The global laser cleaning market is experiencing robust growth, driven by increasing demand for eco-friendly, precision cleaning solutions across industries such as automotive, aerospace, and manufacturing. According to a report by Mordor Intelligence, the laser cleaning market was valued at approximately USD 552.8 million in 2023 and is projected to reach USD 1.26 billion by 2029, growing at a CAGR of over 14.3% during the forecast period. This surge is attributed to the rising adoption of laser technology as a non-abrasive, chemical-free alternative to traditional cleaning methods, along with growing regulatory pressure to reduce environmental impact. As industrial automation accelerates, laser cleaner machine manufacturers are innovating rapidly to meet the demand for efficient, sustainable surface treatment solutions—making now a pivotal time to evaluate the top players shaping the industry.

Top 10 Laser Cleaner Machine For Sale Manufacturers (2026 Audit Report)

(Ranked by Factory Capability & Trust Score)

#1 Laser Cleaning Machine Manufacturers

Website: fortunelaser.com

Key Highlights: … Laser Technology Co., Ltd. is a professional manufacturer of industrial laser equipment, integrated with R&D, production, sales and maintenance services….

#2 Laserax

Website: laserax.com

Key Highlights: Laserax works with the world’s leading manufacturers to implement laser cleaning, welding, texturing, and marking solutions….

#3 P-laser Industrial laser cleaning

Website: p-laser.com

Key Highlights: we engineer and manufacture the most advanced—and most powerful—pulsed industrial laser cleaning systems on the market, built for both manual and automated ……

#4 Laser cleaner machine prices

Website: pulsar-laser.com

Key Highlights: Laser cleaner machine prices and parameters, download our Catalogue….

#5 SFX Laser

Website: sfxlaser.com

Key Highlights: SFX Laser is a 20+ years professional laser equipment manufacturer including laser cleaning machine, laser welding machine, fiber laser engraver, fiber laser…

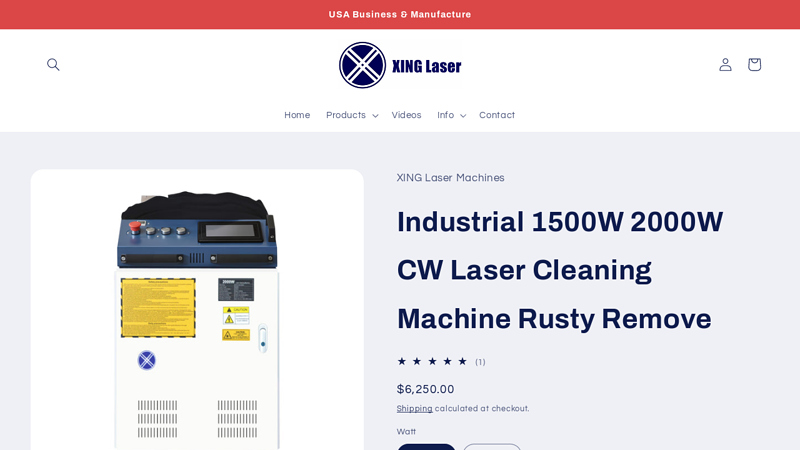

#6 Industrial 1500W 2000W CW Laser Cleaning Machine Rusty Remove

Website: xinglaser.com

Key Highlights: XING Laser (6am Life LLC, DBA XING Laser) specializes in the development and manufacture of high-performance handheld laser cleaning and rust removal equipment….

#7 Industrial Laser Machines & Solutions

#8 Laser Cleaning Machine Manufacturer

Website: hantencnc.com

Key Highlights: HANTENCNC is a professional laser cleaning machine manufacturer with over 20 years of experience. We offer a wide range of laser cleaners, from 100W to 3000W….

#9 Laser Cleaning and Laser Ablation Systems

Website: laserphotonics.com

Key Highlights: Remove rust and surface contaminants with our laser cleaning & laser ablation systems. Experience superior cleaning tech, automation, and eco-friendly ……

#10 Laser Cleaning Machine

Website: baikeopto.com

Key Highlights: Backpack laser cleaning machine Pulse Laser Cleaning Machine Continuous Laser Cleaning Machine. 01|Backpack cleaner. BK-FLC50SC Max 50W Backpack Pulse Laser ……

Expert Sourcing Insights for Laser Cleaner Machine For Sale

2026 Market Trends for Laser Cleaner Machines For Sale

As industries around the world continue to prioritize efficiency, sustainability, and precision, the market for laser cleaner machines for sale is poised for significant growth by 2026. Driven by technological advancements, environmental regulations, and a shift toward automation, the laser cleaning sector is undergoing a transformation that will shape its trajectory in the coming years. This analysis explores key market trends influencing the availability, demand, and innovation in laser cleaner machines by 2026.

Rising Industrial Adoption Across Key Sectors

By 2026, the adoption of laser cleaning technology is expected to expand beyond niche applications into mainstream industrial use. Sectors such as automotive manufacturing, aerospace, electronics, and heavy machinery maintenance are increasingly integrating laser cleaners into their production and maintenance workflows. The ability of laser systems to remove rust, paint, oxides, and contaminants without damaging substrates makes them ideal for precision-critical environments. As manufacturers seek non-abrasive, chemical-free cleaning alternatives, demand for laser cleaner machines for sale is projected to surge.

Environmental and Regulatory Drivers

Growing global emphasis on environmental sustainability is a major catalyst for the laser cleaning market. Unlike traditional cleaning methods that rely on chemicals or abrasive media—generating hazardous waste and emissions—laser cleaning is a dry, eco-friendly process. Stricter environmental regulations across North America, Europe, and parts of Asia-Pacific are pushing companies to adopt greener technologies. By 2026, compliance with environmental standards will make laser cleaning not just a preference but a necessity in many industries, boosting market availability and sales.

Technological Advancements and Cost Reduction

Continuous improvements in fiber laser technology are making laser cleaner machines more powerful, portable, and energy-efficient. By 2026, expect wider availability of handheld and robotic-integrated laser cleaning systems with enhanced user interfaces, real-time monitoring, and AI-assisted operation. As production scales and component costs decline, the overall price of laser cleaning systems is expected to drop, making them more accessible to small and medium-sized enterprises (SMEs). This democratization of technology will expand the pool of buyers actively searching for laser cleaner machines for sale.

Growth in Aftermarket and Rental Models

An emerging trend by 2026 will be the rise of alternative purchasing models, including equipment leasing, rental services, and pay-per-use platforms. These models lower the barrier to entry for companies hesitant to make large upfront investments. Industrial service providers and maintenance contractors are increasingly opting to rent laser cleaning machines for short-term projects, contributing to a dynamic secondary market. Online marketplaces and B2B platforms will play a crucial role in connecting buyers and sellers in this evolving ecosystem.

Regional Market Expansion

While North America and Europe currently lead in laser cleaning adoption, the Asia-Pacific region is expected to witness the fastest growth by 2026. Countries like China, India, and South Korea are investing heavily in advanced manufacturing and infrastructure, driving demand for high-precision cleaning tools. Local manufacturers are also entering the market, increasing competition and expanding the range of laser cleaner machines for sale at various price points. This regional diversification will enhance global supply chains and reduce dependency on a few key suppliers.

Integration with Industry 4.0 and Smart Manufacturing

By 2026, laser cleaning systems will increasingly be integrated into smart factories as part of Industry 4.0 initiatives. IoT-enabled laser cleaners will offer remote diagnostics, predictive maintenance, and seamless data integration with manufacturing execution systems (MES). This connectivity improves operational efficiency and enables real-time process optimization. Buyers will prioritize intelligent, scalable machines, influencing product development and marketing strategies in the laser cleaning sector.

Conclusion

The market for laser cleaner machines for sale in 2026 will be characterized by rapid innovation, broader industrial adoption, and a strong push toward sustainability. With falling costs, improved technology, and supportive regulations, laser cleaning is transitioning from a specialized tool to a standard solution in modern manufacturing and maintenance. Companies looking to invest in this technology should monitor regional trends, explore flexible acquisition models, and prioritize systems with smart capabilities to stay competitive.

Common Pitfalls When Sourcing Laser Cleaner Machines for Sale: Quality and Intellectual Property Concerns

Sourcing a laser cleaner machine for sale can be a strategic investment for industrial cleaning, rust removal, and surface preparation. However, buyers often encounter critical pitfalls related to quality control and intellectual property (IP) issues—especially when sourcing from international or less-regulated suppliers. Being aware of these risks helps ensure you acquire a reliable, safe, and legally compliant machine.

1. Compromised Build Quality and Performance

One of the most frequent issues is receiving a laser cleaner that underperforms or fails prematurely due to poor manufacturing standards. Many suppliers, particularly on online marketplaces, may advertise high-power lasers (e.g., 1000W or 2000W) that don’t deliver the promised output. Key aspects to watch for include:

- Inaccurate power ratings: Some machines are labeled with exaggerated wattage. An advertised 2000W laser may actually operate at 1200W or less, reducing cleaning efficiency.

- Substandard components: Use of low-quality optics, cooling systems, or laser sources (e.g., unbranded or counterfeit laser diodes) can lead to frequent breakdowns.

- Lack of safety certifications: Machines may lack CE, FDA, or IEC 60825 compliance, posing serious safety risks to operators and violating local regulations.

Always request third-party test reports, conduct factory audits, or order a sample before bulk purchasing.

2. Lack of Transparency in Technical Specifications

Many suppliers provide vague or incomplete technical data. Red flags include missing information on:

- Beam quality (M² value)

- Pulse frequency and duration

- Spot size and working distance

- Cooling method (air vs. water-cooled)

Without these details, it’s difficult to assess real-world performance or compare models objectively.

3. Intellectual Property (IP) Infringement

A growing concern in the laser cleaning market is the unauthorized replication of patented technology. Some manufacturers, particularly in regions with lax IP enforcement, produce machines that copy designs, software interfaces, or optical configurations from established brands.

Risks of IP infringement include:

- Legal liability: Importing or using a machine that violates patents can lead to lawsuits, customs seizures, or fines.

- No software/firmware updates: Cloned machines often use pirated or reverse-engineered control software, which may lack updates, security patches, or technical support.

- Limited innovation and support: Infringing manufacturers rarely invest in R&D, resulting in stagnant product development and poor after-sales service.

To mitigate this risk, verify the manufacturer’s original certifications, request IP documentation, and avoid deals that seem too good to be true.

4. Inadequate After-Sales Support and Warranty

Even if the machine functions initially, poor after-sales support can render it useless over time. Common issues include:

- Limited or no English-speaking technical support

- Unavailability of spare parts

- Warranty terms that are difficult to enforce internationally

Ensure the supplier offers a clear warranty (preferably 1–2 years), accessible customer service, and local service partners if possible.

5. Misleading Marketing and Fake Reviews

Some sellers use stock photos, fabricated customer testimonials, or paid reviews to create a false impression of reliability and popularity. Always verify claims independently through:

- Video demonstrations of the actual machine

- Direct communication with past buyers

- Industry forums or third-party review platforms

In summary, while laser cleaner machines offer transformative cleaning capabilities, sourcing them requires due diligence. Prioritize suppliers with verifiable quality standards, transparent specifications, legitimate IP, and reliable support to avoid costly mistakes.

Logistics & Compliance Guide for Laser Cleaner Machine For Sale

Product Classification & Documentation

Before shipping, accurately classify the laser cleaner machine under the correct Harmonized System (HS) code, typically falling under 8515.21 or 8515.30 (laser machines for industrial use), depending on specifications. Confirm with local customs authorities or a customs broker. Prepare essential shipping documents, including a detailed commercial invoice, packing list, bill of lading (or air waybill), and certificate of origin. Include technical specifications such as laser wavelength, power output, and safety classifications on the invoice to facilitate customs clearance.

Export Controls & Regulatory Compliance

Laser cleaning machines may be subject to export control regulations due to their high-power laser components. Verify if the machine requires an export license under your country’s regulations—for instance, under the U.S. Export Administration Regulations (EAR) or the EU Dual-Use Regulation. Classify the laser under the appropriate Export Control Classification Number (ECCN) or determine if it falls under license exceptions. Ensure compliance with international laser safety standards (such as IEC 60825-1) and include required warning labels and safety documentation.

Safety & Hazard Communication

High-power lasers pose significant safety risks, including eye and skin hazards. Ensure the machine complies with safety standards applicable in the destination country (e.g., FDA/CDRH regulations in the U.S., CE marking under the Machinery Directive and EN standards in the EU). Include a user manual with safety instructions, operational training recommendations, and emergency procedures. Provide Material Safety Data Sheets (MSDS) if hazardous materials (e.g., fumes from cleaning processes) are generated during operation. Clearly label the machine with laser safety warnings and classification (e.g., Class 4 Laser Product).

Packaging & Transportation

Use robust, shock-resistant packaging to protect the laser cleaner during transit. Secure all optical components and sensitive electronics with anti-vibration materials. Clearly mark packages with handling labels such as “Fragile,” “This Side Up,” and “Laser Equipment – Do Not Open.” Avoid exposure to extreme temperatures, moisture, and dust during storage and transport. For international shipments, use freight forwarders experienced in handling industrial machinery and laser equipment.

Import Regulations & Duties

Research the import requirements of the destination country, including applicable tariffs, import permits, and conformity assessment procedures. Some countries may require pre-shipment inspections or local representative registration. In the EU, ensure CE certification and technical file availability. In Canada, compliance with the Radiation Emitting Devices Act (REDA) is mandatory. Prepare to pay import duties and value-added taxes (VAT), and consider using Incoterms (e.g., FOB, DDP) clearly in sales contracts to define responsibility for compliance and costs.

After-Sales Support & Warranty Compliance

Provide clear warranty terms that comply with consumer protection laws in the destination market. Offer remote technical support and, if feasible, on-site service or authorized local service partners. Maintain records of shipped units for traceability and recall management. Ensure software components comply with local cybersecurity and data protection standards, especially if the machine includes IoT or remote monitoring features.

Environmental & Disposal Considerations

Inform buyers of proper end-of-life disposal procedures for the laser cleaner, especially for components containing hazardous materials (e.g., batteries, optical elements). Comply with environmental regulations such as the EU’s WEEE Directive or similar local e-waste laws. Offer take-back programs or partner with certified e-waste recyclers to support sustainable compliance.

Conclusion:

Sourcing a laser cleaning machine for sale is a strategic investment that offers long-term benefits in terms of efficiency, precision, and environmental sustainability. As industries increasingly shift toward eco-friendly and non-abrasive cleaning methods, laser cleaning technology stands out for its ability to remove rust, paint, oxides, and contaminants without damaging underlying surfaces or producing harmful waste.

When sourcing a laser cleaner, it is essential to evaluate key factors such as laser power, pulse frequency, portability, safety features, brand reputation, after-sales support, and total cost of ownership. Working with reputable suppliers and choosing machines that meet international safety and quality standards ensures reliability and optimal performance.

Additionally, considering future scalability and the specific cleaning requirements of your application will help in selecting the right model. Whether for industrial maintenance, automotive, aerospace, or heritage restoration, a well-sourced laser cleaning machine can significantly enhance productivity while reducing operational costs and environmental impact.

In conclusion, investing in a high-quality laser cleaning machine from a trusted supplier not only improves cleaning processes but also positions your operations at the forefront of modern, sustainable technology.