The global laser engraving machine market is experiencing robust growth, driven by rising demand for precision personalization and industrial marking solutions. According to Grand View Research, the global laser marking and engraving market size was valued at USD 1.7 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 6.8% from 2023 to 2030. This growth is fueled by increasing adoption across industries such as electronics, healthcare, automotive, and consumer goods, where permanent, high-accuracy marking is essential. With the proliferation of customized décor and personalized gifts, laser engraving on crystal has emerged as a niche yet rapidly expanding segment. As demand for high-quality, reliable crystal engraving machines rises, a select group of manufacturers have distinguished themselves through innovation, precision engineering, and consistent performance. Based on market presence, technological capability, and customer reviews, here are the top 10 laser engraving crystal machine manufacturers shaping the industry.

Top 10 Laser Engraving Crystal Machine Manufacturers (2026 Audit Report)

(Ranked by Factory Capability & Trust Score)

#1 International Laser Marking Machine Manufacturer & Supplier …

Website: hunstlaser.com

Key Highlights: Hunst Laser is a laser marking machine manufacturer which represents high quality laser technology and its application expertise….

#2 Laser Marking Machines for Glass

Website: telesis.com

Key Highlights: You can produce the best glass marking results with a laser marking machine from Telesis Technologies, Inc. Get a quote on a glass laser marker today!…

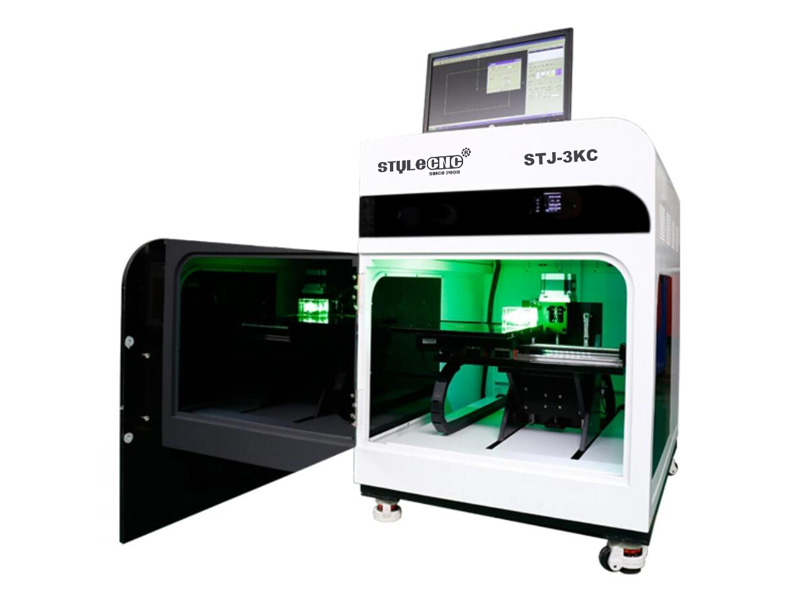

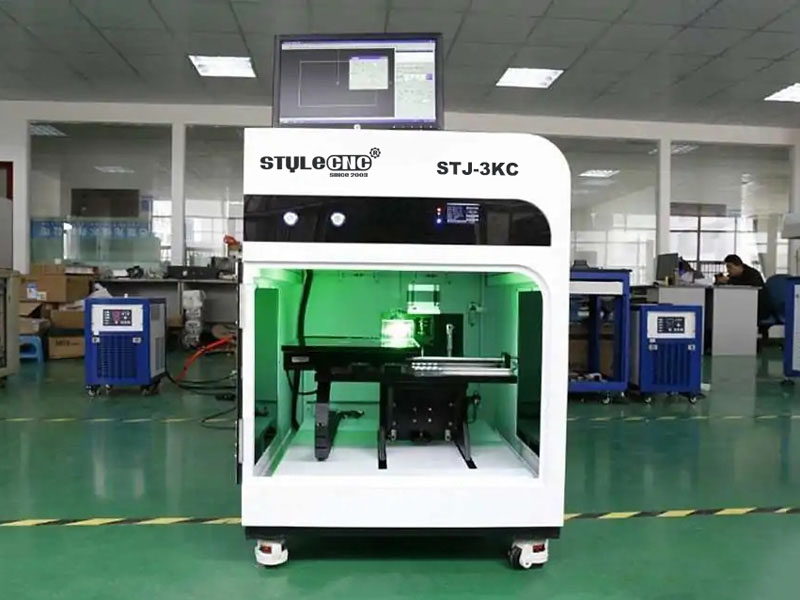

#3 3D crystal laser engraving machine manufacturer

Website: vitro.de

Key Highlights: Our laser systems are compatible for a wide range of applications. Whether small production, individual production, small and large series production….

#4 Laser Equipment Supplier

Website: radianlaser.com

Key Highlights: Radian Laser Systems is a laser equipment supplier specializing in high-speed, customizable laser machinery, including fiber, CO2, and galvo lasers….

#5 Laser engravers & laser cutters

Website: gravotech.us

Key Highlights: Check out Gravotech’s laser engraving and cutting machines. The most efficient and durable engraving solutions on the market. Free trials and quotes!…

#6 Laser Cutting, Engraving & Marking Machines

Website: thunderlaser.com

Key Highlights: Laser Engraver. The best RF laser engraving machine. Integrated camera with a speed of up to 2000 mm/s. Laser engraving photo to precise detail is so easy….

#7 SA Laser

Website: salasers.com

Key Highlights: Explore opportunities in laser engraving with SA Laser’s top-quality fiber & CO2 laser engraving machines, Spark Laser Training, engraving services, ……

#8 Full Spectrum Laser

#9 OneLaser – Performance

Website: 1laser.com

Key Highlights: Marked & Made is a full-service retail gift shop specializing in laser engraving, UV printing, 3D printing, and DTF design. They use OneLaser machines to ……

#10 Laser Engraving and Engraver Machines

Website: epiloglaser.com

Key Highlights: Learn how a laser engraver machine can provide fast, precise, repeatable laser engraving on wood, acrylic, fabric, glass, stone, paper, and more….

Expert Sourcing Insights for Laser Engraving Crystal Machine

H2: Market Trends for Laser Engraving Crystal Machines in 2026

By 2026, the global market for laser engraving crystal machines is expected to experience significant transformation driven by technological advancements, rising consumer demand for personalized products, and expanding industrial applications. Key trends shaping the market include:

-

Increased Demand for Personalization and Customization

The growing consumer preference for personalized gifts, awards, and luxury décor is a major driver. Laser engraving crystal machines enable high-precision, intricate designs on crystal surfaces, making them ideal for custom wedding gifts, corporate awards, and commemorative items. E-commerce platforms are amplifying this trend by offering on-demand customization services, further boosting demand for efficient and scalable laser engraving solutions. -

Advancements in Laser Technology

By 2026, innovations in fiber and CO2 laser systems—such as improved beam quality, faster processing speeds, and enhanced automation—are expected to dominate the market. These advancements allow for finer detail, reduced processing time, and compatibility with a broader range of crystal types, including optical-grade and lead-free crystals. Integration with AI-powered design software will also streamline the engraving process, reducing operator error and increasing throughput. -

Expansion into New Applications

Beyond traditional giftware and awards, laser engraving crystal machines are finding new uses in sectors like medical devices (e.g., engraved surgical tools), luxury packaging, and high-end consumer electronics (e.g., engraved smartphone components or smartwatch faces). This diversification is opening new revenue streams and encouraging manufacturers to develop specialized machines tailored to industry-specific requirements. -

Growth in Asia-Pacific and Emerging Markets

The Asia-Pacific region, particularly China, India, and Southeast Asia, is projected to see rapid market expansion due to rising disposable incomes, a growing middle class, and increasing demand for luxury and customized goods. Local production of laser engraving machines, coupled with government support for advanced manufacturing, will further accelerate market penetration in these regions. -

Sustainability and Energy Efficiency

Environmental concerns are pushing manufacturers to develop energy-efficient, low-waste laser systems. Machines with reduced power consumption, recyclable components, and non-toxic processing methods are gaining favor, especially in eco-conscious markets like Europe and North America. Regulatory pressures and green certifications are likely to influence purchasing decisions among commercial buyers. -

Integration with Smart Manufacturing and Industry 4.0

By 2026, laser engraving crystal machines are increasingly being integrated into smart factories through IoT connectivity, real-time monitoring, and cloud-based design platforms. This enables remote operation, predictive maintenance, and seamless batch customization—critical for scalable, on-demand manufacturing models. -

Competitive Landscape and Price Optimization

As more players enter the market—especially from China and South Korea—competition is intensifying, leading to price reductions and greater accessibility for small businesses and artisans. At the same time, premium brands are differentiating themselves through superior precision, software integration, and after-sales support.

In conclusion, the 2026 market for laser engraving crystal machines is poised for robust growth, fueled by innovation, personalization trends, and industrial diversification. Companies that invest in R&D, embrace digital integration, and target emerging applications will be best positioned to capitalize on these evolving opportunities.

Common Pitfalls When Sourcing a Laser Engraving Crystal Machine

Sourcing a laser engraving crystal machine involves several potential pitfalls, particularly concerning quality and intellectual property (IP). Being aware of these risks can help avoid costly mistakes and ensure a reliable, legally compliant investment.

Quality-Related Pitfalls

Inadequate Laser Precision and Stability

Low-quality machines often suffer from inconsistent beam focus and power control, leading to blurry, uneven, or incomplete engravings. This can result in high defect rates and wasted materials, especially with delicate crystal pieces.

Poor Build Quality and Materials

Units constructed with substandard components—such as flimsy frames, low-grade optics, or unreliable motion systems—tend to degrade quickly. This reduces machine lifespan and increases downtime for maintenance or repairs.

Lack of Calibration and Consistency

Some budget machines are not factory-calibrated or fail to maintain alignment over time. Without consistent performance across multiple engravings, batch production becomes unreliable, affecting output quality and customer satisfaction.

Insufficient Software Integration and Support

Cheap machines often come with proprietary software that is buggy, outdated, or incompatible with common design formats. Limited software updates or poor customer support can severely hinder workflow efficiency.

Intellectual Property (IP) Pitfalls

Use of Counterfeit or Unauthorized Components

Some suppliers use laser diodes, drivers, or control boards that infringe on patented technologies. Purchasing such machines may expose the buyer to legal risks, especially in markets with strict IP enforcement.

Violation of Software Licensing

OEM software bundled with low-cost machines may be pirated or lack proper licensing. Using such software can lead to legal liability, security vulnerabilities, or sudden operational disruptions if discovered.

Design and Technology Copying

Many affordable machines on the market are direct clones of established models from reputable manufacturers. Sourcing these clones not only supports IP theft but may also mean you’re investing in reverse-engineered technology that lacks innovation, reliability, or technical support.

Limited Warranty and Support Due to IP Issues

Suppliers of infringing machines often avoid providing comprehensive warranties or support to minimize legal exposure. This leaves buyers without recourse when technical issues arise.

By carefully vetting suppliers, verifying component authenticity, and ensuring software compliance, buyers can mitigate these risks and invest in a high-quality, legally sound laser engraving solution.

Logistics & Compliance Guide for Laser Engraving Crystal Machine

Product Classification and HS Code

Identify the correct Harmonized System (HS) code for your laser engraving crystal machine to ensure accurate customs clearance. Typical classifications fall under 8479.89 (Machines of a kind used in industrial processes, not elsewhere specified) or 8515.80 (Other electrical machines for soldering, welding, or cutting). Confirm with local authorities, as classifications may vary by country and machine specifications.

Export Controls and Licensing

Laser engraving machines may be subject to export control regulations due to their laser power and dual-use potential. Verify compliance with:

– International Traffic in Arms Regulations (ITAR) – unlikely to apply unless the machine is military-grade.

– Export Administration Regulations (EAR) – check if the machine falls under ECCN 6A003.b.4 (lasers capable of engraving with specific power/wavelength thresholds).

Obtain necessary export licenses from your national authority (e.g., BIS in the U.S.) before shipping.

Laser Safety Certification

Ensure the machine meets international laser safety standards:

– IEC 60825-1: Safety of laser products – Equipment classification and requirements.

– Obtain FDA/CDRH certification if exporting to the United States (21 CFR 1040.10 and 1040.11).

– Include required safety labels (Class 1 or Class 4, depending on enclosure), interlocks, and user manuals with safety warnings.

Electrical and EMC Compliance

Confirm adherence to regional electrical safety and electromagnetic compatibility standards:

– CE Marking for EU: Comply with Low Voltage Directive (LVD) 2014/35/EU and EMC Directive 2014/30/EU.

– UKCA Marking for the United Kingdom.

– FCC Part 15 for electromagnetic emissions in the United States.

– Include technical documentation and Declaration of Conformity.

Packaging and Shipping Requirements

Proper packaging is essential to prevent damage during transit:

– Use robust, shock-absorbent materials with internal bracing.

– Secure all moving parts and optics with transit locks or protective covers.

– Label packages with “Fragile,” “This Side Up,” and handling instructions.

– Include moisture-absorbing desiccants if shipping to humid regions.

Import Duties and Taxes

Research destination country regulations:

– Determine applicable import duties, VAT, or GST based on the product’s HS code.

– Prepare a detailed commercial invoice, packing list, and bill of lading/airway bill.

– Consider using an Incoterm (e.g., FOB, DDP) to clarify responsibility for duties and logistics.

Documentation for Customs Clearance

Provide complete and accurate documentation:

– Commercial Invoice (with value, description, and HS code)

– Packing List

– Certificate of Origin

– Bill of Lading or Air Waybill

– Export License (if required)

– Safety and Compliance Certificates (CE, FDA, etc.)

Environmental and RoHS Compliance

Ensure the machine complies with environmental directives:

– EU RoHS Directive 2011/65/EU: Restricts hazardous substances (e.g., lead, mercury) in electrical equipment.

– Provide a RoHS compliance statement and material declarations if requested.

After-Sales Support and Warranty

- Include multilingual user manuals and safety instructions.

- Clarify warranty terms and service availability in the destination country.

- Provide contact details for technical support and spare parts.

Special Handling for Optical Components

- Protect lenses and mirrors from dust, scratches, and moisture.

- Use anti-static packaging for sensitive electronics.

- Avoid extreme temperatures during storage and transport.

Country-Specific Requirements

Verify any additional local requirements:

– China (CCC Mark): May require certification depending on power and use.

– Russia (EAC TR CU): Mandatory for equipment placed on the Eurasian market.

– Australia (RCM Mark): For electromagnetic compliance.

Consult with customs brokers or freight forwarders familiar with machinery shipments to ensure full compliance and smooth delivery.

Conclusion: Sourcing a Laser Engraving Crystal Machine

After thorough research and evaluation, sourcing a laser engraving crystal machine requires careful consideration of several key factors including precision, engraving quality, software compatibility, machine durability, and after-sales support. Choosing the right machine involves balancing initial investment with long-term operational efficiency and output quality.

For businesses focused on personalized gifts, awards, or high-detail decorative items, a diode or CO2 laser engraver specifically designed for crystal and glass materials is highly recommended. Models with adjustable power settings and high-resolution capabilities ensure clean, intricate engravings without cracking or chipping the material.

Additionally, it is essential to source from reputable suppliers who offer technical support, training, and warranty coverage to minimize downtime and ensure smooth integration into existing workflows. While lower-cost options may be tempting, investing in a reliable, well-reviewed machine ultimately leads to higher customer satisfaction, reduced maintenance costs, and improved scalability.

In conclusion, a strategic approach to sourcing a laser engraving crystal machine—prioritizing quality, reliability, and support—will empower businesses to deliver premium products and maintain a competitive edge in the growing custom engraving market.