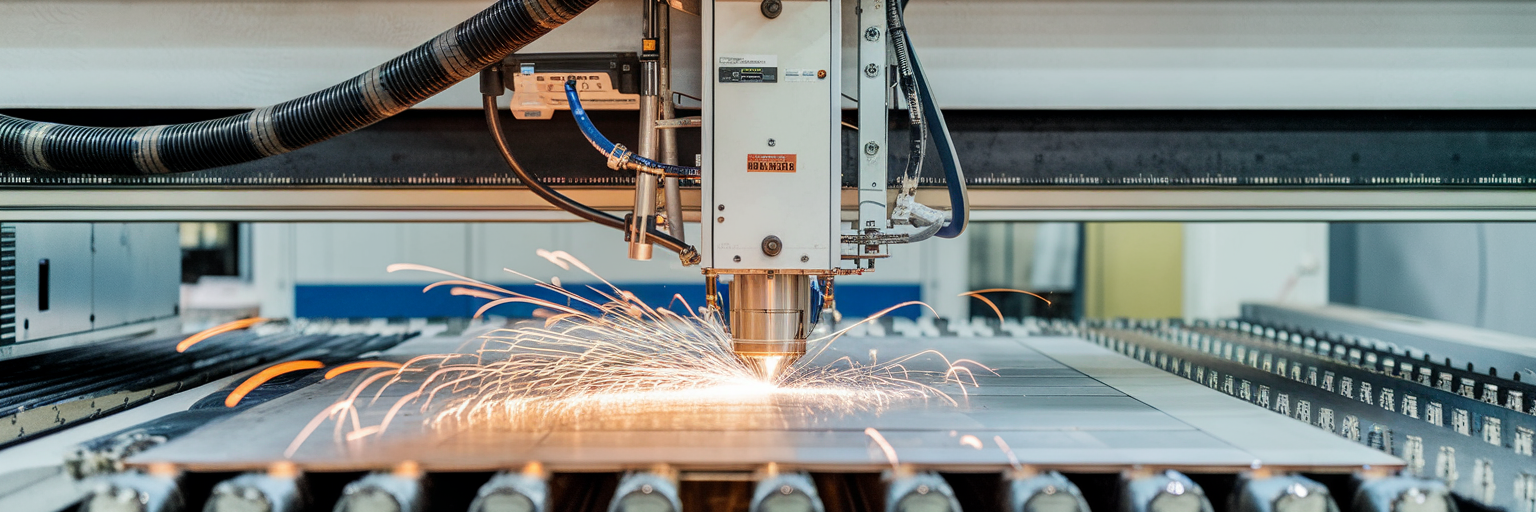

The global laser marking market is experiencing robust growth, driven by increasing demand for precision, permanence, and automation in product traceability across industries such as automotive, electronics, medical devices, and aerospace. According to a report by Mordor Intelligence, the global laser marking machines market was valued at USD 2.47 billion in 2023 and is projected to reach USD 3.85 billion by 2029, growing at a CAGR of approximately 7.6% during the forecast period. This expansion is fueled by the rising adoption of fiber laser technology, which offers superior longevity, lower maintenance, and higher efficiency compared to traditional CO₂ or solid-state lasers. With manufacturers increasingly prioritizing high-speed, non-contact marking solutions for barcodes, QR codes, serial numbers, and logos, fiber laser markers have emerged as the preferred choice in modern production environments. As competition intensifies and technological differentiation becomes critical, identifying leading players in the space is essential. The following list highlights the top 10 fiber laser marker manufacturers recognized for innovation, global reach, product reliability, and market share as of 2024.

Top 10 Laser Fiber Marker Manufacturers (2026 Audit Report)

(Ranked by Factory Capability & Trust Score)

#1 FIBER Laser

Website: gravotech.us

Key Highlights: Our powerful and high-quality industrial Fiber Laser engraver performs precise markings quickly. Compact, with great communication links and simple to integrate ……

#2 Laserax

Website: laserax.com

Key Highlights: Laserax works with the world’s leading manufacturers to implement laser cleaning, welding, texturing, and marking solutions….

#3 Laser Marking for All Industries

Website: lasermarktech.com

Key Highlights: Discover innovative laser marking solutions tailored for various industries. Explore our cutting-edge technology as leaders in laser marking and engraving….

#4 LaserStar Technologies

Website: laserstar.net

Key Highlights: LaserStar Technologies designs and manufactures high-performance laser welding, marking, and cutting systems for industrial, jewelry, ……

#5 Fiber Laser Marker

Website: telesis.com

Key Highlights: Discover Telesis fiber laser markers: reliable, high-speed solutions for product identification, traceability, & branding. Request a quote!…

#6 IPG Photonics

Website: ipgphotonics.com

Key Highlights: IPG Photonics manufactures high-performance fiber lasers, amplifiers, and laser systems for diverse applications and industries. Discover your solution….

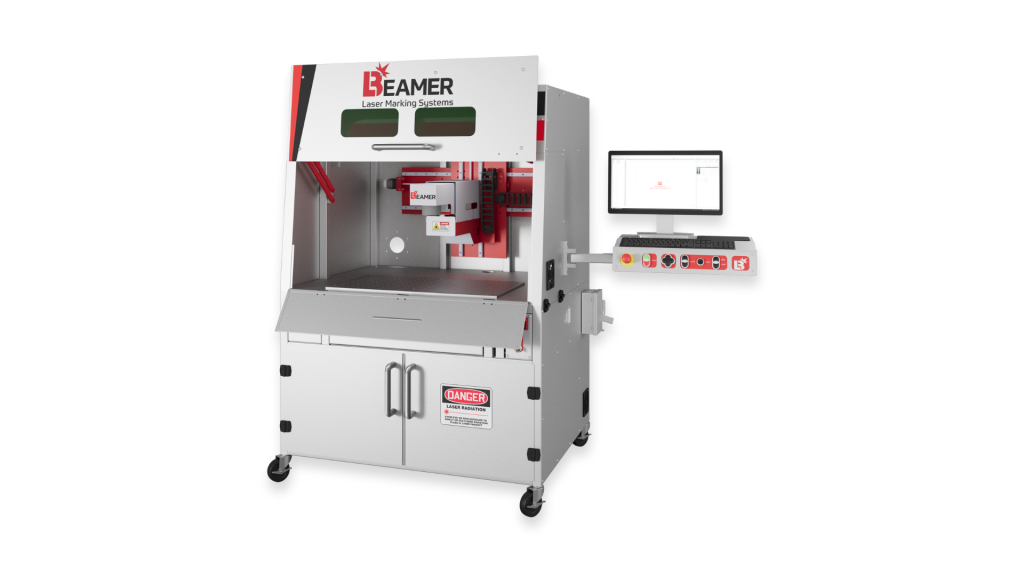

#7 Beamer Laser Marking Systems

Website: beamerlasermarking.com

Key Highlights: We offer a wide range of powerful standard, engineered, and inline 1064nm IR laser marking solutions with unmatched 100,000+ hour lifespan….

#8 MECCO

Website: mecco.com

Key Highlights: Our expertise in automated laser engraving and pin marking systems encompasses a comprehensive range of solutions for your industry, materials, and ……

#9 Fiber Laser Marker Machines & Marking Systems

Website: troteclaser.com

Key Highlights: Fiber Laser Marker Machines & Marking Systems. Our laser marking systems enable you to achieve precise and permanent marking on metals and plastics….

#10 Fiber Laser Marking

Website: keyence.com

Key Highlights: Explore high-speed, precision-focused fiber laser marking machines by KEYENCE. Achieve accurate and permanent markings across a wide range of materials….

Expert Sourcing Insights for Laser Fiber Marker

H2: 2026 Market Trends for Laser Fiber Markers

The global laser fiber marker market is poised for significant transformation by 2026, driven by technological advancements, expanding industrial automation, and evolving manufacturing demands across key sectors. Here’s a comprehensive analysis of the dominant trends shaping the market:

H3: Accelerated Adoption in Electric Vehicles (EVs) and Battery Manufacturing

The explosive growth of the EV industry is a primary catalyst. Fiber laser markers are essential for permanent, high-contrast marking of critical components:

* Battery Traceability: Marking battery cells, packs, and management systems (BMS) with unique IDs (UIDs), barcodes (2D Data Matrix), and manufacturing data for strict traceability, safety compliance (e.g., UL, IEC), and recycling.

* Powertrain Components: Permanent marking of motor housings, inverter parts, and transmission elements for identification and anti-counterfeiting throughout the supply chain.

* Demand Surge: The need for high-speed, reliable marking on diverse battery materials (aluminum, copper, steel, plastics) is driving demand for optimized fiber lasers (e.g., green lasers for copper).

H3: Integration with Industry 4.0 and Smart Factories

Fiber markers are becoming integral nodes in connected manufacturing ecosystems:

* Seamless Connectivity: Standard integration with MES (Manufacturing Execution Systems), ERP systems, and PLCs via Ethernet/IP, Profinet, or OPC UA for real-time data exchange and job management.

* Automated Workflows: Direct integration into robotic cells and automated guided vehicles (AGVs) for in-line, contactless marking without stopping production lines.

* Data-Driven Optimization: Collection of marking data (uptime, job logs, quality metrics) for predictive maintenance, process optimization, and quality control dashboards.

H3: Advancements in Laser Technology and Beam Quality

Technology continues to push performance boundaries:

* Higher Power & Speed: Increased average power (up to 100W+) enables faster marking on challenging materials and deep engraving, boosting throughput in high-volume applications.

* Improved Beam Quality (M²): Superior beam quality allows for finer details, smaller feature sizes, and sharper edges, crucial for micro-marking electronics and medical devices.

* Pulsed Fiber Laser Evolution: Advancements in MOPA (Master Oscillator Power Amplifier) fiber lasers provide unparalleled pulse control (adjustable pulse width, frequency), enabling high-contrast marking on sensitive materials (plastics, anodized aluminum) without damage and superior color marking (black/white on metals).

* Alternative Wavelengths: Wider adoption of Green (532nm) and UV (355nm) fiber lasers for marking highly reflective materials (copper, gold) and heat-sensitive polymers where standard IR (1064nm) lasers struggle.

H3: Focus on Sustainability and Regulatory Compliance

Environmental and regulatory pressures are influencing technology choices:

* “Green” Manufacturing: Fiber lasers are inherently more energy-efficient than older technologies (like CO2 lasers or chemical etching) and produce no consumables or hazardous waste, aligning with ESG goals.

* RoHS/REACH Compliance: Permanent laser marking replaces ink-based methods (prone to fading, solvents, VOCs), ensuring durable, chemical-resistant marks that meet environmental regulations.

* Traceability Mandates: Stricter global regulations (e.g., UDI for medical devices, automotive safety standards) demand permanent, machine-readable marks, solidifying the role of fiber lasers.

H3: Expansion into New Materials and Applications

The versatility of fiber lasers is opening new markets:

* Advanced Composites: Marking carbon fiber reinforced polymers (CFRP) and other composites used in aerospace and high-performance automotive.

* Medical & Dental Implants: High-precision, sterile marking of titanium, stainless steel, and PEEK implants with UDI codes and logos.

* Consumer Electronics: Intricate marking on smartphones, wearables, and laptops (logos, serial numbers, regulatory info) on metals, glass, and anodized finishes.

* Plastics: Enhanced capabilities for high-contrast, non-ablative marking on engineering plastics used in automotive and electronics.

H3: Market Consolidation and Competitive Landscape

The market is seeing increased activity:

* Mergers & Acquisitions: Larger players acquiring niche technology specialists (e.g., in beam delivery, software, or specific wavelengths) to broaden portfolios.

* Intensified Competition: Competition between established giants (Trumpf, IPG Photonics, Coherent) and agile regional players, driving innovation and price pressure, particularly in mid-range systems.

* Software as a Differentiator: Advanced, user-friendly software (featuring CAD/CAM integration, database connectivity, job management, and analytics) is becoming a key competitive advantage.

H3: Geographic Shifts and Emerging Markets

Growth is not uniform:

* Asia-Pacific Dominance: China, India, and Southeast Asia remain the fastest-growing regions due to massive manufacturing bases (electronics, automotive), government initiatives (e.g., “Make in India,” “China Manufacturing 2025”), and rising automation adoption.

* North America & Europe: Steady growth driven by advanced manufacturing, EV adoption, medical device innovation, and replacement cycles for older marking technologies.

* Supply Chain Resilience: Geopolitical factors may drive some onshoring/nearshoring, potentially boosting demand in North America and Europe for localized production lines.

H3: Key Challenges

- High Initial Investment: Cost remains a barrier for SMEs, though TCO (Total Cost of Ownership) is favorable.

- Skilled Labor Shortage: Need for technicians trained in laser operation, maintenance, and integration.

- Material Limitations: While versatile, some very transparent or highly heat-sensitive materials still pose challenges.

Conclusion: By 2026, the laser fiber marker market will be characterized by deeper integration into automated and smart manufacturing, driven by the EV revolution and stringent traceability needs. Technological advancements in power, control, and wavelength diversity will expand applications, while sustainability and connectivity will be paramount. Success will favor suppliers offering not just robust hardware, but comprehensive solutions with intelligent software and seamless system integration capabilities, particularly catering to the high-growth EV and advanced manufacturing sectors in Asia and globally.

Common Pitfalls Sourcing a Laser Fiber Marker: Quality and Intellectual Property (IP)

Sourcing a laser fiber marker, especially from international suppliers or less-established manufacturers, involves several critical risks related to quality and intellectual property. Overlooking these pitfalls can lead to operational inefficiencies, legal exposure, and damage to brand reputation. Below are key areas to watch:

Poor Build Quality and Component Sourcing

Many low-cost suppliers use substandard materials and components to reduce prices. This includes inferior laser diodes, unreliable galvanometers, and low-grade cooling systems. These compromises result in frequent breakdowns, inconsistent marking performance, and shortened machine lifespan. Always verify the specifications and origin of core components like the fiber laser source and control board.

Inaccurate Power Output Claims

Some suppliers exaggerate the actual laser power (e.g., advertising a “50W” laser that performs like a 30W unit). This misleading specification affects marking speed, depth, and material compatibility. Request third-party test reports or conduct on-site power verification before finalizing a purchase.

Lack of Compliance and Safety Certifications

Non-compliant machines may lack essential safety features or fail to meet regional regulations (e.g., CE, FDA, RoHS). Using uncertified equipment poses safety risks and can result in legal penalties or import restrictions. Insist on valid certification documentation and verify authenticity through official databases.

Inadequate or Fake Intellectual Property Rights

A major risk involves suppliers who copy designs or firmware from established brands without proper licensing. Purchasing such machines may expose your business to IP infringement claims, especially if the equipment is used commercially. Ensure the supplier can provide proof of legitimate IP ownership or licensing for the laser system, software, and optical design.

Proprietary Software Lock-ins and Lack of Support

Some manufacturers use closed-source software with restrictive licensing, limiting customization or integration with existing production systems. Additionally, poor technical support and limited firmware updates can render the machine obsolete or difficult to maintain. Evaluate software openness, update policies, and after-sales service capabilities before purchasing.

Insufficient After-Sales Support and Spare Parts Availability

Many budget suppliers offer little to no technical support, training, or spare parts access. When a critical component fails, long lead times or unavailability can halt production. Confirm the supplier’s service network, response times, and spare parts inventory—preferably with local or regional support.

Hidden Costs from Low-Quality Marking Performance

Even if the initial price is low, poor beam quality or unstable output can result in rework, scrap, or slower production cycles. Over time, these hidden costs far exceed the savings from a cheaper machine. Conduct sample marking tests with your actual materials to assess real-world performance.

Failure to Verify Supplier Authenticity

Counterfeit or “white label” resellers may present themselves as original manufacturers. Always verify the supplier’s credentials, factory location, and client references. Site visits or virtual audits can help assess manufacturing capabilities and authenticity.

Mitigating these risks requires due diligence: request detailed technical documentation, test samples, verify certifications, and consult legal counsel when necessary—especially regarding IP rights and compliance.

Logistics & Compliance Guide for Laser Fiber Marker

Product Overview

The Laser Fiber Marker is a high-precision industrial engraving device that uses fiber laser technology to mark metals, plastics, and other materials. It is commonly used in manufacturing, automotive, aerospace, and electronics industries for part identification, serialization, and branding. This guide outlines key logistics and compliance considerations for the safe handling, transportation, import/export, and operational use of the Laser Fiber Marker.

Regulatory Compliance

The Laser Fiber Marker must comply with various international and regional safety and electromagnetic standards. Key regulations include:

– IEC 60825-1: Safety of laser products – Equipment classification and requirements. The device typically falls under Class 1 or Class 4 depending on configuration; proper labeling and safety interlocks are required.

– CE Marking: Mandatory for sale in the European Economic Area (EEA), indicating conformity with health, safety, and environmental protection standards.

– FDA/CDRH (USA): Compliance with 21 CFR Part 1040.10 and 1040.11 for laser products; registration with the Center for Devices and Radiological Health is required.

– RoHS and REACH (EU): Restriction of Hazardous Substances and chemical safety regulations; ensure all components are compliant.

– FCC Part 15 (USA): Electromagnetic interference (EMI) compliance for digital control systems.

End users must verify that the specific model is certified for their region and maintain documentation accordingly.

Packaging and Shipping Requirements

Proper packaging is essential to prevent damage during transit:

– Use the original manufacturer’s packaging, which includes shock-absorbing foam and a rigid outer crate.

– Secure all movable parts (e.g., galvanometer mirrors, lens assembly) with transit locks or protective fixtures.

– Include desiccant packs to prevent moisture damage during sea or long-distance transport.

– Label the package with:

– “Fragile – Handle with Care”

– “This Side Up”

– “Protect from Moisture”

– Laser safety warning labels (if applicable)

Ship via reputable freight carriers experienced in handling precision equipment. Air or ground shipping should be selected based on delivery urgency and environmental conditions.

Import/Export Documentation

International shipment requires accurate documentation:

– Commercial Invoice: Detailed description, HS code (typically 8515.21 or 8479.89), value, and country of origin.

– Packing List: Itemized list of contents, weights, and dimensions.

– Certificate of Conformity (CoC): Proof of compliance with destination country regulations.

– Bill of Lading/Air Waybill: Carrier document for tracking and customs clearance.

– Export License: Required for certain countries under dual-use or strategic trade regulations (e.g., U.S. EAR or EU Dual-Use Regulation). Verify if laser power output exceeds thresholds that trigger licensing (e.g., >500 mW for certain wavelengths).

Consult with a customs broker to ensure compliance with local import duties and restrictions.

Installation and Site Preparation

Before installation:

– Ensure the facility has a stable power supply (typically 100–240 VAC, 50/60 Hz) with proper grounding.

– Provide adequate ventilation or fume extraction systems, especially when marking plastics or coated materials.

– Install in a clean, dry environment with controlled temperature (10–40°C) and humidity (<80% non-condensing).

– Maintain a minimum clearance of 50 cm around the unit for heat dissipation and maintenance access.

– Verify laser safety zoning; use barriers or enclosures if operating in a Class 4 configuration.

Operational Safety and Training

User safety is paramount:

– Only trained personnel should operate the Laser Fiber Marker.

– Wear appropriate personal protective equipment (PPE), including laser safety goggles with correct optical density (OD) for the laser wavelength (commonly 1064 nm).

– Never bypass safety interlocks or open the laser enclosure during operation.

– Implement a lockout/tagout (LOTO) procedure during maintenance.

– Conduct regular safety audits and maintain an operational log.

Maintenance and Servicing

To ensure longevity and compliance:

– Follow the manufacturer’s preventive maintenance schedule (e.g., cleaning lenses, checking cooling systems).

– Only authorized technicians should perform internal repairs or alignments.

– Keep records of all maintenance, calibrations, and safety checks.

– Dispose of worn components (e.g., fiber lasers, electronic boards) in accordance with WEEE (EU) or local e-waste regulations.

End-of-Life Disposal

At end-of-life:

– Recycle the unit through certified e-waste handlers.

– Separate hazardous components (e.g., batteries, capacitors) for proper disposal.

– Remove and securely erase any data stored in the control system (e.g., marking files, user settings).

Adhering to this logistics and compliance guide ensures the safe, legal, and efficient use of the Laser Fiber Marker throughout its lifecycle.

Conclusion on Sourcing a Laser Fiber Marker

After a thorough evaluation of technical requirements, supplier capabilities, cost considerations, and long-term operational needs, sourcing a fiber laser marker represents a strategic investment for enhancing product identification, traceability, and overall manufacturing efficiency. Fiber laser markers offer superior performance in terms of marking speed, precision, durability, and maintenance compared to traditional marking methods. They are particularly well-suited for industrial environments due to their robust design and ability to mark a wide range of materials, including metals and certain plastics.

When selecting a supplier, key factors such as laser power, software compatibility, after-sales support, warranty, and service availability should be prioritized to ensure reliability and minimal downtime. It is also advisable to partner with reputable manufacturers or distributors offering proven track records and technical expertise.

In conclusion, sourcing a high-quality fiber laser marker from a trusted supplier not only improves production accuracy and branding but also supports compliance with industry standards and traceability requirements. With proper selection and integration, the laser fiber marker will deliver a strong return on investment through increased productivity and reduced operational costs over its lifecycle.