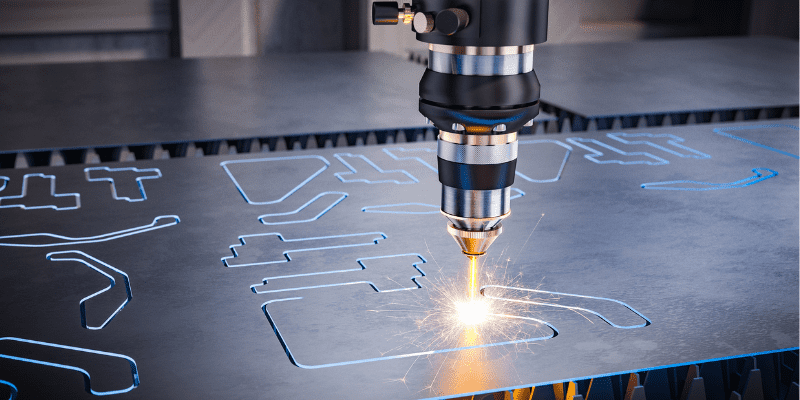

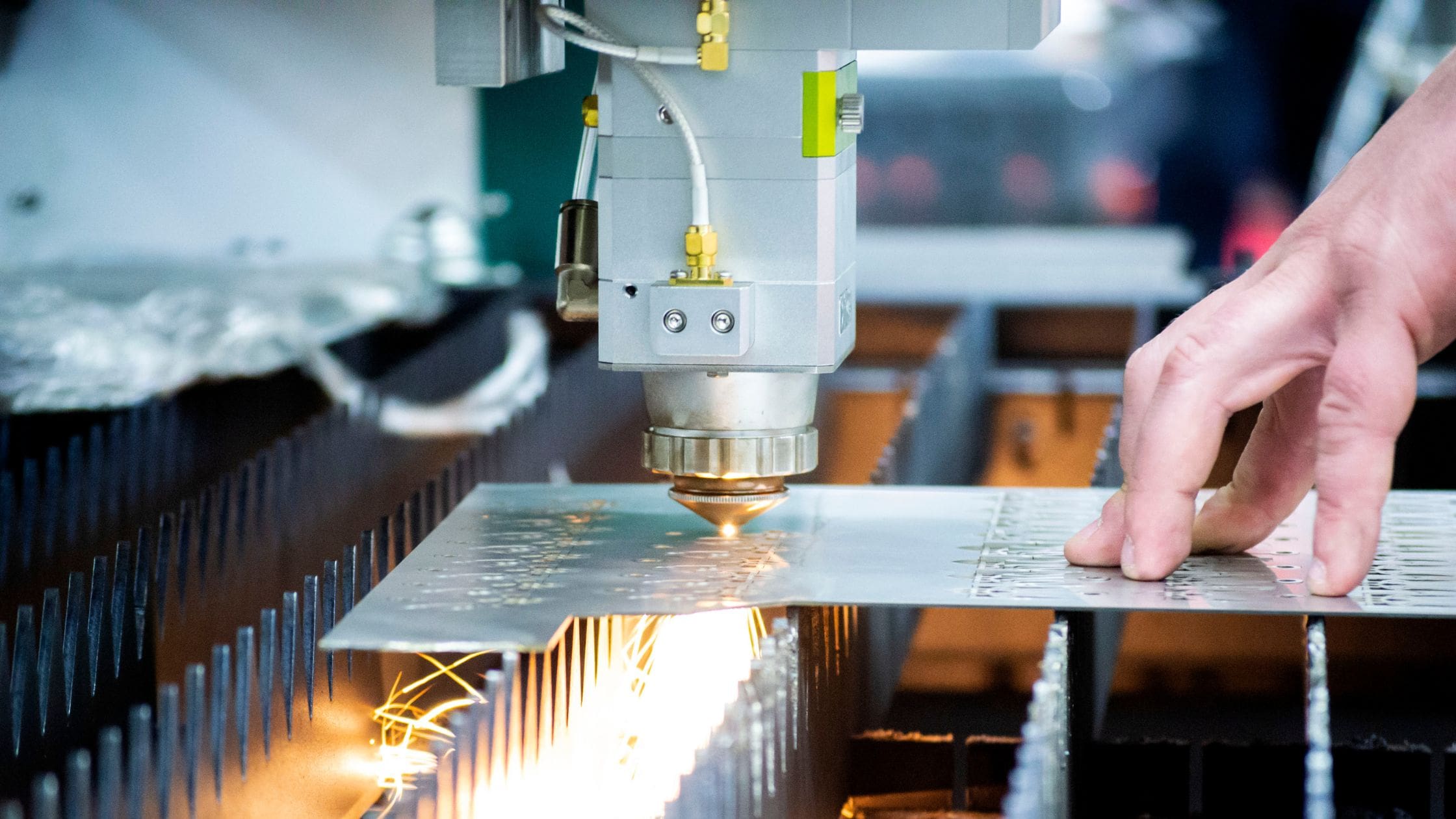

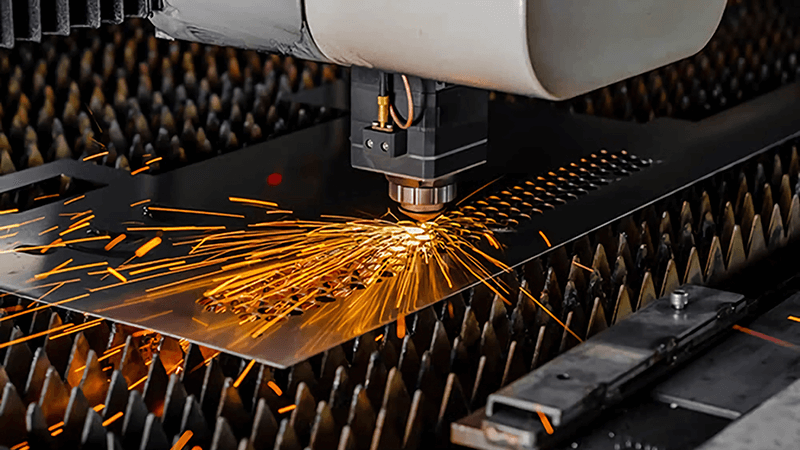

The global laser cutting equipment market is undergoing rapid expansion, driven by increasing demand for high-precision manufacturing across industries such as automotive, aerospace, and electronics. According to a 2023 report by Mordor Intelligence, the market was valued at USD 7.1 billion in 2022 and is projected to grow at a CAGR of 6.8% from 2024 to 2029, reaching an estimated USD 10.3 billion by the end of the forecast period. This growth is underpinned by advancements in fiber laser technology, automation integration, and the rising need for micron-level accuracy in component fabrication. As manufacturers increasingly prioritize repeatability, tight tolerances, and minimal thermal distortion, the competitive landscape has intensified, with select companies emerging as leaders in precision engineering and process control. The following list highlights the top 10 manufacturers renowned for their laser cutting accuracy, innovation, and technological superiority—all backed by performance data, industry certifications, and global adoption metrics.

Top 10 Laser Cutting Accuracy Manufacturers (2026 Audit Report)

(Ranked by Factory Capability & Trust Score)

#1 Laser Processing Solutions

Website: novantaphotonics.com

Key Highlights: Discover laser processing solutions by Novanta, experts in advanced Laser technology. Learn more about our industrial & medical laser solutions….

#2 Focus on laser

Founded: 1996

Website: hanslaser.net

Key Highlights: Han’s Laser Technology Industry Group Co., Ltd, a public company which was established in 1996, has now become the flagship of Chinese national laser ……

#3 EAGLE Lasers

Website: eagle-group.eu

Key Highlights: EAGLE is the producer of the fastest and most efficient laser cutters in the world. Discover our innovative fiber laser products and matching software!…

#4 Fiber Laser Cutting Machine and CO2 Laser Cutter Manufacturer …

Website: gwklaser.com

Key Highlights: Leading manufacturer of laser cutting machine, CO2 laser cutter, laser welding machine, laser bending machine and laser cleaning machine, etc….

#5 Precision in laser processing & metrology

Website: precitec.com

Key Highlights: Precitec offers solutions for laser cutting, welding, metrology and additive manufacturing – leading in precision, quality and process reliability….

#6 IPG Photonics

Website: ipgphotonics.com

Key Highlights: IPG Photonics manufactures high-performance fiber lasers, amplifiers, and laser systems for diverse applications and industries. Discover your solution….

#7 Laser Cutting, Engraving & Marking Machines

Website: thunderlaser.com

Key Highlights: Thunder Laser offers high-quality, reliable laser machines to meet the needs of a variety of industries. ThunderLaser has become a well-recognized icon in ……

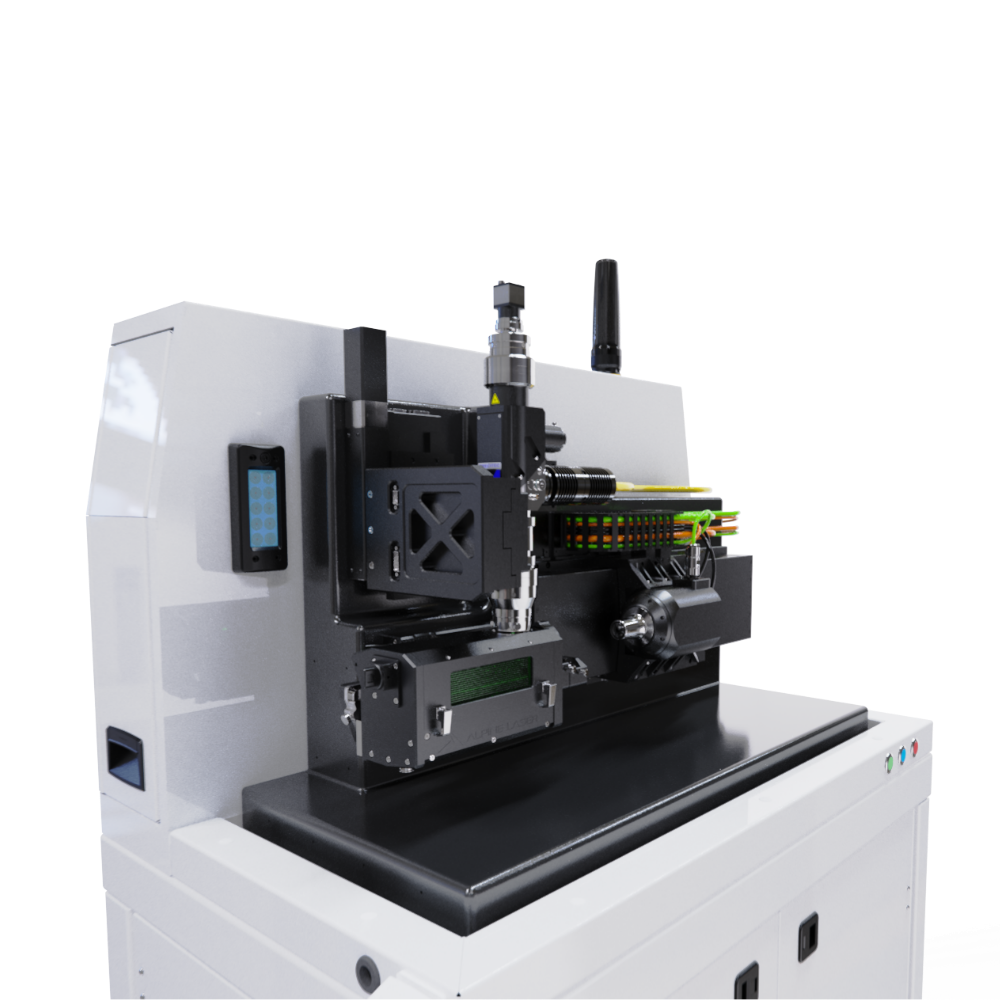

#8 Alpine Laser

Website: alpinelaser.com

Key Highlights: The Medicut PRO Series Laser Workstations offer high performance precision laser tube cutting workstations for small diameter interventional tubular components….

#9 Vytek Laser Systems

Website: vytek.com

Key Highlights: Vytek designs, builds, and sells a complete line of laser solutions for cleaning, engraving, marking, cutting, and welding, built to exacting standards….

#10 Laser Cutting Services

Website: techfoundry.ucdavis.edu

Key Highlights: Laser cutting is a precise subtractive manufacturing process that uses a high-powered laser to cut (through or engrave) a variety of sheet- ……

Expert Sourcing Insights for Laser Cutting Accuracy

2026 Market Trends for Laser Cutting Accuracy

As the manufacturing industry advances toward greater precision and efficiency, laser cutting accuracy is emerging as a critical competitive differentiator. By 2026, several key trends are expected to shape the landscape of laser cutting accuracy, driven by technological innovation, evolving industrial demands, and the integration of smart manufacturing systems.

1. Advancements in Beam Quality and Control

One of the most significant drivers of improved accuracy is the development of ultra-high beam quality lasers, particularly fiber and ultrafast (pulsed) lasers. By 2026, wider adoption of single-mode fiber lasers will enable tighter focus spots—often below 20 microns—allowing for micron-level cutting precision. Enhanced beam shaping technologies and adaptive optics will further refine edge quality and minimize thermal distortion, especially in thin and heat-sensitive materials.

2. Integration of AI and Real-Time Monitoring

Artificial intelligence and machine learning are being increasingly embedded into laser cutting systems to predict and correct deviations in real time. By 2026, predictive maintenance algorithms and closed-loop feedback systems—using sensors for temperature, vibration, and plasma emission—will enable dynamic adjustments during cutting, ensuring sustained accuracy across long production runs. This trend supports the transition to Industry 5.0, where human-machine collaboration emphasizes both precision and adaptability.

3. Demand for Micro and Nano-Scale Precision

Growing applications in medical devices, electronics, and semiconductor packaging are pushing the need for sub-micron cutting accuracy. Laser micromachining with ultrafast (femtosecond and picosecond) lasers is expected to gain traction, offering minimal heat-affected zones and high repeatability. These systems will cater to industries requiring intricate geometries and clean edges, further elevating accuracy expectations across the market.

4. Enhanced Motion Control and Positioning Systems

Improvements in linear motor drives, high-resolution encoders, and active vibration damping will contribute to mechanical precision in laser cutting machines. By 2026, cutting platforms with nanometer-level positioning accuracy and sub-micron repeatability will become standard in high-end systems, reducing cumulative errors and enhancing dimensional consistency.

5. Standardization and Metrology Integration

As accuracy becomes a key performance indicator, standardized testing protocols and in-process metrology will become more prevalent. Integrated non-contact measurement systems—such as machine-vision inspection and laser interferometry—will provide real-time validation of cut quality, enabling immediate corrections and traceability for quality assurance, especially in regulated industries like aerospace and automotive.

In summary, the 2026 market for laser cutting accuracy will be defined by smarter, faster, and more precise systems. The convergence of improved laser sources, intelligent software, and advanced mechanics will enable manufacturers to achieve unprecedented levels of accuracy, supporting innovation across high-tech and traditional manufacturing sectors alike.

Common Pitfalls in Sourcing Laser Cutting Accuracy (Quality, IP)

When sourcing laser cutting services, overlooking critical factors related to accuracy, quality, and intellectual property (IP) protection can lead to costly delays, product failures, and legal risks. Below are common pitfalls to avoid:

Underestimating Tolerance Requirements

Many buyers fail to clearly define or communicate required dimensional tolerances. Assuming standard industry tolerances (e.g., ±0.1 mm) will suffice without verifying specific application needs can result in parts that don’t fit or function as intended. Always specify exact tolerance requirements and confirm the supplier’s capability to consistently meet them.

Ignoring Material-Specific Cutting Behavior

Different materials (e.g., stainless steel, aluminum, acrylic) react uniquely to laser cutting, affecting edge quality, kerf width, and heat-affected zones. Sourcing without considering material properties may lead to warping, burring, or inconsistent cuts. Ensure the supplier has proven experience with your specific material.

Overlooking Machine Calibration and Maintenance

Laser cutting accuracy depends heavily on machine condition. Suppliers using poorly maintained or uncalibrated equipment may deliver inconsistent results. Inquire about their maintenance schedules, calibration records, and quality control processes before committing.

Failing to Request Sample Parts or First-Article Inspection

Relying solely on a supplier’s claims without physical validation is risky. Always request sample parts or conduct a first-article inspection (FAI) to verify dimensional accuracy, edge quality, and surface finish before full production.

Not Verifying Quality Assurance Processes

A lack of documented quality control procedures—such as in-process inspections, statistical process control (SPC), or ISO certifications—increases the risk of defects. Confirm that the supplier implements robust QA protocols and can provide traceable inspection reports.

Neglecting Intellectual Property Protection

Sharing design files without proper IP safeguards exposes your innovations to misuse or unauthorized reproduction. Avoid working with suppliers who don’t sign non-disclosure agreements (NDAs) or lack secure data handling practices. Always clarify IP ownership in contracts.

Assuming All Lasers Deliver the Same Precision

CO2, fiber, and Nd:YAG lasers vary in precision, speed, and suitability for materials. Sourcing based on price alone without matching laser type to your application can compromise cut quality. Ensure the supplier uses the appropriate laser technology for your needs.

Overlooking Post-Processing Requirements

Laser cutting may leave burrs, oxidation, or heat marks that require post-processing (e.g., deburring, polishing). Failing to account for these steps can affect final part quality and delivery timelines. Discuss finishing needs upfront and confirm the supplier can handle or coordinate them.

By proactively addressing these pitfalls, buyers can ensure accurate, high-quality laser-cut parts while protecting their intellectual property and minimizing supply chain risks.

Logistics & Compliance Guide for Laser Cutting Accuracy

Ensuring laser cutting accuracy involves not only precise machinery and skilled operators but also well-managed logistics and adherence to regulatory and quality compliance standards. This guide outlines key considerations across the supply chain and compliance landscape to maintain consistent, high-precision laser cutting outcomes.

Equipment Calibration and Maintenance

Regular calibration of laser cutting machines is essential to maintain dimensional accuracy. Implement a documented maintenance schedule that includes alignment checks, lens and nozzle inspections, and beam quality assessments. Calibration must align with international standards such as ISO 9001 or ANSI Z540 to ensure traceability and compliance. Maintenance logs should be kept up to date and accessible for audit purposes.

Material Handling and Storage

Proper logistics begin with correct material storage and handling. Sheet metals and other substrates must be stored in a controlled environment—free from moisture, dust, and temperature fluctuations—to prevent warping or contamination that could affect cutting precision. Materials should be clearly labeled with batch numbers, material grade, and thickness to ensure traceability and correct setup parameters.

Incoming Material Inspection

All incoming materials must undergo inspection to verify compliance with specified tolerances and material certifications (e.g., mill test reports). Use precision measuring tools such as micrometers and surface profilometers to confirm thickness and flatness. Non-conforming materials should be quarantined and reported following internal quality procedures.

Process Control and Documentation

Implement a standardized operating procedure (SOP) for laser cutting operations, including job setup, parameter validation (power, speed, assist gas), and alignment procedures. Document each production run with settings, operator ID, date, and batch number. Use statistical process control (SPC) methods to monitor cutting accuracy over time and detect deviations early.

Quality Assurance and Testing

Conduct regular quality checks using calibrated inspection tools such as coordinate measuring machines (CMM), optical comparators, or laser scanners. Perform first-article inspections (FAI) for new designs or significant process changes, in accordance with AS9102 (for aerospace) or PPAP (in automotive). Retain inspection records for compliance audits and customer requests.

Regulatory and Industry Standards Compliance

Ensure operations comply with relevant standards, such as:

- ISO 9001: Quality management systems

- ISO 3888: Dimensional accuracy for sheet metal parts

- OSHA 29 CFR 1910.133: Eye and face protection for laser operations

- ANSI Z136.1: Safe use of lasers

- REACH and RoHS: When processing coated or treated materials

Regular internal and external audits should verify adherence to these standards.

Packaging, Labeling, and Shipping

After cutting, parts must be packaged to prevent deformation, scratching, or contamination during transit. Use protective materials such as foam inserts or edge protectors. Label packages with part numbers, revision levels, quantity, and handling instructions. Include compliance labels where necessary (e.g., CE marking, RoHS symbol).

Training and Personnel Certification

Operators and quality inspectors must be trained and certified in laser safety, equipment operation, and quality control procedures. Maintain training records and ensure refresher courses are conducted annually or per regulatory requirements.

Traceability and Record Retention

Establish a traceability system linking raw materials, production batches, inspection results, and shipping data. Digital logs or ERP systems can streamline this process. Retain records for a minimum of 7–10 years depending on industry requirements (e.g., aerospace, medical devices).

By integrating rigorous logistics protocols with strong compliance frameworks, organizations can ensure that laser cutting accuracy is consistently achieved and verified across the production lifecycle.

Conclusion on Sourcing Laser Cutting Accuracy:

Achieving high accuracy in laser cutting largely depends on selecting the right equipment, materials, and service providers. When sourcing laser cutting services, precision is influenced by factors such as laser type (CO₂, fiber, or crystal), machine calibration, material properties, operator expertise, and post-processing techniques. To ensure optimal accuracy, it is essential to partner with reputable suppliers who utilize advanced laser technology, maintain rigorous quality control standards, and offer detailed documentation such as tolerance reports and first-article inspections. Additionally, clear communication of design specifications, proper file preparation (e.g., vector formats with precise dimensions), and material compatibility assessments are critical steps in the sourcing process. Ultimately, prioritizing precision-focused vendors with proven capabilities and certifications will result in consistent, high-quality laser-cut components that meet tight tolerances and project requirements.