The global laser cleaning equipment market is experiencing robust growth, driven by increasing demand for eco-friendly and precision-based surface treatment solutions across industries such as automotive, aerospace, and manufacturing. According to a 2023 report by Mordor Intelligence, the laser cleaning market was valued at USD 720 million in 2022 and is projected to grow at a compound annual growth rate (CAGR) of over 18% from 2023 to 2028. This surge is fueled by stringent environmental regulations limiting the use of chemical and abrasive cleaning methods, as well as the rising adoption of automation in industrial maintenance. Laser derusting, a key application of this technology, offers non-contact, selective, and waste-minimizing rust removal—making it a preferred alternative to traditional techniques. As industries prioritize sustainability and operational efficiency, leading manufacturers are advancing laser derusting capabilities with higher power outputs, improved portability, and AI-assisted targeting. Based on market presence, innovation, and customer reviews, here are the top 9 laser derusting machine manufacturers shaping the future of industrial surface cleaning.

Top 9 Laser Derusting Machine Manufacturers (2026 Audit Report)

(Ranked by Factory Capability & Trust Score)

#1 Laser Machine – Laser Equipment Manufacturer

Website: dplaser.com

Key Highlights: DPLASER is a leading manufacturer & factory of industrial laser welding, laser cutting, laser marking and laser cleaning machines….

#2 Laser Cleaning Machine

Website: pulsar-laser.com

Key Highlights: PULSAR Laser is a manufacturer of professional laser cleaning machines, developed and engineered for industrial maintenance, manufacturing, restoration and ……

#3 Laserax

Website: laserax.com

Key Highlights: Laserax works with the world’s leading manufacturers to implement laser cleaning, welding, texturing, and marking solutions….

#4 P-laser Industrial laser cleaning

Website: p-laser.com

Key Highlights: Specializing in the production of premium-quality, Belgian-made industrial laser cleaning equipment, we take great pride in our craftsmanship and innovative ……

#5 SFX Laser

Website: sfxlaser.com

Key Highlights: SFX Laser is a 20+ years professional laser equipment manufacturer including laser cleaning machine, laser welding machine, fiber laser engraver, fiber laser…

#6 Laser Photonics

Website: laserphotonics.com

Key Highlights: Laser Photonics manufactures reliable, safe, and eco-friendly Laser Cleaning, Laser Cutting, Laser Engraving, Laser Marking, and Laser Welding solutions….

#7 Argento Lux

Website: argentolux.com

Key Highlights: Laser cleaning removes paint, contaminants, rust, and residues with a high-energy laser beam which leaves the substrate untouched. Our Laser Ablation is the ……

#8 ZAC Laser Machine

Founded: 2004

Website: zaclaser.com

Key Highlights: ZAC laser is the professional manufacture since 2004 which sell many laser machines such as laser rust removal-laser cleaning machine, laser engraver-laser ……

#9 Laser cleaning

Website: p-laserusa.com

Key Highlights: Our laser machines are mainly used to remove the following contaminants: Rust – Paint – Coatings – Release Agents – Grease, Oils – Soot – Rubber- Organic ……

Expert Sourcing Insights for Laser Derusting Machine

H2: 2026 Market Trends for Laser Derusting Machines

The global market for laser derusting machines is poised for significant transformation by 2026, driven by technological innovation, industrial automation, and increasing environmental regulations. As industries shift toward sustainable and precision-based surface treatment solutions, laser derusting technology is emerging as a preferred alternative to traditional methods such as sandblasting, chemical cleaning, and mechanical abrasion. Below are the key market trends expected to shape the laser derusting machine industry in 2026:

1. Increased Adoption Across Heavy Industries

By 2026, laser derusting machines are expected to see widespread adoption in sectors such as automotive manufacturing, shipbuilding, aerospace, and infrastructure maintenance. These industries are prioritizing non-contact, high-precision cleaning methods that preserve substrate integrity while removing rust, paint, and contaminants. The demand is particularly strong in regions with aging infrastructure—such as North America and Europe—where maintenance and refurbishment activities are on the rise.

2. Advancements in Fiber Laser Technology

The development of high-power fiber lasers with improved efficiency, portability, and beam quality is a major technological driver. By 2026, fiber laser systems are projected to dominate the market due to their longer lifespans, lower maintenance costs, and compatibility with robotic automation. Innovations in pulse modulation and beam delivery systems will further enhance cleaning speed and effectiveness, making laser derusting viable for large-scale industrial applications.

3. Emphasis on Environmental and Worker Safety Compliance

Stringent environmental regulations—especially in the EU, North America, and parts of East Asia—are accelerating the shift away from abrasive and chemical cleaning methods that generate hazardous waste and airborne pollutants. Laser derusting produces no secondary waste and eliminates the need for chemical solvents, aligning with green manufacturing standards such as ISO 14001. This regulatory tailwind is expected to boost market penetration, particularly among environmentally conscious manufacturers.

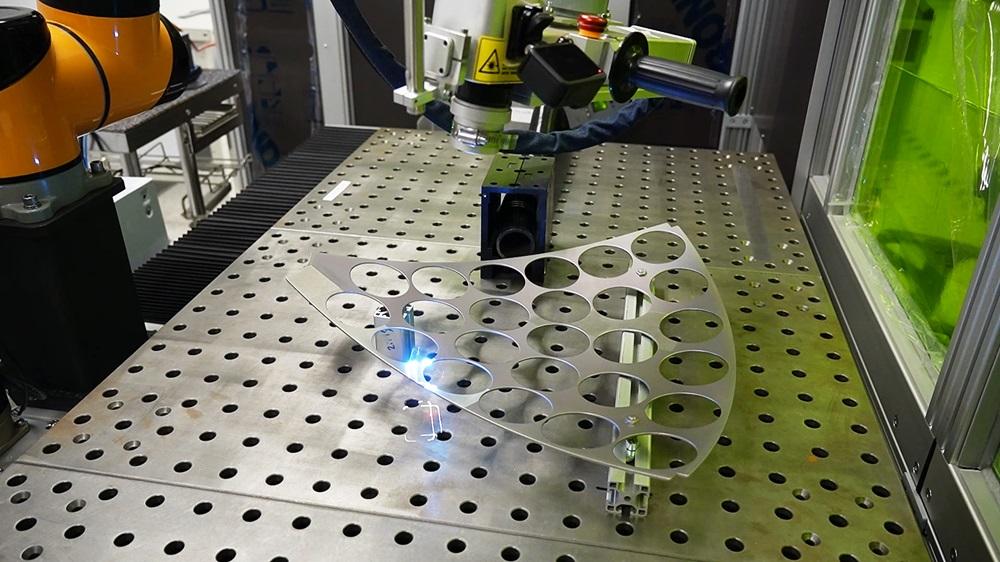

4. Integration with Automation and Industry 4.0

Laser derusting systems are increasingly being integrated into smart manufacturing ecosystems. By 2026, expect widespread use of AI-driven scanning, real-time monitoring, and robotic arms equipped with laser derusting tools. These integrations enable adaptive cleaning based on surface condition analysis, reducing energy consumption and improving process consistency. The synergy with digital twins and predictive maintenance platforms will further enhance operational efficiency.

5. Cost Reduction and Improved ROI

Although initial investment remains higher than conventional methods, the total cost of ownership for laser derusting machines is declining due to falling component prices and increased competition among manufacturers. By 2026, improved return on investment (ROI) from reduced labor costs, minimal consumables, and extended equipment life will make laser systems more accessible to small and medium enterprises (SMEs), expanding the market beyond large industrial players.

6. Regional Growth Dynamics

Asia-Pacific will remain the fastest-growing market, driven by industrial expansion in China, India, and Southeast Asia. China, in particular, is investing heavily in domestic laser technology R&D and manufacturing, positioning itself as both a key consumer and exporter of laser derusting equipment. Meanwhile, North America and Europe will focus on retrofitting existing facilities and adopting laser cleaning for nuclear decommissioning, heritage restoration, and precision engineering.

7. Emergence of Portable and Handheld Systems

The demand for flexible, on-site cleaning solutions is fueling innovation in portable and handheld laser derusting devices. By 2026, these compact systems are expected to gain traction in maintenance, repair, and operations (MRO) sectors, offering mobility and ease of use for field applications such as bridge maintenance and pipeline cleaning.

In summary, the 2026 market for laser derusting machines will be characterized by rapid technological evolution, strong regulatory support, and growing cross-industry adoption. As sustainability and automation become central to industrial strategy, laser derusting is set to transition from a niche solution to a mainstream surface preparation technology.

Common Pitfalls When Sourcing a Laser Derusting Machine (Quality & Intellectual Property)

Sourcing a laser derusting machine offers significant advantages for industrial cleaning, but it comes with critical risks related to both product quality and intellectual property (IP) that buyers must navigate carefully.

Poor Build Quality and Component Sourcing

Many suppliers, especially newer or low-cost manufacturers, compromise on the structural integrity and core components of their laser derusting systems. This includes using substandard laser sources, inadequate cooling systems, or poorly engineered motion components. These shortcuts result in inconsistent cleaning performance, frequent breakdowns, and shortened machine lifespan. Buyers may receive equipment that fails under continuous industrial use, leading to costly downtime and replacement.

Inflated or Unverified Performance Claims

A common issue is exaggerated specifications regarding laser power, cleaning speed, or rust removal depth. Some suppliers quote peak power instead of average power or base performance metrics on ideal lab conditions rather than real-world applications. Without third-party testing data or verifiable references, these claims can mislead buyers into purchasing underperforming machines that fail to meet production requirements.

Lack of Safety Features and Compliance

Laser derusting involves high-power beams that pose serious safety risks. Low-quality or uncertified machines may lack essential safety interlocks, proper beam shielding, or compliant fume extraction systems. Machines not meeting international safety standards (such as CE, FDA, or IEC 60825) can expose operators to hazards and create liability issues for the end-user.

Inadequate After-Sales Support and Technical Training

Many suppliers, particularly those based overseas, offer limited or delayed technical support, spare parts availability, and operator training. This can severely impact machine uptime and effective utilization. Buyers often discover too late that firmware updates, troubleshooting assistance, or replacement components are difficult to obtain, undermining operational efficiency.

Intellectual Property Infringement Risks

Some manufacturers reverse-engineer or clone proprietary designs from leading laser technology companies. Purchasing such machines may expose the buyer to legal risks if the equipment incorporates patented technologies without authorization. Using counterfeit or IP-infringing machines can lead to liability, import restrictions, or reputational damage, particularly in regulated industries.

Absence of Genuine Software and Control Systems

Counterfeit or poorly licensed software is frequently bundled with low-cost machines. This includes unauthorized copies of control interfaces or embedded algorithms that manage laser parameters. Not only does this raise IP concerns, but it can also lead to system instability, lack of updates, and incompatibility with future upgrades.

Insufficient Documentation and Traceability

Reputable suppliers provide comprehensive technical documentation, calibration records, and component traceability. However, many budget suppliers offer minimal or generic documentation, making maintenance, troubleshooting, and compliance audits challenging. This lack of transparency can hinder quality assurance and regulatory compliance efforts.

To mitigate these risks, buyers should conduct thorough due diligence, request live demonstrations, verify certifications, audit the supplier’s IP practices, and prioritize vendors with proven track records and transparent manufacturing processes.

Logistics & Compliance Guide for Laser Derusting Machine

General Overview

The Laser Derusting Machine is a precision industrial cleaning device that uses high-intensity laser beams to remove rust, paint, and contaminants from metal surfaces without damaging the substrate. Due to its technical complexity, laser classification, and electrical components, proper logistics planning and compliance with international and local regulations are essential for safe and legal transportation, import, and operation.

Packaging & Handling

All Laser Derusting Machines must be shipped in custom-designed, shock-resistant packaging with internal foam or rigid supports to secure the laser head, control unit, and power supply. Use sealed, moisture-resistant crates suitable for marine or air transport. Clearly label packages with “Fragile,” “This Side Up,” and “Protect from Moisture.” Avoid stacking heavy items on top of the crate. Always use material handling equipment—never drag or drop the unit.

Shipping & Transportation

Transport the machine via freight carriers experienced in handling industrial or high-value electrical equipment. For international shipping, ensure compliance with IATA (air) or IMDG (sea) regulations if applicable. The machine should be shipped on a pallet with skid-resistant base and secured with straps. Temperature-controlled environments are recommended during transit to prevent condensation. Provide a detailed packing list and shipping manifest with all consignments.

Import & Export Compliance

Verify export control classifications (e.g., ECCN under the U.S. Commerce Control List). Laser systems may fall under Category 6 (Lasers and Directed Energy Systems) and require an export license depending on power output and destination country. Comply with ITAR if applicable, particularly for military-grade models. Importers must confirm local customs requirements, including tariffs, import permits, and conformity assessment procedures.

Laser Safety Regulations

The machine must comply with the IEC 60825-1 standard for laser product safety. Class 4 laser systems require interlocks, emergency stop functions, and protective enclosures. Include a CE mark (for EU), FDA/CDRH registration (for U.S.), or equivalent certification depending on the target market. Operators must receive laser safety training, and the workspace must adhere to controlled access and appropriate signage (e.g., “Laser Radiation – Avoid Eye or Skin Exposure”).

Electrical & EMC Compliance

Ensure the machine meets regional electrical standards: CE (EU), UL/ETL (U.S./Canada), CCC (China), or PSE (Japan). The device must pass electromagnetic compatibility (EMC) testing per standards such as IEC 61326-1 to prevent interference with other equipment. Voltage and frequency must match local supply (e.g., 230V/50Hz or 120V/60Hz); include voltage converters or dual-voltage options if needed.

Environmental & Disposal Considerations

Laser derusting produces metal particulate waste. Provide HEPA-filtered fume extraction systems to meet OSHA (U.S.), COSHH (UK), or local air quality regulations. Classify waste according to local hazardous material rules—some metal dust may require special handling. At end-of-life, recycle electronic components and batteries per WEEE (EU) or equivalent legislation. Avoid landfill disposal of laser optics or electronic boards.

Documentation Requirements

Include the following with every shipment:

– User manual with safety instructions and maintenance guidelines

– CE/UL/FDA compliance certificates

– Laser classification report (IEC 60825-1)

– Bill of Materials (BOM) and technical specifications

– Warranty and service agreement

– Multilingual warning labels and operating instructions (as required)

On-Site Installation & Training

Installation must be performed by trained technicians. Ensure facility has adequate power supply, ventilation, and space for safe operation. Conduct on-site laser safety training for operators and supervisors, including emergency procedures. Provide personal protective equipment (PPE) such as laser safety goggles with appropriate optical density (OD) ratings.

Ongoing Compliance & Maintenance

Maintain logs of laser usage, maintenance, and safety inspections. Recertify laser safety annually or as required by local regulations. Update software and firmware to meet latest compliance standards. Report any incidents involving laser exposure or equipment malfunction to relevant authorities as mandated.

Conclusion for Sourcing a Laser Derusting Machine

After thorough evaluation of technical capabilities, cost implications, safety considerations, and long-term operational benefits, sourcing a laser derusting machine presents a strategic investment for modern surface treatment and industrial maintenance operations. Laser derusting offers a non-abrasive, eco-friendly, and highly precise alternative to traditional methods such as sandblasting, chemical cleaning, or mechanical grinding. It significantly reduces wastewater, chemical waste, and media consumption while ensuring substrate integrity and superior cleaning quality.

While the initial capital expenditure is higher compared to conventional systems, the long-term savings in labor, consumables, maintenance, and waste disposal—combined with increased efficiency and compliance with environmental regulations—justify the investment. Additionally, the versatility of laser derusting across various materials (steel, aluminum, historical artifacts, etc.) and its integration potential with automation and robotics enhance its value in advanced manufacturing and restoration applications.

Therefore, sourcing a laser derusting machine from a reputable supplier with proven technology, strong after-sales support, and customization options is recommended to ensure reliability, safety, and optimal return on investment. As industries move toward cleaner and smarter production methods, laser derusting stands as a future-proof solution aligned with sustainability and precision goals.