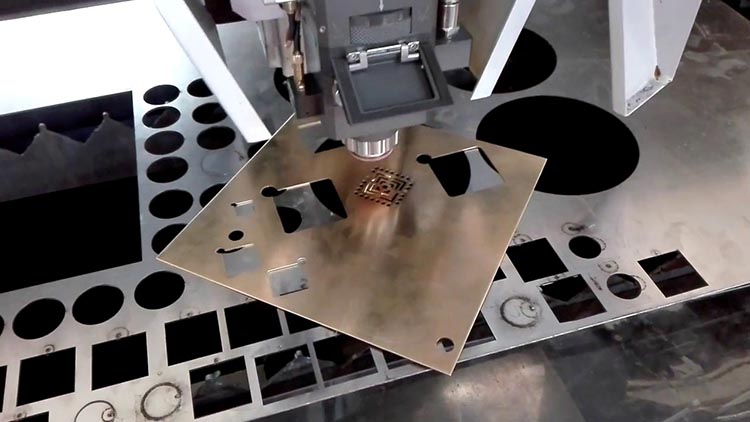

The global jewelry manufacturing industry is undergoing a transformative shift, driven by increasing demand for intricate, customized designs and efficient production processes. According to Grand View Research, the global laser cutting machines market size was valued at USD 3.5 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 7.4% from 2023 to 2030, fueled by advancements in precision engineering and rising adoption across luxury and fashion jewelry sectors. As manufacturers seek to enhance accuracy, reduce material waste, and scale production, laser cutting technology has become indispensable. Mordor Intelligence further projects steady growth in the industrial laser systems market, citing increased automation and the integration of CAD/CAM software in jewelry design workflows. In this evolving landscape, selecting the right laser cutting machine is critical. From fiber lasers ideal for fine metal detailing to hybrid systems offering multi-material versatility, the following nine machines represent the top choices for jewelry manufacturers aiming to combine artistry with advanced manufacturing capabilities.

Top 9 Laser Cutting Machine For Jewelry Manufacturers (2026 Audit Report)

(Ranked by Factory Capability & Trust Score)

#1 Professional Laser Cutting Machine Welding Machine Manufacturer

Website: goldmarklaser.com

Key Highlights: We specialized in design, manufacture fiber laser cutting machine, laser welding machine, laser cleaning machine. Spanning over 20,000 square meters, our modern ……

#2 Laser Cutting, Engraving & Marking Machines

Website: thunderlaser.com

Key Highlights: Thunder Laser offers high-quality, reliable laser machines to meet the needs of a variety of industries. ThunderLaser has become a well-recognized icon in ……

#3 Laser engravers & laser cutters

Website: gravotech.us

Key Highlights: Our laser tables are designed to engrave, mark and cut on a wide variety of materials (plastic, wood, metal, leather, glass, paper, stone) and shapes….

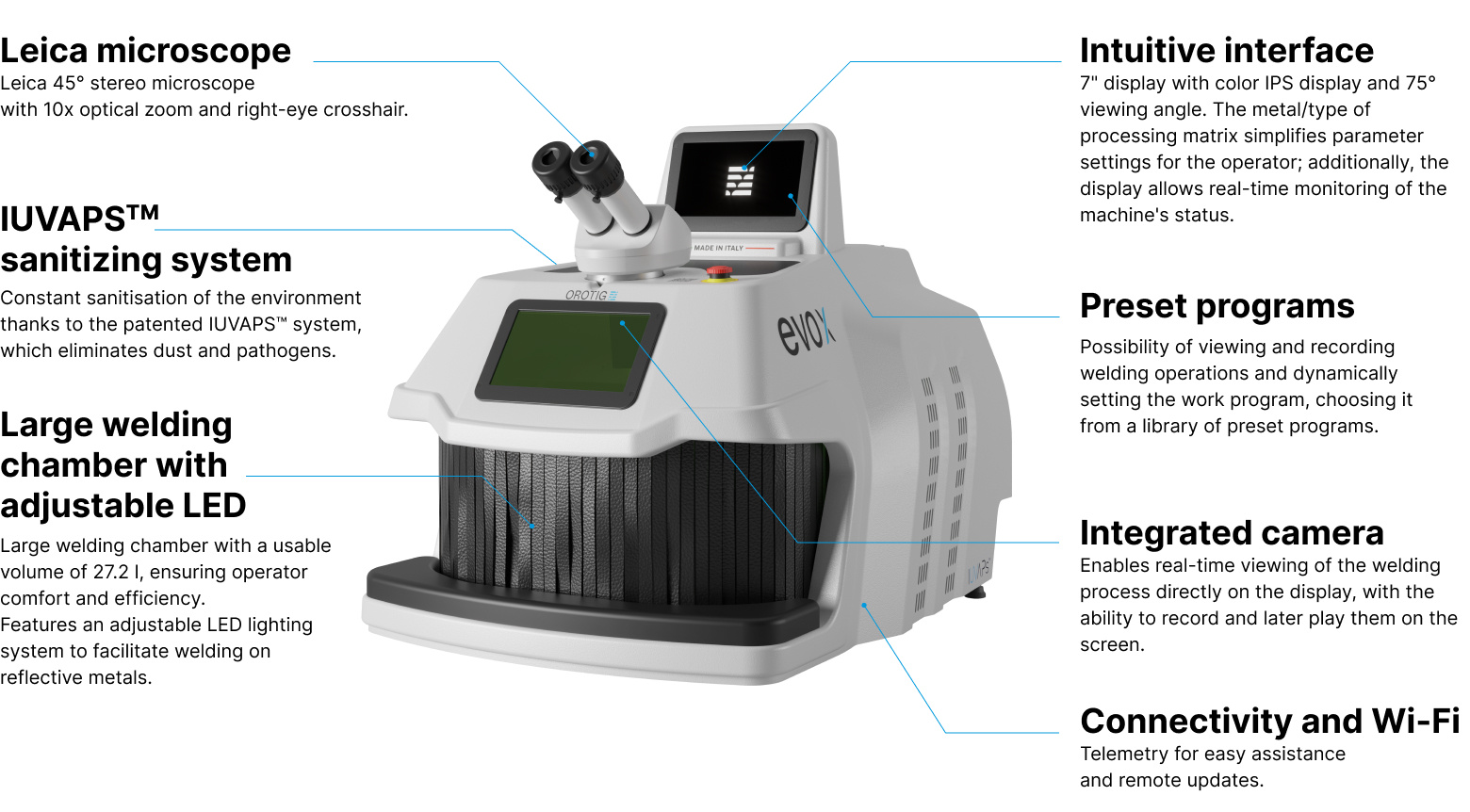

#4 Orotig: Laser Machinery

Website: orotig.com

Key Highlights: We specialise in engineering and manufacturing laser solutions for welding, engraving, casting and cutting precious and non-precious metals in the jewellery, ……

#5 Laser Equipment Supplier

Website: radianlaser.com

Key Highlights: Radian Laser Systems is a laser equipment supplier specializing in high-speed, customizable laser machinery, including fiber, CO2, and galvo lasers….

#6 Desktop Laser Engravers and Cutters for Any Budget

#7 Machinery and laser systems

Website: sisma.com

Key Highlights: More than 130 machine models for the automatic production of gold chains · Laser systems for marking, welding, cutting and engraving. · Laser systems for welding….

#8 Laser cutting and engraving machine

Website: troteclaser.com

Key Highlights: Fastest laser engraver on the market ✓ Engrave and cut acrylic, wood, leather etc. ✓ Work area of 1016 x 610 mm. Check it out now!…

#9 Best Laser Engraving Machine for Jewelry Making

Website: wecreat.com

Key Highlights: Create stunning custom jewelry with WeCreat Laser Machines. Featuring 0.00199mm ultra-fine precision, IR laser for metal engraving, and blazing speed for ……

Expert Sourcing Insights for Laser Cutting Machine For Jewelry

2026 Market Trends for Laser Cutting Machines for Jewelry

The market for laser cutting machines in the jewelry sector is poised for significant transformation by 2026, driven by technological advancements, evolving consumer demands, and a growing emphasis on sustainability and customization. Key trends shaping this specialized niche include:

Heightened Demand for Precision and Miniaturization

Jewelry design is increasingly favoring intricate, delicate patterns and micro-detailing, particularly in high-end and personalized pieces. By 2026, laser cutting machines with ultra-fine beam focus (sub-20 microns) and advanced motion control systems will dominate the market. Fiber and ultrashort-pulse lasers will gain preference for their ability to cut complex geometries in precious metals like gold, platinum, and silver without thermal distortion or material waste.

Integration of AI and Smart Manufacturing

Artificial intelligence will play a pivotal role in optimizing laser cutting processes. By 2026, AI-driven software will enable predictive maintenance, real-time quality inspection, and adaptive power modulation, reducing downtime and increasing yield. Integrated CAM (Computer-Aided Manufacturing) systems will allow seamless transitions from 3D CAD designs to automated cutting, supporting mass customization with minimal operator intervention.

Growth in On-Demand and Custom Jewelry Production

The rise of e-commerce and direct-to-consumer (D2C) jewelry brands is fueling demand for small-batch and made-to-order manufacturing. Laser cutting machines offer the flexibility needed for rapid prototyping and low-volume production without costly tooling. By 2026, compact, desktop laser systems will become more prevalent among independent designers and boutique studios, democratizing access to high-precision fabrication.

Sustainability and Material Efficiency

As environmental responsibility becomes a competitive advantage, jewelers will prioritize laser cutting for its minimal material waste compared to traditional methods. The precise kerf width of laser systems maximizes yield from expensive raw materials. Additionally, closed-loop filtration and fume extraction systems will become standard, aligning with stricter environmental regulations and ethical sourcing expectations.

Expansion of Multi-Material Capabilities

While traditionally focused on metals, next-generation laser cutters will increasingly handle mixed-material designs—such as metal combined with ceramic or engineered polymers—enabling innovative jewelry concepts. Hybrid laser systems capable of cutting, engraving, and welding will gain traction, offering end-to-end solutions for complex fabrication workflows.

Regional Market Growth and Automation Adoption

Asia-Pacific, particularly India and China, will see accelerated adoption due to expanding middle-class demand and government support for advanced manufacturing in the jewelry sector. Meanwhile, North America and Europe will focus on high-automation systems integrated into smart factories, leveraging Industry 4.0 principles to enhance productivity and traceability.

In summary, by 2026, the laser cutting machine market for jewelry will be defined by smarter, more agile, and sustainable technologies, empowering both large manufacturers and independent artisans to meet the rising demand for intricate, personalized, and ethically produced jewelry.

Common Pitfalls When Sourcing a Laser Cutting Machine for Jewelry (Quality & IP)

Sourcing a laser cutting machine for jewelry production requires careful consideration, particularly regarding quality and intellectual property (IP) protection. Overlooking these aspects can lead to significant operational, financial, and legal challenges. Here are the most common pitfalls to avoid:

Inadequate Machine Precision and Resolution

Jewelry often features intricate designs and fine details. Choosing a laser cutter with insufficient beam quality, focal precision, or motion control can result in rough edges, inaccurate cuts, and poor finish—ruining delicate pieces. Low-resolution machines may not support the micron-level accuracy required for detailed engravings or micro-piercing in fine metalwork.

Poor Material Compatibility and Processing Quality

Not all laser machines handle precious metals (gold, silver, platinum) or alloys with the same efficiency. Some systems may cause excessive heat-affected zones, oxidation, or warping, especially with thin or heat-sensitive materials. Failing to verify compatibility with your specific jewelry materials can lead to material waste, post-processing rework, and compromised product integrity.

Lack of Reputable Manufacturer or After-Sales Support

Sourcing from unknown or unreliable suppliers—especially through third-party marketplaces—increases the risk of receiving substandard equipment. Poor build quality, inconsistent performance, and limited technical support can disrupt production. Absence of local service, maintenance, or spare parts access further compounds downtime risks.

Insufficient IP Protection in Software and Design Files

Many laser systems come with proprietary software that stores design files or allows direct transfer from CAD systems. If the machine or software lacks robust security features, your original jewelry designs may be vulnerable to unauthorized access, copying, or export by technicians or third parties. Some low-cost systems may even embed backdoors or lack encryption, exposing valuable IP.

Risk of Counterfeit or Reverse-Engineered Machines

Low-cost offers, especially from regions with weak IP enforcement, may involve machines that are counterfeit versions of reputable brands or reverse-engineered without proper licensing. These units often underperform, lack safety certifications, and expose your business to legal liability if the technology infringes on patents or trademarks.

Failure to Secure Licensing and Usage Rights

When purchasing a laser system, ensure you own or have perpetual rights to use the integrated software and any design libraries. Some suppliers impose restrictive licensing terms, limiting usage or requiring recurring fees. This can become a long-term cost burden and restrict your ability to scale or transfer designs between machines.

Inadequate Data Security and Network Vulnerabilities

Connected laser systems (especially those with Wi-Fi or network capabilities) can be entry points for cyberattacks if not properly secured. Unsecured machines on your network may allow hackers to steal design files, disrupt operations, or install malware—jeopardizing both IP and business continuity.

Overlooking Compliance and Certification Requirements

Laser machines used in jewelry manufacturing must comply with safety, emissions, and electrical standards (e.g., CE, FDA, RoHS). Non-compliant machines may be seized at customs, barred from operation, or pose safety risks to operators. Additionally, using uncertified equipment can invalidate insurance coverage.

By recognizing these pitfalls early and conducting thorough due diligence—verifying machine specifications, supplier credibility, software security, and IP protections—you can safeguard both product quality and your valuable design assets.

Logistics & Compliance Guide for Laser Cutting Machines for Jewelry

Overview

Laser cutting machines used in jewelry manufacturing are precision tools that combine advanced laser technology with intricate motion control systems. Their international shipment involves navigating complex logistics and compliance requirements due to their technical nature, potential laser hazards, and electronic components. This guide outlines essential logistics and compliance considerations for importing or exporting laser cutting machines designed specifically for jewelry applications.

Classification & Harmonized System (HS) Code

Proper classification is critical for customs clearance and duty assessment. Laser cutting machines for jewelry typically fall under the following HS categories:

- HS Code 8456.20: Machines for laser working of metals, stone, or other solid materials.

- Subclassification: May vary by country depending on power output, automation level, and intended material (e.g., precious metals like gold or silver).

- Note: Ensure accurate classification based on machine specifications (e.g., fiber laser vs. CO2, wattage, CNC integration). Misclassification can lead to delays, fines, or seizure.

Export Controls & Licensing

Certain laser systems are subject to export controls due to their dual-use potential (civilian and military applications):

- ITAR/EAR (USA): Machines with high power (typically >500W) or specific technical capabilities may be regulated under the Export Administration Regulations (EAR) administered by the U.S. Department of Commerce.

- Wassenaar Arrangement: Signatory countries (including EU members, Canada, Japan, etc.) regulate lasers with potential for sensitive applications. Verify if your machine meets control thresholds.

- Action Required: Obtain an export license if required. Provide technical specifications to determine EAR99 or controlled status.

Laser Safety Compliance (IEC 60825-1)

Laser cutting machines must comply with international laser safety standards:

- IEC 60825-1: Classifies lasers by hazard level (Class 1 to Class 4). Jewelry laser cutters are typically Class 4 – high-power lasers requiring stringent safety measures.

- Requirements:

- Proper labeling with laser class, wavelength, and output power.

- Interlocks on access panels.

- Emergency stop mechanisms.

- Protective housing and beam containment.

- Certification: Machines must be certified by a notified body (e.g., TÜV, UL, CE) to confirm compliance.

CE Marking (European Union)

For entry into the EU market, the machine must meet EU directives:

- Machinery Directive 2006/42/EC: Ensures mechanical and electrical safety.

- Low Voltage Directive 2014/35/EU: Applies to electrical components.

- EMC Directive 2014/30/EU: Ensures electromagnetic compatibility.

- Laser Product Standard EN 60825-1: Aligns with IEC 60825-1.

- Documentation: Technical file, Declaration of Conformity (DoC), and CE marking are mandatory.

FCC Compliance (USA)

Electronic components and control systems must meet electromagnetic interference (EMI) standards:

- FCC Part 15, Subpart B: Regulates unintentional radiators (e.g., CNC controllers, laser drivers).

- Requirement: FCC certification or supplier declaration (SDoC) may be needed depending on the device.

- Labeling: FCC ID or SDoC statement must appear on the product or packaging.

Packaging & Shipping Requirements

Due to sensitivity and value, proper packaging is essential:

- Crate Specifications: Use wooden export crates (ISPM 15 compliant) for international shipments.

- Shock & Vibration Protection: Include foam padding, corner boards, and internal bracing.

- Moisture Protection: Use desiccants and vapor barriers to prevent condensation.

- Labeling: Mark “Fragile,” “This Side Up,” and include handling instructions.

Import Duties & Taxes

Understand local tax implications:

- Duty Rates: Vary by country (e.g., 0–5% in the EU for machinery under HS 8456).

- VAT/GST: Applicable upon import; rates vary (e.g., 20% in UK, 10% in Japan).

- Customs Broker: Recommend using a licensed broker to ensure accurate duty assessment and clearance.

Documentation Checklist

Ensure all documents are accurate and complete:

- Commercial Invoice (with full technical specs)

- Packing List

- Bill of Lading or Air Waybill

- Certificate of Origin

- CE Certificate or Test Reports (IEC 60825, EMC, etc.)

- FCC Declaration (if applicable)

- Export License (if required)

- User Manual (in destination country language)

After-Sales & Warranty Considerations

- Spare Parts Logistics: Plan for shipment of consumables (lenses, nozzles) and replacement parts.

- Service Access: Ensure qualified technicians are available locally or can travel.

- Compliance with Local Regulations: Verify that on-site installation and maintenance meet local electrical and safety codes.

Conclusion

Shipping laser cutting machines for jewelry requires meticulous attention to technical specifications, safety standards, and regulatory frameworks. By proactively addressing classification, export controls, safety certifications, and logistics, businesses can ensure smooth international transactions and compliance across global markets. Always consult with legal, customs, and regulatory experts in both origin and destination countries.

In conclusion, sourcing a laser cutting machine for jewelry production is a strategic investment that can significantly enhance precision, efficiency, and design flexibility. When selecting the right machine, key factors to consider include laser type (fiber or CO₂), power and accuracy suitable for delicate materials, software compatibility, automation features, and after-sales support. It is essential to evaluate suppliers based on reputation, technical expertise, and ability to provide training and maintenance. Additionally, balancing upfront costs with long-term benefits such as reduced material waste and increased production capacity will ensure a strong return on investment. With the right laser cutting solution, jewelry manufacturers can achieve intricate detailing, improve turnaround times, and stay competitive in a dynamic market.