The global laser cut brass manufacturing industry is experiencing robust growth, driven by rising demand for precision-engineered components in sectors such as electronics, architecture, automotive, and decorative design. According to Grand View Research, the global laser cutting market was valued at USD 9.4 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 7.3% from 2023 to 2030. A key contributor to this growth is the increasing adoption of laser cutting in niche metal applications, particularly with brass—an alloy prized for its malleability, corrosion resistance, and aesthetic appeal. Mordor Intelligence further supports this trend, noting that demand for customized metal fabrications in emerging economies and advancements in CNC and fiber laser technologies are accelerating market expansion. Within this evolving landscape, specialized manufacturers excelling in high-precision laser cut brass components are gaining strategic importance. The following list highlights the top nine manufacturers leading the industry through innovation, quality, and technical expertise.

Top 9 Laser Cut Brass Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 BLM GROUP

Domain Est. 2000

Website: blmgroup.com

Key Highlights: BLM GROUP is a world leading manufacturer of high precision and high performance laser cutting and sawing machines, CNC bending and end-forming machines….

#2 Laserfab Inc.

Domain Est. 2001

Website: laserfabusa.com

Key Highlights: Site Map. Laser Cutting · Plasma Cutting · Brake Forming · Machining · Fabrication · Employment Opportunities · Vote Armor. Business Hours. Puyallup: Mon. – Fri ……

#3 Laser Photonics

Domain Est. 2001

Website: laserphotonics.com

Key Highlights: Laser Photonics manufactures reliable, safe, and eco-friendly Laser Cleaning, Laser Cutting, Laser Engraving, Laser Marking, and Laser Welding solutions….

#4 PBZ Manufacturing

Domain Est. 2006

Website: pbzmfg.com

Key Highlights: PBZ Manufacturing is a full service contract manufacturer located in Lititz, PA. We offer one-stop shop capabilities. Contact us to start your project!…

#5 Laser Cutting Brass

Domain Est. 1998

Website: a-laser.com

Key Highlights: Brass, a gold-colored metal, finds extensive utility across a variety of applications, from decorative embellishments to uses like plumbing fixtures….

#6 Metal Etch And Laser Cutting Services

Domain Est. 1999

Website: metaletching.com

Key Highlights: Metal etching and laser cutting services for thin metal parts. Guaranteed burr free! Learn about our new Our Hybrid Etch-Laser Process, H.E.L.P.™️!…

#7 Precision Laser Cutting & Custom Metal Fabrication CT

Domain Est. 2008

Website: kammetal.com

Key Highlights: Whether you need laser cutting, custom sheet metal fabrication, or complete metal cutting services, we are your trusted partner for high-quality results in CT….

#8 Full Spectrum Laser

Domain Est. 2010

#9 Brass Laser Cutting Services

Domain Est. 2015

Website: xometry.com

Key Highlights: Xometry offers the highest-quality brass laser cutting services, which are able to create precise and attractive components for a multitude of applications….

Expert Sourcing Insights for Laser Cut Brass

H2: Projected 2026 Market Trends for Laser Cut Brass

The global market for laser cut brass is poised for steady growth through 2026, driven by advancements in precision manufacturing, rising demand in decorative and industrial applications, and the increasing adoption of automation in metal fabrication. Key trends shaping the laser cut brass industry in 2026 include:

-

Growth in Architectural and Interior Design Applications

Laser cut brass is increasingly favored in high-end architectural features, decorative panels, and luxury interior design due to its aesthetic appeal, corrosion resistance, and ability to achieve intricate patterns. The demand for customized façades, room dividers, and lighting fixtures in commercial and residential spaces is expected to surge, particularly in regions like North America, Europe, and the Middle East. -

Expansion in Electronics and Industrial Components

Brass’s excellent electrical conductivity and machinability make it ideal for precision components in electronics, telecommunications, and automotive sectors. Laser cutting enables high-tolerance parts for connectors, relays, and shielding components. As the electronics industry continues to miniaturize and innovate, demand for laser-processed brass elements is projected to increase. -

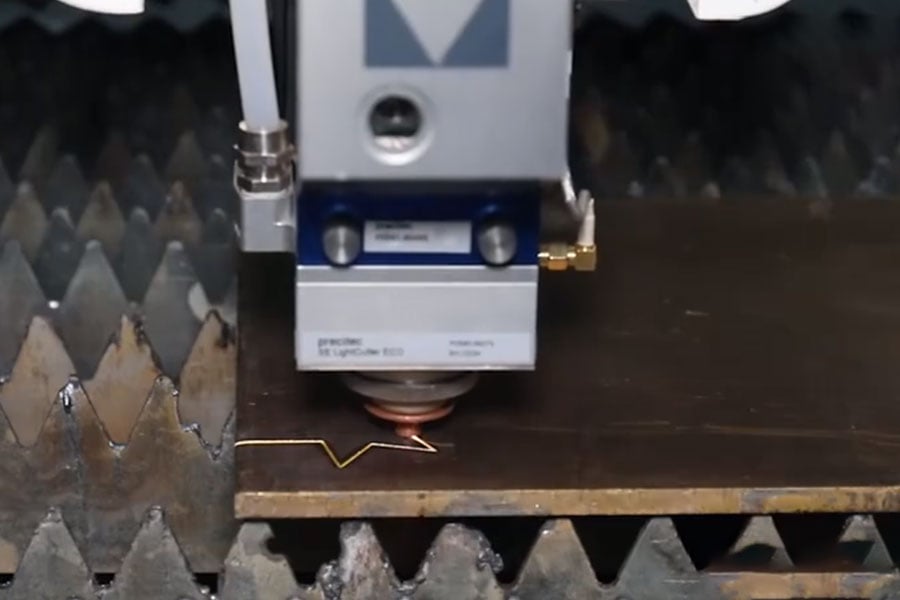

Adoption of Fiber Laser Technology

By 2026, fiber laser systems are expected to dominate the brass cutting market due to their superior precision, energy efficiency, and lower maintenance costs compared to CO₂ lasers. These systems offer faster processing speeds and cleaner cuts on reflective materials like brass, reducing material waste and improving throughput. -

Sustainability and Material Efficiency

Environmental regulations and a growing emphasis on sustainable manufacturing are driving the adoption of laser cutting, which generates minimal waste and allows for nesting optimization. Recycled brass is increasingly used in laser cutting applications, aligning with circular economy principles and reducing the carbon footprint of production. -

Regional Market Shifts and Manufacturing Localization

Asia-Pacific, particularly China and India, is expected to remain a major hub for both brass production and laser cutting services due to lower manufacturing costs and growing domestic demand. Meanwhile, nearshoring trends in North America and Europe may boost local fabrication centers offering quick-turn, custom laser cut solutions. -

Integration with Digital Design and Industry 4.0

The integration of CAD/CAM software, AI-driven design optimization, and IoT-enabled laser systems is enhancing customization capabilities and production efficiency. By 2026, smart factories will increasingly use real-time data analytics to optimize laser parameters for brass, improving consistency and reducing downtime. -

Price Volatility and Supply Chain Considerations

Fluctuations in copper prices—brass being a copper-zinc alloy—may impact material costs. However, advancements in laser cutting efficiency and tighter process controls are helping manufacturers mitigate cost pressures through improved yield and reduced scrap rates.

In summary, the 2026 landscape for laser cut brass will be characterized by technological innovation, heightened customization, and expanding applications across industries. Companies investing in advanced laser systems, sustainable practices, and digital integration are likely to gain a competitive edge in this evolving market.

Common Pitfalls When Sourcing Laser Cut Brass (Quality & IP)

Sourcing laser-cut brass components can be efficient and cost-effective, but several pitfalls related to quality and intellectual property (IP) can undermine your project if not carefully managed. Being aware of these issues helps ensure reliable supply and protects your business interests.

Inconsistent Material Quality

Brass composition varies (e.g., C26000, C36000), and suppliers may use substandard or non-certified alloys. This leads to inconsistent color, machinability, and mechanical properties. Always specify alloy type and request material certifications to verify compliance.

Poor Dimensional Accuracy

Laser cutting heat can cause warping or thermal distortion in thin brass sheets. Inadequate fixturing or incorrect laser parameters result in parts that don’t meet tight tolerances. Confirm the supplier’s capability for precision work and request first-article inspections (FAI) when accuracy is critical.

Surface Finish and Oxidation Issues

Brass is prone to oxidation, especially after laser cutting, which can leave darkened edges or residue. Some suppliers skip post-processing like tumbling or polishing, affecting aesthetics and function. Clearly define surface finish requirements and inquire about deburring and cleaning processes.

Inadequate IP Protection

Sharing detailed CAD files with overseas or third-party suppliers increases the risk of design theft or unauthorized replication. Suppliers may reverse-engineer your parts or sell them to competitors. Use non-disclosure agreements (NDAs), watermark digital files, and work with trusted partners to safeguard your IP.

Lack of Traceability and Documentation

Without proper lot tracking and process documentation, it’s difficult to address quality issues or conduct root cause analysis. Suppliers may not maintain records of cutting parameters or material batches. Insist on traceability and request quality documentation with each shipment.

Overlooking Post-Processing Requirements

Laser-cut brass often requires additional steps—such as plating, anodizing, or assembly—that the supplier may not offer or outsource reliably. Failing to plan for these services can delay timelines and compromise quality. Confirm the supplier’s full-service capabilities or coordinate with secondary vendors early.

By proactively addressing these pitfalls—through clear specifications, supplier vetting, and IP safeguards—you can ensure high-quality laser-cut brass components while protecting your designs and supply chain integrity.

Logistics & Compliance Guide for Laser Cut Brass

Material Specifications and Handling

Laser cut brass components require careful handling due to their susceptibility to tarnishing, scratching, and deformation. Ensure brass sheets or finished parts are stored in a dry, low-humidity environment, preferably sealed in anti-tarnish packaging or vapor corrosion inhibitor (VCI) bags. Use gloves when handling to prevent skin oils from accelerating oxidation. Avoid stacking unsealed parts without protective interleaving paper.

Packaging and Shipping Requirements

Package laser cut brass parts using non-abrasive materials such as bubble wrap, foam inserts, or corrugated dividers to prevent scratching during transit. For international or long-distance shipping, use sturdy double-walled cardboard boxes or reusable plastic containers. Clearly label packages as “Fragile” and “Protect from Moisture.” Include desiccant packs inside sealed packaging to absorb residual moisture and prevent corrosion.

Regulatory Compliance (Domestic and International)

Ensure compliance with relevant regulations based on destination. In the United States, adhere to OSHA and EPA guidelines for metal manufacturing and waste disposal (e.g., brass swarf and slag). For shipments to the European Union, comply with REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) and RoHS (Restriction of Hazardous Substances) directives, verifying that brass alloys (typically CuZn37 or similar) contain no restricted substances like lead above permissible limits (generally <0.1%).

Customs Documentation and Tariff Classification

Accurately classify laser cut brass parts under the Harmonized System (HS) code. Common classifications include:

– 7408.29: Flat-rolled products of brass, not further worked than surface worked, containing by weight >=99.8% copper.

– 8466.30: Parts suitable for use with laser cutting machines (if applicable).

Verify the correct code based on the part’s dimensions, composition, and end use. Provide detailed commercial invoices, packing lists, and certificates of origin. Include material certifications (e.g., mill test reports) upon customer request.

Environmental and Safety Considerations

Laser cutting brass generates zinc oxide fumes, classified as a hazardous air pollutant. Ensure operations are conducted in facilities equipped with proper fume extraction and filtration systems compliant with local air quality regulations (e.g., EPA NESHAP or EU Directive 2004/24/EC). Operators must use appropriate PPE, including respirators with P100 filters. Collect and dispose of brass dust and scrap as non-ferrous metal waste in accordance with local recycling laws.

Import/Export Controls and Restrictions

Check for export restrictions under ITAR (International Traffic in Arms Regulations) or EAR (Export Administration Regulations) if brass components are intended for defense or high-precision aerospace applications. Most commercial laser cut brass parts fall under EAR99 and are eligible for license exceptions (e.g., LVS or TMP), but confirm eligibility based on destination country and end use. Prohibited destinations include sanctioned countries such as Iran, North Korea, and Crimea.

Quality Assurance and Traceability

Maintain batch traceability for raw brass materials and finished laser cut parts. Record lot numbers, cutting parameters, inspection results, and packaging dates. Provide customers with inspection reports, material certifications, and compliance statements upon request. Implement ISO 9001 quality management practices to ensure consistent product standards and customer satisfaction.

Summary and Best Practices

To ensure smooth logistics and compliance:

– Store and ship brass parts with moisture and abrasion protection.

– Use accurate HS codes and complete customs documentation.

– Comply with environmental, safety, and chemical regulations.

– Verify export eligibility and avoid restricted destinations.

– Maintain full traceability and quality records.

Following this guide will minimize delays, reduce compliance risks, and support reliable delivery of laser cut brass components worldwide.

In conclusion, sourcing laser-cut brass requires careful consideration of material quality, precision requirements, supplier capabilities, and cost-efficiency. Laser cutting offers excellent accuracy and clean finishes, making it ideal for intricate brass components used in electronics, architecture, jewelry, and industrial applications. When selecting a supplier, it is essential to evaluate their technical expertise, equipment precision, turnaround time, and ability to meet specific design and volume needs. Additionally, factors such as post-processing requirements, material thickness, and compliance with industry standards should be taken into account. By partnering with a reliable and experienced manufacturer, businesses can ensure high-quality, consistent results while optimizing production timelines and overall project success.