The global laser engraving market is experiencing robust growth, driven by rising demand for precision marking and personalization across industries such as automotive, electronics, medical devices, and consumer goods. According to a report by Grand View Research, the global laser marking and engraving market size was valued at USD 1.76 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 8.2% from 2023 to 2030. This growth is fueled by advancements in laser technology, increasing adoption of fiber lasers for industrial applications, and the shift toward automation in manufacturing processes. As demand surges, a network of specialized suppliers has emerged to provide essential laser engraving supplies—from durable marking materials and consumables to precision optics and compatible software solutions. Based on market reach, product innovation, and customer review analytics, the following are the top 10 laser engraving supplies manufacturers shaping the industry’s trajectory.

Top 10 Laser Engraving Supplies Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Universal Laser Systems

Domain Est. 1996

Website: ulsinc.com

Key Highlights: Solve Material Processing Challenges. Overcome your most demanding and complex applications. ULS helps companies evaluate the feasibility of laser technology….

#2 Rowmark

Domain Est. 1997

Website: rowmark.com

Key Highlights: With over 30 years experience Rowmark is the premier sign plastic manufacturer in the world. Manufactured with you in mind. Tough. Tested. Trusted….

#3 Trotec Laser

Domain Est. 2002

Website: troteclaser.com

Key Highlights: Trotec is a leading international laser manufacturer and makes the work of laser users easier, faster and more profitable….

#4 MECCO

Domain Est. 1996

Website: mecco.com

Key Highlights: Our expertise in automated laser engraving and pin marking systems encompasses a comprehensive range of solutions for your industry, materials, and ……

#5 Laser engravers & laser cutters

Domain Est. 2007

Website: gravotech.us

Key Highlights: Our laser tables are designed to engrave, mark and cut on a wide variety of materials (plastic, wood, metal, leather, glass, paper, stone) and shapes….

#6 Full Spectrum Laser

Domain Est. 2010

Website: fslaser.com

Key Highlights: 7–15 day delivery 30-day returnsFull Spectrum Laser is a US based company that designs, manufactures, and sells powerful and affordable laser cutting & laser engraving products….

#7 Laser Cutting, Engraving & Marking Machines

Domain Est. 2010

Website: thunderlaser.com

Key Highlights: Thunder Laser offers high-quality, reliable laser machines to meet the needs of a variety of industries. ThunderLaser has become a well-recognized icon in ……

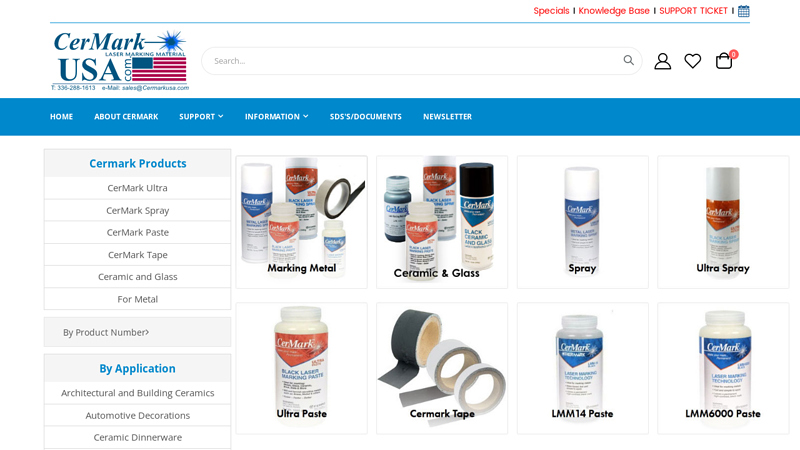

#8 Laser Marking

Domain Est. 2016

Website: cermarkusa.com

Key Highlights: Laser marking is a cost-effective and reliable way to mark parts and components with information such as serial numbers, barcodes, logos, and text….

#9 Gravotech Engraving Materials Superstore

Domain Est. 2017

Website: gravostoreusa.com

Key Highlights: We manufacture laser and rotary engravers, materials, and much more.Gravotech, engraving materials, Gravograph Lasers, Rotary engraving, colored plastics ……

#10 Laser Engraving Supplies

Domain Est. 2020

Website: laserengravingsupplies.com

Key Highlights: LES supplies a large range of laser and rotary laminates in a variety of colours and thicknesses. They are especially made for laser cutting and engraving….

Expert Sourcing Insights for Laser Engraving Supplies

2026 Market Trends for Laser Engraving Supplies: Key Developments and Forecasts

The global laser engraving supplies market is poised for significant transformation by 2026, driven by technological advancements, evolving industrial applications, and shifting consumer demands. This analysis explores the major trends shaping the supply ecosystem—materials, components, software, and accessories—over the next few years.

Rising Demand for Advanced and Specialty Materials

By 2026, the market will see increased demand for high-performance and niche engraving materials. Manufacturers and hobbyists are moving beyond standard wood, acrylic, and leather. Expect growth in supplies like high-temperature polymers (e.g., PEEK, PPS), biodegradable composites, engineered stone surfaces, and smart materials embedded with conductive inks or RFID tags. These specialty materials cater to applications in aerospace, medical device marking, and IoT product personalization, requiring precise laser compatibility and driving innovation in substrate development.

Integration of Smart and IoT-Enabled Components

Laser engraving systems are becoming smarter, and the supplies market is following suit. By 2026, expect a rise in intelligent consumables and components such as self-calibrating lenses, sensors-integrated workholding fixtures, and RFID-tagged material rolls that communicate specifications to the laser machine. These IoT-enabled supplies enhance precision, reduce setup time, minimize errors, and support predictive maintenance—critical for industrial automation and high-volume production environments.

Sustainability and Eco-Friendly Supply Solutions

Environmental regulations and consumer preferences are pushing the market toward greener alternatives. In 2026, suppliers will emphasize recyclable, biodegradable, and low-emission engraving materials. Water-based coatings, non-toxic marking sprays, and energy-efficient laser components (like diode modules with lower power consumption) will gain market share. Manufacturers will also adopt closed-loop systems for fume extraction and waste reduction, aligning with global ESG standards.

Growth in On-Demand and Customization Platforms

The rise of mass customization and direct-to-consumer (DTC) e-commerce is fueling demand for flexible supply chains. By 2026, laser engraving supply providers will increasingly offer on-demand material cutting, pre-treated blanks, and just-in-time delivery models. Online platforms integrating design software with supply ordering will streamline workflows, allowing users to select materials, finishes, and dimensions in real time—boosting efficiency for small businesses and creators.

Software-Driven Supply Optimization

Advanced software will play a central role in supply management. AI-powered material recommendation engines will analyze engraving parameters and suggest optimal settings and compatible supplies. Cloud-based inventory systems will enable automated reordering of consumables like lenses, mirrors, and marking sprays based on usage patterns. This integration reduces downtime and ensures consistent output quality across diverse applications.

Expansion in Emerging Markets and Industrial Applications

Developing economies in Asia-Pacific, Latin America, and Africa will contribute significantly to market growth by 2026. Increased adoption of laser engraving in local manufacturing, crafts, and small-scale industries will drive demand for affordable, durable supplies. Simultaneously, industrial sectors such as automotive (for VIN and part traceability), electronics (PCB marking), and renewable energy (solar panel engraving) will require high-reliability consumables capable of withstanding harsh environments.

Conclusion

By 2026, the laser engraving supplies market will be defined by innovation, intelligence, and sustainability. Suppliers who adapt to trends in smart integration, eco-conscious materials, and digital supply chain solutions will gain competitive advantage. As laser technology becomes more accessible and versatile, the demand for reliable, high-quality, and application-specific supplies will continue to surge across both industrial and consumer segments.

Common Pitfalls When Sourcing Laser Engraving Supplies: Quality and Intellectual Property Risks

Sourcing laser engraving supplies—ranging from consumables like lenses and mirrors to design files and software—can be fraught with challenges, particularly concerning product quality and intellectual property (IP) compliance. Avoiding these pitfalls is crucial for maintaining production efficiency, protecting your business legally, and ensuring customer satisfaction.

Poor Quality Materials and Components

One of the most frequent issues when sourcing laser engraving supplies is receiving substandard materials. Low-quality lenses, mirrors, focus modules, and chiller units may appear cost-effective initially but often lead to inconsistent engraving results, increased machine downtime, and higher long-term costs due to frequent replacements. For example, lenses with inadequate anti-reflective coatings can degrade quickly under laser exposure, reducing beam accuracy and damaging the laser tube.

Additionally, low-grade consumables such as compressed air filters or assist gas nozzles may fail to protect the optical path, leading to contamination and reduced laser performance. Suppliers from unverified sources, especially in international markets, may provide misleading specifications or use inferior materials that do not meet industry standards. Always request samples, verify certifications (e.g., ISO), and read independent reviews before committing to bulk purchases.

Counterfeit or Non-OEM Parts

Many suppliers offer “compatible” or “OEM-style” parts at lower prices, but these can be counterfeit or poorly reverse-engineered. Using such parts may void equipment warranties and cause compatibility issues or hardware damage. For instance, a counterfeit laser tube might not have the correct power output or cooling requirements, leading to overheating or inconsistent engraving depth.

To mitigate this risk, source critical components directly from the original equipment manufacturer (OEM) or authorized distributors. When third-party parts are necessary, ensure the supplier provides verifiable performance data and guarantees compatibility.

Intellectual Property Infringement in Design Files and Software

Another significant risk involves the unauthorized use of copyrighted or trademarked designs and software. Many suppliers offer pre-made design files (e.g., SVG or DXF files) marketed as “free for commercial use,” but these may actually be stolen or improperly licensed. Using such designs in customer projects or product creation can expose your business to legal claims, fines, or reputational damage.

Similarly, pirated or cracked laser control software poses both legal and cybersecurity risks. These unauthorized versions may contain malware, lack technical support, and violate software licensing agreements. Always verify the licensing terms of design files and software tools, and purchase from reputable platforms that guarantee IP compliance, such as licensed marketplaces or official software vendors.

Inadequate Documentation and Support

Suppliers may fail to provide adequate technical documentation, material safety data sheets (MSDS), or user guides, especially for imported goods. This lack of information can result in improper use of consumables or accessories, increasing the risk of accidents or equipment failure. For example, not knowing the correct focal length for a lens or the safe operating temperature of a laser tube can compromise both safety and output quality.

Ensure suppliers offer comprehensive documentation and accessible customer support. A reliable supplier should be able to answer technical questions promptly and provide troubleshooting assistance when needed.

Conclusion

To avoid these common pitfalls, conduct thorough due diligence when selecting suppliers. Prioritize quality assurance, verify IP rights for digital assets, and establish relationships with trustworthy vendors. Investing time upfront in vetting sources can save significant costs and legal complications down the line, ensuring smooth and compliant laser engraving operations.

Logistics & Compliance Guide for Laser Engraving Supplies

Product Classification and HS Codes

Properly classifying laser engraving supplies under the Harmonized System (HS) is essential for international shipping and customs compliance. Common items and their typical HS codes include:

– Laser engraving machines: 8456.11 or 8456.12 (depending on laser type and application)

– CO2 laser tubes: 8543.70 (electronic components)

– Laser lenses and mirrors: 9001.10 or 7015.90 (optical elements)

– Chiller units: 8415.82 (refrigeration equipment)

– Rotary attachments: 8466.30 (machine tool accessories)

Always verify codes with local customs authorities, as classifications may vary by country.

Import and Export Regulations

Laser engraving supplies are subject to international trade regulations due to their technical nature and potential dual-use applications. Key considerations include:

– Export controls: High-powered laser components may be restricted under dual-use regulations (e.g., U.S. EAR, EU Dual-Use Regulation). Check if items require export licenses.

– Laser safety standards: Equipment must comply with safety standards such as IEC 60825 (laser radiation) and FDA 21 CFR 1040.10 (in the U.S.). Non-compliant devices may be detained at borders.

– Country-specific restrictions: Some nations restrict import of certain laser power levels or CNC equipment. Research destination country requirements before shipment.

Packaging and Shipping Requirements

To ensure safe transport and compliance:

– Use anti-static and shock-resistant packaging for sensitive components like laser tubes and control boards.

– Clearly label packages with handling instructions (e.g., “Fragile,” “This Side Up”).

– Include proper documentation: commercial invoice, packing list, and bill of lading/air waybill.

– For lithium batteries (e.g., in portable engravers), follow IATA/IMDG regulations for hazardous materials, including UN38.3 testing and appropriate labeling.

Safety and Certification Compliance

Ensure all products meet relevant safety certifications:

– CE marking: Required for sale in the European Economic Area; indicates compliance with health, safety, and environmental standards.

– FCC certification: Required in the U.S. for electronic devices emitting radio frequencies.

– RoHS and REACH: Compliance with restrictions on hazardous substances in electrical equipment (EU).

Maintain technical documentation and test reports to demonstrate compliance during audits or customs inspections.

Documentation and Recordkeeping

Accurate documentation is critical for smooth logistics and regulatory compliance:

– Retain records of product certifications, test reports, and export licenses for at least 5 years.

– Include detailed product descriptions on invoices (e.g., “CO2 Laser Tube, 40W, for Engraving Machines”).

– Provide user manuals and safety warnings in the destination country’s official language when required.

Environmental and Disposal Regulations

Laser engraving supplies may contain materials subject to environmental regulations:

– Dispose of laser tubes (containing glass and trace gases) per local hazardous waste rules.

– Recycle electronic components (PCBs, drivers) in accordance with WEEE (EU) or state-level e-waste laws (e.g., California).

– Inform customers of proper end-of-life handling procedures in product documentation.

Carrier and Logistics Partner Selection

Choose logistics providers experienced in handling technical and regulated goods:

– Verify carrier compliance with IATA, IMDG, and customs-secure freight standards.

– Use partners familiar with laser equipment shipping requirements and customs brokerage.

– Consider freight forwarders with expertise in high-tech or industrial machinery for complex shipments.

In conclusion, sourcing laser engraving supplies requires careful consideration of quality, compatibility, cost, and supplier reliability. By evaluating materials such as acrylic, wood, leather, and anodized metals, along with essential components like lenses, mirrors, and software, businesses and hobbyists can ensure optimal performance and longevity of their laser engraving systems. Establishing relationships with reputable suppliers, comparing prices, and staying informed about industry advancements contribute to making cost-effective and sustainable procurement decisions. Ultimately, a well-informed sourcing strategy enhances productivity, improves end-product quality, and supports long-term success in laser engraving applications.