The global laser engraving machine market is experiencing robust growth, driven by rising demand for precision marking and customization across industries such as automotive, electronics, healthcare, and consumer goods. According to a report by Mordor Intelligence, the laser marking and engraving market was valued at USD 1.56 billion in 2023 and is projected to reach USD 2.21 billion by 2029, growing at a CAGR of 6.05% during the forecast period. Similarly, Grand View Research highlights increasing adoption of fiber laser technology and advancements in automation as key growth accelerators. With expanding applications and intensifying competition, manufacturers are optimizing cost structures to deliver high-performance machines at competitive price points. This growing accessibility has made it essential for buyers to evaluate not only performance but also the total cost of ownership. Below is a data-driven overview of the top 10 laser engraving machine manufacturers known for their cost-effective solutions without compromising on quality and reliability.

Top 10 Laser Engraving Machine Cost Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 MECCO

Domain Est. 1996

Website: mecco.com

Key Highlights: Our expertise in automated laser engraving and pin marking systems encompasses a comprehensive range of solutions for your industry, materials, and ……

#2 Laser cutting and engraving machine

Domain Est. 2002

Website: troteclaser.com

Key Highlights: Fastest laser engraver on the market ✓ Engrave and cut acrylic, wood, leather etc. ✓ Work area of 1016 x 610 mm. Check it out now!…

#3 Laser engravers & laser cutters

Domain Est. 2007

Website: gravotech.us

Key Highlights: Check out Gravotech’s laser engraving and cutting machines. The most efficient and durable engraving solutions on the market. Free trials and quotes!…

#4 Full Spectrum Laser

Domain Est. 2010

Website: fslaser.com

Key Highlights: 7–15 day delivery 30-day returnsFull Spectrum Laser is a US based company that designs, manufactures, and sells powerful and affordable laser cutting & laser engraving products….

#5 Laser Cutting, Engraving & Marking Machines

Domain Est. 2010

Website: thunderlaser.com

Key Highlights: Thunder Bolt Plus. The best home desktop laser engraving machine. Up to 1500mm/s speed and a design so small that just two people can easily lift it….

#6 Ortur Laser Official Store

Domain Est. 2019

#7 LaserPecker US Official

Domain Est. 2019

Website: us.laserpecker.net

Key Highlights: LaserPecker offers innovative laser engraving and cutting machines designed to provide powerful, portable DIY tools. Empowering creativity with cutting-edge ……

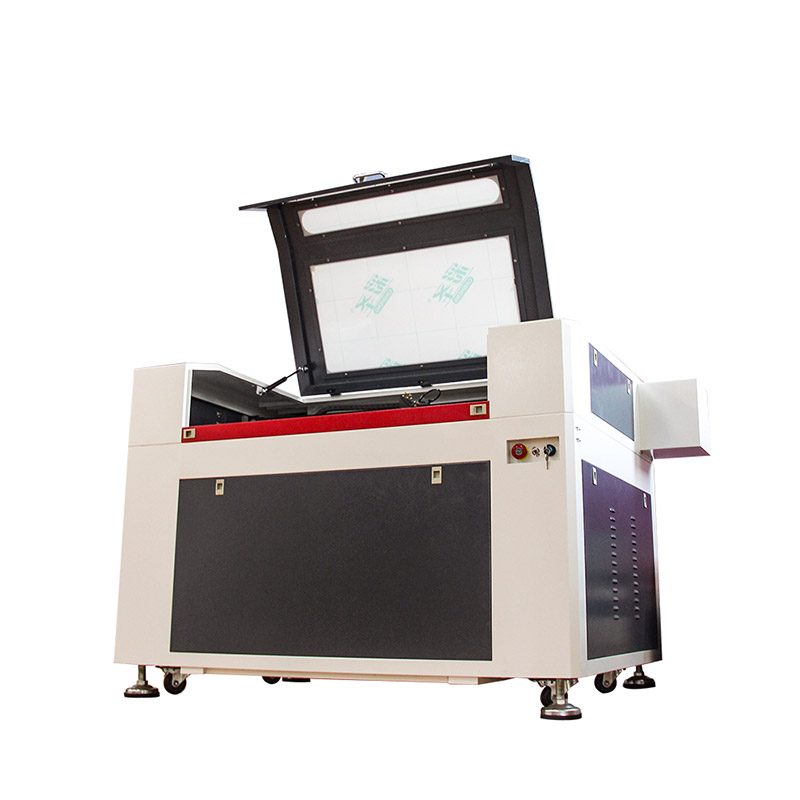

#8 CO2 Laser Cutters and Engravers, Fiber Lasers, and More

Domain Est. 2023

Website: omtech.com

Key Highlights: Free deliveryFrom CO2 laser engravers and cutters to the best fiber laser engravers for metal marking, find your laser machine here at OMTech Laser….

#9 Best Laser Cutting and Engraving Machine, Metal …

Domain Est. 2014

Website: longer3d.com

Key Highlights: Free delivery over $49Longer Nano Pro 12W&Nano 6W Portable Laser Engraver. Price: From $489.99. Longer Nano 6W Portable Laser Engraver. Price: From $489.99. Longer Ray5 20W Laser ….

#10 6 Best Laser Engraving Cutting Machines

Domain Est. 1999

Expert Sourcing Insights for Laser Engraving Machine Cost

2026 Market Trends for Laser Engraving Machine Cost

Technological Advancements Driving Efficiency and Affordability

By 2026, the cost of laser engraving machines is expected to be significantly influenced by rapid technological advancements. Innovations in diode and fiber laser technology are increasing power output and precision while reducing energy consumption and maintenance requirements. These improvements enhance machine longevity and performance, allowing manufacturers to offer higher-value units without proportionate price increases. Additionally, the integration of AI-driven automation and smart calibration systems is streamlining production, lowering labor costs, and enabling economies of scale—factors that contribute to more competitive pricing across entry-level and industrial-grade models.

Rising Demand in Small Businesses and Hobbyist Markets

The growing adoption of laser engraving by small enterprises, artisans, and makerspaces is expanding market competition. As demand increases, especially for compact and desktop models, manufacturers are investing in mass production and modular designs to meet the needs of budget-conscious users. This shift is driving down the average cost of entry-level machines, with high-quality diode lasers expected to remain under $500, while mid-range CO2 systems may see price reductions of 10–15% compared to 2023 levels. Increased competition from Asian manufacturers and direct-to-consumer sales models will further pressure pricing.

Supply Chain Stabilization and Material Cost Trends

Following post-pandemic disruptions, the global supply chain for laser components is expected to stabilize by 2026. Improved availability of critical parts—such as laser tubes, lenses, and control boards—will reduce production bottlenecks and logistics surcharges that previously inflated prices. Additionally, advancements in semiconductor manufacturing may lower the cost of key electronic components. However, fluctuations in rare earth material prices (used in fiber lasers) and geopolitical factors could introduce volatility, potentially offsetting some cost reductions in high-power industrial systems.

Sustainability and Regulatory Influences on Pricing

Environmental regulations, particularly in Europe and North America, are pushing manufacturers toward energy-efficient and recyclable designs. Compliance with these standards may initially increase production costs, but long-term savings from energy-efficient systems could make such models more cost-effective over their lifecycle. Furthermore, incentives for adopting green manufacturing technologies may subsidize the purchase of compliant laser engraving machines, effectively lowering net costs for end users.

Consolidation of Software and Service Bundles

The trend toward integrated software platforms and cloud-based design tools is reshaping the value proposition of laser engraving systems. By 2026, many vendors will likely bundle advanced software, remote diagnostics, and subscription-based support services with hardware purchases. While this may slightly increase upfront costs, it enhances ROI by reducing training time and downtime. Alternatively, budget models may adopt freemium software models, keeping initial costs low while generating revenue through service upsells.

In summary, the 2026 laser engraving machine market will likely see modest overall price reductions, especially in the consumer and small business segments, driven by technological innovation, supply chain improvements, and heightened competition. Industrial systems may maintain stable or slightly elevated prices due to added features and compliance requirements, but total cost of ownership is expected to improve across all segments.

Common Pitfalls When Sourcing Laser Engraving Machine Cost (Quality, IP)

Sourcing a laser engraving machine involves more than just finding the lowest price. Overlooking quality and intellectual property (IP) concerns can lead to significant long-term costs and risks. Here are key pitfalls to avoid:

Underestimating Total Cost of Ownership

Focusing solely on the upfront purchase price can be misleading. Hidden costs such as maintenance, replacement parts, software licenses, training, and downtime significantly impact the total cost of ownership. Low-cost machines often use inferior components that wear out quickly, resulting in higher repair expenses and reduced productivity.

Prioritizing Price Over Build Quality

Choosing a machine based on low cost alone often means compromising on materials, precision engineering, and durability. Poorly constructed machines may have misaligned optics, unstable frames, or inadequate cooling systems, leading to inconsistent engraving results and frequent breakdowns.

Ignoring Laser Source Quality and Origin

The laser source is the heart of the machine. Low-cost systems may use unbranded or underperforming laser tubes or diodes with shorter lifespans and inconsistent power output. This affects engraving speed, depth, and accuracy. Always verify the laser manufacturer and specifications.

Overlooking Software Limitations and Licensing

Some budget machines come with proprietary software that limits design capabilities, file compatibility, or require recurring license fees. These restrictions can hinder productivity and increase long-term costs. Ensure the software supports standard file formats and offers flexibility.

Falling for Misleading Power Ratings

Vendors may exaggerate laser power (e.g., advertising a 100W machine that actually performs like a 60W). This misrepresentation leads to poor performance on dense materials. Always request real-world performance data or third-party testing results.

Neglecting Intellectual Property Risks

Purchasing machines from unverified suppliers—especially low-cost imports—can expose buyers to IP infringement risks. Some manufacturers copy designs, software, or components protected by patents or copyrights. Using such equipment may result in legal liability or shipment seizures.

Lack of Technical Support and Spare Parts Availability

Cheap machines often come from suppliers with limited or no local support. When issues arise, obtaining replacement parts or technical assistance can take weeks, leading to costly downtime. Verify the availability of after-sales service before purchasing.

Skipping On-Site or Video Demonstrations

Failing to test the machine with your specific materials and applications can result in unsuitable performance. Always request a live demonstration or sample engravings to assess quality, speed, and reliability under real conditions.

Not Verifying Compliance and Safety Standards

Low-cost machines may not meet international safety and regulatory standards (e.g., FDA, CE, FCC). Non-compliant units pose safety risks and may be illegal to operate in certain regions, leading to fines or shutdowns.

Assuming All Lasers Are Interchangeable

Different applications require specific laser types (CO2, fiber, diode). Choosing the wrong type based on cost alone can render the machine ineffective for your use case. Ensure the laser technology matches your materials and production needs.

Logistics & Compliance Guide for Laser Engraving Machine Cost

When budgeting for a laser engraving machine, it’s essential to consider not only the purchase price but also the full scope of logistics and compliance-related expenses. These factors can significantly impact the total cost of ownership and operational readiness. Below is a comprehensive guide outlining key cost considerations in these areas.

Transportation and Shipping Costs

Shipping a laser engraving machine involves several cost variables depending on the machine size, weight, origin, and destination. These costs must be factored into the total investment.

- Freight Method: Options include air freight (fast, expensive), sea freight (slower, cost-effective for heavy machinery), or ground shipping (domestic or regional). Sea freight is common for international purchases but may involve additional handling and port fees.

- Crating and Packaging: Industrial-grade crating is often required to protect sensitive components during transit. Custom wooden crates with shock absorption increase shipping costs but reduce damage risk.

- Insurance: Freight insurance is highly recommended to cover potential damage or loss. Premiums are typically a percentage of the machine’s declared value.

- Customs Clearance Fees: For international shipments, customs brokers may charge handling fees for documentation and import processing.

Import Duties and Tariffs

Importing a laser engraving machine may incur government-imposed duties and tariffs, which vary by country and product classification.

- Harmonized System (HS) Code: Laser engraving machines typically fall under HS code 8456.20 (laser cutting machines). Accurate classification is essential to determine applicable duty rates.

- Tariff Rates: Duty rates range from 0% to 15% or more depending on the importing country and trade agreements. For example, under US-Mexico-Canada Agreement (USMCA), certain machinery may qualify for reduced or zero tariffs.

- Value-Added Tax (VAT) or Goods and Services Tax (GST): Most countries apply VAT or GST on imported machinery, often calculated on the sum of the machine cost, shipping, and insurance (CIF value). Rates typically range from 5% to 25%.

Regulatory Compliance and Certification Costs

Laser engraving machines are subject to safety, emissions, and electromagnetic compatibility regulations. Non-compliant machines may be denied entry or require costly retrofitting.

- Laser Safety Standards (e.g., FDA/CDRH in the U.S.): In the United States, the FDA’s Center for Devices and Radiological Health (CDRH) requires compliance with 21 CFR 1040.10/1040.11. Manufacturers must provide a certification report and product classification (e.g., Class 1 enclosure). Importers may need to file a Laser Notice or product report, incurring administrative time and potential third-party testing costs.

- CE Marking (Europe): Machines sold in the EU must meet Machinery Directive (2006/42/EC), Electromagnetic Compatibility (EMC) Directive, and Laser Product Safety standards (EN 60825). Certification may require testing by a Notified Body, costing $1,000–$5,000 depending on complexity.

- Other Regional Certifications: Countries like Australia (RCM), Canada (ICES-001), and China (CCC) have their own compliance requirements, each potentially adding fees for testing, labeling, and documentation.

Installation and Site Preparation

Proper setup is critical for safe and efficient operation, often involving facility modifications.

- Power Requirements: High-powered lasers may require 220V or 3-phase power. Upgrading electrical circuits or installing dedicated lines can cost $500–$3,000.

- Ventilation and Fume Extraction: Laser engraving produces hazardous fumes. Installing a compliant exhaust system with filtration (e.g., HEPA or carbon filters) may cost $1,000–$5,000.

- Workspace Zoning: Compliance with OSHA or local regulations may require designated laser operation zones with safety signage, interlocks, and protective barriers. Installation of safety enclosures or curtains adds to setup costs.

Ongoing Compliance and Maintenance

Post-purchase compliance ensures continued legal operation and machine longevity.

- Regular Safety Audits: Periodic inspections to verify laser safety, interlock functionality, and ventilation performance may require internal labor or external consultants.

- Calibration and Maintenance: Scheduled maintenance ensures compliance with performance standards and prevents downtime. Service contracts typically range from $500–$2,000 annually.

- Training and Documentation: OSHA and other regulators require documented operator training on laser safety. Developing or purchasing training materials and sessions may cost $200–$1,000.

Summary of Hidden Costs

To avoid budget overruns, consider the following potential add-ons:

| Cost Category | Estimated Range |

|——————————-|————————|

| International Shipping | $500 – $5,000+ |

| Import Duties & VAT/GST | 5% – 25% of CIF value |

| Compliance Certification | $1,000 – $5,000 |

| Site Preparation | $1,000 – $8,000 |

| Annual Maintenance & Training | $500 – $3,000 |

By accounting for these logistics and compliance factors, businesses can make informed purchasing decisions and ensure a smooth, cost-effective integration of laser engraving technology into their operations.

Conclusion on Sourcing a Laser Engraving Machine: Cost Considerations

When sourcing a laser engraving machine, cost is a critical factor that should be evaluated not only in terms of the initial purchase price but also through the lens of long-term value and operational efficiency. While entry-level machines offer an affordable entry point—ideal for small businesses or hobbyists—they may lack the power, precision, and durability required for high-volume or industrial applications. Mid-range and high-end models, though more expensive upfront, often provide superior build quality, advanced features, faster processing speeds, and better software integration, leading to improved productivity and lower total cost of ownership over time.

Additional costs such as maintenance, replacement parts, training, software licenses, ventilation systems, and consumables must also be factored into the budget. Sourcing from reputable suppliers—whether domestic or international—affects not just pricing but also support, warranty, and lead times. While imported machines may offer lower sticker prices, potential hidden costs related to shipping, import duties, and limited technical support can offset the savings.

Ultimately, the most cost-effective choice is the machine that best aligns with your specific production needs, material requirements, and scalability goals. Conducting a thorough cost-benefit analysis, obtaining multiple quotes, and considering the total lifecycle cost will ensure a smart and sustainable investment in laser engraving technology.