The global laptop heat sink market is experiencing robust growth, driven by increasing demand for high-performance computing devices and the rising need for efficient thermal management solutions. According to a report by Mordor Intelligence, the global heat sink market was valued at approximately USD 9.8 billion in 2023 and is projected to grow at a compound annual growth rate (CAGR) of over 7.5% from 2024 to 2029. This expansion is fueled by advancements in portable electronics, greater processing power in laptops, and the proliferation of gaming and ultrabook segments—all of which generate higher thermal output and necessitate advanced cooling mechanisms. As manufacturers strive to balance performance with device thinness and reliability, the role of high-efficiency heat sinks has become critical. In this competitive landscape, a select group of innovators are leading the way in materials, design, and thermal conductivity, setting industry benchmarks in cooling performance and scalability. Here’s a data-driven look at the top 10 laptop heat sink manufacturers shaping the future of thermal management.

Top 10 Laptop Heat Sink Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

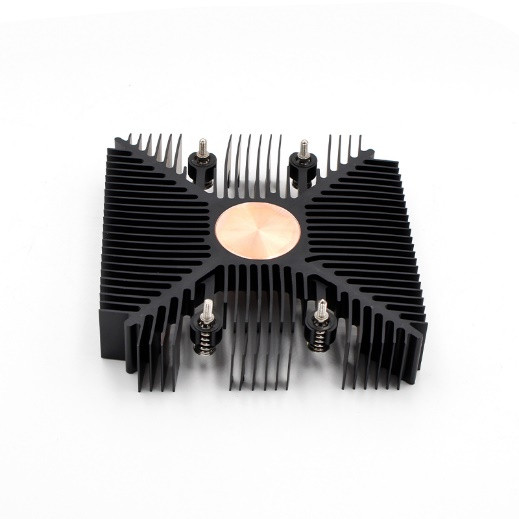

#1 ODM Laptop Heatsink Factory, Pricelist

Domain Est. 2018

Website: tongyucooler.com

Key Highlights: Discover top-quality laptop heatsinks at Dongguan Tongyu Electronics Co., Ltd. Enhance cooling efficiency and extend laptop lifespan with our expert ……

#2 Radian Thermal Products

Domain Est. 2001

Website: radianheatsinks.com

Key Highlights: Our custom heatsinks are made from materials like aluminum and copper. We use advanced manufacturing techniques, including CNC machining, thermal analysis, and ……

#3 Heatsink Manufacturers

Domain Est. 2003

Website: manufacturers.com.tw

Key Highlights: Source for Heat Sink Manufacturers. B2BManufactures.com incorporates full list of Taiwan & China CPU heatsink manufacturers and heat sink suppliers….

#4 YS Tech USA

Domain Est. 2003

Website: ystechusa.com

Key Highlights: YS Tech USA is a leading designer and manufacturer of thermal solutions, specializing in low noise, high performance DC axial fans, blowers, and heat sink ……

#5 Heat Sink Manufacturer

Domain Est. 2012

Website: celsiainc.com

Key Highlights: Custom heat sink manufacturer specializing in high-performance heat pipe and vapor chamber solutions. 91% customer retention. ITAR | ISO Compliance….

#6 Novark Technologies: Heat Sink Manufacturer

Domain Est. 2017

Website: novarktechnologies.com

Key Highlights: Novark manufactures a wide variety of custom-designed heat pipes, vapor chambers, heat columns, and other two-phase flow technologies….

#7 Your Motor Heatsink Leading Supplier and Manufacturer

Domain Est. 2020

Website: heatell.com

Key Highlights: As a professional motor heatsink manufacturer and supplier, Heatell possesses hundreds of standard motor heatsinks that come in multiple specifications….

#8 Thermalright

Domain Est. 2000

Website: thermalright.com

Key Highlights: THERMALRIGHT PRODUCTS · TUF GAMING ALLIANCE · HYDRO COOLING · HYDRO COOLING (WORKSTATION&SERVER) · HEATSINK · SYSTEM FAN · POWER SUPPLY · PC CASES ……

#9 Dynatron Cooling Solutions

Domain Est. 2017

Website: dynatron.co

Key Highlights: Dynatron delivers high-performance cooling solutions for servers, AI systems, and edge computing. Explore our range of heatsinks, air and liquid coolers ……

#10 Heat Sink Store

Domain Est. 2024

Website: theheatsink.com

Key Highlights: We stock heat sinks of multiple sizes that can be used with components such as transistors, regulators, processor chips etc….

Expert Sourcing Insights for Laptop Heat Sink

H2: Emerging Market Trends for Laptop Heat Sinks in 2026

As the demand for high-performance computing continues to surge across consumer, enterprise, and gaming sectors, laptop heat sink technology is poised for significant evolution by 2026. Driven by advancements in processor design, material science, and thermal management systems, the laptop heat sink market is expected to witness transformative trends. Below are the key developments shaping the industry landscape:

1. Rising Adoption of Vapor Chamber and Heat Pipe Hybrid Solutions

By 2026, hybrid thermal solutions combining vapor chambers with advanced heat pipes are projected to dominate premium and gaming laptops. These systems offer superior heat dissipation in compact form factors, essential for high-TDP (Thermal Design Power) processors like Intel’s Lunar Lake and AMD’s Ryzen AI 300 series. Market analysis suggests a compound annual growth rate (CAGR) of over 12% for vapor chamber-integrated heat sinks between 2023 and 2026.

2. Shift Toward Ultra-Thin and Lightweight Designs

With OEMs prioritizing sleek, portable laptops, heat sink manufacturers are innovating with ultra-thin fin stacks, micro-channel designs, and lightweight aluminum-graphene composites. These materials reduce weight by up to 30% while maintaining thermal efficiency, catering to the growing ultrabook and 2-in-1 device segments.

3. Integration with AI-Driven Thermal Management Systems

Artificial intelligence is playing an increasing role in dynamic thermal regulation. By 2026, AI-powered firmware will optimize fan speeds and heat distribution in real time, working in tandem with intelligent heat sink designs. This integration improves energy efficiency and extends device lifespan, especially in AI-accelerated workloads.

4. Growth in Demand from Gaming and Creator Laptops

The gaming laptop market, expected to exceed $20 billion by 2026, is a major driver for high-efficiency heat sinks. Similarly, content creators using resource-intensive applications demand robust cooling solutions. OEMs like ASUS ROG, MSI, and Dell Alienware are investing in multi-heat-pipe arrays and liquid metal thermal interface materials (TIMs), pushing innovation in heat sink design.

5. Sustainability and Recyclable Materials

Environmental regulations and consumer demand for eco-friendly electronics are prompting manufacturers to adopt recyclable aluminum and biodegradable thermal compounds. The European Union’s revised Ecodesign Directive will likely influence global standards, encouraging sustainable heat sink production by 2026.

6. Regional Manufacturing Shifts and Supply Chain Resilience

Geopolitical factors and supply chain disruptions are driving a relocalization trend. North America and Southeast Asia are emerging as key manufacturing hubs for heat sink components, reducing dependency on single-source suppliers and enhancing agility in response to market demands.

In conclusion, the 2026 laptop heat sink market will be defined by innovation in materials, integration with intelligent systems, and responsiveness to performance and sustainability demands. As laptops become more powerful and compact, heat sink technology will remain a critical enabler of next-generation computing.

Common Pitfalls When Sourcing Laptop Heat Sinks (Quality and Intellectual Property)

Sourcing laptop heat sinks involves more than just finding the lowest price—critical risks related to quality consistency and intellectual property (IP) rights can significantly impact product performance, reliability, and legal compliance. Below are common pitfalls to avoid:

Quality Inconsistencies and Performance Deficiencies

Many suppliers, particularly those offering low-cost options, may compromise on materials, manufacturing precision, or thermal design. Poor-quality heat sinks often use substandard aluminum alloys, inadequate fin density, or imprecise CNC machining, leading to reduced thermal conductivity and inefficient heat dissipation. This can result in laptop overheating, throttling, or premature component failure. Additionally, inconsistent anodization or coating processes may reduce corrosion resistance and longevity. Without rigorous quality control (e.g., thermal testing, dimensional inspection), sourced heat sinks may not meet OEM-level performance standards.

Intellectual Property Infringement Risks

Laptop heat sink designs—especially those tailored for specific models or OEMs—often incorporate proprietary engineering, patented fin structures, vapor chamber integration, or unique mounting mechanisms. Sourcing from suppliers who replicate branded or patented designs without authorization exposes buyers to legal liability, including cease-and-desist orders, product seizures, or litigation. Even if the heat sink appears functionally similar, copying design elements such as fin geometry, base flatness tolerances, or heat pipe layout may violate existing patents or design rights. Failing to conduct IP due diligence or obtain proper licensing agreements can jeopardize product launches and damage brand reputation.

Lack of Traceability and Material Certification

OEMs and high-reliability applications require full traceability of materials and manufacturing processes. Many low-tier suppliers cannot provide material certifications (e.g., RoHS, REACH compliance) or batch-specific test reports. Without documentation, it’s difficult to verify the use of lead-free alloys or confirm thermal performance claims. This lack of transparency increases supply chain risk and complicates compliance with environmental and safety regulations.

Inadequate Testing and Validation

Some suppliers rely solely on theoretical thermal models without empirical validation. A heat sink that performs well in simulation may underperform in real-world conditions due to variations in airflow, thermal interface materials, or system integration. Sourcing components without access to thermal testing data (e.g., thermal resistance under load, airflow curves) increases the risk of field failures and costly redesigns.

Supplier Lock-In and Design Dependency

Relying on a single supplier for custom heat sink designs can create dependency, especially if the supplier retains design rights or tooling ownership. This limits flexibility in scaling production or switching vendors. Always clarify IP ownership in contracts and ensure designs are transferable or licensed for multi-source production.

Avoiding these pitfalls requires thorough supplier vetting, independent quality audits, IP risk assessments, and clear contractual terms defining quality standards and intellectual property rights.

Logistics & Compliance Guide for Laptop Heat Sink

Product Classification and HS Code

Laptop heat sinks are typically classified under the Harmonized System (HS) code 8473.30, which covers “Parts and accessories suitable for use solely or principally with machines of headings 8471.” Since heat sinks are essential cooling components specifically designed for laptop computers (classified under 8471), this code ensures accurate customs declaration and appropriate duty assessment during international shipping.

Shipping and Packaging Requirements

Heat sinks should be packaged in anti-static bags or containers to prevent electrostatic discharge (ESD) damage during transit. Outer packaging must be sturdy (e.g., corrugated cardboard) with sufficient cushioning to protect against physical shock. Packages should be clearly labeled with product identifiers, handling instructions (e.g., “Fragile,” “ESD Sensitive”), and proper shipping marks to ensure safe and efficient logistics handling.

Import/Export Regulations

Exporters and importers must comply with the regulations of both origin and destination countries. This includes obtaining necessary export licenses if shipping to restricted regions and ensuring conformity with import standards such as CE (Europe), FCC (USA), or KC (South Korea), where applicable. Documentation such as commercial invoices, packing lists, and certificates of origin must be accurately completed to avoid customs delays.

Environmental and RoHS Compliance

Laptop heat sinks must comply with the Restriction of Hazardous Substances (RoHS) Directive (2011/65/EU and amendments), which limits the use of lead, mercury, cadmium, and other hazardous materials in electronic components. Manufacturers must provide RoHS compliance documentation, including a Declaration of Conformity, to demonstrate adherence, especially when shipping to EU markets.

REACH and Chemical Safety

Under the EU’s REACH regulation (Registration, Evaluation, Authorization, and Restriction of Chemicals), heat sink materials—particularly metal alloys (e.g., aluminum, copper) and any surface coatings—must be registered and evaluated for Substances of Very High Concern (SVHC). Suppliers should provide a REACH SVHC declaration if any regulated substances are present above threshold levels.

Battery and Hazardous Materials Considerations

Laptop heat sinks do not contain batteries or hazardous materials under IATA or IMDG regulations when shipped standalone. As non-powered passive components, they are generally exempt from dangerous goods classification, simplifying air and sea freight logistics. However, always verify with the carrier to confirm non-hazardous status prior to shipment.

Country-Specific Compliance

Certain countries may impose additional compliance requirements. For example, China requires the China Compulsory Certification (CCC) mark for certain electronic components, though heat sinks may be exempt. India may require BIS (Bureau of Indian Standards) registration depending on product scope. Always verify local market requirements before entering new regions.

Recordkeeping and Traceability

Maintain detailed records of material sourcing, compliance certifications (RoHS, REACH), test reports, and shipping documentation for a minimum of five years. Implement a traceability system (e.g., batch/lot numbering) to facilitate rapid response in case of recalls or compliance audits.

Recommended Carrier and Insurance

Use reputable logistics providers experienced in handling electronic components (e.g., DHL, FedEx, UPS). Opt for shipping insurance that covers the full replacement value of the goods to protect against loss or damage during transit. Choose tracking-enabled services for real-time shipment visibility.

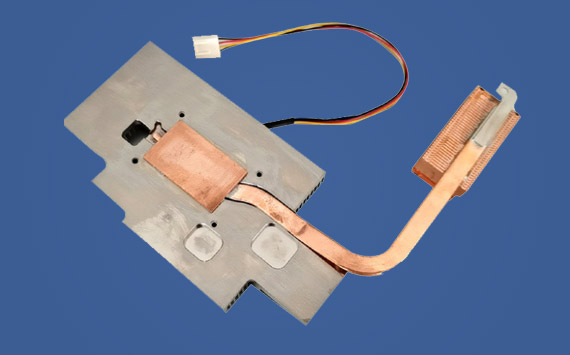

In conclusion, sourcing a laptop heat sink requires careful consideration of compatibility, thermal performance, build quality, and cost-effectiveness. It is essential to match the heat sink to the specific laptop model and processor to ensure proper fit and efficient heat dissipation. Evaluating materials, such as copper or aluminum, and design features like heat pipe integration, helps optimize cooling performance and system reliability. Whether sourcing OEM parts for authenticity or third-party alternatives for affordability, verifying supplier credibility and product reviews is crucial. Ultimately, a well-sourced heat sink contributes significantly to maintaining optimal laptop temperatures, enhancing performance, and extending the device’s lifespan.