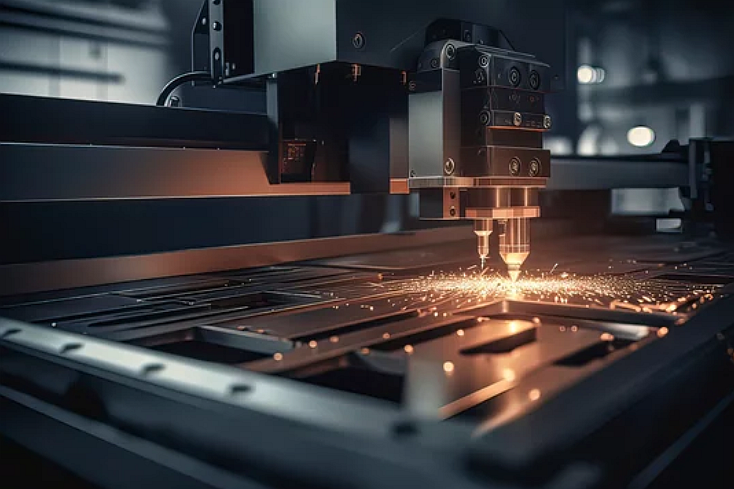

The global laser cutting CNC machine market is experiencing robust growth, driven by increasing demand for precision manufacturing across industries such as automotive, aerospace, and electronics. According to Mordor Intelligence, the global laser cutting machine market was valued at USD 3.85 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 7.4% from 2024 to 2029. This expansion is fueled by advancements in fiber laser technology, automation integration, and rising adoption in emerging economies. Additionally, Grand View Research highlights that the broader computer numerical control (CNC) machinery market is expected to grow steadily due to industrial digitization and the shift toward smart manufacturing. As competition intensifies, a select group of manufacturers has emerged at the forefront, combining innovation, reliability, and scalability to meet evolving industrial demands. Here, we present a data-driven look at the top 10 laser cut CNC machine manufacturers leading the charge in this high-growth sector.

Top 10 Laser Cut Cnc Machine Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Mazak Leading Laser Machine Manufacturer

Domain Est. 1998

Website: mazak.com

Key Highlights: Mazak provides products and solutions that can support a wide range of parts machining processes, such as high-speed and high-accuracy machines….

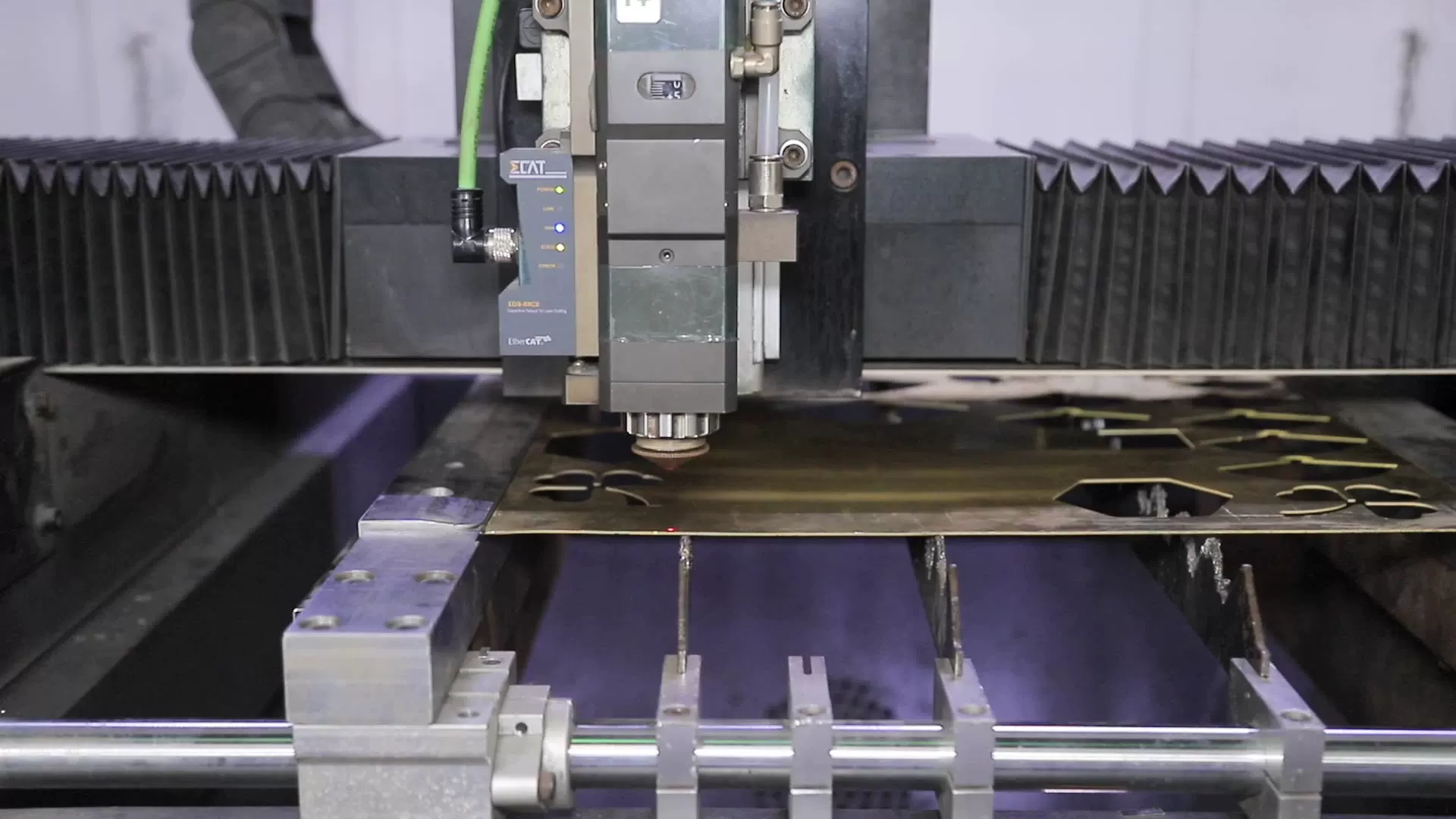

#2 Laser Technologies Inc

Domain Est. 1998

Website: lasertechnologiesinc.com

Key Highlights: Laser Technologies is a fully integrated turnkey manufacturer specializing in laser cutting and stamping laminations for the motor and generator industry as ……

#3 FlexMax Laser & CNC Machines for Cutting Engraving Welding and …

Domain Est. 1998

Website: flexmax.com

Key Highlights: Free delivery 30-day returnsFlexMax manufactures and sells industrial-grade laser and CNC machines for cutting, engraving, and welding. Our systems deliver precision, consistency, …

#4 BLM GROUP

Domain Est. 2000

Website: blmgroup.com

Key Highlights: BLM GROUP is a world leading manufacturer of high precision and high performance laser cutting and sawing machines, CNC bending and end-forming machines….

#5 Bodor

Domain Est. 2003

Website: bodor.com

Key Highlights: Bodor laser is a fiber laser cutting machine manufacturer specialized in cnc fiber laser cutting machine equipment with integrating development, production, ……

#6 Fiber Laser Cutting Machine and CO2 Laser Cutter Manufacturer …

Domain Est. 2016

Website: gwklaser.com

Key Highlights: Leading manufacturer of laser cutting machine, CO2 laser cutter, laser welding machine, laser bending machine and laser cleaning machine, etc….

#7 Wattsan

Domain Est. 2016

Website: wattsan.com

Key Highlights: Wattsan is a manufacturer of laser and cnc milling machines of European quality at affordable prices with worldwide delivery….

#8 Langmuir Systems

Domain Est. 2017

Website: langmuirsystems.com

Key Highlights: Powerful, affordable, and well-supported CNC Machines for hobbyists, small business owners, educational institutions, and industrial facilities….

#9 CNC Fiber LASER Metal Cutting Machines

Domain Est. 1999

Website: piranhafab.com

Key Highlights: CNC Fiber LASER Metal Cutting Machines. starting at $132,900. Piranha Whitney CNC Fiber Lasers deliver unmatched cut quality and reliability — backed by U.S. ……

#10 Full Spectrum Laser

Domain Est. 2010

Website: fslaser.com

Key Highlights: 7–15 day delivery 30-day returnsFull Spectrum Laser is a US based company that designs, manufactures, and sells powerful and affordable laser cutting & laser engraving products….

Expert Sourcing Insights for Laser Cut Cnc Machine

2026 Market Trends for Laser Cut CNC Machines

Rising Demand Across Key Industries

By 2026, the global market for laser cut CNC machines is expected to experience accelerated growth, driven by increasing adoption in industries such as automotive, aerospace, electronics, and medical device manufacturing. The need for high-precision, repeatable cutting solutions continues to fuel demand, especially as manufacturers shift toward automation and smart factory environments. Lightweight material usage in electric vehicles (EVs) and advanced aerospace components will further boost the need for fiber and CO₂ laser cutting systems capable of handling composites, aluminum, and high-strength alloys.

Technological Advancements and Smart Integration

Laser cut CNC machines in 2026 will increasingly feature AI-powered predictive maintenance, real-time error correction, and IoT-enabled remote monitoring. Integration with digital twin technology and cloud-based platforms will allow manufacturers to simulate cutting processes, optimize workflows, and reduce material waste. Additionally, hybrid CNC systems combining laser cutting with additive manufacturing or multi-axis machining are expected to gain traction, offering greater versatility and reducing production cycles.

Growth of Fiber Lasers and High-Power Systems

Fiber laser technology is projected to dominate the market by 2026 due to its superior energy efficiency, lower maintenance costs, and ability to cut reflective metals like copper and brass. High-power fiber lasers (10 kW and above) are becoming standard in heavy-duty industrial applications, enabling faster cutting speeds and thicker material processing. This shift is particularly evident in shipbuilding, heavy machinery, and large-scale fabrication sectors seeking improved throughput and operational efficiency.

Regional Expansion and Competitive Landscape

Asia-Pacific will remain the largest market for laser cut CNC machines, led by China, India, and South Korea, where rapid industrialization and government support for advanced manufacturing are strong growth drivers. North America and Europe will see steady growth, supported by reshoring trends and investments in Industry 4.0 infrastructure. The competitive landscape will intensify, with key players focusing on R&D, strategic partnerships, and expansion into emerging markets to capture market share.

Sustainability and Energy Efficiency Focus

Environmental regulations and corporate sustainability goals will push manufacturers to adopt energy-efficient laser systems. By 2026, machine designs will emphasize reduced power consumption, recyclable components, and greener cooling systems. Additionally, advancements in beam delivery and cutting head technology will minimize material waste and improve overall resource utilization, aligning with circular economy principles.

Conclusion

The laser cut CNC machine market in 2026 will be shaped by technological innovation, industry-specific demands, and a strong push toward automation and sustainability. As manufacturers seek greater precision, speed, and flexibility, laser cutting systems will continue to evolve, becoming smarter, more efficient, and integral to modern production ecosystems.

Common Pitfalls When Sourcing Laser Cut CNC Machines (Quality and IP)

Sourcing a laser cutting CNC machine involves significant investment and long-term operational impact. Overlooking key quality and intellectual property (IP) considerations can lead to costly mistakes. Below are the most common pitfalls to avoid.

Poor Build Quality and Component Selection

Many suppliers, especially lower-cost offshore manufacturers, use substandard materials and components to reduce prices. This includes inferior linear rails, stepper motors instead of servo systems, or low-grade laser sources. These compromises lead to reduced accuracy, shorter machine lifespan, higher maintenance, and unplanned downtime. Always verify the specifications of critical components and request third-party certifications or test reports.

Inadequate Laser Source Quality and Longevity

The laser source is the heart of the machine. Sourcing from suppliers using unbranded or reconditioned laser tubes or fiber lasers can result in inconsistent cutting performance, frequent failures, and high replacement costs. Ensure the laser source is from a reputable manufacturer (e.g., IPG, Raycus, or SPI) and confirm warranty terms and expected operational life.

Lack of Real-World Performance Validation

Suppliers often provide idealized specifications based on controlled conditions. Without independent verification or on-site testing, actual performance—especially cutting speed, precision, and material compatibility—may fall short. Request live demonstrations with your target materials and conduct factory acceptance tests before final purchase.

Hidden Software Limitations and Licensing Issues

Some machines come with proprietary control software that may lack essential features, restrict file formats, or require expensive annual licensing. Worse, the software may use unlicensed third-party code, exposing you to legal risks. Audit software capabilities, check for open or standard protocols (e.g., support for LightBurn or compatibility with common CAD/CAM tools), and ensure compliance with licensing agreements.

Intellectual Property (IP) Infringement Risks

Low-cost suppliers sometimes replicate designs, control systems, or software from established brands without authorization. Purchasing such machines can expose your business to IP litigation, especially in regulated markets. Perform due diligence on the supplier’s design origin, request proof of IP ownership, and avoid machines that appear suspiciously similar to well-known models.

Incomplete or Poor Technical Documentation

Lack of comprehensive manuals, wiring diagrams, or maintenance guides increases dependency on the supplier for troubleshooting. This becomes critical if support is unresponsive. Ensure full documentation is provided in your language and covers all subsystems, including safety protocols and calibration procedures.

Inadequate After-Sales Support and Service Network

Even high-quality machines require maintenance and repairs. Sourcing from suppliers without local technicians or spare parts inventory leads to prolonged downtime. Confirm the availability of technical support, response times, and access to replacement parts—especially for consumables and critical components.

Non-Compliance with Safety and Regulatory Standards

Laser machines must meet regional safety standards (e.g., CE, FDA, IEC 60825). Some suppliers provide machines that appear compliant but lack proper certification or safety interlocks. This poses safety risks and can result in legal or insurance complications. Always verify compliance certificates and conduct independent safety audits if necessary.

Avoiding these pitfalls requires thorough vetting, clear contractual terms, and, when possible, legal review of IP and compliance claims. Prioritize transparency, proven performance, and long-term support over initial cost savings.

Logistics & Compliance Guide for Laser Cut CNC Machine

Import Regulations and Documentation

When importing a laser-cut CNC machine, compliance with the destination country’s regulations is essential. Required documentation typically includes a commercial invoice, bill of lading, packing list, and certificate of origin. Additionally, some countries may require a customs declaration form and import license. Ensure that the machine complies with international trade standards such as Incoterms (e.g., FOB, CIF) to clarify responsibilities between buyer and seller.

Safety and Technical Standards

Laser-cut CNC machines must meet specific safety and technical standards to be legally operated. Key certifications include CE (European Union), FCC (United States), and UKCA (United Kingdom). These certifications confirm compliance with electromagnetic compatibility, laser safety (IEC 60825), and machinery directives (e.g., EU Machinery Directive 2006/42/EC). Verify that the machine includes proper safety enclosures, emergency stop functions, and adequate ventilation systems.

Electrical and Operational Requirements

Ensure compatibility with local electrical specifications such as voltage (e.g., 110V or 220V), phase (single or three-phase), and frequency (50Hz or 60Hz). The laser CNC machine should come with appropriate power adaptors or transformers if needed. Confirm that the facility has sufficient power capacity, grounding, and circuit protection to support safe operation.

Laser Safety and Regulatory Compliance

Laser-cutting machines are subject to strict laser safety regulations due to the risk of eye and skin exposure. Compliance with ANSI Z136.1 (U.S.) or IEC 60825 (International) standards is mandatory. Operators must have access to appropriate personal protective equipment (PPE), including laser safety goggles, and the workspace should be equipped with warning signs and interlocks. Registration with national laser safety authorities may be required in some jurisdictions.

Environmental and Emissions Controls

Laser cutting produces fumes and particulate matter that must be managed to meet environmental and workplace health standards. Install a certified fume extraction or filtration system compliant with OSHA (U.S.) or local occupational safety regulations. Ensure proper disposal of waste materials, including metal shavings and filter residues, in accordance with environmental protection laws.

Transportation and Handling

Due to their size and weight, laser-cut CNC machines require specialized logistics planning. Use palletized crating and secure packaging to prevent damage during transit. Coordinate freight services capable of handling heavy machinery, including forklift or crane unloading at the destination. Plan for clear access routes and adequate space for installation upon delivery.

Installation and Commissioning

Installation should be performed by qualified technicians in accordance with the manufacturer’s guidelines. Verify machine leveling, alignment, and calibration. Conduct a full operational test to ensure all safety systems and cutting functions are working correctly. Maintain records of commissioning for compliance audits and warranty purposes.

Training and Operational Compliance

Provide certified training for all operators and maintenance personnel. Training should cover machine operation, emergency procedures, maintenance schedules, and safety protocols. Document training completion to demonstrate compliance with workplace safety regulations such as OSHA or local labor laws.

Maintenance and Recordkeeping

Implement a preventive maintenance program as specified by the manufacturer. Keep detailed logs of inspections, repairs, and component replacements. Retain compliance documentation, calibration records, and safety certifications for audit readiness and regulatory inspections.

Export Controls and Dual-Use Considerations

Be aware that certain high-powered laser or precision CNC equipment may be subject to export control regulations (e.g., EAR in the U.S. or EU Dual-Use Regulation). Verify if your machine contains components classified as dual-use technology and obtain necessary export licenses when shipping internationally.

Conclusion for Sourcing a Laser Cut CNC Machine

Sourcing a laser cutting CNC machine is a strategic decision that can significantly enhance manufacturing capabilities, precision, and operational efficiency. After careful evaluation of technical specifications, budget constraints, supplier reliability, and long-term maintenance support, selecting the right machine involves balancing performance with cost-effectiveness.

Key considerations such as cutting capacity, laser power, material compatibility, automation features, software integration, and after-sales service play a crucial role in ensuring the chosen machine meets current production demands and allows for future scalability. Additionally, evaluating warranty terms, training availability, and local technical support helps minimize downtime and ensures smooth integration into existing workflows.

Ultimately, investing in a high-quality laser cutting CNC machine from a reputable supplier not only improves product quality and throughput but also provides a strong return on investment through increased productivity and reduced material waste. A well-informed sourcing decision positions the business for long-term competitiveness in an evolving manufacturing landscape.