The global laser cleaning machine market is experiencing robust growth, driven by increasing demand for eco-friendly, precise, and non-abrasive surface treatment solutions across industries such as automotive, aerospace, and heritage conservation. According to a 2023 report by Mordor Intelligence, the market was valued at USD 386.4 million in 2022 and is projected to reach USD 822.5 million by 2028, growing at a CAGR of approximately 13.5% during the forecast period. This surge is fueled by stringent environmental regulations, the push to replace chemical-based paint removal methods, and advancements in fiber laser technology. As industrial players prioritize efficiency and sustainability, laser cleaning has emerged as a preferred solution for paint stripping applications—offering minimal substrate damage, reduced waste, and lower operational costs. With North America, Europe, and Asia-Pacific leading in adoption, manufacturers are innovating rapidly to enhance power output, portability, and automation capabilities. Against this backdrop, the following nine companies have distinguished themselves as leading manufacturers of laser cleaning machines specifically engineered for high-performance paint removal.

Top 9 Laser Cleaning Machine Paint Removal Manufacturers (2026 Audit Report)

(Ranked by Factory Capability & Trust Score)

#1 Laserax

Website: laserax.com

Key Highlights: Laserax works with the world’s leading manufacturers to implement laser cleaning, welding, texturing, and marking solutions….

#2 P-laser Industrial laser cleaning

Website: p-laser.com

Key Highlights: we engineer and manufacture the most advanced—and most powerful—pulsed industrial laser cleaning systems on the market, built for both manual and automated ……

#3 Clean Laser Systems

Website: cleanlaser.de

Key Highlights: Our laser systems are primarily in operation with mold and tool cleaning, paint stripping and decoating as well as cleaning and modification of metallic ……

#4 Laser Cleaning Machine

Website: pulsar-laser.com

Key Highlights: Explore PULSAR Laser P CL laser cleaning machines for industrial rust removal and paint stripping. Compare SHARK P CL, PANDA P CL and FOX P CL….

#5 Industrial 1500W 2000W CW Laser Cleaning Machine Rusty Remove

Website: xinglaser.com

Key Highlights: XING Laser (6am Life LLC, DBA XING Laser) specializes in the development and manufacture of high-performance handheld laser cleaning and rust removal equipment….

#6 SFX Laser

Website: sfxlaser.com

Key Highlights: SFX Laser is a 20+ years professional laser equipment manufacturer including laser cleaning machine, laser welding machine, fiber laser engraver, ……

#7 Laser Cleaning and Laser Ablation Systems

Website: laserphotonics.com

Key Highlights: Remove rust and surface contaminants with our laser cleaning & laser ablation systems. Experience superior cleaning tech, automation, and eco-friendly ……

#8 Handheld Laser Cleaning Machines

Website: ipgphotonics.com

Key Highlights: Handheld and portable laser cleaning machines designed for manual applications including rust removal, paint stripping, restoration, and more….

#9 Laser Cleaning Machine

Website: baikeopto.com

Key Highlights: BK-FLC300S New Handheld Fiber Laser Cleaner Machine 300W for Paint Removal Welding Seam Cleaning. Model: BK-FLC300S Laser Power:300W Supply Voltage: Single ……

Expert Sourcing Insights for Laser Cleaning Machine Paint Removal

H2: 2026 Market Trends for Laser Cleaning Machines in Paint Removal

The global market for laser cleaning machines, particularly in the paint removal segment, is poised for significant transformation by 2026. Driven by technological advancements, growing environmental regulations, and rising demand for precision and non-abrasive cleaning methods, the paint removal application of laser cleaning is emerging as a pivotal growth area. Several key trends are expected to shape this market by 2026:

1. Increased Adoption Across Automotive and Aerospace Industries

Laser cleaning machines are gaining traction in high-value manufacturing sectors such as automotive and aerospace, where precision paint stripping is essential without damaging underlying substrates like aluminum or composites. By 2026, OEMs and MRO (Maintenance, Repair, and Overhaul) facilities are projected to increasingly replace traditional methods—such as sandblasting and chemical solvents—with laser systems due to their accuracy, repeatability, and compliance with environmental standards.

2. Advancements in Fiber Laser Technology

The development of high-power, pulsed fiber lasers is enhancing the efficiency and speed of paint removal. These lasers offer better control over ablation depth, enabling selective removal of coatings while preserving base materials. By 2026, expect widespread integration of smart laser systems with adjustable wavelengths and pulse durations tailored for specific paint types and substrates, improving versatility and user-friendliness.

3. Environmental and Regulatory Drivers

With tightening global regulations on volatile organic compounds (VOCs) and hazardous waste disposal, industries are seeking eco-friendly alternatives to chemical paint strippers. Laser cleaning produces no secondary waste and eliminates the need for chemical solvents, aligning with sustainability goals. Regulatory pressure from agencies such as the EPA and EU REACH will continue to accelerate adoption, especially in North America and Europe.

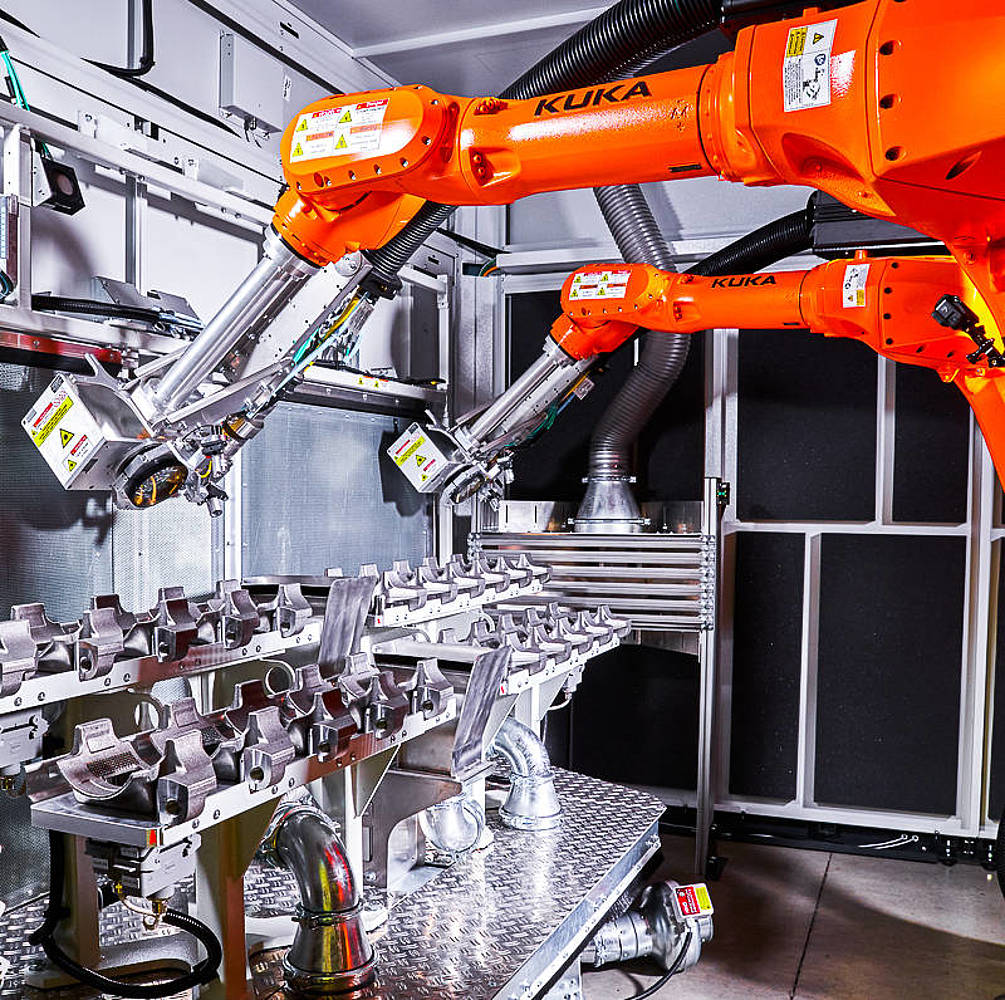

4. Growth in Robotics and Automation Integration

By 2026, the integration of laser cleaning systems with robotic arms and automated guided vehicles (AGVs) is expected to expand. This trend enables consistent, large-scale paint removal in industrial settings, such as shipyards, railcar maintenance, and aircraft hangars. Automation reduces labor costs, enhances safety, and improves throughput—making laser systems more accessible for large-scale operations.

5. Expansion into New Application Sectors

Beyond traditional industrial uses, laser paint removal is penetrating heritage restoration, military equipment refurbishment, and infrastructure maintenance (e.g., bridges and pipelines). The non-contact nature of laser cleaning preserves delicate surfaces, making it ideal for restoring historical artifacts or stripping coatings from sensitive military hardware.

6. Regional Market Growth Patterns

Asia-Pacific, particularly China and India, is expected to witness the fastest market growth due to rapid industrialization, government initiatives in smart manufacturing, and rising environmental awareness. Meanwhile, North America and Western Europe will remain key markets, driven by stringent environmental laws and high investment in advanced manufacturing technologies.

7. Cost Reduction and Market Democratization

As production scales and component costs decline, laser cleaning machines are becoming more affordable for small and medium enterprises (SMEs). By 2026, modular and portable laser systems are expected to enter the market, offering flexible and cost-effective paint removal solutions for niche applications and field services.

In conclusion, the 2026 landscape for laser cleaning machines in paint removal will be defined by technological innovation, regulatory support, and expanding industrial applications. Companies that invest in R&D, automation, and eco-friendly solutions are likely to lead the market, positioning laser cleaning as the gold standard for modern, sustainable surface preparation.

Common Pitfalls When Sourcing Laser Cleaning Machines for Paint Removal

Sourcing a laser cleaning machine for paint removal requires careful evaluation to avoid costly mistakes. Overlooking key aspects of quality and intellectual property (IP) can lead to underperforming equipment, legal risks, and operational downtime. Below are critical pitfalls to watch for:

Poor Build Quality and Component Selection

Many low-cost laser cleaners on the market use substandard components to reduce manufacturing costs. This includes inferior lasers, optics, cooling systems, and mechanical structures. Machines built with poor-quality parts often suffer from inconsistent cleaning performance, frequent breakdowns, reduced lifespan, and safety hazards. Always verify the specifications and brands of core components—such as the laser source (e.g., fiber laser type and wattage), scanning head, and cooling system—and request third-party certifications or test reports.

Lack of Real-World Performance Validation

Some suppliers provide impressive lab results under ideal conditions that don’t reflect real-world industrial environments. Without validated field testing on actual substrates (e.g., steel, aluminum, or composite materials with varying paint types), performance claims can be misleading. Request on-site demonstrations or case studies involving paint removal tasks similar to your application. Pay attention to cleaning speed, residue levels, substrate damage, and ease of integration.

Inadequate Safety Features and Compliance

Laser cleaning involves Class 4 lasers, which pose serious safety risks including eye and skin hazards, fume emissions, and fire risks. Machines lacking proper safety interlocks, fume extraction integration, protective enclosures, or compliance with international standards (e.g., IEC 60825) are dangerous and may not meet workplace regulations. Ensure the machine is CE, FDA, or equivalent certified and comes with comprehensive safety documentation and training.

Hidden IP Infringement Risks

A significant but often overlooked pitfall is sourcing machines that violate intellectual property rights. Some manufacturers, especially in competitive markets, may incorporate patented technologies—such as specific beam delivery systems, control algorithms, or software interfaces—without proper licensing. Purchasing such equipment can expose your company to legal liability, import bans, or forced equipment seizure. Conduct due diligence by requesting proof of IP ownership, patent documentation, or legal opinions, particularly when sourcing from lesser-known suppliers.

Limited Software and Control System Capabilities

Effective paint removal often requires precise parameter control (pulse frequency, power, scanning speed, etc.). Machines with proprietary, non-upgradable, or poorly documented software limit flexibility and long-term usability. Ensure the control system allows for parameter customization, data logging, and integration with automation systems. Verify whether software updates are supported and whether the interface is user-friendly.

Insufficient After-Sales Support and Service Network

Even high-quality machines require maintenance and technical support. Sourcing from suppliers without established service networks or clear warranty terms can lead to extended downtime. Confirm availability of technical support, spare parts lead times, training programs, and on-site service options—especially if operating in remote locations.

Misleading Power Ratings and Performance Claims

Some suppliers exaggerate laser power output or cleaning efficiency. For example, stating “2000W” when the actual average power is much lower due to pulsing cycles. Always request detailed performance data under defined operating conditions and compare specifications using standardized metrics. Independent testing or peer-reviewed benchmarks can help validate claims.

Avoiding these pitfalls requires thorough vetting of suppliers, requesting references, conducting pilot tests, and consulting with technical experts. Prioritizing quality and IP integrity ensures a reliable, safe, and legally compliant laser cleaning solution for paint removal applications.

H2: Logistics & Compliance Guide for Laser Cleaning Machine Paint Removal

Deploying laser cleaning machines for paint removal requires careful attention to logistics and strict compliance with safety, environmental, and regulatory standards. This guide outlines the key considerations for safe, efficient, and legally compliant operations.

H2: Equipment Logistics & Deployment

- Transportation & Handling:

- Securely package and transport the laser cleaning machine, power supply, and accessories (handpieces, cables, fume extraction) to prevent damage. Use original packaging or equivalent protection.

- Ensure vehicles and lifting equipment (forklifts, cranes) have sufficient capacity. Follow manufacturer guidelines for lifting points.

- Protect optical components (lenses, mirrors) from dust, moisture, and impact during transit and setup.

- Site Setup & Power Requirements:

- Conduct a pre-site survey to confirm adequate electrical supply (voltage, phase, amperage, grounding) matching the machine’s specifications. Industrial three-phase power is often required.

- Ensure sufficient workspace with clear access to the target area and a safe distance for operators and bystanders.

- Set up the machine on a level, stable surface. Allow ample clearance for ventilation and cable management.

- Establish a dedicated, secure area for the machine and related equipment when not in use.

- Fume Extraction System Integration:

- Critical: Laser ablation of paint generates hazardous fumes and particulates. A high-efficiency fume extraction system with HEPA (and potentially activated carbon) filtration is mandatory.

- Size the extraction system appropriately for the machine’s power and expected contaminant load.

- Position the extraction hood/nozzle as close as possible to the laser interaction point (ideally within 6 inches) to maximize capture efficiency.

- Ensure exhaust is vented safely outdoors, away from air intakes and personnel, or through a certified filtration system meeting local air quality regulations. Regularly maintain filters.

H2: Safety Compliance & Operational Protocols

- Laser Safety (ANSI Z136.1 / IEC 60825-1):

- Laser Safety Officer (LSO): Appoint a trained LSO responsible for the laser safety program.

- Controlled Access: Establish a Nominal Hazard Zone (NHZ). Use physical barriers (curtains, walls), warning signs (“Laser Radiation,” “Danger”), and interlocks to prevent unauthorized access.

- Personal Protective Equipment (PPE): Mandatory for all personnel within the NHZ:

- Laser Safety Glasses: Wavelength-specific (OD 6+ for typical paint removal lasers – e.g., 1064nm Fiber Lasers) with the correct Optical Density (OD). Ensure proper fit and condition.

- Respiratory Protection: NIOSH-approved respirator (e.g., N95/P2 minimum, often P100 or PAPR required depending on paint composition and extraction efficiency) as a backup to engineering controls.

- Skin Protection: Flame-resistant clothing (e.g., cotton, Nomex), gloves, and face shield to protect against spatter, debris, and potential UV exposure.

- Training: Comprehensive training for all operators and affected personnel on laser hazards, safe operating procedures, emergency shutdown, and PPE use.

- Interlocks & Emergency Stops: Ensure all safety interlocks (on doors, covers) and emergency stop buttons are functional. Never bypass safety features.

- Electrical Safety:

- Follow lockout/tagout (LOTO) procedures during maintenance.

- Ensure proper grounding of all equipment.

- Protect cables from damage and tripping hazards. Use cable ramps if necessary.

- Fire Prevention & Control:

- Laser interaction can ignite flammable materials (paint, substrates, dust). Keep a class ABC fire extinguisher readily accessible within the work area.

- Remove or shield flammable materials near the work zone.

- Monitor the process continuously for signs of ignition (smoke, flame). Have a fire watch if required.

- Clean up accumulated debris and flammable dust regularly.

H2: Environmental & Regulatory Compliance

- Hazardous Waste Management:

- Paint Composition is Key: Identify the paint being removed (lead-based, chromates, other heavy metals, isocyanates, etc.). Lead-based paint removal is highly regulated.

- Waste Stream Classification: Collected debris (ablated paint particles, substrate material) is likely hazardous waste if the paint contains regulated substances (e.g., lead > 1.0 mg/cm², cadmium, chromium VI).

- Containment: Use the fume extractor’s collection system (HEPA filter cartridges/bags) to capture the majority of particulate waste. Prevent spills.

- Storage & Disposal: Store collected waste in clearly labeled, leak-proof, compatible containers. Follow RCRA (US), EPA state regulations, or equivalent local hazardous waste regulations for storage time limits, labeling, manifesting, and disposal through licensed hazardous waste handlers. Obtain a waste profile and disposal quote before starting.

- Spill Response: Have spill kits (absorbents, PPE, containment) readily available. Train personnel on spill response procedures.

- Air Emissions:

- Ensure the fume extraction system effectively captures and filters >99.97% of particulates (HEPA) and any volatile organic compounds (VOCs) or hazardous air pollutants (HAPs) generated (potentially requiring activated carbon filtration).

- Verify exhaust complies with local air quality district regulations (e.g., EPA NESHAP, local VOC limits). Permitting may be required.

- Monitor filter performance and change schedules; document maintenance.

- Regulatory Frameworks:

- OSHA (US): General Duty Clause, Hazard Communication (HazCom), Respiratory Protection (29 CFR 1910.134), Lead (29 CFR 1910.1025), Hazardous Waste Operations (HAZWOPER 29 CFR 1910.120 – may apply depending on waste volume/type), Eye and Face Protection (29 CFR 1910.133).

- EPA (US): Resource Conservation and Recovery Act (RCRA) for hazardous waste, Clean Air Act (CAA) for emissions, Toxic Substances Control Act (TSCA) for PCBs (if present), Lead Renovation, Repair and Painting (RRP) Rule (if applicable to building components).

- Local/State Regulations: Often more stringent than federal rules. Check with state environmental and occupational safety agencies.

- International: Adhere to equivalent regulations (e.g., REACH, RoHS, WEEE in EU; COSHH in UK; local environmental protection laws).

H2: Documentation & Record Keeping

- Maintain detailed records for compliance and safety audits:

- Equipment manuals, maintenance logs, and calibration records.

- Laser Safety Program documentation (LSO appointment, NHZ assessments, interlock checks).

- Employee training records (laser safety, hazardous materials, HAZWOPER if applicable).

- PPE inspection and usage logs.

- Fume extraction system maintenance logs (filter changes, airflow checks).

- Hazardous waste manifests, disposal receipts, and waste profiles.

- Air monitoring results (if required).

- Incident/accident reports.

Key Takeaway: Successful laser paint removal hinges on meticulous planning. Prioritize safety through engineering controls (especially fume extraction), rigorous PPE, comprehensive training, and strict adherence to hazardous waste and environmental regulations. Always consult the machine manufacturer, safety professionals, and regulatory authorities specific to your location and project scope.

Conclusion: Sourcing a Laser Cleaning Machine for Paint Removal

Sourcing a laser cleaning machine for paint removal presents a forward-thinking, efficient, and environmentally sustainable solution for industrial and precision cleaning applications. Compared to traditional methods such as sandblasting, chemical stripping, or mechanical abrasion, laser cleaning offers numerous advantages including non-contact processing, high precision, minimal substrate damage, reduced waste, and compliance with environmental and safety regulations.

When sourcing a laser cleaning system, key considerations include laser power, wavelength, pulse duration, automation compatibility, ease of integration into existing workflows, and total cost of ownership. It is essential to evaluate both the technical specifications and the supplier’s reputation, support services, and training offerings to ensure long-term reliability and performance.

Investing in a laser cleaning machine not only enhances operational efficiency and paint removal quality but also aligns with growing industry demands for cleaner, safer, and more sustainable manufacturing practices. As technology continues to advance and costs become more accessible, laser cleaning is poised to become the standard in surface preparation and restoration across aerospace, automotive, marine, heritage conservation, and other critical sectors.

Therefore, sourcing a laser cleaning machine for paint removal is a strategic decision that supports innovation, regulatory compliance, and long-term cost savings—making it a valuable asset for modern industrial maintenance and manufacturing operations.