The global laser engraving market is experiencing robust growth, driven by increasing demand for personalized and precision-marked products across industries such as gifts, electronics, medical devices, and industrial manufacturing. According to Mordor Intelligence, the laser engraving market was valued at USD 1.56 billion in 2023 and is projected to grow at a CAGR of over 7.2% from 2024 to 2029, fueled by advancements in laser technology and rising consumer preference for customized décor and corporate awards. A significant segment of this growth is attributed to laser-engraved crystal products, widely used in luxury gifting, commemorative awards, and high-end branding solutions. As demand surges, manufacturers are investing in high-precision CO2 and fiber laser systems to deliver intricate 3D engravings with exceptional clarity. This growing market momentum has intensified competition among crystal producers, pushing innovation in material quality, automation, and customization capabilities. In this evolving landscape, identifying the top-performing manufacturers becomes essential for businesses seeking reliable, scalable, and technologically advanced sourcing partners. The following list highlights the top 10 laser engrave crystal manufacturers leading the industry through technical expertise, production scale, and global reach.

Top 10 Laser Engrave Crystal Manufacturers (2026 Audit Report)

(Ranked by Factory Capability & Trust Score)

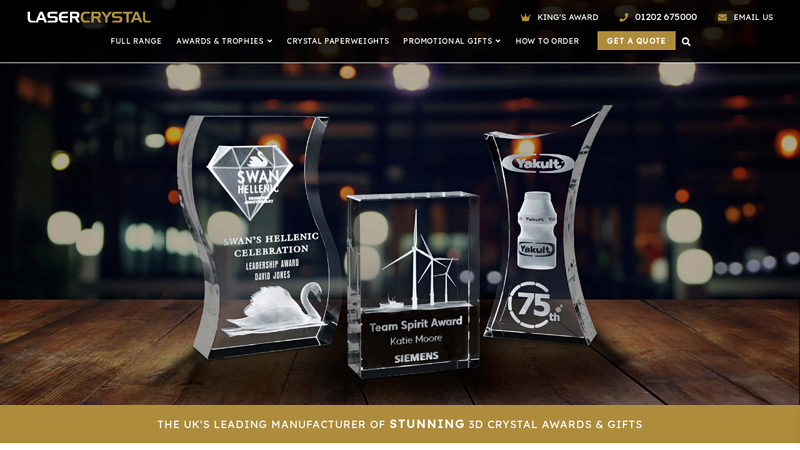

#1 Laser Crystal

Website: lasercrystal.co.uk

Key Highlights: Here at Laser Crystal, we are the UK’s leading manufacturer of high-quality bespoke 3D laser engraved glass awards, trophies and paperweights….

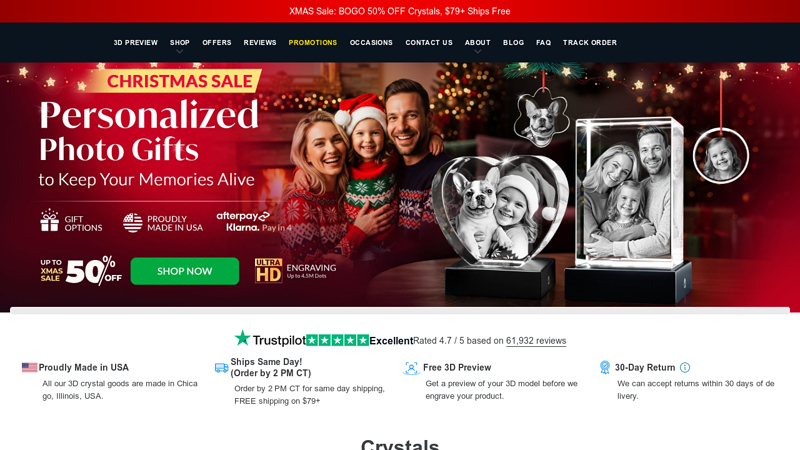

#2 3D Crystals by ArtPix 3D®

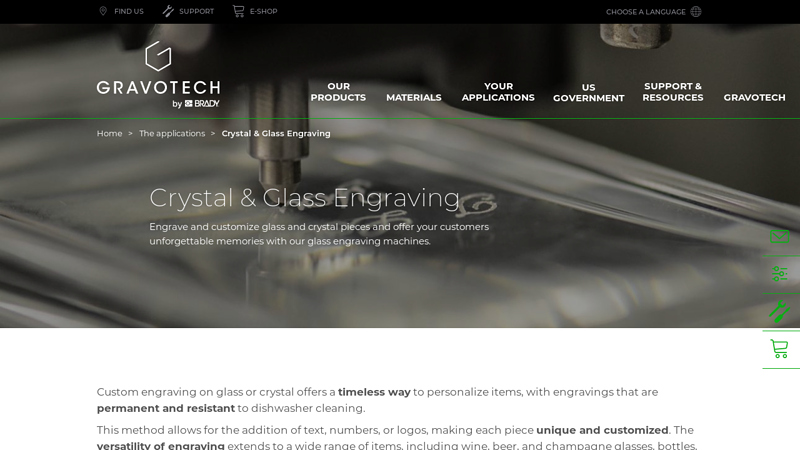

#3 Crystal & Glass Engraving

Website: gravotech.us

Key Highlights: Engrave and customize glass and crystal pieces and offer your customers unforgettable memories with our glass engraving machines….

#4 3D Crystal

Website: 3d-crystal.com

Key Highlights: 3D laser engraving and marking on all materials by Grüner Laser Products GmbH. 3D Crystal: we guarantee you best reliability and unbeatable Quality….

#5 Personalized 3D Crystal Photos by Beyond Memories®

Website: beyond-memories.com

Key Highlights: Your source for personalized 3D crystal engraving. Beyond Memories® uses the newest innovation of capturing memories in crystals, the perfect gift….

#6 3D Subsurface Laser Engraving

Website: crystal-d.com

Key Highlights: Our 3D subsurface engraving process comes in, allowing us to recreate any image inside a crystal award or gift in two or three dimensions….

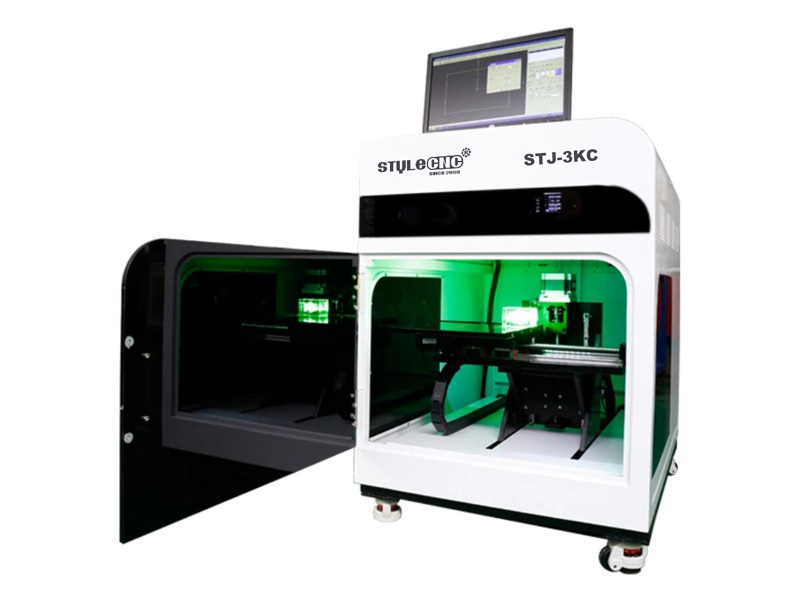

#7 Laser Equipment Supplier

Website: radianlaser.com

Key Highlights: Radian Laser Systems is a laser equipment supplier specializing in high-speed, customizable laser machinery, including fiber, CO2, and galvo lasers….

#8 Arribas Brothers

Website: arribas.com

Key Highlights: Carefully crafted glass & crystal figurines, sculptures & jewelry inspired by your favorite Disney characters & stories….

#9 Glass and crystal laser engraving

Website: barchlaser.com

Key Highlights: Our UV laser it can engrave over different kind of crystals or glass. Armor glass, optical glass, tempered glass, and kitchen glass….

#10 CrystalProteins

Website: crystalproteins.com

Key Highlights: 3D models lasered into glass. CrystalProteins creates accurate 3D etchings inside blocks of glass, giving real-world insight into complex structures….

Expert Sourcing Insights for Laser Engrave Crystal

H2: 2026 Market Trends for Laser Engraved Crystal

The global market for laser engraved crystal is poised for significant transformation by 2026, driven by evolving consumer preferences, technological advancements, and expanding application sectors. This analysis explores key market trends expected to shape the industry in the coming years.

1. Rising Demand in Personalization and Gifting

The demand for personalized products continues to surge, with laser engraved crystal emerging as a premium choice for commemorative gifts, corporate awards, and luxury items. By 2026, the gifting segment is expected to dominate due to increasing consumer interest in unique, customized experiences. E-commerce platforms equipped with AI-driven design tools will empower users to create bespoke engravings, fueling market growth.

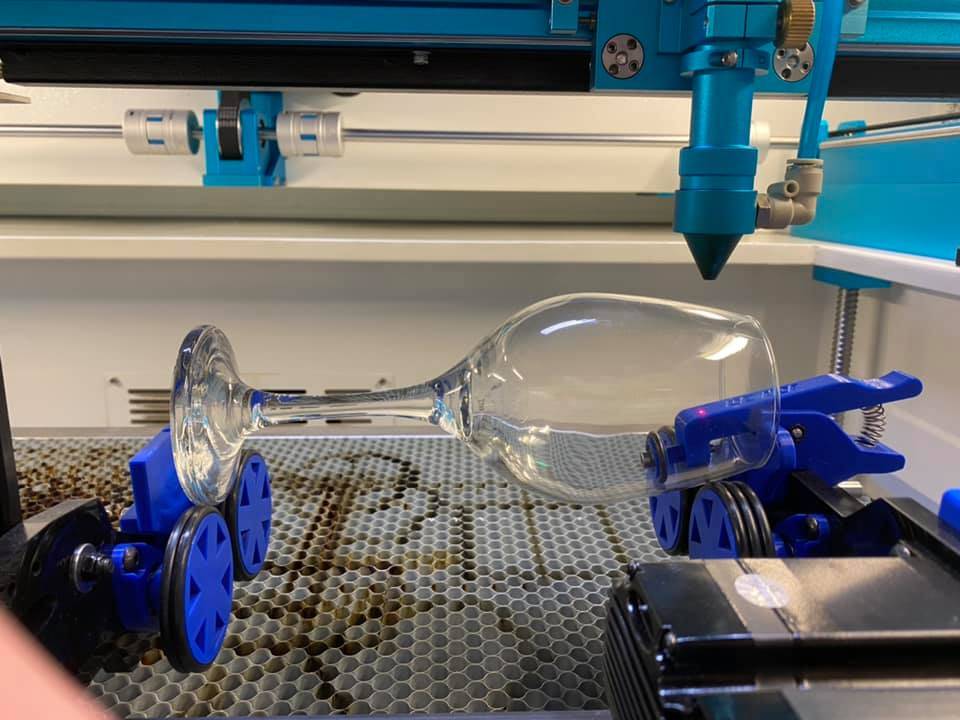

2. Advancements in Laser Technology

Precision and efficiency in laser engraving are improving rapidly. By 2026, ultra-fast femtosecond lasers and 3D internal engraving techniques will enable intricate, multi-layered designs within crystal blocks, enhancing artistic and commercial value. These advancements will reduce production time and waste, making high-quality engraving more accessible to small and medium enterprises.

3. Expansion into New Industries

Beyond traditional uses in awards and souvenirs, laser engraved crystal is gaining traction in high-tech and medical fields. Applications include engraved optical components, data storage prototypes, and biotech lab equipment. The integration of nanoscale engraving for functional purposes will open new revenue streams and diversify market applications.

4. Sustainability and Ethical Sourcing

Consumers and corporations are increasingly prioritizing sustainability. By 2026, demand for ethically sourced, recycled, or lab-grown crystal materials will rise. Manufacturers adopting eco-friendly production processes and transparent supply chains will gain competitive advantage, particularly in Europe and North America.

5. Growth in Emerging Markets

Asia-Pacific and Latin America are expected to witness accelerated growth due to rising disposable incomes and expanding middle classes. Local manufacturers are investing in laser engraving technology to meet regional demand for luxury and corporate gifts, reducing reliance on Western imports.

6. Integration with Digital Platforms and NFTs

The convergence of physical and digital assets will drive innovation. By 2026, laser engraved crystals may serve as tangible representations of NFTs (non-fungible tokens), combining physical art with blockchain authentication. This hybrid model will appeal to collectors and tech-savvy consumers, creating a niche luxury segment.

Conclusion

The laser engraved crystal market in 2026 will be shaped by personalization, technological innovation, sustainability, and digital integration. Companies that embrace these trends—investing in advanced machinery, eco-conscious materials, and digital engagement—will be well-positioned to lead the market in the next decade.

Common Pitfalls When Sourcing Laser Engraved Crystal (Quality, IP)

Sourcing laser engraved crystal products can enhance branding, gifting, or awards programs—but it comes with significant risks if not managed carefully. Two major areas where buyers often stumble are product quality and intellectual property (IP) concerns. Avoiding these pitfalls ensures a successful, legally compliant procurement.

Poor Material and Engraving Quality

One of the most frequent issues in sourcing laser engraved crystal is receiving products that fall short in clarity, durability, or precision. Low-quality crystal may appear cloudy, contain bubbles or inclusions, or have uneven edges, undermining the premium perception of the finished item. Inconsistent laser engraving—such as faint, blurry, or misaligned designs—can result from outdated equipment or unskilled operators. Additionally, some suppliers may use glass instead of genuine optical crystal, which lacks the refractive brilliance and heft associated with high-end products. Without strict quality control and clear specifications, buyers risk receiving subpar items that damage brand reputation.

Intellectual Property Infringement Risks

Sourcing laser engraved crystal products also poses significant IP risks, especially when designs include logos, artwork, or copyrighted elements. Unintentional infringement can occur if suppliers use unauthorized templates or reproduce protected designs without proper licensing. Some overseas manufacturers may not adhere to the same IP protections as domestic producers, increasing the chance of counterfeit or pirated goods. Furthermore, if a supplier retains a copy of your design files, they may reproduce and resell them to competitors. To mitigate these risks, ensure all designs are legally cleared for use, work with reputable suppliers who sign IP agreements, and include clauses in contracts that assign ownership of custom designs to your company.

Logistics & Compliance Guide for Laser Engraved Crystal

Product Classification & HS Codes

Laser engraved crystal items are typically classified under specific Harmonized System (HS) codes based on composition, function, and decoration. Common classifications include:

– 7013.37: Glassware for table or kitchen use, of lead crystal, decorated.

– 7013.49: Other glassware for table or kitchen use, decorated.

– 9614.00: Smoking pipes and pipe bowls, of glass (if applicable).

Verify the exact classification with your customs broker, as engravings may affect categorization. Always provide detailed product descriptions, including material (e.g., K9 optical crystal, lead-free crystal), dimensions, and intended use.

Import/Export Regulations

Compliance with international trade regulations is essential:

– Export Controls: Ensure no dual-use technology (e.g., precision laser systems) is involved. Most laser engraved crystal items are civilian goods and not subject to ITAR or EAR restrictions.

– Import Duties & Taxes: Duties vary by destination country. For example:

– USA: Duties range from 4.5% to 10% depending on classification.

– EU: Typically 4–6% for decorative crystal.

– UK: Post-Brexit, check UK Global Tariff rates; usually 4.7%.

Utilize trade agreements (e.g., USMCA, RCEP) where applicable to reduce tariffs.

Packaging & Shipping Requirements

Proper packaging safeguards fragile items during transit:

– Use double-walled corrugated boxes with internal dividers or foam inserts.

– Individually wrap each crystal in bubble wrap or microfiber cloth.

– Label boxes as “Fragile,” “This Side Up,” and include handling instructions.

– Use temperature- and humidity-controlled shipping for high-value or large orders.

– Select carriers with experience in handling delicate goods (e.g., DHL Express, FedEx).

Labeling & Marking Compliance

Accurate labeling is mandatory for customs clearance and consumer safety:

– Country of Origin: Clearly mark “Made in [Country]” on packaging and product (if feasible).

– Material Disclosure: Indicate “Lead-Free Crystal” or “K9 Optical Crystal” as applicable.

– Prop 65 (California): If crystal contains lead above thresholds, include warning: “WARNING: This product can expose you to chemicals including lead, which is known to the State of California to cause cancer and birth defects.”

– CE Marking (EU): Required for decorative items placed on the EU market; confirms compliance with safety, health, and environmental standards.

Environmental & Chemical Compliance

Ensure adherence to global chemical regulations:

– REACH (EU): Confirm no restricted substances (e.g., lead, cadmium) exceed allowable limits.

– RoHS (EU/UK): Applies if crystal includes electronic components (e.g., LED bases).

– TSCA (USA): Comply with toxic substance regulations; most crystal compositions are exempt but verify.

Documentation Requirements

Maintain accurate export documentation:

– Commercial Invoice (with full product description, value, HS code)

– Packing List (itemizing contents, weights, dimensions)

– Certificate of Origin (for preferential tariff treatment)

– Bill of Lading or Air Waybill

Retain records for a minimum of 5 years per most customs authorities.

Special Considerations for Gifts & Promotional Items

If shipping laser engraved crystals as gifts or corporate merchandise:

– Declare true value on invoices; undervaluation risks penalties.

– For US imports, gifts under $100 may qualify for de minimis entry but must still comply with safety standards.

– Include end-user information to avoid customs delays related to prohibited imports.

Risk Mitigation & Best Practices

- Partner with a licensed customs broker familiar with handicrafts and glass products.

- Conduct pre-shipment compliance audits.

- Insure shipments for full replacement value.

- Monitor updates from customs authorities (e.g., CBP, HMRC, EU Commission) for regulatory changes.

Adhering to this guide ensures smooth logistics operations and full compliance across global markets.

Conclusion: Sourcing Laser Engraved Crystals

Sourcing laser engraved crystals requires careful consideration of quality, customization capabilities, production capacity, and cost-effectiveness. After evaluating various suppliers and factors, it is clear that selecting a reliable manufacturer with advanced laser technology, high-grade crystal materials, and strong attention to detail is essential for achieving premium results. Whether for corporate awards, promotional gifts, or personalized keepsakes, the clarity, precision, and elegance of laser engraving significantly enhance the product’s value and appeal.

Establishing a partnership with a supplier who offers consistent quality, timely delivery, and excellent customer service ensures long-term success. Additionally, considering eco-friendly practices and scalability can further support sustainable and growing business needs. Ultimately, investing in a trusted source for laser engraved crystals not only elevates brand perception but also delivers lasting impressions through beautifully crafted, high-precision crystal products.