The global personalized signage market has experienced robust growth in recent years, driven by rising demand for customized home décor, commercial branding, and sustainable gifting solutions. According to a report by Grand View Research, the global custom signage market was valued at USD 28.7 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 5.3% from 2023 to 2030. A key contributor to this expansion is the increasing popularity of laser-engraved wood products, which combine artisanal aesthetics with precision manufacturing. Mordor Intelligence projects that the laser engraving market will grow at a CAGR of over 7% from 2023 to 2028, fueled by technological advancements and growing small business adoption of personalized branding tools. Within this niche, laser burned wood signs have emerged as a sought-after category, prized for their durability, natural appeal, and intricate design capabilities. As demand surges, manufacturers specializing in this craft are scaling operations, refining laser accuracy, and integrating sustainable sourcing practices to meet consumer expectations. The following list highlights the top nine manufacturers leading innovation and quality in the laser burned wood signs industry.

Top 9 Laser Burned Wood Signs Manufacturers (2026 Audit Report)

(Ranked by Factory Capability & Trust Score)

#1 Laser Engraved

Website: stokessigncompany.com

Key Highlights: Breathe new life into your signs with locally crafted, vibrant laser-engraved signage. Discover a world of precision and durability.Missing: burned manufacturer…

#2 Wood Laser Engraving

Website: gravurelaser.ca

Key Highlights: We are the specialists in industrial laser engraving on wood. For almost 15 years, we have been serving commercial customers throughout Quebec….

#3 Custom Signs: Wood Burned Business Signs

#4 Custom Wood Burning Sign

Website: weavercustomengravings.com

Key Highlights: Bring your ideas to life with our Custom Burned Wood Sign, perfect for adding a personalized, rustic touch to your home or as a heartfelt gift….

#5 Custom Wood Signs

Website: woodlandmanufacturing.com

Key Highlights: 1-day deliveryCustom wood signs, engraved wood signs, reclaimed wood signs and sand blasted wood signs of any size, shape or color. Easily make and install wooden signs….

#6 WOOD BURNED SIGNS

Website: saunzee.com

Key Highlights: We create beautiful wood burned signs for the sign industry. We make custom outdoor wood burned signs and indoor custom wood burned signs….

#7 Wood Dimensional Signage

Website: parallaxdigital.com

Key Highlights: Engraved wood signs involve cutting or etching designs into the wood surface using laser engraving or other tools. This method allows for precision and detailed ……

#8 E2 Laser Engraving LLC

Website: e2laserengraving.com

Key Highlights: E2 Laser Engraving LLC makes laser engraved & cut crafts out of wood and acrylic materials. We can also love to make photo engravings that are special to ……

#9 Leader In Permanent Marking Solutions

Website: gravotech.us

Key Highlights: Gravotech designs, manufactures, and distributes innovative engraving, marking, and cutting solutions….

Expert Sourcing Insights for Laser Burned Wood Signs

H2: 2026 Market Trends for Laser Burned Wood Signs

The market for laser burned wood signs is poised for continued evolution in 2026, driven by technological advancements, shifting consumer preferences, and expanding applications. Here’s an analysis of key trends expected to shape the industry:

1. Heightened Demand for Hyper-Personalization & Customization (H2)

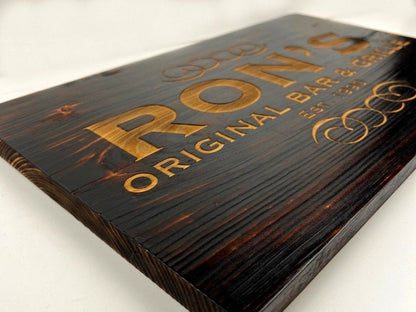

By 2026, consumers will increasingly seek unique, one-of-a-kind decor and gifts. Laser burning enables intricate, precise customization—names, dates, quotes, monograms, and custom illustrations—making it ideal for personalized home decor, wedding favors, pet memorials, and corporate gifts. Expect mass customization platforms to emerge, allowing customers to design signs online with real-time previews, driving broader market reach.

2. Integration of Advanced Laser Technology (H2)

Adoption of higher-powered and AI-assisted laser engravers will become more widespread. These systems offer faster production, finer detail resolution, and improved consistency. Fiber lasers for metal inlays and hybrid systems (laser + CNC routing) will allow for multi-material signage, expanding creative possibilities. Automation in material loading/unloading will also boost efficiency for mid-to-large scale producers.

3. Sustainability as a Key Selling Point (H2)

Eco-conscious consumers will prioritize sustainable materials and processes. Suppliers using FSC-certified wood, reclaimed lumber, and non-toxic finishes will gain a competitive edge. Marketing efforts will increasingly highlight the renewable nature of wood and the low-waste, energy-efficient aspects of laser engraving compared to traditional signage methods.

4. Expansion into Commercial and Branded Environments (H2)

Beyond home decor, laser burned wood signs will see growing use in commercial spaces—boutique hotels, cafes, retail stores, and offices—seeking warm, artisanal branding. Businesses will use custom wooden signage for directional cues, menu boards, and brand storytelling, valuing the natural aesthetic that complements modern interior design trends.

5. Rise of Niche and Themed Markets (H2)

Specialized segments such as rustic farmhouse, coastal, industrial, and minimalist designs will continue to thrive. Additionally, seasonal and holiday-themed signs (e.g., personalized advent calendars, Halloween decor) will see increased demand, supported by timely digital marketing and e-commerce strategies.

6. E-Commerce and Direct-to-Consumer Dominance (H2)

Online marketplaces (Etsy, Shopify, Amazon Handmade) will remain primary sales channels. Brands investing in strong digital marketing, SEO, social media engagement (especially Instagram and Pinterest), and user-generated content will capture greater market share. Subscription models for seasonal decor or rotating signage could emerge as a novel trend.

In summary, by 2026, the laser burned wood sign market will be defined by deeper personalization, enhanced technology, sustainability, and broader commercial adoption—positioning it as a resilient and innovative segment within the custom decor industry.

Common Pitfalls When Sourcing Laser Burned Wood Signs

Sourcing laser burned wood signs can be cost-effective and efficient, but several common pitfalls can impact quality, timelines, and intellectual property (IP) protection. Being aware of these issues helps ensure a successful partnership with suppliers.

Poor Material Quality and Inconsistent Wood Selection

One of the most frequent issues is inconsistent or subpar wood quality. Suppliers may use low-grade plywood, warped boards, or wood with excessive knots, grain variation, or moisture content. This leads to uneven burning, charring, or warping after laser engraving. Always specify wood type (e.g., birch, bamboo, walnut), thickness, and grading standards in your purchase agreement.

Inadequate Laser Precision and Design Fidelity

Lower-tier manufacturers may use outdated or poorly calibrated laser machines, resulting in blurry, shallow, or misaligned engravings. Fine details may be lost, and fonts or intricate patterns can appear distorted. Request physical samples before placing bulk orders to assess engraving depth, edge sharpness, and consistency across multiple pieces.

Lack of Quality Control Processes

Many suppliers—especially overseas or high-volume shops—lack stringent quality control (QC). This can result in signs with burn marks, splinters, inconsistent staining, or incomplete cuts. Ask about their QC procedures, defect rates, and whether each piece is inspected before shipping. Consider third-party inspections for large orders.

Intellectual Property (IP) Infringement and Unauthorized Reproduction

This is a critical risk when sharing custom designs. Unethical suppliers may reproduce your artwork, sell duplicates to competitors, or list your designs in their own catalogs. Always use a clear Non-Disclosure Agreement (NDA) and include IP ownership clauses in contracts. Watermark design files sent for quotes and limit distribution to trusted partners.

Hidden Costs and Minimum Order Quantity (MOQ) Traps

Some suppliers advertise low per-unit prices but impose high MOQs or charge extra for setup, design adjustments, or packaging. Shipping, import duties, and handling fees may also be underestimated. Clarify all costs upfront, including tooling, revisions, and freight, to avoid budget overruns.

Delays Due to Communication and Production Bottlenecks

Time zone differences, language barriers, and unclear communication can delay production and revisions. Confirm lead times, production capacity, and responsiveness before committing. Establish a point of contact and set milestones to monitor progress.

Environmental and Safety Compliance Oversights

Wood sourcing and laser burning can raise sustainability and safety concerns. Some suppliers use uncertified wood or fail to manage VOC emissions from laser cutting. Ensure compliance with environmental standards (e.g., FSC-certified wood) and safety regulations, especially for signs intended for children or indoor use.

By addressing these pitfalls proactively—through vetting suppliers, securing IP, and validating quality—you can source laser burned wood signs that meet both aesthetic and business standards.

Logistics & Compliance Guide for Laser Burned Wood Signs

Product Description and Classification

Laser burned wood signs are decorative items created by using a laser engraving machine to burn designs, text, or images onto wooden surfaces such as birch, pine, or bamboo. These products fall under HS (Harmonized System) code 4421.99 in most international markets, which covers other articles of wood not elsewhere specified. Proper classification ensures accurate duty assessment and compliance with customs regulations.

Material Sourcing and Sustainability Compliance

Ensure all wood used in production is legally sourced and complies with international forestry regulations such as the Lacey Act (U.S.) and EU Timber Regulation (EUTR). Maintain documentation including supplier declarations, species identification, and country of origin. Use FSC (Forest Stewardship Council) or PEFC-certified wood where possible to meet sustainability standards and enhance marketability.

Packaging and Labeling Requirements

Package signs securely using recyclable or biodegradable materials to prevent damage during transit. Clearly label each package with:

– Product name and description

– Country of origin (e.g., “Made in USA”)

– Dimensions and weight

– Care instructions (e.g., “Keep dry, avoid direct sunlight”)

For international shipments, include multilingual labeling if required by destination country.

Domestic and International Shipping Considerations

Use carriers experienced in handling fragile, low-weight goods (e.g., USPS, UPS, DHL). For domestic U.S. shipments, ensure compliance with USPS or carrier-specific guidelines for wood products. For international shipping:

– Declare accurate product value and purpose (commercial gift vs. retail sale)

– Include a packing list and commercial invoice

– Comply with phytosanitary regulations if applicable (though raw untreated wood may require inspection)

Avoid using wood packaging materials (e.g., pallets, crates) unless ISPM 15 compliant (heat-treated and stamped).

Regulatory Compliance and Safety Standards

Laser burned signs are generally exempt from safety certifications (e.g., ASTM, CPSC) unless marketed as children’s toys. However, ensure:

– No hazardous finishes or adhesives are used

– Laser processing complies with local air quality and emissions standards (capture systems for wood particulate and fumes)

– Business operations adhere to OSHA guidelines for laser and woodworking equipment safety

Import/Export Documentation

For exports, prepare:

– Commercial invoice (with HS code, value, buyer/seller details)

– Packing list

– Certificate of Origin (if claiming preferential tariffs)

For imports, verify tariff rates and restrictions in the destination country. Some countries may restrict certain wood species or require import permits.

Hazard Communication and Disposal

Provide safety data sheets (SDS) if chemical finishes are applied. Advise customers that burned wood signs are for decorative use only and not intended for food contact or outdoor permanent installation unless sealed appropriately. Recommend proper disposal via composting or wood waste recycling programs.

Recordkeeping and Traceability

Maintain records of material sourcing, production batches, shipping documents, and customer transactions for a minimum of five years. This supports compliance audits, recall management, and customs inquiries. Implement batch numbering or QR codes for end-to-end traceability.

Summary

Successfully managing logistics and compliance for laser burned wood signs requires attention to material sourcing, accurate classification, proper documentation, and adherence to environmental and shipping regulations. Proactive compliance reduces delays, avoids penalties, and supports sustainable, scalable operations.

In conclusion, sourcing laser-burned wood signs offers a unique blend of craftsmanship, customization, and durability, making them ideal for home decor, gifts, branding, and commercial signage. With the precision of laser technology, intricate designs and personalized details can be consistently achieved, ensuring high-quality results. When sourcing these products, it is essential to evaluate suppliers based on material quality, laser precision, customization capabilities, and sustainability practices. Whether sourcing from local artisans, online marketplaces, or manufacturing partners, conducting due diligence ensures reliable, ethically produced signs that meet both aesthetic and functional needs. Overall, laser-burned wood signs represent a valuable investment in timeless, handcrafted appeal with modern technological precision.