility with a wide range of materials including metal, composites, and delicate surfaces. Additionally, laser cleaning systems offer long-term cost savings through decreased consumable use, lower disposal costs, and increased process automation.

When sourcing such a system, critical factors include laser power, wavelength, portability, safety features (e.g., integrated fume extraction and protective enclosures), ease of integration into existing production lines, and vendor support. Selecting a reputable supplier with proven industry experience, strong after-sales service, and compliance with international safety standards (e.g., ISO, CE) is essential for maximizing return on investment and ensuring operational reliability.

In conclusion, adopting a laser light cleaning system aligns with modern industrial goals of sustainability, precision, and efficiency. With careful supplier selection and proper implementation, organizations can achieve significant improvements in cleaning performance, workplace safety, and environmental compliance—positioning themselves at the forefront of advanced manufacturing and maintenance practices.