The global laser blasting machine market is experiencing robust growth, driven by increasing demand for precision surface treatment across industries such as aerospace, automotive, and electronics. According to Grand View Research, the global laser cleaning and surface treatment market was valued at USD 924.7 million in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 18.6% from 2023 to 2030. This surge is fueled by the growing adoption of eco-friendly cleaning technologies and the need for efficient, non-abrasive surface preparation methods. As industries prioritize automation and sustainability, laser blasting—offering high precision and minimal environmental impact—has emerged as a preferred alternative to traditional sandblasting and chemical cleaning. In this competitive landscape, several manufacturers are leading innovation through advanced laser technologies, scalability, and global service networks. Based on market presence, technological capabilities, and customer reviews, the following ten companies represent the top laser blasting machine manufacturers shaping the future of industrial surface treatment.

Top 10 Laser Blasting Machine Manufacturers (2026 Audit Report)

(Ranked by Factory Capability & Trust Score)

#1 Laser Machine – Laser Equipment Manufacturer

Website: dplaser.com

Key Highlights: DPLASER is a leading manufacturer & factory of industrial laser welding, laser cutting, laser marking and laser cleaning machines….

#2 P-laser Industrial laser cleaning

Website: p-laser.com

Key Highlights: we engineer and manufacture the most advanced—and most powerful—pulsed industrial laser cleaning systems on the market, built for both manual and automated ……

#3 Laserax

Website: laserax.com

Key Highlights: Laserax works with the world’s leading manufacturers to implement laser cleaning, welding, texturing, and marking solutions….

#4 Laser Photonics

Website: laserphotonics.com

Key Highlights: Laser Photonics manufactures reliable, safe, and eco-friendly Laser Cleaning, Laser Cutting, Laser Engraving, Laser Marking, and Laser Welding solutions….

#5 Clean Laser Systems

Website: cleanlaser.de

Key Highlights: IPG | cleanLASER has been developing and producing high-precision laser systems for cleaning and industrial surface treatment for more than 20 years….

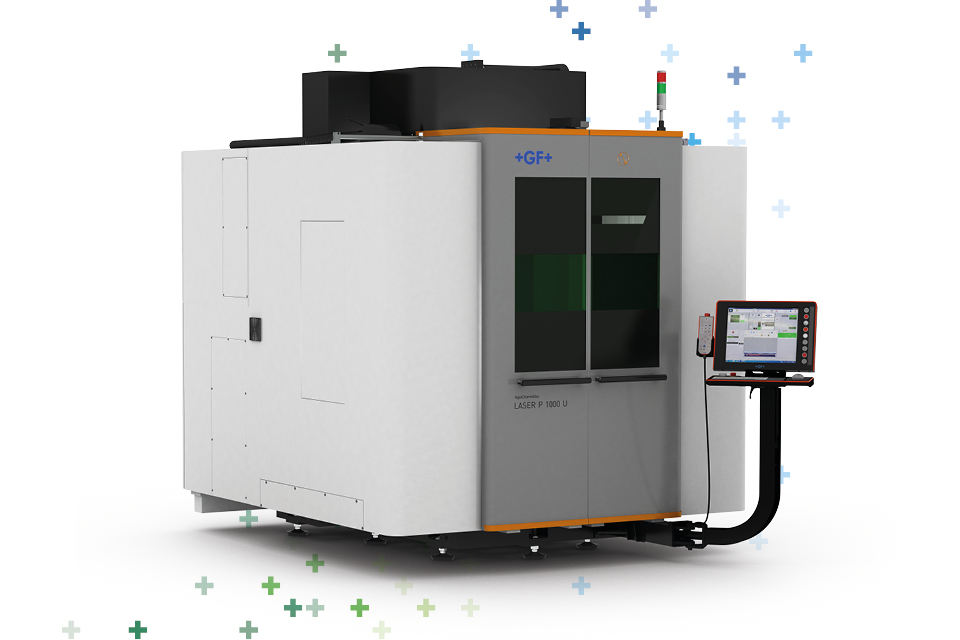

#6 LASER P series

Website: gfms.com

Key Highlights: GF Machining Solutions’ digital Laser texturing technology—fully digital, precise and ecologically sound—is already a proven solution for adding distinct ……

#7 Laser Cleaning

Website: ipgphotonics.com

Key Highlights: Laser cleaning is used across a variety of industries to remove unwanted surface materials like coatings, paints, rust, oil, and for surface preparation for ……

#8 Fonon

Website: fonon.us

Key Highlights: Fonon specializes in creating advanced laser technologies and laser solutions for the military & defense industry. Laser cleaning, marking and defense ……

#9 Laser Cleaning vs. Dustless Blasting

Website: dustlessblasting.com

Key Highlights: While laser cleaning excels in precision for delicate surfaces, Dustless Blasting is superior for tough jobs like removing coatings and profiling surfaces….

#10 Vytek Laser Systems

Website: vytek.com

Key Highlights: Vytek designs, builds, and sells a complete line of laser solutions for cleaning, engraving, marking, cutting, and welding, built to exacting standards….

Expert Sourcing Insights for Laser Blasting Machine

2026 Market Trends for Laser Blasting Machines

The global market for laser blasting machines is poised for significant transformation by 2026, driven by technological advancements, rising industrial automation, and growing demand for precision surface treatment across key sectors. As industries shift toward eco-friendly and efficient manufacturing processes, laser blasting—also known as laser cleaning or ablation—is emerging as a superior alternative to traditional abrasive and chemical cleaning methods. This analysis explores the major market trends expected to shape the laser blasting machine industry in 2026.

Technological Innovation and System Integration

By 2026, laser blasting machines are expected to feature enhanced automation and integration with Industry 4.0 systems. Advancements in fiber laser technology will deliver higher peak powers, improved beam quality, and greater energy efficiency, enabling faster processing speeds and deeper cleaning capabilities. Integration with robotics and artificial intelligence (AI) will allow for real-time monitoring, adaptive cleaning paths, and predictive maintenance, reducing downtime and optimizing performance. Smart sensors and IoT-enabled devices will become standard, providing remote diagnostics and operational data analytics to improve productivity across manufacturing and maintenance workflows.

Expansion in Automotive and Aerospace Applications

The aerospace and automotive sectors are projected to be primary growth drivers for laser blasting machines by 2026. In aerospace, the need for non-contact, residue-free surface preparation for coating, welding, and maintenance operations makes laser blasting ideal for turbine blade cleaning, paint stripping, and corrosion removal. Similarly, in the automotive industry, laser systems will be increasingly adopted for engine part refurbishment, weld zone cleaning, and EV battery component preparation. Stringent environmental regulations and the push for lightweight materials will further accelerate adoption in these high-precision industries.

Environmental and Regulatory Advantages

Environmental sustainability will play a critical role in the adoption of laser blasting technology by 2026. Unlike sandblasting or chemical solvents, laser cleaning produces no secondary waste, harmful emissions, or contaminated media, aligning with global environmental standards such as REACH and RoHS. Governments and industrial regulators are expected to incentivize green manufacturing technologies, making laser blasting a preferred choice in regions with strict environmental policies, including the European Union and North America. This regulatory tailwind will encourage wider industrial adoption, particularly in heavy manufacturing and infrastructure maintenance.

Cost Reduction and Market Accessibility

Although initial investment costs for laser blasting systems remain higher than conventional methods, prices are expected to decline by 2026 due to economies of scale, increased competition, and advancements in diode-pumped solid-state lasers. As production volumes rise and modular designs become more common, mid-sized and even small enterprises will gain access to affordable laser cleaning solutions. Rental models and on-demand service platforms may also emerge, further lowering entry barriers and expanding market reach into sectors such as heritage restoration, mold cleaning, and shipbuilding.

Regional Market Growth

Asia-Pacific is anticipated to lead global market growth by 2026, fueled by rapid industrialization in China, India, and South Korea, along with strong government support for advanced manufacturing. Europe will maintain a strong foothold due to its emphasis on sustainable practices and high adoption in automotive and aerospace industries. North America will see steady growth, particularly in defense, energy, and nuclear decommissioning applications. Emerging markets in Latin America and the Middle East will begin to adopt laser blasting for oil & gas infrastructure and large-scale construction projects.

Conclusion

By 2026, the laser blasting machine market will be characterized by technological sophistication, environmental compliance, and broadening industrial applications. As companies prioritize efficiency, precision, and sustainability, laser blasting will transition from a niche technology to a mainstream surface treatment solution. Stakeholders who invest in R&D, strategic partnerships, and scalable system designs will be best positioned to capitalize on the expanding opportunities in this dynamic market.

Common Pitfalls When Sourcing a Laser Blasting Machine: Quality and Intellectual Property Risks

Sourcing a laser blasting machine (also known as laser cleaning or laser ablation equipment) involves significant investment and technical complexity. Buyers often encounter critical pitfalls related to quality assurance and intellectual property (IP) protection. Overlooking these areas can lead to operational failures, legal disputes, and financial losses.

Poor Machine Quality and Performance Inconsistencies

One of the most frequent issues is receiving a machine that fails to meet promised performance standards. Many suppliers, especially those from emerging manufacturing regions, may offer competitive pricing but deliver subpar build quality. Key concerns include unreliable laser sources, inadequate cooling systems, and poorly integrated motion controls. These flaws result in inconsistent cleaning efficiency, frequent downtime, and shortened equipment lifespan. Buyers should insist on third-party validation, on-site testing, and detailed technical specifications before finalizing procurement.

Lack of Certification and Compliance Documentation

Reputable laser systems must comply with international safety and electromagnetic compatibility standards (e.g., CE, FDA, IEC 60825). However, some suppliers provide falsified or incomplete certification documents. This not only poses safety risks but can also lead to legal liability and customs delays. Always verify certifications directly with issuing bodies and request full technical files, including laser classification reports and risk assessments.

Inadequate After-Sales Support and Spare Parts Availability

Even high-quality machines require maintenance and technical support. A major pitfall is sourcing from suppliers with limited global service networks. Delays in obtaining spare parts or accessing skilled technicians can halt production. Ensure the supplier offers a clear service agreement, local support channels, and long-term availability of consumables and critical components like laser diodes or optics.

Intellectual Property Infringement Risks

Purchasing a laser blasting machine with unauthorized or cloned technology exposes buyers to significant IP risks. Some manufacturers replicate patented laser control systems, software algorithms, or optical designs without licensing. If your company uses such equipment, you may face legal action from original technology holders—even if you were unaware of the infringement. Conduct due diligence on the supplier’s R&D capabilities, request IP ownership documentation, and avoid deals that seem too good to be true.

Ambiguous Software Licensing and Proprietary Rights

Laser machines rely heavily on embedded software for process control and automation. Suppliers may claim full ownership while restricting user access or modifications. Others use open-source code without proper licensing, creating compliance risks. Clarify software licensing terms upfront: who owns the code, can it be updated or transferred, and are there restrictions on usage? Ensure your organization retains necessary operational rights.

Hidden Technology Dependencies and Vendor Lock-In

Some suppliers design their machines to work exclusively with proprietary consumables, software updates, or cloud platforms. This creates long-term dependency, inflating operational costs and reducing flexibility. Evaluate whether the system uses open protocols (e.g., OPC UA) and supports third-party integration. Avoid contracts that mandate exclusive service or consumable purchases.

By proactively addressing these quality and IP-related pitfalls, buyers can make informed decisions, mitigate risks, and ensure a reliable, legally sound investment in laser blasting technology.

Logistics & Compliance Guide for Laser Blasting Machine

This guide provides essential information for the safe, efficient, and legally compliant transportation, handling, and operation of a Laser Blasting Machine. Adherence to these guidelines ensures protection of personnel, equipment, and regulatory compliance throughout the machine’s lifecycle.

Shipping and Transportation

Ensure the Laser Blasting Machine is securely packed in a robust, custom-fitted crate that meets international shipping standards (e.g., ISPM 15 for wooden packaging). Use shock-absorbing materials to protect sensitive optical and electronic components. Clearly label the crate with handling instructions: “Fragile,” “This Side Up,” “Do Not Stack,” and “Protect from Moisture.” Confirm that the shipping method complies with IATA (air), IMDG (sea), or ADR (road) regulations if applicable. Provide the carrier with a detailed packing list and technical specifications. Arrange insurance coverage that reflects the full replacement value of the equipment.

Import/Export Compliance

Verify export control classifications such as ECCN (Export Control Classification Number) under the U.S. Commerce Control List (CCL) or equivalent in your jurisdiction, as laser systems may be subject to dual-use regulations (e.g., Wassenaar Arrangement). Obtain necessary export licenses or authorizations before shipment. For import, ensure compliance with destination country regulations, including customs documentation (commercial invoice, packing list, bill of lading/airway bill), and potential requirements for certification (e.g., CE, UKCA, CCC). Confirm that the machine meets voltage, frequency, and plug standards of the receiving country. Consult with a licensed customs broker to facilitate smooth clearance.

Site Preparation and Receiving

Prepare the installation site according to the manufacturer’s specifications, including floor load capacity, ventilation, power supply (voltage, phase, grounding), and ambient conditions (temperature, humidity, dust levels). Ensure the area allows safe access and clearance for operation and maintenance. Upon delivery, inspect the packaging for damage before accepting. Document any visible damage with photos and file a claim with the carrier immediately. Verify contents against the packing list and store components in a dry, secure location until installation.

Installation and Commissioning

Installation must be performed by qualified technicians following the manufacturer’s manual. Ensure all safety interlocks, emergency stops, and ventilation/exhaust systems are correctly connected and functional. Perform laser alignment and calibration according to specified procedures. Conduct a safety audit before powering the system, including verification of laser enclosure integrity and proper labeling (Class 4 laser warning signs). Document the commissioning process and retain records for compliance audits.

Regulatory and Safety Compliance

The Laser Blasting Machine typically falls under Class 4 laser product regulations. Comply with relevant standards such as IEC 60825-1 (Safety of laser products) and ANSI Z136.1 (Safe Use of Lasers). Register the equipment with the appropriate national or local regulatory body if required (e.g., FDA in the U.S. under 21 CFR 1040.10). Implement an approved Laser Safety Program including a designated Laser Safety Officer (LSO), standard operating procedures (SOPs), and employee training. Provide appropriate personal protective equipment (PPE), such as laser safety goggles with correct optical density for the laser wavelength.

Operational Documentation and Record Keeping

Maintain a comprehensive compliance file including the user manual, safety certifications, installation records, maintenance logs, laser safety training records, and incident reports. Conduct regular audits to ensure ongoing compliance with health, safety, and environmental regulations. Retain all documentation for a minimum of seven years or as required by local law.

End-of-Life and Disposal

Dispose of the Laser Blasting Machine in accordance with local, national, and international environmental regulations (e.g., WEEE Directive in the EU). Decommission the laser system safely by a qualified technician, ensuring capacitors are discharged and hazardous materials (e.g., laser gases, batteries, optical components) are handled by certified waste disposal providers. Retain disposal certificates for compliance records.

Conclusion on Sourcing a Laser Blasting Machine

After a thorough evaluation of technical requirements, cost implications, supplier capabilities, and market options, sourcing a laser blasting machine represents a strategic investment in advanced surface preparation technology. Laser blasting offers numerous advantages over traditional methods, including precision, environmental friendliness (no chemicals or media waste), minimal substrate damage, and reduced operational downtime.

The decision to proceed with procurement should be based on aligning the machine’s specifications—such as power output, beam quality, automation compatibility, and cooling systems—with the intended applications and production volume. Additionally, choosing a reputable supplier that provides technical support, training, and warranty coverage is critical to ensuring long-term performance and return on investment.

While the initial capital expenditure is higher compared to conventional blasting systems, the long-term benefits in terms of lower operating costs, improved quality control, and compliance with environmental regulations justify the investment—particularly for industries such as aerospace, automotive, and precision manufacturing.

In conclusion, sourcing a laser blasting machine is a forward-thinking move that enhances operational efficiency, supports sustainability goals, and positions the organization at the forefront of modern surface treatment technology. Proper due diligence in selection and implementation will ensure successful integration and optimal performance.