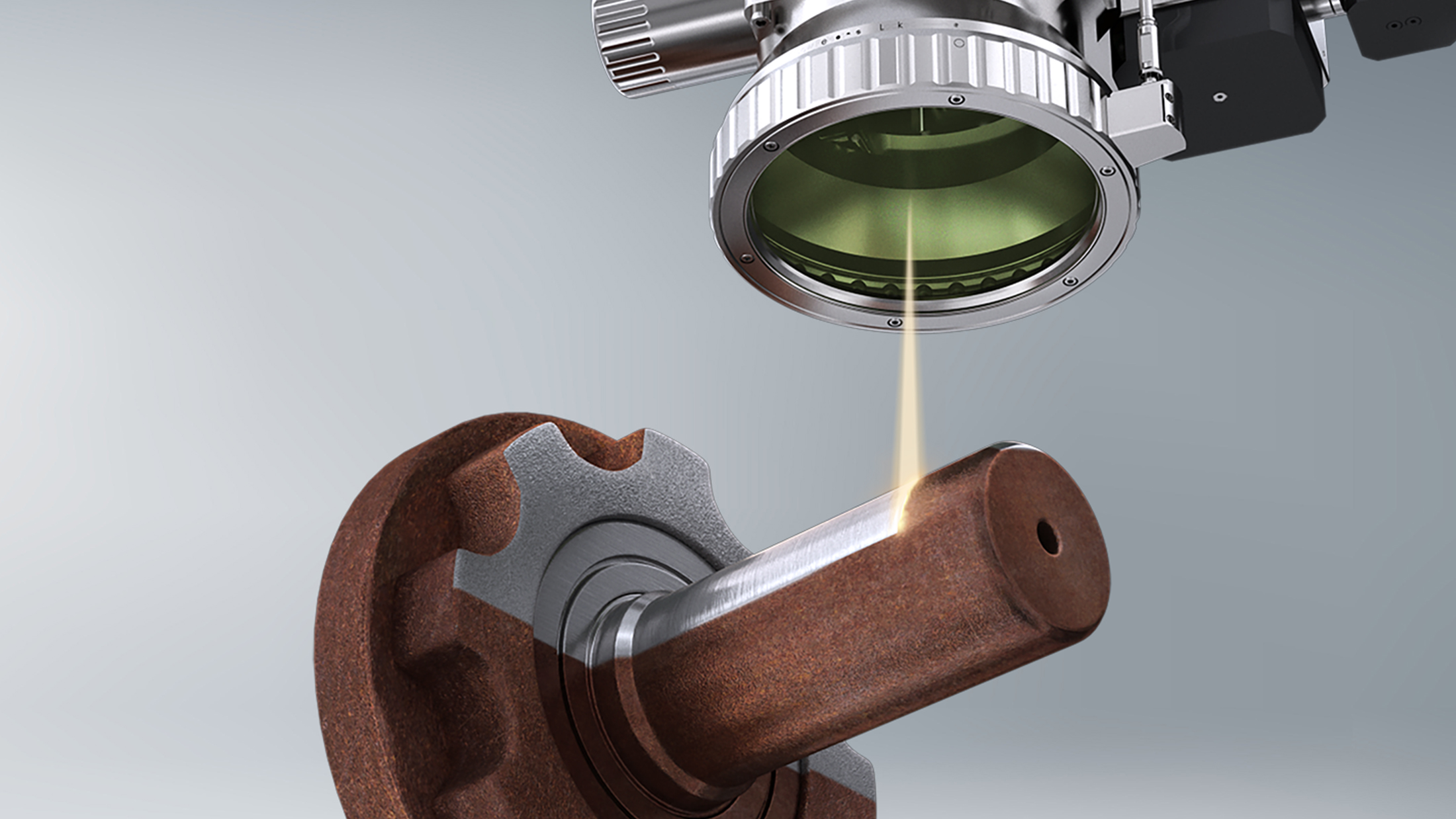

The global laser cleaning machine market is experiencing robust growth, driven by increasing demand for eco-friendly, precision-based cleaning solutions across industries such as automotive, aerospace, and heritage conservation. According to a report by Mordor Intelligence, the market was valued at USD 468.5 million in 2023 and is projected to reach USD 947.3 million by 2029, growing at a CAGR of 12.4% during the forecast period. This expansion is fueled by the growing replacement of traditional cleaning methods—such as sandblasting and chemical treatments—with laser technology that offers non-abrasive, chemical-free, and highly efficient surface decontamination. As industrial automation and sustainability initiatives gain momentum, manufacturers are scaling production and optimizing costs, leading to increased accessibility of laser cleaning systems worldwide. In this competitive landscape, nine key manufacturers stand out for their cost-effective solutions, technological innovation, and strong return on investment—making them top contenders in today’s evolving market.

Top 9 Laser Cleaning Machine Cost Manufacturers (2026 Audit Report)

(Ranked by Factory Capability & Trust Score)

#1 Laser cleaner machine prices

Website: pulsar-laser.com

Key Highlights: Laser cleaner machine prices and parameters, download our Catalogue….

#2 Laserax

Website: laserax.com

Key Highlights: Laserax works with the world’s leading manufacturers to implement laser cleaning, welding, texturing, and marking solutions….

#3 P-laser Industrial laser cleaning

Website: p-laser.com

Key Highlights: we engineer and manufacture the most advanced—and most powerful—pulsed industrial laser cleaning systems on the market, built for both manual and automated ……

#4 Laser Cleaning Machine

Website: baikeopto.com

Key Highlights: BK-FLC500SL Cost-Effective Laser Rust Removal 500W Industrial Pulsed Laser Cleaning Machine for … © 2025 BAIKEOPTO LASER GLOBAL OFFICIAL WEBSITE. Copy right ……

#5 Laser Cleaning Machine Manufacturer

Website: hantencnc.com

Key Highlights: We offer a wide range of laser cleaners, from 100W to 3000W. Our lineup includes handheld, backpack, and trolley-type products to meet diverse cleaning needs….

#6 Industrial 1500W 2000W CW Laser Cleaning Machine Rusty Remove

Website: xinglaser.com

Key Highlights: XING Laser (6am Life LLC, DBA XING Laser) specializes in the development and manufacture of high-performance handheld laser cleaning and rust removal equipment….

#7 Laser Cleaning Machines

Website: lasersonly.com

Key Highlights: Free delivery 30-day returnsThe price for a laser cleaning machine depends on the machine’s functionality, model, and components. The price for a laser cleaning machine is $9,000-$…

#8 500W 1000W Pulse Laser Cleaning Machine Laser Metal Rust Oil …

Website: sfxlaser.com

Key Highlights: In stock Free deliverySFX 500w 1000w pulse laser cleaning machine is suitable for rust, oil, paint, coating, mold cleaning, adhesive layer removal, cultural relic restoration, etc….

#9 Portable Laser Cleaning Machine

Website: laserphotonics.com

Key Highlights: The Marlin PF-1010 is an effective tool for speedy polishing, meticulous cleaning, top-layer coating removal, and other surface preparation needs for small- ……

Expert Sourcing Insights for Laser Cleaning Machine Cost

2026 Market Trends for Laser Cleaning Machine Cost

As we approach 2026, the global market for laser cleaning machines is undergoing significant transformation, driven by technological innovation, expanding industrial applications, and shifting economic dynamics. These factors are collectively influencing the cost structure of laser cleaning systems, making them more accessible while simultaneously increasing demand for higher-performance models. Below is an analysis of key trends expected to shape laser cleaning machine pricing in 2026.

Technological Advancements Driving Efficiency and Cost Reduction

By 2026, continuous improvements in fiber laser technology—such as increased power efficiency, longer operational lifespans, and modular designs—are expected to lower manufacturing costs. Advancements in beam delivery systems and automation integration are enhancing cleaning speed and precision, allowing manufacturers to achieve higher throughput with fewer resources. As these technologies mature and scale, economies of scale are expected to reduce unit costs, particularly for mid-range industrial models. Additionally, software enhancements, including AI-driven process optimization and predictive maintenance, are adding value without proportionally increasing hardware expenses.

Increased Market Competition and Price Diversification

The laser cleaning market is becoming increasingly competitive, with a growing number of manufacturers in Asia—particularly China—offering cost-effective alternatives to established European and North American brands. This competition is expected to drive price differentiation across segments. By 2026, consumers will likely see a wider range of pricing tiers: entry-level portable units priced under $15,000 for small businesses and maintenance operations, mid-range systems ($15,000–$50,000) for industrial integration, and high-end automated solutions exceeding $100,000 for aerospace and precision manufacturing. This fragmentation allows businesses of all sizes to adopt laser cleaning based on their budget and application needs.

Rising Demand in Key Industries

Industries such as automotive restoration, aerospace, shipbuilding, and heritage preservation are adopting laser cleaning at a faster pace due to its non-abrasive, eco-friendly nature. Regulatory pressures to reduce chemical solvent use and meet environmental standards are accelerating this shift. As demand grows, production volumes are expected to rise, leading to further cost reductions through economies of scale. However, specialized systems tailored for high-precision or large-scale applications may maintain or even see increased pricing due to custom engineering and integration requirements.

Supply Chain and Raw Material Considerations

Global supply chain stabilization post-pandemic, coupled with localized manufacturing initiatives in regions like Southeast Asia and Eastern Europe, should contribute to more predictable component pricing—particularly for diodes, optical fibers, and cooling systems. However, potential fluctuations in rare earth elements and semiconductor availability could introduce volatility. Manufacturers investing in vertical integration or alternative materials may gain a cost advantage, influencing overall market pricing trends.

Total Cost of Ownership Becomes a Key Metric

By 2026, buyers are expected to focus less on upfront cost and more on total cost of ownership (TCO). Although initial investment remains higher than traditional cleaning methods, the long-term savings from reduced consumables, lower maintenance, and improved worker safety are driving adoption. Vendors are responding by offering leasing models, pay-per-use services, and bundled maintenance packages—making high-end systems more financially accessible and reshaping how cost is perceived in the market.

In conclusion, the laser cleaning machine market in 2026 will likely feature lower average prices due to technological maturity and competition, while premium systems for advanced applications maintain higher price points. The overall trend points toward greater affordability, broader adoption, and a shift in purchasing decisions toward long-term value rather than initial cost alone.

Common Pitfalls When Sourcing Laser Cleaning Machines: Cost, Quality, and Intellectual Property

Logistics & Compliance Guide for Laser Cleaning Machine Cost

Understanding the full cost of acquiring and operating a laser cleaning machine goes beyond the initial purchase price. Logistics and compliance factors significantly impact both upfront and long-term expenses. This guide outlines key considerations to help you accurately assess total costs and ensure smooth operations.

Shipping and Transportation Costs

The size, weight, and fragility of laser cleaning machines influence shipping expenses. Larger industrial units may require specialized freight services, crating, and liftgate deliveries, all adding to the cost. International shipments involve additional complexities such as customs clearance, import duties, and longer transit times, which can increase total landed costs significantly. Always request detailed shipping quotes and confirm insurance coverage during transit.

Import Duties and Taxes

When sourcing machines from overseas, import duties, value-added taxes (VAT), or goods and services taxes (GST) apply and vary by country. These fees are typically based on the machine’s declared value, shipping costs, and insurance (CIF value). Failure to account for these can lead to unexpected expenses upon delivery. Consult with a customs broker or freight forwarder to determine applicable tariffs and ensure accurate product classification under the Harmonized System (HS) code.

Regulatory Compliance Requirements

Laser cleaning machines are subject to safety and environmental regulations. In the U.S., compliance with the FDA’s Center for Devices and Radiological Health (CDRH) standards is mandatory, including proper laser classification labeling and safety interlocks. The European Union requires CE marking, demonstrating conformity with health, safety, and environmental protection standards under directives such as the Machinery Directive and the Electromagnetic Compatibility (EMC) Directive. Non-compliance can result in fines, shipment delays, or import bans.

Safety Certification and Documentation

Ensure the machine meets international safety standards such as IEC 60825 (laser safety) and IEC 61010 (safety requirements for electrical equipment). Suppliers should provide a Declaration of Conformity (DoC), technical file, and user manuals in the local language. Machines lacking proper certification may require costly third-party testing or modifications before use, increasing overall costs.

Installation and Site Preparation

Site requirements—such as power supply specifications (voltage, phase, amperage), ventilation for fumes, and workspace layout—must be assessed before delivery. Some machines require reinforced flooring or dedicated exhaust systems. Failure to prepare the site properly can lead to installation delays, additional contractor fees, or operational inefficiencies.

Training and Operational Compliance

Proper operator training is essential for safety and regulatory compliance. Many jurisdictions require documented evidence of laser safety training, especially for Class 3B and Class 4 lasers. Budget for initial and periodic refresher training to reduce accident risks and ensure adherence to OSHA (U.S.) or equivalent local workplace safety regulations.

Maintenance and Spare Parts Logistics

Factor in ongoing maintenance costs and the availability of spare parts. Machines sourced from overseas may have longer lead times for replacements, potentially causing downtime. Consider suppliers offering local service support or stocking critical components to minimize operational interruptions.

Environmental and Waste Disposal Compliance

Laser cleaning can generate hazardous particulates or fumes, depending on the substrate. Compliance with environmental regulations (e.g., EPA in the U.S. or REACH in the EU) may require air filtration systems or proper disposal of collected debris. Neglecting these requirements can lead to environmental violations and associated penalties.

By thoroughly evaluating logistics and compliance factors, businesses can avoid hidden costs and ensure a seamless integration of laser cleaning technology into their operations. Always request a comprehensive cost breakdown from suppliers and consult legal or regulatory experts when operating in new markets.

Conclusion on Sourcing Laser Cleaning Machine Costs

Sourcing a laser cleaning machine involves evaluating a range of cost factors beyond the initial purchase price. While prices can vary significantly—typically from $10,000 to over $50,000 depending on power, brand, portability, and automation features—it is essential to consider total cost of ownership. This includes maintenance, operational efficiency, training, safety requirements, and potential downtime savings due to the machine’s precision and eco-friendliness compared to traditional cleaning methods.

Sourcing from reputable suppliers, whether domestic or international, impacts cost, warranty, after-sales support, and delivery timelines. While lower-cost options from certain regions may be attractive, they may come with trade-offs in reliability, technical support, or compliance with safety standards. Investing in a higher-quality machine may yield long-term savings through improved durability, better performance, and reduced operational waste.

Ultimately, the decision should be driven by specific application needs, return on investment, and lifecycle benefits. Conducting thorough market research, requesting detailed quotes, and evaluating vendor credibility will ensure a cost-effective and reliable sourcing outcome. Laser cleaning represents a forward-thinking, sustainable solution, and strategic procurement can maximize both technical and financial returns.