The global laser drilling machine market is experiencing robust growth, driven by increasing demand for high-precision manufacturing across industries such as aerospace, automotive, medical devices, and electronics. According to Mordor Intelligence, the laser machining market—including drilling, cutting, and marking—is projected to grow at a CAGR of over 7.5% from 2023 to 2028, with laser drilling gaining traction due to its ability to produce micro-scale, clean, and consistent holes in hard and heat-sensitive materials. Advances in ultrafast lasers—particularly picosecond and femtosecond systems—are enabling non-thermal ablation processes, reducing material deformation and expanding applications in semiconductor and medical device manufacturing. As automation and Industry 4.0 integration accelerate, equipment reliability, repeatability, and throughput have become critical selection criteria for end users. This demand has fostered innovation and competition among leading manufacturers, positioning the market for continued expansion. Based on market presence, technological advancement, application versatility, and customer adoption, the following ten companies stand out as the top laser drilling machine manufacturers worldwide.

Top 10 Laser Drilling Machine Manufacturers (2026 Audit Report)

(Ranked by Factory Capability & Trust Score)

#1 Focus on laser

Founded: 1996

Website: hanslaser.net

Key Highlights: Han’s Laser Technology Industry Group Co., Ltd, a public company which was established in 1996, has now became the flagship of Chinese national laser industry ……

#2 Laser Drilling

Website: keyence.com

Key Highlights: Unleash precision with laser drilling for micro holes. Explore laser drilling machines and drill laser technology for efficient and accurate drilling….

#3 Laser Drilling Machines

Website: mitsubishielectric.com

Key Highlights: Mitsubishi Electric takes laser drilling machines to a whole new level. Key components such as laser oscillators, galvano scanners, f-theta lenses and control ……

#4 Laser Drilling

Website: ebtec.hanwhaaerospaceusa.com

Key Highlights: EBTEC Corporation is a leading supplier in the US laser drilling industry serving; Aerospace, Medical, Power Generation, and Industrial markets….

#5 LPKF PCB Prototype Technology & Laser Material Processing

Website: lpkf.com

Key Highlights: LPKF Laser & Electronics is the leading provider of laser manufacturing solutions. ✓✓✓Find out more about our industries and technologies here ⇒…

#6 LaserCube Laser Drilling System

Website: ipgphotonics.com

Key Highlights: LaserCube Driller is a high-speed laser drilling system capable of creating hundreds of uniformly spaced holes per second. Designed for drilling millions of ……

#7 Laser micro machining system ABLASER

Website: nidec.com

Key Highlights: The laser head adopts a prism rotator that adjusts and rotates the laser beam to an arbitrary hole diameter, enabling shape processing with sharp edges….

#8 LASERTEC PowerDrill: Laser Drilling Machines

Website: us.dmgmori.com

Key Highlights: With the LASERTEC 50 PowerDrill and the LASERTEC 100 / 160 PowerDrill, DMG MORI delivers a wide range of components for five-axis laser precision drilling….

#9 Laser Drilling Machines

Website: rwhartnett.com

Key Highlights: RW Hartnett’s laser drills are one of the most accurate and efficient ways to create sub-millimeter apertures in your pharmaceutical tablets and capsules….

#10 Laser Cutting & Drilling Systems – Precision Solutions

Website: coherent.com

Key Highlights: StarCut Tube. StarCut Tube Lasers are fully-automated, multi-axis CNC precision laser cutting machines for tubes and flat materials, including medical devices….

Expert Sourcing Insights for Laser Drilling Machine

H2: 2026 Market Trends for Laser Drilling Machines

The global laser drilling machine market is poised for significant transformation by 2026, driven by technological advancements, expanding industrial applications, and evolving manufacturing demands. Key trends shaping the market include:

1. Rising Demand in Aerospace & Defense:

The aerospace sector remains a primary growth driver, with increasing demand for lightweight, high-performance components requiring precision hole drilling in difficult-to-machine materials like titanium, Inconel, and composites. By 2026, stricter fuel efficiency regulations and the production ramp-up of next-generation aircraft and engines will accelerate the adoption of laser drilling, particularly for cooling holes in turbine blades and aero-engine components. Defense applications, including directed energy systems and advanced avionics, will further bolster market growth.

2. Growth in Electric Vehicles (EVs) and Battery Manufacturing:

The EV revolution is creating new opportunities for laser drilling. Micro-drilling is essential in battery manufacturing for processes such as separator perforation, electrode structuring, and safety vent creation. As EV production scales globally, demand for high-speed, high-precision laser drilling systems capable of processing thin foils and layered materials will surge. By 2026, this sector is expected to be one of the fastest-growing end-user segments for laser drilling machines.

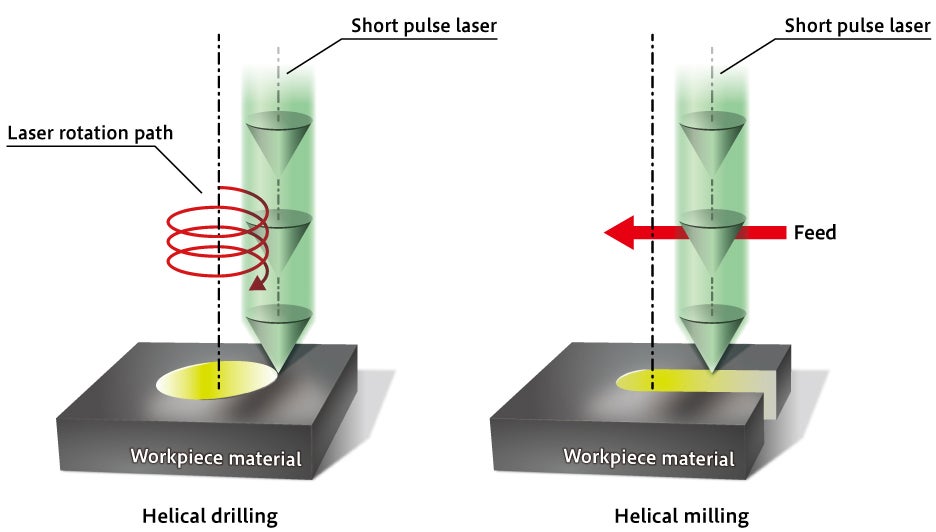

3. Advancement of Ultrafast (Pulsed) Lasers:

Ultrafast lasers (picosecond and femtosecond) are gaining prominence due to their ability to perform cold ablation—drilling with minimal heat-affected zones (HAZ), high precision, and superior edge quality. By 2026, falling costs and improved reliability of ultrafast laser sources will make them more accessible, enabling their use in high-value applications in medical devices (e.g., stents), semiconductors, and consumer electronics. This shift will drive demand for advanced multi-axis and automated laser drilling platforms.

4. Integration of Automation and Smart Manufacturing:

Laser drilling machines are increasingly being integrated into automated production lines and Industry 4.0 ecosystems. By 2026, the adoption of AI-driven process optimization, real-time monitoring, and predictive maintenance will enhance throughput, reduce downtime, and ensure consistent quality. Robotic integration and digital twin technologies will enable adaptive drilling strategies, particularly in high-mix, low-volume manufacturing environments.

5. Expansion in Medical Device Manufacturing:

The medical sector demands extreme precision and biocompatibility, making laser drilling ideal for applications such as catheter drilling, drug delivery devices, and surgical tools. As minimally invasive procedures grow, so will the need for micro-hole drilling in polymers, metals, and ceramics. By 2026, regulatory support and innovation in biocompatible materials will expand laser drilling’s role in medical manufacturing.

6. Regional Market Shifts and Supply Chain Localization:

Asia-Pacific—led by China, Japan, and South Korea—will remain the largest market due to robust electronics and automotive manufacturing. However, by 2026, increasing investments in semiconductor and EV production in North America and Europe (e.g., U.S. CHIPS Act, European Green Deal) will drive regional demand and encourage localized supply chains, boosting laser drilling machine sales in these regions.

7. Sustainability and Energy Efficiency Focus:

Manufacturers are prioritizing energy-efficient laser sources and systems with lower environmental impact. Fiber lasers, known for their high wall-plug efficiency and low maintenance, will dominate the market. By 2026, sustainability criteria will influence procurement decisions, favoring laser solutions over traditional mechanical drilling in terms of energy use and waste reduction.

Conclusion:

By 2026, the laser drilling machine market will be defined by precision, speed, and intelligence. Advances in laser technology, coupled with growing demand from high-tech industries like aerospace, EVs, and medical devices, will fuel market expansion. Companies that invest in automation, ultrafast lasers, and sustainable manufacturing solutions will be best positioned to capture value in this dynamic landscape.

Common Pitfalls When Sourcing a Laser Drilling Machine (Quality and Intellectual Property)

Sourcing a laser drilling machine involves significant investment and technical complexity. Overlooking key aspects related to quality and intellectual property (IP) can lead to performance issues, legal disputes, and financial losses. Below are critical pitfalls to avoid:

Poor Quality Control and Machine Reliability

One of the most frequent challenges is acquiring a laser drilling machine that does not meet expected performance standards. Low-cost suppliers, especially from regions with less stringent manufacturing oversight, may deliver systems with inconsistent beam quality, poor motion control, or inadequate cooling systems. These shortcomings result in inaccurate hole placement, tapering, or damaged workpieces. It’s essential to verify the supplier’s quality certifications (e.g., ISO 9001), request third-party inspection reports, and conduct on-site testing or factory acceptance tests (FAT) before finalizing procurement.

Lack of Transparency in Technical Specifications

Suppliers may exaggerate machine capabilities—such as drilling speed, precision, or material compatibility—without providing verifiable data. Hidden limitations in pulse duration, beam mode, or software control can severely impact process outcomes. Always demand detailed technical documentation, including laser source specifications (e.g., from IPG or Trumpf), motion system accuracy, and software features. Cross-check claims with independent reviews or user references.

Inadequate After-Sales Support and Spare Parts Availability

Even high-quality machines require maintenance and occasional repairs. Sourcing from vendors without a local service network or clear spare parts policy can lead to prolonged downtime. Ensure the supplier offers comprehensive support, including training, remote diagnostics, and a guaranteed supply of consumables and critical components for at least 5–10 years.

Intellectual Property Infringement Risks

A significant but often overlooked risk is purchasing a machine that incorporates stolen or unlicensed technology. Some manufacturers may use counterfeit laser sources, cloned control software, or patented motion systems without authorization. This exposes the buyer to legal liability, especially in regions with strict IP enforcement (e.g., EU, USA). Always verify the authenticity of core components and request IP indemnification clauses in contracts.

Unclear Ownership of Process-Specific IP

When customizing a laser drilling machine for a proprietary manufacturing process, ambiguity about who owns the resulting IP—such as optimized drilling parameters, software routines, or fixture designs—can lead to disputes. Clearly define in the procurement agreement which party retains rights to process innovations and whether the supplier can reuse or disclose such information.

Incomplete or Non-Compliant Documentation

Missing or inaccurate technical manuals, safety certifications (e.g., CE, FDA), or compliance documents (e.g., laser safety Class 1 enclosure) can delay machine commissioning or lead to regulatory penalties. Ensure all documentation is provided in your required language and meets local regulatory standards prior to shipment.

Hidden Software Limitations and Licensing

The control software is critical to machine performance, yet suppliers may restrict functionality through licensing tiers or proprietary formats. Some systems prevent integration with external automation or limit user access to advanced parameters. Confirm software openness, compatibility with existing factory systems (e.g., Industry 4.0 protocols), and licensing terms upfront.

By proactively addressing these pitfalls, buyers can mitigate risks and ensure they acquire a reliable, high-performance laser drilling machine that protects both their operational integrity and intellectual property.

Logistics & Compliance Guide for Laser Drilling Machine

Overview

Laser drilling machines are high-precision industrial equipment used in manufacturing, aerospace, automotive, and medical device sectors. Due to their technical complexity, high value, and potential regulatory implications, shipping and importing these machines require careful attention to logistics and compliance protocols.

Packaging and Handling

Laser drilling machines must be packaged securely to prevent damage during transit. Use custom wooden crates with internal shock-absorbing materials such as foam or air-ride suspension. Ensure all optical components, laser sources, and sensitive electronics are individually protected and immobilized. Clearly label the package with “Fragile,” “This Side Up,” and “Do Not Stack” indicators. Climate-controlled packaging may be required if components are sensitive to temperature and humidity.

Transportation Mode Selection

Choose the appropriate transportation method based on shipment size, urgency, and destination. For international deliveries, air freight is recommended for time-sensitive or high-value units, while sea freight is more cost-effective for larger or multiple machines. Overland transport (road or rail) is suitable for regional deliveries. Coordinate with freight forwarders experienced in handling high-tech industrial equipment.

Export Controls and Licensing

Laser drilling machines may be subject to export control regulations due to their dual-use potential (civilian and military applications). In the United States, check the Export Administration Regulations (EAR) under the Commerce Control List (CCL). Many laser systems fall under ECCN 6A003 or 6A005, requiring a license for certain destinations. Similarly, in the European Union, comply with the Dual-Use Regulation (EU) 2021/821. Obtain necessary export licenses before shipment and maintain records for audit purposes.

Customs Documentation

Prepare comprehensive documentation for customs clearance, including:

– Commercial Invoice (detailing value, description, and Harmonized System (HS) code)

– Packing List

– Certificate of Origin

– Bill of Lading or Air Waybill

– Export License (if applicable)

– Technical specifications and user manuals (for classification verification)

Ensure the HS code is correctly classified—common codes include 8456.30 for laser cutting and drilling machines. Incorrect classification may lead to delays or penalties.

Import Regulations and Duties

Research import requirements in the destination country. Some countries impose additional inspections, safety certifications, or registration for laser equipment. For example, in Canada, compliance with the Radiation Emitting Devices Act (REDA) may be required. In China, obtain an CCC (China Compulsory Certification) mark if applicable. Be prepared to pay import duties, VAT, and any applicable anti-dumping or countervailing duties.

Safety and Technical Compliance

Ensure the machine complies with international safety standards such as:

– IEC 60825 (Laser Product Safety)

– IEC 61496 (Electro-sensitive Protection Equipment)

– ISO 13849 (Safety of Machinery – Control Systems)

Provide CE marking for exports to the EU, UKCA marking for the UK, and FDA registration for U.S. imports if the laser is classified as a radiation-emitting device.

Installation and On-Site Compliance

Coordinate with the receiving party for safe unpacking and installation. Provide technical documentation, safety training materials, and emergency shutdown procedures. Verify local electrical, ventilation, and fire safety codes are met. In some jurisdictions, registration with occupational safety or environmental agencies may be required before operation.

Warranty, Service, and Spare Parts Logistics

Establish a logistics plan for spare parts and service support. Maintain an inventory of critical components in strategic locations. Ensure compliance with local warranty and consumer protection laws. Service technicians may require work permits or visas for on-site support—plan accordingly.

Environmental and Disposal Regulations

Plan for end-of-life compliance. Laser machines may contain hazardous materials (e.g., batteries, optics, cooling fluids). Follow the EU’s WEEE Directive or local e-waste regulations for proper recycling and disposal. Avoid non-compliant export of electronic waste under the Basel Convention.

Conclusion

Shipping a laser drilling machine demands meticulous planning across logistics, regulatory compliance, and safety standards. Partner with experienced freight forwarders, legal advisors, and compliance experts to ensure smooth international delivery and adherence to all applicable laws. Maintain thorough documentation at every stage to support audits and future shipments.

Conclusion for Sourcing a Laser Drilling Machine:

After thorough evaluation of technical requirements, production needs, and financial considerations, sourcing a laser drilling machine presents a strategic investment to enhance precision, efficiency, and versatility in manufacturing processes. The selected machine meets critical criteria including drilling accuracy, speed, material compatibility, automation capabilities, and long-term maintenance support.

Key factors such as vendor reliability, after-sales service, training availability, and scalability have been carefully assessed to ensure seamless integration into existing operations. Additionally, the adoption of laser drilling technology aligns with goals of process optimization, reduced waste, and improved product quality.

In conclusion, proceeding with the procurement of the recommended laser drilling machine will strengthen operational capabilities, support future growth, and provide a competitive advantage in high-precision manufacturing. Proper implementation and operator training will be essential to fully realize the benefits of this advanced technology.