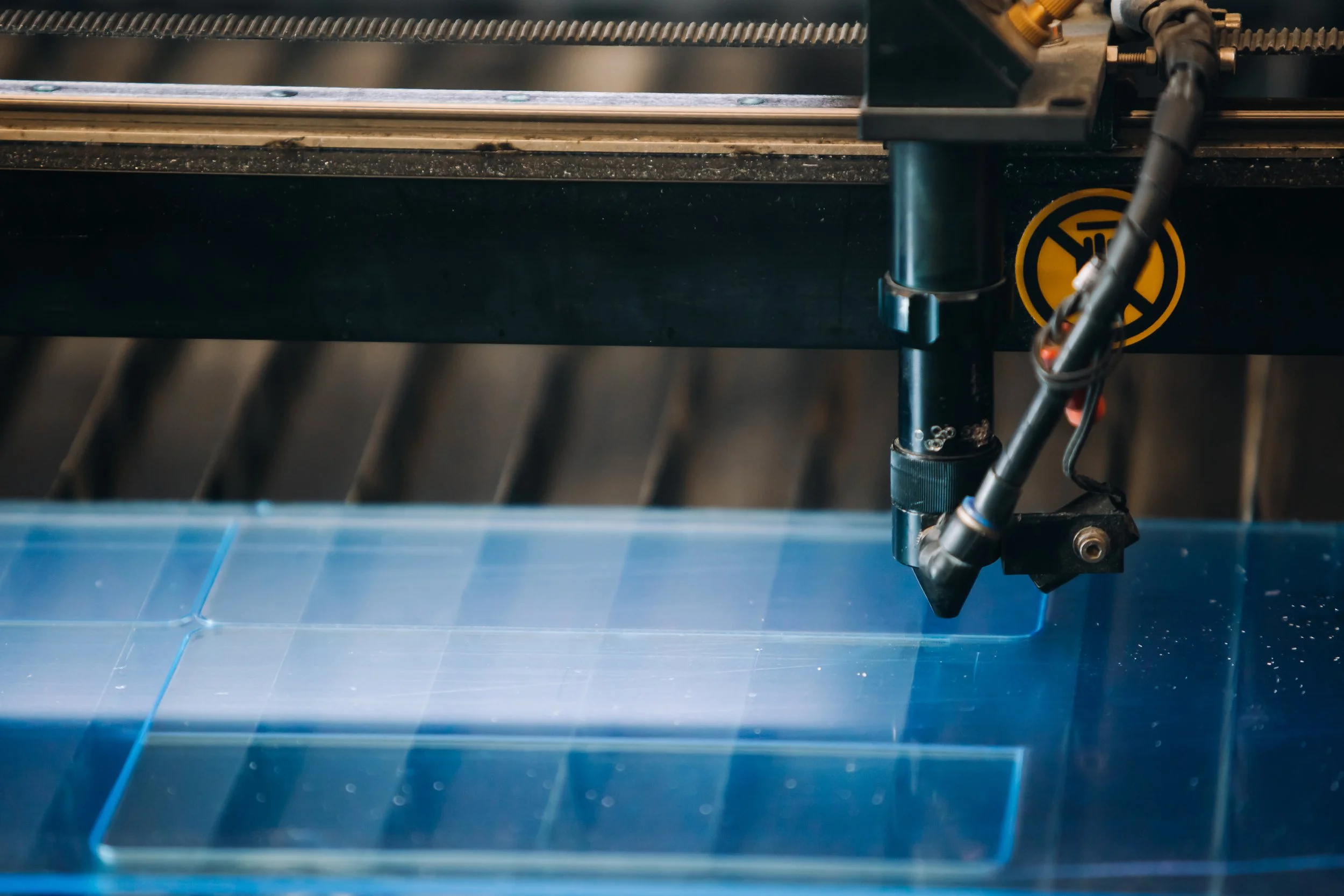

The global laser etching market is experiencing robust growth, driven by increased demand for precision marking and engraving across industries such as automotive, electronics, and consumer goods. According to Grand View Research, the global laser marking market was valued at USD 3.43 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 6.8% from 2023 to 2030. As acrylic materials like plexiglass (PMMA) gain popularity for their clarity, durability, and versatility, manufacturers are increasingly adopting laser etching for high-resolution, permanent markings without compromising structural integrity. This surge in demand has prompted the rise of specialized plexiglass manufacturers integrating advanced laser technologies into their production lines—ensuring accuracy, scalability, and customization. In this evolving landscape, identifying industry leaders who combine material expertise with cutting-edge laser capabilities is critical for businesses seeking reliable and high-quality etching solutions.

Top 10 Laser Etching Plexiglass Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Laser Cutting Plastic and Other Non

Domain Est. 2000

Website: espemfg.com

Key Highlights: As a pioneer in the laser cutting field, ESPE Manufacturing Co., Inc. continues to lead the way in providing quality industrial laser cutting solutions for ……

#2 Rowmark

Domain Est. 1997

Website: rowmark.com

Key Highlights: With over 30 years experience Rowmark is the premier sign plastic manufacturer in the world. Manufactured with you in mind. Tough. Tested. Trusted….

#3 Trotec Laser

Domain Est. 2002

Website: troteclaser.com

Key Highlights: Trotec is a leading international laser manufacturer and makes the work of laser users easier, faster and more profitable….

#4 Laserax

Domain Est. 2012

Website: laserax.com

Key Highlights: Laserax works with the world’s leading manufacturers to implement laser cleaning, welding, texturing, and marking solutions….

#5 Acrylic Laser Cutting Service

Domain Est. 1997

Website: acmeplastics.com

Key Highlights: Free delivery 15-day returnsOur acrylic laser cutting service is ideal for one-off parts, prototyping and small production runs. We can laser cut acrylic up to .5″ thick….

#6 Min Plastics

Domain Est. 2000

Website: minplastics.com

Key Highlights: Official distributor of PLEXIGLAS®, Polycarbonate, Expanded/Foamed PVC, HDPE, Starboard, and Laser-Engraveable sheets. Supporting projects from cut-to-size ……

#7 Laser Etching Plastic

Domain Est. 2002

Website: welchplastics.com

Key Highlights: We provide high-definition laser etching services that will enhance your branding, create traceability, maintain compliance, and do it all faster and better ……

#8 JPPlus: Engraving, Sublimation, Heat Transfer & UV-LED

Domain Est. 2005

Website: jpplus.com

Key Highlights: Johnson Plastics Plus is your home for products and equipment for laser and rotary engraving, sublimation, heat transfer printing and UV-LED printing….

#9 PMMA, Plexiglas® and Acrylic engraving, etching and cutting

Domain Est. 2007

Website: gravotech.us

Key Highlights: Gravotech markets various laser and mechanical materials made from acrylic, suitable for any acrylic engraving and cutting application. Find out more:…

#10 Laser Equipment Supplier

Domain Est. 2007

Website: radianlaser.com

Key Highlights: Radian Laser Systems is a laser equipment supplier specializing in high-speed, customizable laser machinery, including fiber, CO2, and galvo lasers….

Expert Sourcing Insights for Laser Etching Plexiglass

H2: Projected 2026 Market Trends for Laser Etching Plexiglass

The market for laser etching plexiglass (acrylic) is poised for significant evolution by 2026, driven by technological advancements, shifting consumer demands, and expanding applications. Key trends shaping this market include:

1. Accelerated Adoption of Fiber Lasers for High-Precision Applications: While CO2 lasers remain dominant for general acrylic etching due to their excellent material interaction and cost-effectiveness, fiber lasers are gaining substantial ground. Their superior beam quality enables ultra-fine detail, smoother edge finishes, and faster processing speeds for intricate designs and micro-features. This trend is particularly strong in high-value sectors like medical devices, electronics (e.g., membrane switches, light guides), and premium consumer goods, where precision and consistency are paramount. By 2026, expect fiber laser adoption for acrylic etching to increase significantly, especially in automated production lines demanding high throughput and quality.

2. Integration of AI and Machine Learning for Process Optimization: The integration of Artificial Intelligence (AI) and Machine Learning (ML) into laser control systems will be a major differentiator. By 2026, AI-driven software will be commonplace for:

* Automated Parameter Optimization: AI will analyze material properties (thickness, grade, color), desired etch depth/opacity, and design complexity to instantly calculate optimal power, speed, frequency, and focus settings, minimizing trial-and-error and waste.

* Predictive Maintenance: ML algorithms will monitor laser performance data to predict component failures (e.g., tubes, optics) before they occur, reducing downtime.

* Real-time Quality Control: Integrated vision systems combined with AI will enable real-time inspection of etched marks for defects (inconsistencies, charring, incomplete etching), allowing for immediate process adjustment or rejection of faulty parts.

3. Growth in On-Demand and Personalized Manufacturing: The demand for customization across consumer products, signage, awards, and home decor will continue to fuel the market. Laser etching offers unparalleled flexibility for creating unique, one-off designs or short production runs. By 2026, seamless integration between e-commerce platforms and laser etching services will be standard, enabling consumers and businesses to easily upload designs for rapid, automated production. This trend favors smaller, more agile manufacturers and service bureaus equipped with versatile laser systems.

4. Expansion into Advanced Applications and Materials: Beyond traditional signage and decoration, laser etching plexiglass will see growth in sophisticated applications:

* Functional Optics: Creation of diffusers, light guides, and micro-lens arrays for architectural lighting, displays, and automotive interiors.

* Smart Surfaces & Haptics: Etching conductive traces or creating textured surfaces for touch-sensitive interfaces on acrylic panels.

* Biomedical Devices: Precision etching for microfluidic channels, lab-on-a-chip components, and identification marking on surgical tools/housings, driven by stringent traceability requirements (e.g., UDI).

* Sustainable Materials: Increased focus on etching recycled or bio-based acrylics, requiring optimized laser parameters to ensure quality and minimize environmental impact.

5. Emphasis on Sustainability and Efficiency: Environmental concerns will drive trends towards:

* Reduced Energy Consumption: Development of more energy-efficient laser sources (especially newer diode-pumped solid-state lasers) and optimized processes.

* Minimized Waste: Advanced nesting software and AI-driven optimization will maximize material utilization from acrylic sheets.

* Fume Extraction & Filtration: Stricter regulations will necessitate more sophisticated, closed-loop fume extraction and filtration systems to handle acrylic off-gassing (primarily methyl methacrylate), improving workplace safety and environmental compliance. Closed-loop systems recycling filtered air will gain traction.

6. Democratization through Accessible Technology: The continued decline in the cost of reliable desktop and benchtop laser engravers will further democratize access. By 2026, more small businesses, makerspaces, educational institutions, and even hobbyists will possess capable laser etching systems for plexiglass, fostering innovation and expanding the overall market base. Cloud-based design and control platforms will simplify operation for non-experts.

7. Increased Focus on Traceability and Anti-Counterfeiting: Laser etching provides a permanent, tamper-evident marking solution. Demand will grow for:

* Unique Identifiers: Etching serialized barcodes (1D/2D), QR codes, or Data Matrix codes directly onto acrylic components for supply chain tracking (automotive, electronics, aerospace).

* Security Features: Creating intricate, micro-etched patterns or covert markings for brand protection and anti-counterfeiting on high-value products or packaging.

In conclusion, the 2026 laser etching plexiglass market will be characterized by smarter, faster, more precise, and more sustainable processes, fueled by AI integration and fiber laser adoption. Growth will be strongest in high-value, customized, and functional applications, alongside a broadening base of users enabled by accessible technology, all operating under increasing pressure for efficiency and environmental responsibility.

Common Pitfalls When Sourcing Laser Etching Plexiglass: Quality and Intellectual Property Risks

Sourcing laser-etched plexiglass (acrylic) involves several potential pitfalls, particularly concerning material quality and intellectual property (IP) protection. Failing to address these can lead to production delays, increased costs, legal disputes, and compromised end products.

Quality-Related Pitfalls

Inconsistent Material Grade and Clarity

Not all plexiglass is created equal. Suppliers may offer lower-grade acrylic containing impurities, internal stresses, or uneven thickness. Such inconsistencies result in poor laser etching outcomes—including blurred etching, charring, or uneven depths—especially under high-volume or precision requirements. Always specify optical-grade or laser-grade acrylic with tight manufacturing tolerances.

Improper Material Formulation for Laser Processing

Some acrylics are formulated with UV stabilizers, colorants, or coatings that react unpredictably to laser energy. This can cause undesirable effects such as bubbling, discoloration, or incomplete etching. Ensure the material is explicitly suitable for CO₂ laser etching and verify compatibility with your laser parameters.

Lack of Post-Processing Standards

Poor edge finishing, residue from masking films, or inadequate cleaning after etching can degrade the final product’s appearance and performance. Suppliers may overlook post-processing steps critical for high-quality output. Define clear finishing requirements—such as polished edges, debris removal, and protective film application—in your sourcing agreement.

Inadequate Quality Control and Testing

Suppliers without robust QC protocols may deliver inconsistent batches. Absence of sample validation, material certifications (e.g., ASTM D4802), or in-process inspections increases the risk of defects going undetected until final delivery. Require documented QC procedures and approve pre-production samples before full-scale manufacturing.

Intellectual Property (IP) Risks

Unsecured Design Files and Data Transfer

Laser etching requires digital design files (e.g., vector or raster formats), which can be easily copied or misused. Transmitting designs to suppliers without Non-Disclosure Agreements (NDAs) or secure file-sharing protocols exposes your IP to unauthorized replication or distribution.

Lack of IP Ownership Clauses in Contracts

Generic supply agreements often fail to clarify who owns the etched designs, tooling, or custom fixturing developed during production. Without explicit terms, suppliers may claim partial rights or reuse designs for competing clients. Ensure contracts affirm that all IP related to your designs remains your exclusive property.

Unauthorized Reproduction or Overproduction

Unscrupulous suppliers may produce excess units beyond your order and sell them independently, diluting your brand or market exclusivity. Implement strict production oversight, audit rights, and serialization/tracking mechanisms to prevent unauthorized replication.

Third-Party Tooling and Subcontracting Risks

Some suppliers outsource etching to subcontractors without your knowledge, increasing the risk of IP leakage. Verify that any subcontracting is disclosed and bound by the same IP protections. Avoid suppliers who refuse transparency into their production chain.

Mitigation Strategies

To avoid these pitfalls, conduct thorough supplier vetting, demand material certifications, enforce NDAs and IP clauses in contracts, and require sample approvals. Regular audits and secure digital workflows further safeguard both quality and intellectual property throughout the sourcing process.

Logistics & Compliance Guide for Laser Etching Plexiglass

Material Handling and Storage

Plexiglass, or acrylic sheet, requires careful handling to prevent damage before and after laser etching. Always store sheets vertically in a cool, dry environment away from direct sunlight to avoid warping or yellowing. Use protective films on both sides to minimize surface scratches. When transporting, secure sheets in racks or edge protectors to prevent shifting and impact damage. Avoid stacking heavy objects on top of stored acrylic.

Laser Equipment Setup and Safety

Ensure the laser etching machine is specifically configured for acrylic materials. Use appropriate wattage (typically 30–60W CO₂ lasers) and focus settings to achieve clean etching without melting or flaming. Install proper ventilation or a fume extraction system capable of filtering acrylic vapors, which may contain methyl methacrylate—a respiratory irritant. Conduct regular maintenance on lenses and mirrors to maintain etching precision and prevent fire hazards.

Ventilation and Air Quality Compliance

Laser etching of plexiglass releases hazardous fumes. Compliance with OSHA and local air quality regulations is mandatory. Use a certified fume extraction system equipped with HEPA and activated carbon filters to capture particulates and volatile organic compounds (VOCs). Ensure airflow rate meets manufacturer specifications (typically 100–200 CFM). Monitor air quality periodically and maintain logs to demonstrate compliance during inspections.

Fire Prevention and Emergency Response

Acrylic is flammable and can ignite under improper laser settings. Equip the workspace with Class B fire extinguishers and install thermal sensors or laser interlocks that shut down the machine if overheating is detected. Never leave the laser unattended during operation. Establish an emergency response plan, including evacuation procedures and first aid protocols for chemical exposure or burns.

Waste Management and Disposal

Post-etching, collect acrylic dust and debris using a vacuum with HEPA filtration—do not sweep, as this can aerosolize particles. Dispose of waste in sealed containers labeled for non-hazardous plastic waste, unless local regulations classify acrylic dust as hazardous. Check with local environmental agencies for disposal guidelines. Recycle off-cuts and unused sheets whenever possible to support sustainability goals.

Regulatory and Industry Standards

Adhere to relevant standards such as OSHA 29 CFR 1910 (general industry), NFPA 70 (National Electrical Code), and ANSI Z87.1 (eye protection). If producing consumer goods, comply with ASTM D1925 for acrylic material specifications. For export, ensure compliance with REACH and RoHS directives where applicable. Maintain documentation of equipment certifications, safety training, and compliance audits.

Personal Protective Equipment (PPE)

Operators must wear ANSI Z87.1-rated safety goggles to protect against laser radiation and flying debris. Use nitrile gloves to avoid skin contact with acrylic dust or residues. Respiratory protection (NIOSH-approved N95 or higher) should be worn if engineering controls are insufficient. Lab coats or protective clothing minimize skin exposure and contamination.

Training and Documentation

Provide comprehensive training for all personnel on laser operation, chemical hazards, emergency procedures, and compliance requirements. Maintain training records and machine logs, including settings used, maintenance schedules, and incident reports. Conduct periodic safety drills and review compliance protocols annually or when equipment/processes change.

Environmental and Sustainability Considerations

Minimize material waste through efficient nesting software and reuse of scrap pieces for test runs. Opt for low-emission laser systems and energy-efficient equipment. Partner with certified recyclers for end-of-life acrylic materials. Document environmental impact metrics to support corporate sustainability reporting.

Conclusion: Sourcing Laser Etching Plexiglass

Sourcing laser etching plexiglass requires careful consideration of material quality, etching precision, supplier reliability, and cost-effectiveness. Acrylic (plexiglass) is an ideal medium for laser etching due to its clarity, durability, and ability to produce clean, detailed designs. When selecting a supplier, it is essential to verify their capability to handle specific thicknesses, colors, and design complexities while maintaining consistent finish quality.

Partnering with experienced manufacturers or fabricators equipped with high-resolution laser systems ensures professional results suitable for signage, awards, displays, or decorative applications. Additionally, evaluating factors such as lead times, customization options, and post-processing services (e.g., polishing, cutting to size) can enhance overall project efficiency and outcome.

In conclusion, successful sourcing hinges on balancing quality and cost while establishing a reliable supply chain for both prototyping and large-scale production. Conducting sample testing and maintaining clear communication with suppliers will help ensure the final product meets both aesthetic and functional requirements.