The global laser cleaning market is experiencing robust expansion, driven by increasing demand for eco-friendly, non-abrasive surface treatment technologies across industries—including furniture manufacturing. According to Grand View Research, the global laser cleaning market size was valued at USD 878.6 million in 2023 and is expected to grow at a compound annual growth rate (CAGR) of 19.8% from 2024 to 2030. This surge is fueled by stricter environmental regulations, growing emphasis on precision cleaning, and the shift away from chemical- and sand-based methods that damage delicate wood and finish surfaces. As furniture manufacturers seek sustainable and efficient solutions for restoring antique pieces, removing coatings, and preparing surfaces, laser cleaning has emerged as a transformative technology. In this landscape, a select group of manufacturers has distinguished itself by delivering high-performance, furniture-specific laser cleaning systems—combining advanced optics, user-friendly interfaces, and application expertise. Based on market presence, technological innovation, and customer adoption, here are the top 9 laser cleaning equipment manufacturers shaping the future of furniture restoration and production.

Top 9 Laser Cleaning Furniture Manufacturers (2026 Audit Report)

(Ranked by Factory Capability & Trust Score)

#1 P-laser Industrial laser cleaning

Website: p-laser.com

Key Highlights: With over 35 years of expertise in surface treatment and more than 450 systems installed worldwide, P-Laser is at the forefront of industrial laser cleaning ……

#2 LASER CLEANING MACHINE

Website: chutianlasergroup.com

Key Highlights: Discover Chutian Laser’s handheld, backpack, and automatic laser cleaning machines for precise rust removal and industrial surface cleaning solutions….

#3 SHARK P CL Industrial Laser Cleaning Machines (100

Website: pulsar-laser.com

Key Highlights: SHARK P CL is an industrial pulsed laser cleaning machine series by PULSAR Laser with outputs from 100 W to 1000 W, air-cooled up to 500 W….

#4 Argento Lux

Website: argentolux.com

Key Highlights: Our company provides state-of-the-art Industrial Laser Equipment Sales and Mobile Laser Cleaning Services for a wide range of applications and industries….

#5 Laser Cleaning Machine Manufacturer

Website: hantencnc.com

Key Highlights: HANTENCNC is a professional laser cleaning machine manufacturer with over 20 years of experience. We offer a wide range of laser cleaners, from 100W to 3000W….

#6 Laser Cleaning Machine for Wood

Website: bogonglaser.com

Key Highlights: Laser cleaning technology provides an efficient and environmentally friendly solution for rust removal on metal surfaces….

#7 Laser Machines

Website: lclasers.com

Key Highlights: We offer comprehensive solutions in cleaning, welding and laser marking. At LC Lasers we seek laser solutions for our customers and distributors….

#8 Laser Cleaning Machine

Website: lmelaser.com

Key Highlights: LME Laser is a laser cleaning machine manufacture with 17 years experience. The Products including continuous laser cleaner and pulse laser cleaner….

#9 Laser Cleaning and Laser Ablation Systems

Website: laserphotonics.com

Key Highlights: Remove rust and surface contaminants with our laser cleaning & laser ablation systems. Experience superior cleaning tech, automation, and eco-friendly ……

Expert Sourcing Insights for Laser Cleaning Furniture

H2: 2026 Market Trends for Laser Cleaning in the Furniture Industry

The laser cleaning market within the furniture industry is poised for significant transformation by 2026, driven by technological advancements, rising environmental concerns, and shifting consumer preferences toward sustainable and high-precision restoration methods. Below are the key trends expected to shape the laser cleaning furniture segment over the next few years:

-

Increased Adoption of Eco-Friendly Cleaning Solutions

As global regulations tighten around chemical usage and waste disposal, furniture manufacturers and restoration specialists are turning to laser cleaning as a solvent-free, non-abrasive alternative. By 2026, laser cleaning is expected to become a standard in eco-conscious furniture refinishing, particularly in Europe and North America, where environmental compliance is strictly enforced. -

Growth in Heritage and Antique Furniture Restoration

Laser cleaning offers unmatched precision in removing contaminants such as grime, old varnish, and paint layers without damaging delicate wood surfaces or historical integrity. This makes it ideal for heritage conservation projects. The expanding market for antique furniture restoration—driven by luxury and collectors’ demand—is projected to significantly boost the adoption of laser systems in specialized workshops and museums. -

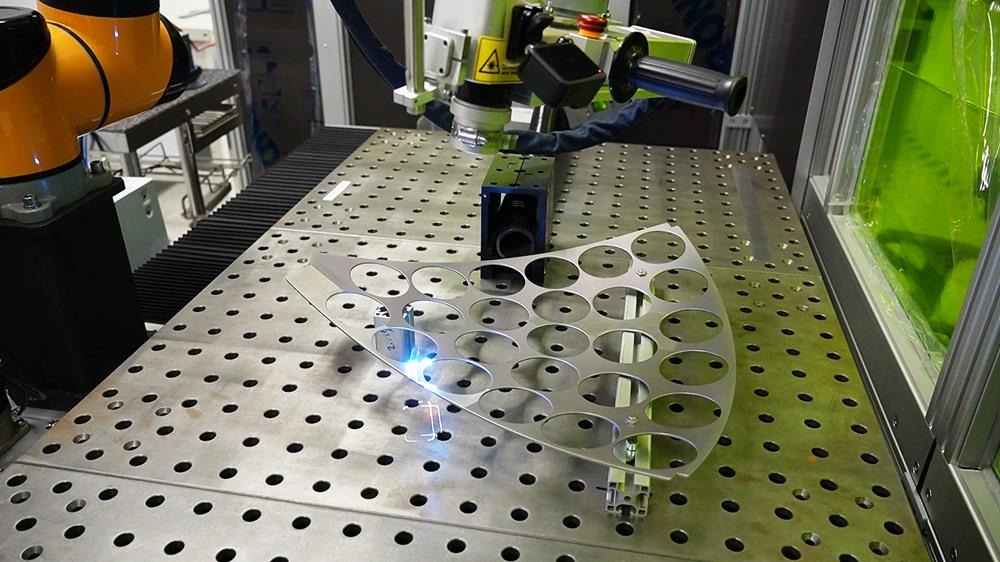

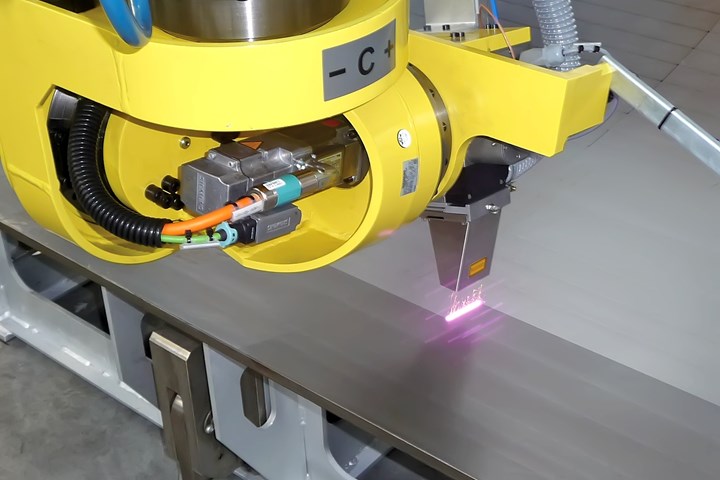

Integration with Automation and AI

By 2026, advances in robotics and artificial intelligence are expected to enable fully automated laser cleaning stations. These systems will use computer vision to detect surface types and contamination levels, adjusting laser parameters in real time. Furniture production lines, especially in high-end custom manufacturing, will increasingly integrate these smart systems to improve efficiency and consistency. -

Miniaturization and Portability of Laser Systems

A notable trend is the development of compact, handheld laser cleaning devices tailored for on-site furniture restoration. These portable units will allow craftsmen to perform precise cleaning in situ—such as in historic homes or retail showrooms—without dismantling or transporting large pieces. This flexibility will open new service opportunities and support market penetration among small businesses and independent artisans. -

Cost Reduction and Improved Accessibility

While laser cleaning systems have historically been expensive, ongoing improvements in diode and fiber laser technologies are expected to lower equipment costs by 2026. As prices decline and return-on-investment becomes clearer through reduced labor and material costs, small-to-medium enterprises (SMEs) in the furniture sector will increasingly adopt the technology. -

Demand for Sustainable Refinishing in Circular Economy Models

With the rise of circular economy principles, furniture refurbishment and upcycling are gaining momentum. Laser cleaning supports these initiatives by enabling repeated, high-quality surface restoration without material degradation. Brands promoting sustainability are likely to highlight laser-based processes as part of their green credentials, further driving market acceptance. -

Regional Market Expansion in Asia-Pacific

While Europe and North America lead in laser cleaning adoption, the Asia-Pacific region—particularly China, Japan, and South Korea—is expected to witness rapid growth by 2026. Increasing investments in smart manufacturing and rising demand for premium furniture restoration services will fuel regional market expansion.

In conclusion, by 2026, laser cleaning is set to revolutionize the furniture industry by offering a sustainable, precise, and scalable solution for surface preparation and restoration. As technology becomes more accessible and integrated into broader digital manufacturing ecosystems, its role in enhancing product quality and environmental performance will solidify its position as a key enabler of innovation in the furniture sector.

Common Pitfalls When Sourcing Laser Cleaning Equipment for Furniture (Quality and Intellectual Property)

Sourcing laser cleaning equipment for furniture restoration or manufacturing presents unique challenges. While the technology offers precision and eco-friendly benefits, buyers often encounter critical pitfalls related to quality consistency and intellectual property (IP) risks. Being aware of these issues is essential for making informed procurement decisions.

Poor Build Quality and Component Reliability

Many low-cost laser cleaning machines, particularly from less-established suppliers, use substandard components such as underpowered or unstable laser sources, inadequate cooling systems, and poorly designed motion controls. These shortcomings result in inconsistent cleaning performance, frequent breakdowns, and shortened equipment lifespan. For furniture applications—where delicate wood finishes, veneers, or intricate carvings are common—unreliable equipment can easily damage valuable pieces, leading to costly rework or client dissatisfaction.

Inadequate Power and Precision for Furniture Surfaces

Furniture often requires fine-tuned cleaning that balances effectiveness with surface preservation. Generic or poorly calibrated lasers may lack the adjustable power settings or beam focus necessary for treating sensitive materials like antique wood, painted finishes, or inlays. Sourcing equipment without verifying its performance on actual furniture samples can lead to over-cleaning, scorching, or incomplete contaminant removal.

Lack of Safety Features and Compliance

Laser cleaning systems must comply with international safety standards (e.g., IEC 60825) to protect operators from harmful radiation and fumes. Some suppliers, especially those targeting price-sensitive markets, may omit essential safety interlocks, fume extraction compatibility, or proper enclosure designs. Using non-compliant equipment exposes companies to regulatory penalties and workplace liability, particularly in environments where staff work closely with the machinery.

Misrepresentation of Technical Specifications

Exaggerated claims about cleaning speed, depth, or material compatibility are common. Some suppliers inflate laser power ratings (e.g., listing diode power instead of actual output) or fail to disclose duty cycle limitations. Without third-party verification or on-site testing, buyers may receive equipment that underperforms in real-world furniture applications, disrupting production timelines and increasing operational costs.

Intellectual Property Infringement Risks

A significant but often overlooked pitfall is sourcing equipment that violates intellectual property rights. Some manufacturers reverse-engineer or copy patented laser designs, control software, or user interfaces from reputable brands. Purchasing such equipment—even unknowingly—can expose your business to legal liability, especially if the machine is imported across borders where IP enforcement is strict. Additionally, cloned systems typically lack software updates, technical support, and firmware security patches.

Limited After-Sales Support and Spare Parts Availability

Low-cost suppliers may offer attractive upfront pricing but provide minimal technical support, training, or access to replacement parts. Given the complexity of laser systems, downtime due to a faulty component or software glitch can halt production. For furniture workshops relying on consistent output, the absence of reliable service networks—especially outside the supplier’s home country—can be a major operational setback.

Conclusion

To avoid these pitfalls, conduct thorough due diligence: request live demonstrations on representative furniture samples, verify certifications, audit supplier IP documentation, and prioritize vendors with proven industry experience and service infrastructure. Investing in high-quality, IP-compliant laser cleaning equipment ensures long-term reliability, protects your brand reputation, and safeguards against legal and operational risks.

Logistics & Compliance Guide for Laser Cleaning Furniture

Overview of Laser Cleaning in Furniture Restoration

Laser cleaning is a non-abrasive, environmentally friendly method used in furniture restoration to remove contaminants such as dirt, paint, varnish, and oxidation without damaging the underlying material. This technology uses focused laser beams to vaporize surface impurities while preserving the integrity of wood, metal, or other furniture components. Due to its precision and minimal waste generation, it is increasingly adopted in heritage conservation and high-end furniture manufacturing.

Regulatory Compliance Requirements

Laser cleaning operations must comply with national and international safety and environmental regulations. Key compliance areas include:

– Laser Safety Standards (IEC 60825-1): Equipment must meet classification standards for laser radiation, with proper labeling, interlocks, and protective housings.

– Occupational Health and Safety (OSHA, EU Directive 2006/25/EC): Employers must conduct risk assessments, provide personal protective equipment (PPE), and ensure controlled access to laser operation zones.

– Air Quality Regulations (EPA, REACH, RoHS): Although laser cleaning produces minimal waste, operators must manage fumes and particulates using certified filtration systems (e.g., HEPA filters) and comply with VOC emission limits when applicable.

– Heritage and Cultural Artifact Handling: For antique or historically significant furniture, adherence to conservation guidelines (e.g., ICOM-CC standards) is required to prevent irreversible damage.

Transportation and Handling of Equipment

Laser cleaning systems are sensitive and often heavy, requiring careful logistics:

– Packaging: Use manufacturer-approved crates with shock-absorbing materials to prevent damage during transit.

– Shipping Documentation: Include technical specifications, safety data sheets (SDS), and conformity certificates (CE, FCC) for international shipments.

– Installation Site Preparation: Ensure the destination has adequate power supply (voltage and grounding), ventilation, and space with controlled temperature and humidity to maintain equipment performance.

Operational Safety Protocols

Safe operation is critical to protect personnel and materials:

– Controlled Access Zones: Establish a laser-controlled area with warning signs and interlocked doors to prevent unauthorized access.

– PPE Requirements: Operators must wear laser safety goggles (wavelength-specific), respiratory protection if fumes are generated, and flame-resistant clothing.

– Training and Certification: Personnel should be trained in laser operation, emergency shutdown procedures, and first aid for laser-related injuries.

Waste Management and Environmental Considerations

Despite being a clean technology, laser cleaning generates particulate byproducts:

– Fume Extraction: Use integrated fume extractors with HEPA and activated carbon filters to capture fine particles and volatile organic compounds.

– Waste Disposal: Collected residue may contain regulated substances (e.g., lead-based paint debris). Classify waste according to local regulations (e.g., EPA hazardous waste codes) and dispose of through licensed waste handlers.

– Environmental Reporting: Maintain logs of emissions and waste disposal for audits and regulatory compliance (e.g., ISO 14001).

Import/Export and Cross-Border Considerations

When moving laser equipment across borders:

– Customs Classification: Laser cleaning systems typically fall under HS Code 8515.21 or 8479.89, depending on configuration. Accurate classification ensures correct duties and avoids delays.

– Export Controls: High-powered lasers may be subject to export restrictions under regimes like the Wassenaar Arrangement. Verify licensing requirements before shipment.

– Documentation: Provide commercial invoices, packing lists, certificates of origin, and conformity (CE, UKCA, etc.) to facilitate customs clearance.

Recordkeeping and Audits

Maintain comprehensive documentation to demonstrate compliance:

– Equipment maintenance logs

– Operator training records

– Safety inspection reports

– Waste disposal manifests

– Regulatory permits and certifications

Regular internal audits help identify gaps and ensure ongoing compliance with evolving standards.

Conclusion: Sourcing Laser Cleaning Equipment for Furniture Restoration

Sourcing laser cleaning technology for furniture restoration presents a forward-thinking, environmentally sustainable, and highly effective solution for removing contaminants, old finishes, and surface defects without damaging delicate wood or intricate details. Unlike traditional methods such as sanding or chemical stripping, laser cleaning offers precision, reduced labor costs, and minimal waste, making it ideal for high-value or antique furniture.

While the initial investment in laser cleaning systems may be higher than conventional tools, the long-term benefits—such as improved efficiency, enhanced restoration quality, and compliance with environmental and safety regulations—justify the cost, particularly for professional restoration studios or heritage conservation projects.

When sourcing laser cleaning equipment, it is essential to consider factors such as laser power, wavelength, portability, ease of use, and manufacturer support. Selecting a reputable supplier that offers training and after-sales service ensures optimal integration into existing workflows.

In conclusion, laser cleaning is a transformative technology for the furniture restoration industry. By carefully sourcing the right equipment and investing in operator training, businesses can elevate their craftsmanship, reduce environmental impact, and gain a competitive edge in the market.