The global laser cleaning machine market is experiencing robust growth, driven by increasing demand for eco-friendly and precision surface treatment solutions across industries such as automotive, aerospace, and manufacturing. According to a report by Mordor Intelligence, the market was valued at USD 317.6 million in 2023 and is projected to reach USD 726.5 million by 2029, growing at a CAGR of approximately 14.8% during the forecast period. This expansion is fueled by the rising adoption of laser cleaning as a replacement for traditional methods like sandblasting and chemical treatments, due to its non-abrasive nature, minimal maintenance, and compliance with environmental regulations. As industrial automation accelerates and manufacturers prioritize efficiency and sustainability, investment in advanced laser cleaning technologies has surged. In this competitive landscape, a select group of manufacturers have emerged as leaders, combining technological innovation, global reach, and strong R&D capabilities. Based on market presence, product performance, and industry reputation, the following eight companies represent the forefront of laser cleaning machine manufacturing worldwide.

Top 8 Laser Clean Machine Manufacturers (2026 Audit Report)

(Ranked by Factory Capability & Trust Score)

#1 Laserax

Website: laserax.com

Key Highlights: Laserax works with the world’s leading manufacturers to implement laser cleaning, welding, texturing, and marking solutions….

#2 Clean Laser Systems

Website: cleanlaser.de

Key Highlights: IPG | cleanLASER has been developing and producing high-precision laser systems for cleaning and industrial surface treatment for more than 20 years….

#3 P-laser Industrial laser cleaning

Website: p-laser.com

Key Highlights: Specializing in the production of premium-quality, Belgian-made industrial laser cleaning equipment, we take great pride in our craftsmanship and innovative ……

#4 Laser Photonics

Website: laserphotonics.com

Key Highlights: Laser Photonics manufactures reliable, safe, and eco-friendly Laser Cleaning, Laser Cutting, Laser Engraving, Laser Marking, and Laser Welding solutions….

#5 SFX Laser

Website: sfxlaser.com

Key Highlights: SFX Laser is a 20+ years professional laser equipment manufacturer including laser cleaning machine, laser welding machine, fiber laser engraver, fiber laser…

#6 Laser cleaner machine prices

Website: pulsar-laser.com

Key Highlights: PULSAR Laser – official logo of professional laser rust and paint removal cleaners · NEW EXCLUSIVE DISTRIBUTOR for USA and CANADA. CLICK ME ……

#7 Netalux

Website: netalux.com

Key Highlights: Discover our award-winning Laser Cleaning Solutions for the world’s most demanding industries. Discover our products and global service now….

#8 Handheld Laser Cleaning Machines

Website: ipgphotonics.com

Key Highlights: Handheld and portable laser cleaning machines designed for manual applications including rust removal, paint stripping, restoration, and more….

Expert Sourcing Insights for Laser Clean Machine

H2: 2026 Market Trends for Laser Cleaning Machines

The global laser cleaning machine market is poised for transformative growth by 2026, driven by technological advancements, increasing environmental regulations, and broader industrial adoption. As industries seek more sustainable, efficient, and precise cleaning solutions, laser cleaning technology is emerging as a preferred alternative to traditional methods such as sandblasting, chemical cleaning, and dry ice blasting.

1. Technological Advancements and Automation Integration

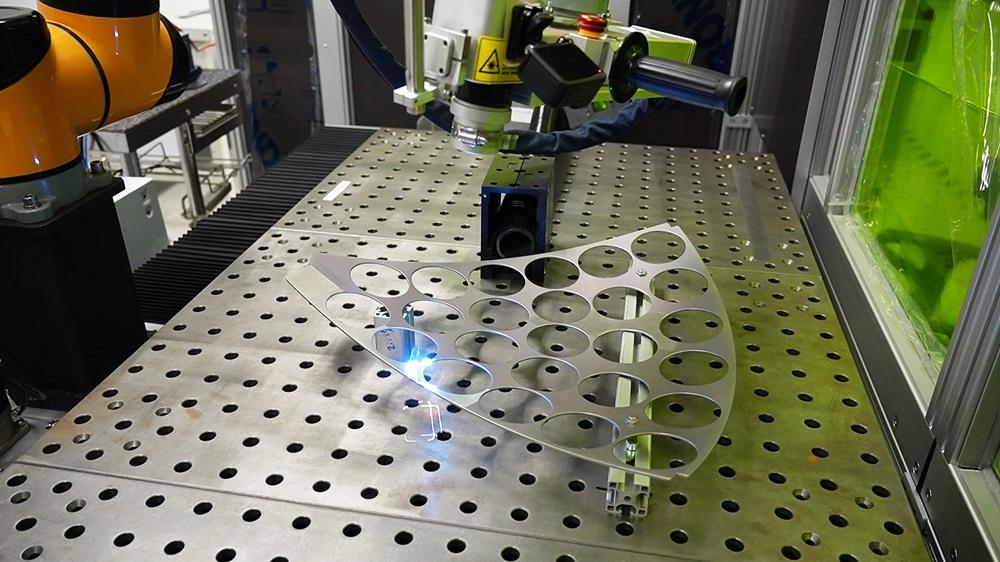

By 2026, laser cleaning machines are expected to feature enhanced automation, artificial intelligence (AI), and robotics integration. Smart laser systems with real-time monitoring, adaptive power control, and predictive maintenance capabilities will improve reliability and reduce operational downtime. Portable and handheld laser cleaners will gain popularity due to improved ergonomics, battery efficiency, and user-friendly interfaces, expanding their use in field applications such as heritage restoration and ship maintenance.

2. Rising Demand from Key Industries

The automotive, aerospace, and manufacturing sectors will remain primary drivers of market growth. In automotive, laser cleaning is increasingly used for surface preparation before welding, paint stripping, and mold cleaning. Aerospace manufacturers are adopting laser technology for precision cleaning of turbine blades and critical components without causing substrate damage. Additionally, the energy sector—especially in nuclear decommissioning and renewable energy equipment maintenance—will boost demand due to the non-abrasive and contamination-free nature of laser cleaning.

3. Environmental and Regulatory Drivers

Stringent environmental regulations worldwide are pushing industries to phase out chemical and abrasive cleaning methods that generate hazardous waste. Laser cleaning, being a dry, chemical-free process with minimal secondary waste, aligns with green manufacturing initiatives. By 2026, compliance with environmental standards such as REACH, RoHS, and EPA regulations will accelerate the shift toward laser-based solutions, particularly in Europe and North America.

4. Expansion in Emerging Markets

Asia-Pacific, particularly China and India, will witness robust market expansion due to rapid industrialization, government support for advanced manufacturing, and growing awareness of laser technology benefits. Local manufacturers are investing in R&D to produce cost-effective laser cleaning systems, making the technology more accessible to small and medium enterprises (SMEs).

5. Cost Reduction and Market Democratization

Although high initial investment has historically limited adoption, ongoing improvements in fiber laser efficiency and component miniaturization are reducing costs. By 2026, competitive pricing and leasing/subscription models are expected to democratize access, enabling wider deployment across diverse industrial segments.

6. Focus on Safety and Standardization

As adoption grows, there will be increased emphasis on safety protocols and international standards for laser cleaning operations. Regulatory bodies and industry consortia are likely to establish clearer guidelines for laser class usage, operator training, and workplace safety, fostering greater confidence among end-users.

Conclusion

By 2026, the laser cleaning machine market will be characterized by innovation, sustainability, and broad industrial integration. With a projected CAGR of over 15% from 2022 to 2026 (depending on region and segment), the market is on track to exceed USD 1.5 billion globally. Companies investing in R&D, strategic partnerships, and application-specific solutions will be best positioned to capitalize on this upward trajectory.

Common Pitfalls When Sourcing Laser Cleaning Machines (Quality, IP)

Sourcing laser cleaning machines, especially from overseas or less-established suppliers, can present significant challenges related to product quality and intellectual property (IP) risks. Being aware of these pitfalls is essential to protect your investment and business operations.

Quality-Related Pitfalls

Under-Specification and Inaccurate Performance Claims

Many suppliers exaggerate key performance metrics such as laser power, cleaning speed, and effective working distance. A machine advertised as “1000W” may actually deliver significantly less due to measurement inconsistencies or poor beam quality. This results in reduced cleaning efficiency and longer cycle times, undermining operational productivity.

Use of Low-Grade Components

To cut costs, some manufacturers use substandard optical components, cooling systems, or power supplies. These compromises lead to shorter lifespans, frequent breakdowns, and inconsistent cleaning results. Poor beam delivery optics, for example, can cause beam divergence and hotspots, damaging treated surfaces.

Inadequate Safety Features

Laser cleaning involves Class 4 lasers, which pose serious safety risks. Some machines lack proper safety interlocks, protective housings, or laser emission indicators. Sourcing from suppliers who ignore international safety standards (e.g., IEC 60825) exposes users to regulatory non-compliance and workplace hazards.

Poor Build Quality and Durability

Machines assembled with poor craftsmanship may suffer from misalignment, vibration issues, or electrical faults. This is especially problematic in industrial environments where reliability and ruggedness are critical. Inconsistent quality control during production further compounds these issues.

Lack of After-Sales Support and Spare Parts Availability

Even if the initial machine performs well, sourcing from suppliers with limited regional service networks can lead to long downtimes. A lack of readily available spare parts or trained technicians can render the machine unusable for extended periods, disrupting operations.

Intellectual Property (IP) Pitfalls

Risk of IP Infringement

Some manufacturers reverse-engineer or copy designs from established brands, potentially violating patents or copyrights. Purchasing such equipment may inadvertently involve your company in IP disputes, especially if the machine is used in markets with strong IP enforcement.

Unclear or Hidden IP Ownership

Suppliers may not disclose whether key technologies (e.g., control software, beam delivery systems) are licensed or proprietary. This lack of transparency can expose buyers to legal risks, particularly if the original IP holder takes action against downstream users.

Use of Unlicensed Software or Firmware

Many laser machines rely on embedded software for control and diagnostics. Some low-cost suppliers use pirated or unlicensed software, which may contain malware, lack updates, or expose your business to liability under software compliance laws.

Limited Ability to Customize or Innovate

When sourcing from generic manufacturers, you may receive closed systems with no access to source code or technical documentation. This restricts your ability to modify, integrate, or improve the machine—hindering innovation and limiting long-term adaptability.

Reputational Damage from Association

Partnering with suppliers known for IP violations or poor quality can harm your brand reputation, especially if end customers or regulators discover the origin of the technology.

Mitigation Strategies

To avoid these pitfalls, conduct thorough due diligence: verify technical specifications with third-party testing, audit supplier facilities, request compliance certifications (CE, FDA, RoHS), and consult legal experts to assess IP risks. Prioritize suppliers with transparent supply chains, robust warranties, and established service networks.

Logistics & Compliance Guide for Laser Clean Machine

This guide outlines the essential logistics considerations and compliance requirements for the safe and legal transportation, handling, and operation of Laser Clean Machines.

Shipping and Transportation

Ensure the laser cleaning machine is securely packed in a robust, shock-resistant crate using anti-static and moisture-resistant materials. Properly label the packaging with “Fragile,” “This Side Up,” and “Do Not Stack” indicators. For international shipments, comply with IATA (air), IMDG (sea), or ADR (road) regulations as applicable. Include all necessary shipping documents such as commercial invoice, packing list, bill of lading/air waybill, and export declaration. Verify that the destination country has no import restrictions on laser equipment and obtain any required permits or licenses prior to shipment.

Import and Customs Compliance

Verify the correct HS (Harmonized System) code for laser cleaning machines—typically under 8515.21 or 8515.80, depending on technical specifications. Prepare and submit all required customs documentation, including a Certificate of Origin, detailed technical specifications, and a conformity declaration. Be aware of import duties, VAT, and potential anti-dumping measures. For shipments to the EU, ensure compliance with CE marking requirements; for the U.S., verify FDA/CDRH registration if the laser falls under performance standard 21 CFR 1040.10. Engage a licensed customs broker in the destination country to facilitate clearance.

Regulatory and Safety Certification

The laser cleaning machine must comply with relevant safety and electromagnetic compatibility standards. In the European Union, ensure CE marking according to the Machinery Directive (2006/42/EC), Low Voltage Directive (2014/35/EU), and EMC Directive (2014/30/EU). Use appropriate laser safety classifications (typically Class 4) and include warning labels in the local language. In the United States, comply with OSHA, ANSI Z136.1 (Safe Use of Lasers), and FDA/CDRH reporting requirements. Maintain technical files and Declaration of Conformity for audit purposes.

On-Site Handling and Installation

Use appropriate lifting equipment (e.g., forklifts, pallet jacks) and trained personnel to unload and move the machine. Ensure the installation site has adequate floor load capacity, ventilation, and access to required power supply (voltage, phase, grounding). Observe all local electrical codes and safety standards during setup. Provide clear space around the machine for operation, maintenance, and emergency access. Install safety barriers, interlocks, and emergency stop mechanisms as specified in the user manual.

Operational Compliance and Training

Only trained and authorized personnel should operate the laser cleaning machine. Provide comprehensive training covering laser safety, personal protective equipment (PPE), emergency procedures, and proper use of fume extraction systems. Operators must wear appropriate PPE, including laser safety goggles with the correct optical density for the laser wavelength. Maintain an up-to-date laser safety program, including standard operating procedures (SOPs) and risk assessments. Keep logs of maintenance, safety inspections, and operator training records.

Environmental and Waste Management

Laser cleaning processes may generate particulate matter, fumes, and debris. Install and maintain a HEPA-filtered fume extraction system to capture airborne contaminants. Dispose of collected waste according to local environmental regulations—classify waste properly (e.g., hazardous vs. non-hazardous) based on material being cleaned. Avoid cleaning surfaces containing regulated substances (e.g., lead-based paint, cadmium coatings) without proper environmental permits and containment procedures. Monitor air quality if required by local occupational health standards.

Documentation and Record Keeping

Maintain a comprehensive compliance dossier including: user manuals, technical specifications, safety data sheets (if applicable), certificates of conformity (CE, FDA, etc.), import/export documents, maintenance logs, training records, and incident reports. Store documentation securely and ensure it is accessible for audits, inspections, or regulatory inquiries. Update records regularly to reflect modifications, repairs, or changes in compliance status.

Conclusion for Sourcing a Laser Cleaning Machine

In conclusion, sourcing a laser cleaning machine represents a strategic investment in advanced, eco-friendly, and efficient surface treatment technology. After evaluating various suppliers, models, technical specifications, cost structures, and after-sales support, it is evident that laser cleaning offers significant advantages over traditional methods—such as reduced environmental impact, minimal substrate damage, lower operational costs over time, and compliance with health and safety regulations.

The selected machine aligns with our operational requirements in terms of cleaning capacity, portability, ease of integration, and durability. Additionally, partnering with a reputable manufacturer ensures access to reliable technical support, training, and spare parts, which are crucial for long-term performance and minimal downtime.

Moving forward, implementation of the laser cleaning system will enhance productivity, improve cleaning precision, and support sustainability goals. Regular performance monitoring and operator training will be essential to maximize return on investment. Overall, sourcing this technology positions the organization at the forefront of industrial innovation and responsible manufacturing practices.