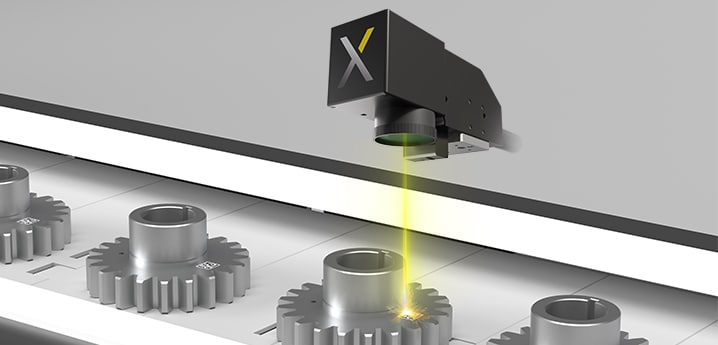

The global laser marking machine market is experiencing robust expansion, driven by increasing demand for precision, traceability, and permanent marking across industries such as automotive, electronics, medical devices, and packaging. According to a report by Mordor Intelligence, the market was valued at USD 1.79 billion in 2023 and is projected to reach USD 2.74 billion by 2029, growing at a CAGR of approximately 7.5% during the forecast period. This growth is fueled by the rising adoption of fiber laser technology, advancements in automation, and stringent regulatory requirements for product traceability. As industries shift toward Industry 4.0 and smart manufacturing, the need for reliable, high-speed, and low-maintenance laser marking solutions has surged, prompting innovation and competition among key players worldwide. Against this backdrop, the following list highlights the top 10 laser marking machine manufacturers leading the market through technological excellence, global reach, and a strong portfolio of industrial solutions.

Top 10 Laser De Marquage Manufacturers (2026 Audit Report)

(Ranked by Factory Capability & Trust Score)

#1 Industrial laser marking machines, laser engraving solution

Website: sic-marking.com

Key Highlights: Laser marking technology is particularly used for direct and permanent marking of metal or plastic parts depending on the hardness and their surface condition….

#2 Célébrons 50 ans d’innovation par Laser Cheval

Website: geode.lasercheval.com

Key Highlights: Cheval Frères became the leading manufacturer of industrial lasers in France. The company quickly established its reputation in the field. It designs machines ……

#3 Laserax

Website: laserax.com

Key Highlights: Laserax works with the world’s leading manufacturers to implement laser cleaning, welding, texturing, and marking solutions….

#4 Experts in Industrial Laser Marking + Engraving

Website: fobalaser.com

Key Highlights: For five decades, we have been writing with light, developing and manufacturing leading laser marking solutions for direct part and product marking….

#5 Laser marking machine

Website: technomark-marking.com

Key Highlights: Our laser marking machines are equipped with fiber technology for fast, precise marking on all types of materials….

#6 Laser Marking Machine & Industrial Laser Marking Systems

Website: videojet.com

Key Highlights: Shop Videojet laser marking machines and industrial laser marking systems. Get a free quote and optimize your production line today!…

#7 Fiber Laser Cutting Machines

Website: xtlaser.com

Key Highlights: XT LASER is a laser equipment manufacturer. XT laser is sheet metal laser cutting machines, metal pipe laser cutting machines, welding machines, ……

#8 Fiber Laser Marking Machine, Laser Engraving System Price

Website: alldolaser.com

Key Highlights: Alldo fiber laser marking machine is mainly used for marking and engraving various metals, and some non-metals with amazing speedy marking. RFQ Now….

#9 Laser Marking Systems

Website: tri-star-technologies.com

Key Highlights: Tri-Star Technologies manufactures a full line of ink jet and laser marking systems that are perfect for applications in aviation, manufacturing, and more….

#10 Expert in marking machines

Website: thermoflan.com

Key Highlights: With 60 years of experience, Thermoflan advises you in the sale of marking equipment and machines, printing, laser engraving and the manufacture of marker pads ……

Expert Sourcing Insights for Laser De Marquage

H2: Market Trends for Laser De Marquage in 2026

As we approach 2026, the global market for Laser de Marquage (laser marking) is undergoing significant transformation, driven by advancements in industrial automation, increasing demand for traceability, and stricter regulatory requirements across key sectors. This analysis explores the major trends shaping the laser marking equipment market in 2026, with a focus on technology, regional dynamics, industry adoption, and emerging opportunities.

1. Increased Adoption in High-Precision Industries

Industries such as medical devices, aerospace, and electronics are leading the demand for high-precision, non-contact laser marking solutions. In 2026, the need for permanent, tamper-proof, and high-resolution markings on sensitive components—such as surgical tools, microchips, and turbine blades—is accelerating the shift from traditional marking methods (e.g., inkjet or mechanical engraving) to fiber and UV laser systems. These lasers offer superior durability, fine detail resolution, and compliance with ISO and FDA traceability standards.

2. Growth in Smart Manufacturing and Industry 4.0 Integration

The integration of laser marking systems into smart factories is a defining trend in 2026. Laser markers are increasingly connected to Manufacturing Execution Systems (MES) and Enterprise Resource Planning (ERP) platforms via IoT-enabled interfaces. This allows real-time serialization, data tracking, and dynamic marking of unique identifiers (e.g., Data Matrix codes, QR codes), supporting end-to-end supply chain transparency and anti-counterfeiting efforts.

3. Expansion of Fiber Laser Dominance

Fiber lasers continue to dominate the laser marking market in 2026 due to their low maintenance, high efficiency, and compatibility with a wide range of materials—including metals, plastics, and ceramics. Advancements in pulsed fiber laser technology now allow for color marking on stainless steel and improved contrast on dark plastics, expanding their application scope in consumer electronics and automotive sectors.

4. Sustainability and Regulatory Pressure Driving Change

Environmental regulations are pushing manufacturers toward eco-friendly marking processes. Laser marking eliminates the need for inks, solvents, and consumables, making it a sustainable alternative. In Europe and North America, directives such as the EU Medical Device Regulation (MDR) and U.S. FDA UDI (Unique Device Identification) mandate permanent product identification, further boosting laser marking adoption in 2026.

5. Emerging Markets Driving Regional Growth

While North America and Western Europe remain strong markets, Asia-Pacific—especially China, India, and Southeast Asia—is experiencing the fastest growth in laser marking adoption. This is fueled by expanding electronics manufacturing, automotive production, and government initiatives promoting advanced manufacturing. Localized production of laser systems is also reducing costs and improving market accessibility.

6. Advancements in Ultrafast and Green Lasers

Ultrafast (picosecond and femtosecond) lasers are gaining traction in niche applications requiring minimal heat-affected zones, such as marking on heat-sensitive polymers or transparent materials. Green lasers (532 nm) are seeing increased use in marking on plastics and solar panels, where traditional infrared lasers may cause material degradation.

7. Rise of Compact and Portable Laser Marking Systems

In 2026, there is growing demand for compact, handheld, and portable laser marking devices, particularly in maintenance, repair, and operations (MRO) and field-service applications. These systems offer flexibility for on-site asset identification and are increasingly adopted in oil & gas, utilities, and defense sectors.

Conclusion

By 2026, the Laser de Marquage market is characterized by technological sophistication, deeper integration with digital manufacturing ecosystems, and strong growth across both developed and emerging economies. As industries prioritize traceability, sustainability, and precision, laser marking is poised to become an indispensable component of modern production lines. Companies investing in R&D, smart connectivity, and application-specific solutions are expected to lead the market in this pivotal year.

Common Pitfalls When Sourcing Laser Marking Systems (Quality and Intellectual Property)

Poor Quality Control and Inconsistent Marking Performance

One of the most frequent issues when sourcing laser marking systems—especially from low-cost manufacturers—is inconsistent quality. Units may vary significantly in build quality, component selection, and calibration. This leads to unreliable marking results, such as uneven depth, fading, or incomplete engravings. Without rigorous quality assurance processes, buyers risk receiving systems that fail under continuous operation or don’t meet industry standards (e.g., ISO, automotive, or aerospace requirements).

Use of Substandard or Counterfeit Components

Some suppliers cut costs by using inferior lasers, optics, or control electronics. These components degrade faster, reduce system lifespan, and compromise precision. For example, a fiber laser module labeled as 30W might actually deliver only 20–25W due to poor manufacturing tolerances. Additionally, counterfeit or reconditioned parts can lead to early system failure and increase maintenance costs.

Lack of Compliance with International Safety and Emission Standards

Many low-cost laser systems, particularly those imported from regions with lax regulations, may not comply with essential safety standards such as FDA (U.S.), CE (Europe), or IEC 60825 (laser safety). Non-compliant systems pose safety risks to operators and may be confiscated or banned upon importation. Always verify certification documentation before purchase.

Inadequate After-Sales Support and Spare Parts Availability

Sourcing from overseas suppliers often means limited access to technical support, software updates, and replacement parts. If the supplier lacks a local service network, troubleshooting and repairs can lead to extended downtime. Some vendors also discontinue support for older models, making long-term maintenance difficult.

Intellectual Property (IP) Risks and Unauthorized Cloning

Purchasing from unverified suppliers increases the risk of acquiring systems that infringe on patented technologies. Some manufacturers reverse-engineer branded laser systems and sell clones without proper licensing. Buyers could face legal exposure, especially in markets with strong IP enforcement. Additionally, using pirated or unlicensed software embedded in the control system may violate software copyrights.

Hidden Software Limitations and Licensing Restrictions

Some laser systems come with proprietary software that limits functionality unless additional (often expensive) licenses are purchased. In certain cases, software may be region-locked or require online activation that becomes inaccessible if the supplier goes out of business. Without full access to software APIs or development tools, integration into automated production lines becomes challenging.

Misrepresentation of Technical Specifications

Suppliers may exaggerate key performance metrics—such as laser power, marking speed, or accuracy—to appear competitive. For instance, “peak power” might be advertised instead of “average power,” misleading buyers about actual capabilities. Always request third-party test reports or conduct on-site demonstrations before finalizing procurement.

Failure to Protect Custom Marking Designs and Programs

When working with suppliers for custom integration or programming, there’s a risk they retain copies of your proprietary marking patterns, logos, or production workflows. Without clear contractual agreements on data ownership and confidentiality, your intellectual property could be reused or shared with competitors.

Conclusion

To mitigate these risks, conduct thorough due diligence: verify certifications, audit suppliers, request sample testing, and use legally binding agreements that address quality, IP ownership, and support obligations. Partnering with reputable suppliers—rather than choosing based solely on price—ensures long-term reliability and protects your business from legal and operational pitfalls.

Logistics & Compliance Guide for Laser Marking Machines

Introduction to Laser Marking Equipment

Laser marking machines are industrial systems used to permanently engrave or mark materials such as metal, plastic, glass, and ceramics using a focused laser beam. These machines are widely used in manufacturing, automotive, aerospace, medical devices, and electronics for part identification, traceability, and branding. Ensuring proper logistics and compliance is essential for safe transport, regulatory adherence, and successful deployment.

Regulatory Classification and Documentation

Laser marking machines are classified under specific Harmonized System (HS) codes, typically falling within 8456.10 (Laser machines for working metal) or 8456.30 (Laser machines for working other materials). Accurate classification is crucial for customs clearance and import duties. Required documentation includes a commercial invoice, packing list, bill of lading or air waybill, certificate of origin, and technical specifications. For medical or aerospace applications, additional certifications (e.g., ISO 13485, AS9100) may be required.

Laser Safety and Regulatory Compliance

Laser marking systems are subject to laser safety regulations governed by international and national standards. Key compliance standards include:

– IEC 60825-1: Safety of laser products – Equipment classification and requirements.

– FDA 21 CFR Part 1040.10/1040.11: U.S. regulations for laser products, requiring manufacturers to file a product report and provide a certification label.

– CE Marking (EU): Compliance with the Machinery Directive (2006/42/EC) and the Electromagnetic Compatibility (EMC) Directive (2014/30/EU).

Ensure all machines are labeled with appropriate laser class (typically Class 1 or Class 4 depending on enclosure), include safety interlocks, and are accompanied by a user manual with safety instructions.

Packaging and Handling Requirements

Proper packaging is critical to prevent damage during transit. Laser marking machines should be:

– Secured in wooden crates or robust export-grade pallets with shock-absorbing materials.

– Protected against moisture using desiccants and vapor barriers.

– Clearly labeled with handling instructions (e.g., “Fragile,” “This Side Up,” “Do Not Stack”).

– Grounded to prevent electrostatic discharge (ESD), especially for sensitive control systems.

Transportation and Shipping Considerations

Laser marking machines are often heavy and sensitive to vibration, temperature, and humidity. Opt for:

– Freight shipping (sea or air) based on urgency and destination.

– Temperature-controlled environments when shipping to extreme climates.

– Insurance coverage for full replacement value.

For international shipments, verify compliance with destination country import restrictions, especially for high-powered lasers (Class 3B and Class 4), which may require special permits or end-user undertakings.

Import/Export Controls and Permits

Certain countries regulate the export of laser equipment due to dual-use (civilian and military) potential. Key considerations include:

– Export Administration Regulations (EAR) in the U.S., which may require a license for certain laser specifications (e.g., wavelength, power output).

– Wassenaar Arrangement guidelines affecting transfers to specific countries.

– Local import permits in destinations such as China, India, or Brazil, where industrial machinery may require pre-approval or conformity assessment.

Installation and On-Site Compliance

Upon arrival, ensure:

– Site readiness (power supply, ventilation, floor space, and grounding).

– Verification of machine integrity after transport.

– Installation by qualified technicians following manufacturer guidelines.

– On-site safety evaluation, including laser hazard zone assessment and operator training.

Maintain compliance with local occupational safety regulations, such as OSHA (U.S.) or the Provision and Use of Work Equipment Regulations (PUWER) in the UK.

Maintenance, Record-Keeping, and Audits

Keep detailed records of:

– Machine calibration and service logs.

– Laser safety training for operators.

– Regulatory certifications and compliance documentation.

Regular audits should verify ongoing compliance with safety standards and traceability requirements, especially in regulated industries like medical devices (FDA, MDR) or automotive (IATF 16949).

Conclusion

Successful logistics and compliance for laser marking machines require a proactive approach to classification, safety, transportation, and regulatory adherence. By following international standards and local requirements, businesses can ensure smooth deployment, legal operation, and long-term reliability of their laser marking systems.

Conclusion pour la sourcing d’un laser de marquage

Le sourcing d’un laser de marquage est une étape stratégique essentielle pour garantir une intégration efficace, durable et rentable dans un processus industriel. Après analyse des différents critères – tels que le type de matériau à marquer, la précision requise, la productivité, la maintenance, le coût total de possession (TCO) et la conformité aux normes industrielles – il apparaît crucial de choisir un équipement adapté non seulement aux besoins actuels, mais aussi aux évolutions futures de la chaîne de production.

L’identification de fournisseurs fiables, capables d’offrir un bon rapport qualité-prix, un support technique réactif et des garanties solides, permet d’assurer une mise en œuvre réussie du système de marquage laser. De plus, l’intégration de solutions connectées ou compatibles avec l’industrie 4.0 (traçabilité, supervision à distance, etc.) constitue un levier supplémentaire de performance et de compétitivité.

En définitive, une démarche de sourcing rigoureuse, centrée sur une analyse technique et économique approfondie, permet non seulement de sélectionner le laser de marquage le plus adapté, mais aussi de maximiser le retour sur investissement et de renforcer la qualité et la traçabilité des produits finis.