The global furniture refinishing and restoration market has seen steady growth, driven by increasing demand for sustainable home improvement solutions and the resurgence of vintage and heirloom furniture. According to Grand View Research, the global laser cleaning market—encompassing industrial and precision applications such as furniture stripping—was valued at USD 1.2 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 18.3% from 2023 to 2030. A key growth driver is the adoption of non-abrasive, eco-friendly technologies in artisanal and commercial furniture restoration, where laser stripping offers precision, reduced waste, and compliance with environmental regulations. As manufacturers seek efficient, chemical-free alternatives to traditional sanding and solvents, laser-based systems are gaining traction across woodworking, antiques, and high-end design sectors. This shift has led to the emergence of specialized laser furniture stripping equipment providers, combining industrial laser technology with user-centric design. Below are the top 10 manufacturers leading innovation, performance, and market penetration in this rapidly evolving niche.

Top 10 Laser Furniture Stripping Manufacturers (2026 Audit Report)

(Ranked by Factory Capability & Trust Score)

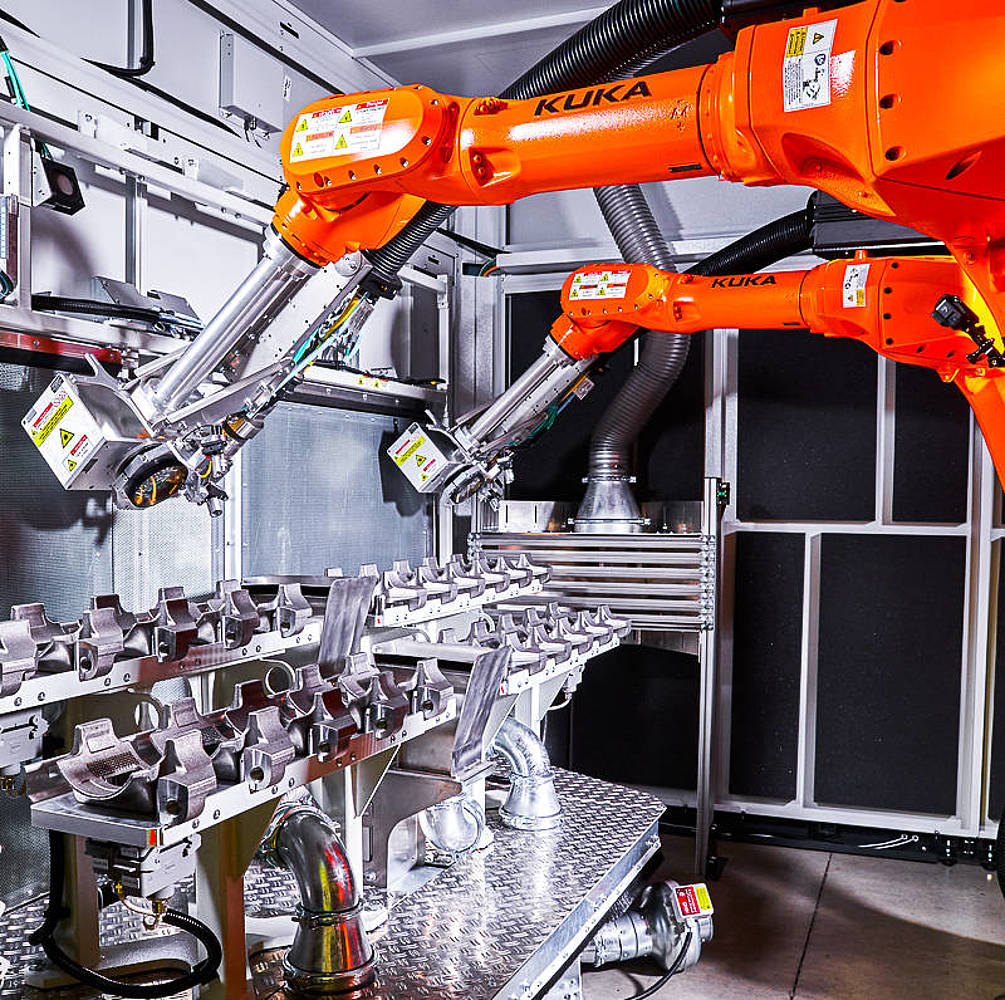

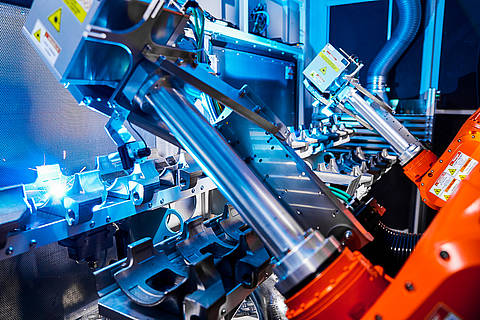

#1 Laserax

Website: laserax.com

Key Highlights: Laserax works with the world’s leading manufacturers to implement laser cleaning, welding, texturing, and marking solutions….

#2 P-laser Industrial laser cleaning

Website: p-laser.com

Key Highlights: With over 35 years of expertise in surface treatment and more than 450 systems installed worldwide, P-Laser is at the forefront of industrial laser cleaning ……

#3 Clean Laser Systems

Website: cleanlaser.de

Key Highlights: Our laser systems are primarily in operation with mold and tool cleaning, paint stripping and decoating as well as cleaning and modification of metallic ……

#4 Laser Photonics

Website: laserphotonics.com

Key Highlights: Laser Photonics manufactures reliable, safe, and eco-friendly Laser Cleaning, Laser Cutting, Laser Engraving, Laser Marking, and Laser Welding solutions….

#5 Laser cleaner machine prices

Website: pulsar-laser.com

Key Highlights: Laser cleaner machine prices and parameters, download our Catalogue….

#6 Argento Lux

Website: argentolux.com

Key Highlights: Argento Lux, experts in laser cleaning, utilizing high-powered lasers to remove contamination from various surfaces. Similar to sandblasting without the ……

#7 Laser Coating Removal Solutions for Industry

Website: surclean.com

Key Highlights: SurClean manufactures laser coating removal and surface preparation equipment that is precise, safe and clean….

#8 Laser Furniture Stripper

Website: winteklaser.com

Key Highlights: The laser furniture stripper offers a new way to remove paint, varnish, or coatings from furniture without chemicals, abrasives, or damage to the substrate….

#9 The 4JET Group

Website: 4jet.de

Key Highlights: 4JET develops innovative laser systems for cleaning, patterning, marking, cutting and modifying materials to achieve high-quality component surfaces….

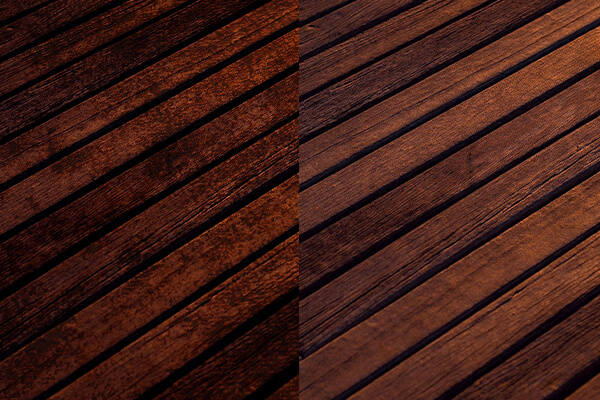

#10 Laser Wood Cleaning & Restoration

Website: advancedlaserrestoration.com

Key Highlights: Laser stripping is incredibly precise, removing layers of paint, varnish, or other coatings without damaging the underlying wood….

Expert Sourcing Insights for Laser Furniture Stripping

H2: Projected 2026 Market Trends for Laser Furniture Stripping

The laser furniture stripping market is poised for significant transformation by 2026, driven by technological innovation, growing environmental awareness, and evolving consumer preferences. Here are the key trends expected to shape the industry:

1. Accelerated Adoption Driven by Environmental Regulations:

Stricter global regulations on VOCs (Volatile Organic Compounds) and hazardous chemical disposal will push restoration shops, conservators, and manufacturers toward eco-friendly alternatives. Laser stripping, which produces no chemical waste and minimal particulates (when paired with filtration), will see increased adoption as a sustainable solution. Regions like the EU and North America will lead this shift, with compliance becoming a major purchasing driver.

2. Technological Advancements Enhancing Precision and Efficiency:

By 2026, expect significant improvements in laser systems:

– AI Integration: Smart lasers with AI-powered vision systems will automatically detect material types (wood, paint, varnish) and adjust parameters in real time, reducing operator skill requirements and minimizing substrate damage.

– Faster Processing Speeds: Higher-powered yet more energy-efficient lasers will reduce cycle times, making the technology viable for larger-scale operations and commercial restoration projects.

– Improved Portability: Compact, ergonomic handheld units will become more prevalent, enabling on-site furniture restoration and expanding service offerings for mobile professionals.

3. Expansion Beyond Niche Applications:

While currently used in high-end restoration and conservation, laser stripping will penetrate broader markets by 2026:

– Furniture Refinishing Industry: Mid-tier restoration businesses will adopt lasers to differentiate services, reduce labor costs, and offer “chemical-free” refinishing as a premium service.

– Antique and Art Conservation: Increased trust in non-contact methods will solidify lasers as a standard tool in museum and heritage preservation.

– Sustainable Manufacturing: Furniture manufacturers may integrate laser stripping into circular economy models for refurbishing and reusing components.

4. Cost Reduction and Improved ROI:

As production scales and technology matures, the initial investment for commercial-grade laser systems is expected to decrease. Coupled with lower operational costs (no chemical purchases, reduced disposal fees, less labor time), the return on investment (ROI) will improve, making lasers accessible to smaller workshops and independent artisans.

5. Growing Consumer Demand for Eco-Conscious Restoration:

End consumers are increasingly seeking sustainable home solutions. The ability to market furniture restoration as “zero-chemical” and “eco-friendly” using laser technology will become a powerful differentiator. This trend will drive demand from both professional restorers and DIY enthusiasts exploring rental or shared laser services.

6. Emergence of Service-Based Models:

Alongside equipment sales, a growing ecosystem of laser stripping services is expected. Mobile laser technicians and specialized restoration studios will offer on-demand stripping, lowering the barrier for furniture businesses that don’t want to invest in equipment.

In summary, by 2026, laser furniture stripping will transition from a specialized tool to a mainstream solution, driven by sustainability, technological innovation, and market demand for cleaner, more efficient restoration methods.

Common Pitfalls in Sourcing Laser Furniture Stripping (Quality, IP)

Sourcing laser furniture stripping services or equipment presents unique challenges, particularly regarding quality consistency and intellectual property (IP) protection. Overlooking these aspects can lead to subpar results, legal disputes, or loss of competitive advantage.

Inconsistent Stripping Quality and Finish

One of the most frequent issues is variability in the quality of the stripped finish. Factors such as incorrect laser settings, uneven beam focus, or operator inexperience can result in surface pitting, incomplete paint removal, or damage to the underlying wood or metal. Without clear quality benchmarks and real-time process monitoring, suppliers may deliver inconsistent results across batches, compromising the final product’s appearance and value.

Lack of Process Standardization

Many suppliers lack standardized operating procedures for different furniture materials and coatings. Each type of finish—varnish, lacquer, paint—reacts differently to laser parameters. A one-size-fits-all approach leads to poor outcomes. When sourcing, it’s critical to verify that the supplier has documented, repeatable processes tailored to specific substrates and coating types to ensure reliable results.

Inadequate Equipment Calibration and Maintenance

Laser systems require precise calibration and regular maintenance. Sourcing from providers who neglect equipment upkeep can result in degraded performance over time, leading to uneven stripping and increased downtime. Always assess the supplier’s maintenance logs and technical capabilities before engagement.

Insufficient Expertise in Furniture-Specific Applications

Not all laser stripping providers have experience with delicate furniture components. Furniture often features intricate carvings, thin veneers, or mixed materials, which demand high precision and adaptability. Choosing a vendor without domain-specific expertise risks irreversible damage and costly rework.

Intellectual Property Exposure

Laser stripping often involves reverse engineering or replicating proprietary designs, especially when restoring vintage or branded furniture. Sharing detailed designs or product samples with third-party suppliers can expose your IP to theft or unauthorized replication. Without robust confidentiality agreements and secure data handling practices, your designs may be vulnerable.

Weak Contractual IP Protections

Many sourcing agreements fail to clearly define IP ownership, usage rights, and data handling protocols. Ensure contracts explicitly state that all designs, process data, and derivative works remain your exclusive property. Include clauses prohibiting the supplier from using your designs for other clients or retaining digital copies post-project.

Supply Chain Transparency Gaps

Limited visibility into the supplier’s sub-contracting practices or facility security can increase IP risks. Some providers may outsource work to less secure facilities or lack cybersecurity measures to protect digital design files. Conduct due diligence on their operational transparency and security protocols.

Failure to Validate Outcomes Before Full-Scale Production

Rushing into full production without thorough pilot testing increases the risk of quality failures and IP misuse. Always require sample stripping runs under real conditions and audit the supplier’s handling of your materials and files before scaling up.

Logistics & Compliance Guide for Laser Furniture Stripping

Laser furniture stripping is an advanced, eco-friendly method for removing finishes, paint, and coatings from wooden and other furniture surfaces. While it reduces chemical waste and offers precision, it requires careful logistics planning and strict compliance with safety, environmental, and regulatory standards. This guide outlines key considerations to ensure smooth operations and legal adherence.

Equipment Transportation and Setup

Transport laser stripping systems—such as fiber or CO₂ lasers with robotic arms or handheld wands—using climate-controlled, shock-absorbing vehicles to prevent damage. Ensure all components are securely packed and comply with carrier regulations for sensitive electronics. Upon arrival, conduct a site assessment to confirm power requirements (typically 208–480V, three-phase), ventilation, and floor load capacity. Assemble equipment in a dedicated, isolated workspace with clear access and emergency exits.

Facility Requirements and Workspace Design

Designate a controlled stripping area with non-combustible flooring, proper grounding, and adequate space for material handling. Install local exhaust ventilation (LEV) systems with HEPA filtration to capture particulates and volatile organic compounds (VOCs) generated during ablation. Mark laser operation zones with warning signage and interlock access points to prevent unauthorized entry. Equip the workspace with fire suppression systems (e.g., Class D extinguishers) and emergency shut-offs.

Material Handling and Inventory Management

Establish protocols for receiving, labeling, and storing furniture items pre- and post-treatment. Use non-sparking tools and pallets to avoid ignition risks. Segregate items based on material type (e.g., hardwood, veneer, mixed substrates) and coating composition (e.g., lead-based paint, polyurethane) to optimize laser settings and comply with hazardous material regulations. Track inventory using digital logs to ensure traceability and job-specific processing.

Regulatory Compliance

Adhere to federal, state, and local regulations governing laser operations and hazardous materials. Key standards include:

- OSHA 29 CFR 1910.97 and ANSI Z136.1: Mandate laser safety officers (LSOs), employee training, and protective eyewear with appropriate optical density for laser wavelength.

- EPA Regulations (e.g., NESHAP, RCRA): Require capture and proper disposal of hazardous residues (e.g., lead, chromium) as hazardous waste if testing confirms contamination. Maintain manifests and disposal records.

- NFPA 70 (NEC) and NFPA 70E: Govern electrical installations and arc flash safety for high-power laser systems.

- Local Air Quality Permits: May require emissions reporting for particulate matter; ensure filtration systems meet allowable limits.

Worker Safety and Training

Provide comprehensive training covering laser hazards (eye/skin exposure, fumes), machine operation, emergency procedures, and PPE use (e.g., laser safety goggles, respirators, flame-resistant clothing). Conduct annual refreshers and document all training. Appoint a certified Laser Safety Officer (LSO) to oversee compliance, perform risk assessments, and audit safety protocols.

Waste Management and Environmental Controls

Treat all debris from laser stripping as potentially hazardous until tested. Collect residue using HEPA-filtered vacuums and store in sealed, labeled containers. Test samples for regulated substances (e.g., lead, cadmium) per EPA TCLP protocols. Dispose of hazardous waste through licensed facilities with proper documentation. Recycle uncontaminated wood and metal components where feasible.

Documentation and Auditing

Maintain detailed records of equipment maintenance, laser settings, operator certifications, waste manifests, air quality monitoring, and incident reports. Conduct quarterly compliance audits to verify adherence to internal policies and regulatory standards. Retain records for a minimum of three years or as required by jurisdiction.

Emergency Preparedness

Develop and post emergency response plans for fire, laser exposure, or chemical release. Equip the facility with first aid kits, eye wash stations, and accessible fire extinguishers. Conduct biannual drills and review procedures with all personnel to ensure readiness.

By integrating these logistics and compliance measures, laser furniture stripping operations can achieve high efficiency, worker safety, and environmental responsibility while remaining fully compliant with applicable laws and industry standards.

Conclusion: Sourcing Laser Furniture Stripping Solutions

In conclusion, sourcing laser technology for furniture stripping presents a forward-thinking, sustainable, and highly effective alternative to traditional methods such as chemical solvents or sandblasting. Laser stripping offers precision, minimal substrate damage, reduced environmental impact, and lower long-term operational costs, making it ideal for use in high-value furniture restoration and heritage conservation.

When sourcing laser stripping systems, it is essential to evaluate key factors including laser type (e.g., fiber or pulsed lasers), power output, automation compatibility, safety features, and vendor support. Partnering with experienced suppliers who offer customization, training, and service maintenance is critical to ensuring smooth integration into existing workflows.

While the initial investment may be higher than conventional methods, the long-term benefits—such as improved worker safety, reduced waste disposal costs, compliance with environmental regulations, and superior finish quality—justify the expenditure, especially for specialty or artisanal furniture operations.

As the demand for eco-friendly and efficient restoration techniques grows, investing in laser furniture stripping not only enhances operational efficiency but also positions businesses as leaders in sustainable craftsmanship. Therefore, sourcing the right laser solution is a strategic move toward innovation, quality, and environmental responsibility in the furniture restoration industry.