The global laptop battery tester market is experiencing steady growth, driven by rising demand for reliable battery performance assessment across consumer electronics, enterprise IT, and after-sales service sectors. According to a report by Mordor Intelligence, the global battery testing equipment market was valued at USD 3.2 billion in 2023 and is projected to grow at a CAGR of over 7.5% through 2028. This expansion is fueled by increasing laptop penetration, the proliferation of remote work, and the expanding secondary market for refurbished devices—all of which underscore the critical need for accurate battery health diagnostics. As lithium-ion batteries remain the dominant power source in portable computing, OEMs and service providers alike are investing in advanced testing solutions to ensure longevity, safety, and consistent performance. In this competitive landscape, a select group of manufacturers have emerged as leaders, combining precision engineering, software integration, and scalability to meet evolving industry demands. The following list highlights the top 10 laptop battery tester manufacturers shaping this growing market.

Top 10 Laptop Battery Tester Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Battery Safety Testing and Certification

Domain Est. 1994

Website: ul.com

Key Highlights: We are a global leader in battery safety testing and help manufacturers of batteries and battery-operated products streamline their market access activities….

#2 Midtronics

Domain Est. 1996

Website: midtronics.com

Key Highlights: Midtronics is trusted by leading vehicle manufacturers, service centers and battery retailers around the world for battery testing & charging equipment….

#3 Battery Testing and Energy Storage Solutions

Domain Est. 2001

Website: intertek.com

Key Highlights: Intertek offers industry-leading battery testing, energy storage, and lifecycle evaluation services that help manufacturers, developers, and innovators ……

#4 NEWARE

Domain Est. 2023

Website: neware.net

Key Highlights: NEWARE, battery test equipment manufacturer, offers battery cyclers, environmental test chambers, automatic production and a variety of test accessories….

#5 Intel® Battery Life Diagnostic Tool

Domain Est. 1986

Website: intel.com

Key Highlights: This tool helps monitor and diagnose battery life impact of the system configuration and installed software on computer systems with an Intel® CPU….

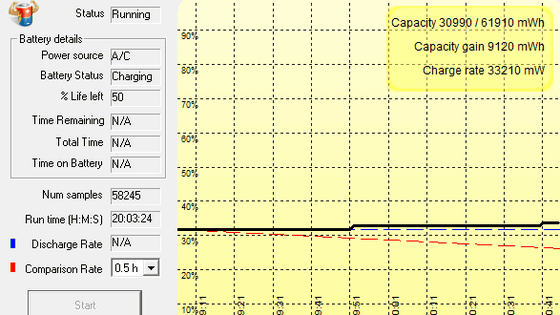

#6 PassMark BatteryMon

Domain Est. 1999

Website: passmark.com

Key Highlights: Monitor batteries for laptops ; Diagnose problematic battery cells with detailed statistics ; Compare and measure your batteries performance with expected ……

#7 Battery Analyzer

Domain Est. 2002

Website: mtixtl.com

Key Highlights: 8-Channel Hybrid Battery Tester and Potentiostat up to 5A-5V w/ Laptop & Software – BST8-HBP-5A · 8 Channel Battery Analyzer (10A 30V Max) with Laptop ……

#8 BatteryCare

Domain Est. 2010

Website: batterycare.net

Key Highlights: BatteryCare – Application and good practice guide for maintaining and optimizing the battery of the modern laptop….

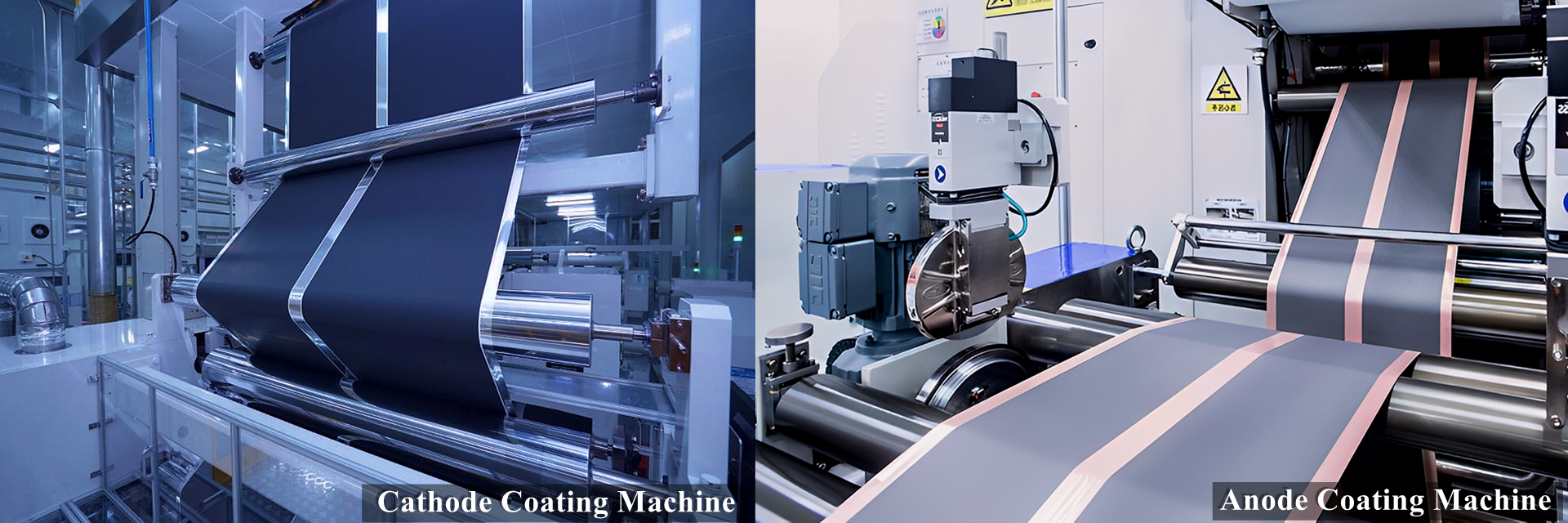

#9 Finished Battery Tester

Domain Est. 2014

Website: tobmachine.com

Key Highlights: TOB NEW ENERGY provides a full set of finished battery tester for lithium-ion battery manufacturing and research….

#10 Battery Tester

Domain Est. 2016

Website: tmaxcn.com

Key Highlights: Tmax Battery Equipments Limited. offers an extensive range of high quality battery tester and much more. Please visit: www.tmaxcn.com….

Expert Sourcing Insights for Laptop Battery Tester

H2: 2026 Market Trends for Laptop Battery Tester

The global market for laptop battery testers is poised for significant transformation by 2026, driven by rising demand for battery diagnostics, increased laptop usage across personal and professional domains, and advancements in portable electronics. Below are the key trends expected to shape the laptop battery tester market in 2026:

1. Surge in Remote Work and Digital Learning

The continued adoption of remote work and online education post-pandemic has led to increased laptop dependency. As device usage intensifies, so does battery degradation, creating a growing need for reliable battery health assessment tools. Consumers and enterprises alike are investing in laptop battery testers to monitor performance, extend device lifespan, and reduce replacement costs.

2. Integration with Smart Diagnostics and IoT

By 2026, laptop battery testers are expected to incorporate smart diagnostic features, including Bluetooth connectivity, mobile app integration, and cloud-based reporting. These IoT-enabled testers allow users to track battery health over time, receive alerts for degradation, and optimize charging habits—enhancing user experience and preventive maintenance.

3. Growth in Refurbished and Second-Hand Electronics Market

The booming market for refurbished laptops is fueling demand for accurate battery testing. Resellers and consumers require precise battery capacity and cycle count data before purchase or resale. As a result, advanced, affordable laptop battery testers are becoming essential tools in this ecosystem.

4. Advancements in Battery Technology and Tester Compatibility

With the evolution of lithium-ion and emerging solid-state batteries, testers must adapt to varying voltage levels, chemistries, and communication protocols (e.g., SMBus, I2C). By 2026, multi-chemistry compatible testers with automatic detection features are expected to dominate, catering to a wide range of laptop models and brands.

5. Focus on Sustainability and E-Waste Reduction

Environmental concerns are pushing consumers and organizations to extend device lifespans. Battery testing supports sustainability by identifying repairable issues instead of premature replacements. Governments and NGOs promoting circular economy models may further incentivize the use of diagnostic tools like battery testers.

6. Expansion of Aftermarket and DIY Repair Culture

The “Right to Repair” movement is gaining momentum globally, encouraging users to perform their own maintenance. This trend is increasing demand for user-friendly, portable battery testers available through e-commerce platforms and electronics retailers. Companies offering intuitive interfaces and clear diagnostic readouts will gain competitive advantage.

7. Regional Market Growth in Emerging Economies

Markets in Asia-Pacific, Latin America, and Africa are witnessing rapid laptop adoption, often relying on second-hand or budget devices with limited battery life. As affordability and access grow, so will the need for cost-effective battery testing solutions tailored to these regions.

8. Competitive Landscape and Innovation

Major electronics tool manufacturers and startups are investing in R&D to develop compact, versatile, and AI-assisted battery testers. By 2026, differentiation will come through features like predictive analytics, AI-driven health forecasts, and integration with device management software for enterprise IT departments.

In conclusion, the 2026 laptop battery tester market will be shaped by digitalization, sustainability, and the need for performance optimization in an increasingly mobile world. Manufacturers who align with these trends—offering smart, accurate, and accessible testing solutions—will be well-positioned for growth.

Common Pitfalls When Sourcing a Laptop Battery Tester (Quality and Intellectual Property)

Sourcing a laptop battery tester—especially from overseas suppliers or lesser-known manufacturers—can present several risks related to both product quality and intellectual property (IP) protection. Being aware of these pitfalls helps ensure a reliable, compliant, and legally secure procurement process.

Poor Build Quality and Inaccurate Testing

One of the most frequent issues is receiving a battery tester that fails to deliver accurate or consistent results. Low-cost units may use substandard components, such as imprecise voltage regulators, unreliable current sensors, or poorly calibrated circuitry. This leads to false readings, which can result in misdiagnosing battery health, reduced device performance, or even safety hazards like over-discharging. Additionally, flimsy construction, lack of proper heat dissipation, and inadequate shielding can shorten the device’s lifespan and compromise safety.

Lack of Calibration and Certification

Many sourced testers, especially from unverified suppliers, lack proper calibration documentation or traceable certification (e.g., ISO, CE, or RoHS). Without calibration, the device cannot guarantee repeatable measurements, making it unsuitable for professional or industrial use. Buyers may unknowingly purchase testers that do not meet regional regulatory standards, leading to compliance issues or product recalls.

Inadequate Safety Features

Low-quality testers might omit essential safety mechanisms such as overvoltage protection, short-circuit prevention, or thermal cutoffs. This increases the risk of damaging the laptop battery being tested—or even causing fire or injury. Reliable testers should include multiple layers of protection to handle various battery chemistries (e.g., Li-ion, Li-Po) safely.

Misrepresentation of Specifications

Suppliers may exaggerate capabilities, such as supported voltage ranges, current loads, or compatibility with different laptop models. Some units advertised as “universal” may only work with specific brands or fail under real-world conditions. This misrepresentation often becomes evident only after deployment, causing operational delays and additional costs.

Intellectual Property Infringement

A significant but often overlooked risk is the potential for IP violations. Some manufacturers produce clones or reverse-engineered versions of popular branded testers, infringing on patents, trademarks, or copyrighted firmware. Purchasing such devices—even unknowingly—can expose your business to legal liability, especially if the product is resold or used in a commercial service environment. Additionally, counterfeit devices may lack software updates or technical support, limiting long-term usability.

Hidden Software Limitations and Proprietary Lock-ins

Certain testers rely on proprietary software that may not be fully licensed or could include embedded code violating open-source licenses (e.g., GPL). Others may lock users into specific ecosystems, making data export or integration with existing systems difficult. Lack of API access or firmware documentation restricts customization and scalability, reducing return on investment.

Inadequate Documentation and Support

Poorly documented testers often come with incomplete user manuals, unclear schematics, or no technical support. This complicates troubleshooting, maintenance, and employee training. In the absence of responsive supplier support, resolving issues becomes time-consuming and costly.

Supply Chain and Counterfeit Risks

Sourcing from unreliable vendors increases the chance of receiving counterfeit or refurbished units misrepresented as new. This is particularly common in online marketplaces where seller verification is weak. Without proper due diligence, businesses risk investing in equipment that fails prematurely or doesn’t meet promised performance standards.

To avoid these pitfalls, conduct thorough supplier vetting, request product samples, verify certifications, and consult legal counsel when IP concerns arise. Prioritizing quality and compliance over initial cost savings ensures long-term reliability and protects your business from legal and operational risks.

Logistics & Compliance Guide for Laptop Battery Tester

Product Classification & Regulatory Overview

The Laptop Battery Tester is classified as an electronic test equipment device designed to assess the health, voltage, capacity, and performance of laptop batteries. It falls under the broader category of electrical and electronic measuring instruments. Key regulatory considerations include electrical safety, electromagnetic compatibility (EMC), and environmental compliance, especially when shipping internationally.

International Shipping & Customs Requirements

When shipping the Laptop Battery Tester across borders, ensure compliance with international trade regulations:

– HS Code: Typically classified under HS 9030.89 (measuring or checking instruments, appliances and machines not elsewhere specified). Confirm with local customs authorities for precise categorization.

– Export Controls: Verify if the device contains components subject to dual-use or ITAR restrictions. In most cases, standard battery testers are not controlled, but firmware with advanced diagnostic capabilities may require review.

– Documentation: Provide commercial invoices, packing lists, and certificates of origin. Include technical specifications to support accurate customs classification.

Electrical Safety Compliance

The device must meet electrical safety standards in target markets:

– North America: Comply with UL 61010-1 (Safety Requirements for Electrical Equipment for Measurement, Control, and Laboratory Use).

– European Union: Conform to EN 61010-1 and carry the CE marking. A Declaration of Conformity (DoC) must be issued.

– Other Regions: Check local requirements (e.g., PSE in Japan, CCC in China, RCM in Australia/New Zealand).

Electromagnetic Compatibility (EMC)

Ensure the Laptop Battery Tester does not emit excessive electromagnetic interference and is immune to common disturbances:

– EU: Comply with the EMC Directive 2014/30/EU; standards include EN 61326-1 (for measurement equipment).

– USA: FCC Part 15, Class B for residential environments.

– Testing must be performed by an accredited lab, and results documented in the technical file.

Packaging & Transportation Safety

Proper packaging ensures product integrity and compliance with shipping regulations:

– Use anti-static packaging to protect sensitive electronic components.

– Include cushioning materials to prevent damage during transit.

– Label packages with handling symbols (e.g., “Fragile,” “This Side Up”).

– Avoid including lithium batteries in packaging unless intended for use with the device; if included, follow IATA/IMDG regulations for lithium battery transport.

Environmental & RoHS Compliance

The device must comply with environmental directives restricting hazardous substances:

– EU RoHS Directive 2011/65/EU: Limits use of lead, mercury, cadmium, and other hazardous materials.

– REACH: Ensure no use of Substances of Very High Concern (SVHC) above threshold levels.

– WEEE: Provide information on proper end-of-life disposal. Affix the crossed-out wheeled bin symbol on product or packaging.

Software & Firmware Regulatory Notes

If the Laptop Battery Tester includes downloadable software or firmware updates:

– Comply with GDPR or CCPA if collecting user data.

– Provide clear end-user license agreements (EULA).

– Ensure cybersecurity measures are in place if the device connects to networks or computers.

Import Duties & Taxation

Duties and taxes vary by destination:

– Leverage free trade agreements where applicable (e.g., USMCA, EU-South Korea FTA).

– Consider using an Incoterm such as DDP (Delivered Duty Paid) or DAP (Delivered At Place) to clarify responsibility for customs clearance and duties.

After-Sales & Warranty Logistics

Plan for reverse logistics:

– Establish a repair or replacement process compliant with local consumer laws.

– Provide multilingual user manuals and safety instructions.

– Maintain compliance records for at least 10 years post-manufacturing for audit purposes.

Summary & Action Checklist

- [ ] Confirm HS code and customs documentation

- [ ] Obtain required safety and EMC certifications

- [ ] Implement RoHS/WEEE compliance

- [ ] Use compliant packaging and labeling

- [ ] Train logistics partners on handling requirements

- [ ] Maintain technical files and DoC for all markets

Adhering to this guide ensures smooth global distribution and regulatory compliance for the Laptop Battery Tester.

Conclusion for Sourcing a Laptop Battery Tester:

Sourcing a reliable laptop battery tester is essential for ensuring battery performance, safety, and longevity, especially in environments involving repair, refurbishment, or quality control. After evaluating various options, it is clear that the ideal tester should offer accurate voltage, current, and capacity measurements, compatibility with multiple battery models, a user-friendly interface, and built-in safety protections. Additionally, factors such as cost-effectiveness, durability, supplier reputation, and after-sales support play a crucial role in the decision-making process. Opting for a tester from a trusted manufacturer with positive user reviews and compliance with relevant industry standards ensures consistent and trustworthy results. Ultimately, investing in a high-quality laptop battery tester enhances operational efficiency, reduces the risk of faulty batteries entering the market, and supports sustainable practices through better battery management and recycling.