The global laser engraving machine market is experiencing robust growth, driven by rising demand for precision customization across industries such as consumer goods, manufacturing, and personalization services. According to Grand View Research, the global laser marking and engraving market size was valued at USD 2.1 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 6.8% from 2023 to 2030. The increasing popularity of personalized drinkware—including stainless steel tumblers—has fueled demand for compact, high-precision laser engraving systems tailored for small businesses and artisans. Mordor Intelligence further highlights that growth in the e-commerce and promotional products sector is accelerating adoption of fiber and CO₂ laser engravers, particularly in North America and Europe. As the tumbler customization niche expands, manufacturers are investing in reliable, user-friendly laser systems that deliver consistent results on curved and metallic surfaces. In this evolving landscape, selecting the right laser engraving machine is critical for quality, efficiency, and scalability—making it essential to evaluate the top manufacturers shaping the industry.

Top 9 Laser Engraving Machine For Tumblers Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Laser Engraving Stainless Steel Tumblers

Domain Est. 1997

Website: epiloglaser.com

Key Highlights: Here we’ll walk you through the steps of customizing a stainless steel tumbler using the Rotary Attachment along with a metal marking compound….

#2 Automated Laser Marking for High

Domain Est. 1997

Website: cmslaser.com

Key Highlights: The Tumbler Laser Engraving Machine employs a CO2 laser to ablate paint on the surface of a tumbler based on preset parameters, creating a ……

#3 VertiGo Vertical Laser Engraver for Tumblers, Cups, Mugs & Bottles

Domain Est. 1999

Website: 1laser.com

Key Highlights: Preorder. $5,899.00 ; Vertical Engraving. Stand tumblers, mugs, cups, bottles, or dog bowls upright for perfect alignment every time with the self-centering ……

#4 Laser engravers & laser cutters

Domain Est. 2004

Website: gravotech.com

Key Highlights: Our laser tables are designed to engrave, mark and cut on a wide variety of materials (plastic, wood, metal, leather, glass, paper, stone) and shapes….

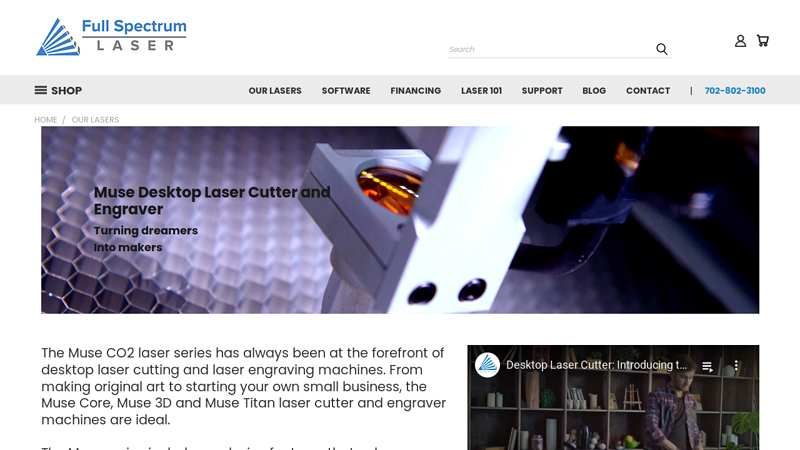

#5 Muse Desktop Laser Cutter and Engraver

Domain Est. 2010

Website: fslaser.com

Key Highlights: Take your laser cutting and engraving creations to the next level with the large 48″x24″ workspace and more powerful laser tube options. Titan comes packed with ……

#6 Laser Engraver for Tumblers

Domain Est. 2010

Website: thunderlaser.com

Key Highlights: Laser engravers are excellent for customizing tumblers with unique designs, logos, and personalization….

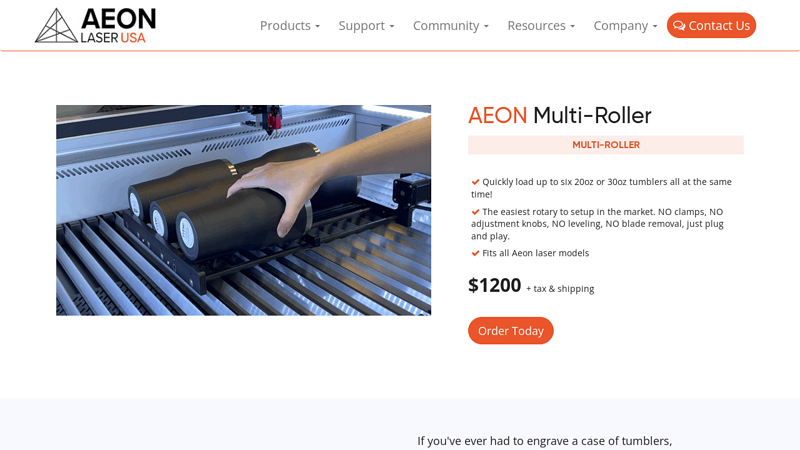

#7 Multi-Roller

Domain Est. 2018

#8 OMTech Laser

Domain Est. 2023

Website: omtech.com

Key Highlights: Turn your creative dreams into reality with our laser engraving and cutting machines, from desktop CO2 lasers to fiber lasers, which are perfect for ……

#9 Top Rotary Laser Engravers For Tumblers

Domain Est. 2024

Website: craftetch.com

Key Highlights: The xTool P2 is the best laser engraver for tumblers, cups, and mugs for several reasons. First, the machine is powerful enough to engrave ……

Expert Sourcing Insights for Laser Engraving Machine For Tumblers

H2: 2026 Market Trends for Laser Engraving Machines for Tumblers

The market for laser engraving machines tailored for tumblers is poised for substantial transformation by 2026, driven by technological advancements, shifting consumer preferences, and the growth of personalized product demand. Here’s an in-depth analysis of key trends shaping this niche sector:

-

Rise in Personalization and Customization Demand

By 2026, the demand for personalized drinkware—especially stainless steel tumblers—will continue to surge, fueled by social media trends, gift-giving culture, and brand marketing strategies. Consumers increasingly seek unique, one-of-a-kind designs, prompting small businesses, entrepreneurs, and crafters to adopt laser engraving machines. This trend is accelerating the penetration of desktop and compact CO2/fiber laser systems in home-based and small commercial workshops. -

Advancements in Entry-Level Laser Technology

Affordable, user-friendly laser engraving machines are becoming more accessible. By 2026, expect significant improvements in precision, speed, and software integration for budget-friendly models (under $1,000). Enhanced compatibility with design platforms like Adobe Illustrator, Canva, and proprietary tumbler-design software will streamline workflows, enabling faster turnaround for custom orders. -

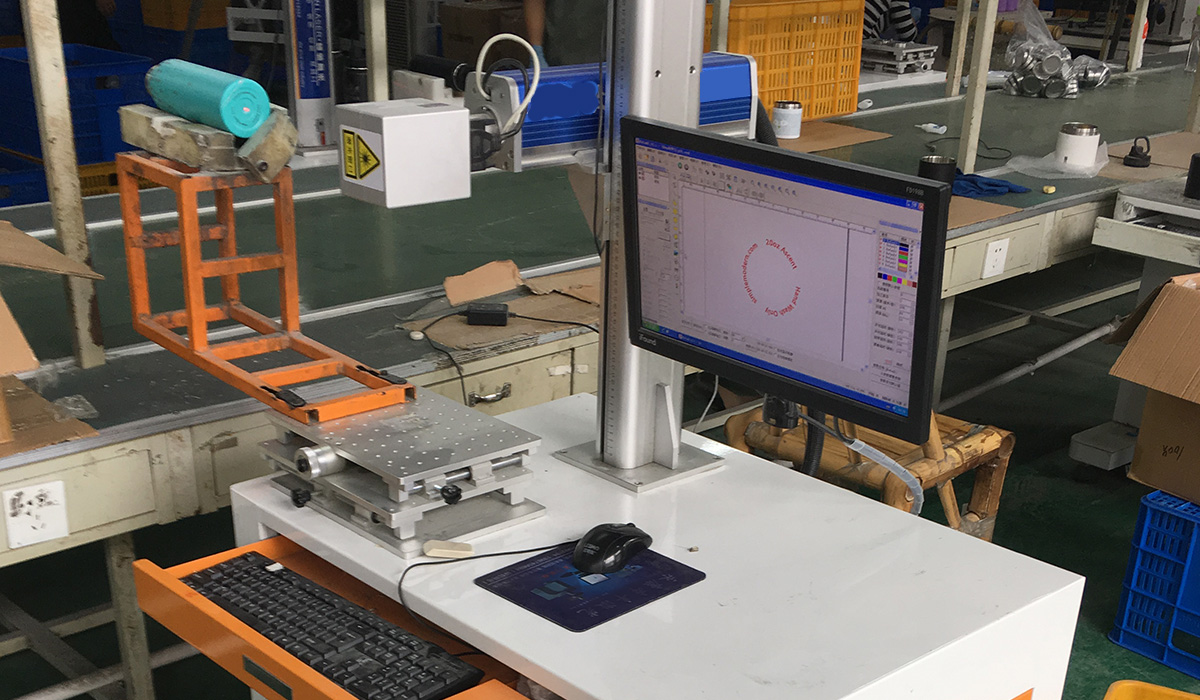

Integration with Rotary Attachments and Automation

Rotary axis attachments, essential for cylindrical engraving on tumblers, will become standard features or bundled accessories. Manufacturers will focus on plug-and-play rotary modules with improved alignment and stability. Additionally, semi-automated loading systems and batch processing capabilities will gain traction, especially among mid-tier businesses aiming to scale production. -

Growth of E-Commerce and On-Demand Manufacturing

The synergy between e-commerce platforms (Etsy, Shopify, Amazon Handmade) and on-demand tumbler engraving will drive market expansion. By 2026, integrated solutions that link online storefronts directly to laser machines—via APIs or cloud-based workflows—will become commonplace, reducing manual input and minimizing errors. -

Shift Toward Fiber Lasers for Metal Tumblers

While CO2 lasers dominate the market for coated stainless steel tumblers, fiber laser adoption will increase due to their superior performance on bare metal surfaces. Fiber lasers offer permanent, high-contrast marks without requiring coating, aligning with eco-conscious consumer preferences for minimal chemical use. This shift will be especially notable in commercial and industrial applications. -

Emphasis on Sustainability and Low Maintenance

Consumers and businesses alike are prioritizing sustainable practices. Laser engraving is inherently eco-friendly compared to vinyl or paint-based customization. By 2026, manufacturers will market machines with energy-efficient components, longer diode life, and recyclable parts, appealing to environmentally conscious buyers. -

Expansion of Educational and DIY Markets

Maker spaces, schools, and hobbyist communities will contribute to market growth. Laser engraving kits bundled with tumbler-specific templates and safety features will target educational institutions and DIY enthusiasts, further democratizing access to customization technology. -

Increased Competition and Price Pressure

With more brands entering the space—especially from China and the U.S.—competition will intensify. This will lead to aggressive pricing, bundled software packages, and value-added services such as free training or design libraries. Differentiation will hinge on customer support, durability, and ease of use. -

Regulatory and Safety Considerations

As laser machines become more widespread, regulatory scrutiny around safety (e.g., FDA compliance for food-contact items, laser emission standards) may tighten. Vendors will need to ensure their machines meet regional safety certifications, particularly for home-use models. -

AI and Smart Engraving Features

By 2026, AI-powered features such as automatic focus, material detection, and design optimization will begin appearing in mid- to high-end tumbler engraving systems. These innovations will reduce skill barriers and enhance consistency, especially for novice users.

In conclusion, the 2026 landscape for laser engraving machines for tumblers will be defined by accessibility, automation, and personalization at scale. Businesses that leverage these trends—through smart technology adoption, agile production, and customer-centric design—will be best positioned to thrive in this dynamic and growing market.

Common Pitfalls When Sourcing Laser Engraving Machines for Tumblers (Quality & IP)

Sourcing a laser engraving machine specifically for tumblers can be rewarding, but it comes with several risks—especially concerning product quality and intellectual property (IP) protection. Being aware of these pitfalls helps ensure you invest wisely and avoid legal or operational setbacks.

Poor Machine Build Quality and Performance

Many low-cost laser engravers, especially those sourced from overseas suppliers, suffer from subpar construction. Common issues include flimsy frames, inconsistent laser power output, and unreliable cooling systems. These flaws lead to inaccurate engravings, frequent breakdowns, and shorter machine lifespan, ultimately increasing downtime and maintenance costs.

Inadequate or Misrepresented Laser Specifications

Suppliers may exaggerate laser power (e.g., advertising a 50W laser when it performs like a 30W) or provide misleading specs about engraving speed and precision. This results in machines that cannot handle high-volume tumbler production or deliver the fine detail required for custom designs, undermining product quality and customer satisfaction.

Lack of IP Protection and Risk of Design Theft

When working with third-party manufacturers or shared production facilities, there’s a significant risk of your custom tumbler designs being copied or sold to competitors. Without strong non-disclosure agreements (NDAs) or formal IP ownership clauses in contracts, your unique artwork and branding may be exploited without recourse.

Use of Counterfeit or Unlicensed Software/Firmware

Some machines come preloaded with pirated control software or modified firmware that lacks updates and technical support. This not only violates copyright laws but also exposes your business to security vulnerabilities, compatibility issues, and potential legal action from software developers.

Insufficient After-Sales Support and Spare Parts Availability

Many budget-friendly suppliers offer little to no technical support, training, or access to replacement parts. If a critical component fails, long shipping times and language barriers can result in extended downtime, directly affecting your production timeline and revenue.

Non-Compliance with Safety and Regulatory Standards

Certain imported machines may not meet local safety regulations (e.g., FDA, CE, or FCC standards), particularly regarding laser classification, ventilation, and electrical safety. Using non-compliant equipment can lead to workplace hazards, failed inspections, or even legal liability.

Hidden Costs from Incompatibility and Setup

Machines may require additional investments in rotary attachments, exhaust systems, or software licenses to function properly with tumblers. Failing to account for these hidden costs during sourcing can strain your budget and delay operations.

Avoiding these pitfalls requires thorough due diligence—verify supplier credentials, request live demonstrations, insist on IP agreements, and prioritize machines with proven reliability and support.

Logistics & Compliance Guide for Laser Engraving Machines for Tumblers

When importing, shipping, or operating a laser engraving machine specifically designed for tumblers, adherence to logistics best practices and regulatory compliance is essential. This guide outlines key considerations to ensure safe, legal, and efficient operations.

Import Regulations and Customs Clearance

Before importing a laser engraving machine, verify compliance with the destination country’s import regulations. Required documentation typically includes a commercial invoice, packing list, bill of lading or air waybill, and a certificate of origin. Many countries classify laser engraving machines under HS Code 8456.11 or 8456.12 (laser cutting or engraving machines). Confirm the correct tariff classification to avoid delays or unexpected duties. Some jurisdictions may require additional permits or pre-shipment inspections for industrial machinery.

Laser Safety Certification (FDA/CDRH in the U.S.)

In the United States, laser products are regulated by the Food and Drug Administration (FDA) under the Center for Devices and Radiological Health (CDRH). All laser engraving machines must comply with 21 CFR 1040.10 and 1040.11. Manufacturers must file a product report and provide a certification stating the device meets performance standards, including proper labeling, safety interlocks, and emission indicators. Importers are responsible for ensuring machines meet these requirements before entry into the U.S. Non-compliant machines may be refused entry or subject to penalties.

CE Marking and EU Compliance

For machines sold in the European Union, CE marking is mandatory. The laser engraver must comply with relevant EU directives, including the Machinery Directive (2006/42/EC), the Electromagnetic Compatibility (EMC) Directive (2014/30/EU), and the Low Voltage Directive (2014/35/EU). Compliance requires a technical file, risk assessment, user manual in local languages, and proper safety labeling. Laser safety under EN 60825-1 must also be addressed, including classification (typically Class 1 or Class 4 with enclosed operation), protective housing, and emergency stop functions.

Electrical and Operational Standards

Ensure the machine meets electrical safety standards such as UL (U.S.), CSA (Canada), or IEC standards (internationally). Verify voltage compatibility (e.g., 110V vs. 220V) and include appropriate power adapters or transformers if necessary. Machines should have overload protection, proper grounding, and insulated wiring to prevent fire hazards. Always follow the manufacturer’s installation instructions to avoid operational risks.

Hazardous Materials and Fumes Management

Laser engraving tumblers—especially those made from coated stainless steel, plastic, or painted materials—can emit hazardous fumes such as metal oxides, volatile organic compounds (VOCs), or particulates. Use machines equipped with an integrated exhaust system or connect to an external fume extractor with HEPA and activated carbon filters. Ensure workplace ventilation complies with OSHA (U.S.) or local occupational health and safety regulations. Provide operators with proper training and personal protective equipment (PPE) when necessary.

Packaging and Shipping Requirements

When shipping a laser engraving machine, use sturdy, original packaging with internal bracing to protect sensitive components like lenses and motors. Secure the laser head and moving parts according to manufacturer guidelines. Clearly label packages with “Fragile,” “This Side Up,” and “Do Not Stack” indicators. For international shipments, include a detailed packing list and ensure compliance with IATA/ICAO regulations if air freight is used. Insure the shipment for its full replacement value.

Import Duties and Taxation

Calculate applicable import duties, value-added tax (VAT), or goods and services tax (GST) based on the machine’s value, origin, and classification. Use free trade agreements (e.g., USMCA, RCEP) where applicable to reduce tariffs. Keep accurate records of all transactions for audit purposes. Consider using a licensed customs broker to streamline clearance and ensure accurate duty assessment.

Environmental and Disposal Compliance

Dispose of consumables such as filters, waste materials, and obsolete machines in accordance with local environmental regulations. Used filters may contain hazardous residues and should be handled as electronic or hazardous waste where required. Follow WEEE (Waste Electrical and Electronic Equipment) directives in the EU or equivalent programs in other regions.

Training and Operational Compliance

Provide comprehensive operator training on machine use, safety protocols, maintenance, and emergency shutdown procedures. Maintain logs of training, maintenance, and safety inspections. Ensure all operators understand the risks associated with laser operation, including fire hazards and exposure to fumes or reflected beams.

Documentation and Record-Keeping

Maintain a complete compliance file including:

– Manufacturer’s declaration of conformity

– FDA or CDRH accessions (U.S.)

– CE technical documentation (EU)

– Safety data sheets (SDS) for materials used

– Maintenance logs and calibration records

– Operator training records

Proper documentation supports regulatory audits and ensures long-term compliance.

Conclusion: Sourcing a Laser Engraving Machine for Tumblers

After evaluating various factors such as precision, speed, durability, and compatibility with different tumbler materials (stainless steel, coated, or colored finishes), sourcing a fiber laser engraving machine emerges as the most effective solution for high-quality, permanent, and professional-grade tumbler customization. Fiber lasers offer excellent performance on metal surfaces, require minimal maintenance, and provide consistent results ideal for both small businesses and high-volume production.

When sourcing the machine, it is essential to consider key factors including laser power (typically 20W–50W), rotary attachment compatibility for cylindrical engraving, software ease-of-use, customer support, and long-term ROI. Opting for a reputable supplier with proven experience in tumbler engraving applications ensures reliability, training, and technical assistance.

Additionally, investing in safety features, fume extraction systems, and proper training enhances workplace safety and operational efficiency. Ultimately, a well-chosen laser engraver not only improves product quality and branding but also enables scalability and differentiation in a competitive market. With the right machine and setup, laser engraving presents a profitable and sustainable business opportunity for personalization and merchandise production.