The global lubricants market, driven by increasing industrialization and demand across automotive, manufacturing, and heavy machinery sectors, continues to expand steadily. According to a report by Mordor Intelligence, the global lubricants market was valued at USD 69.42 billion in 2023 and is projected to grow at a CAGR of over 3.8% from 2024 to 2029. Within this landscape, lanolin grease—a high-performance, water-resistant lubricant derived from wool wax—has gained traction due to its biodegradability, corrosion resistance, and effectiveness in extreme conditions. Its applications span aerospace, marine, food processing, and renewable energy equipment, where reliability under moisture and high pressure is critical. As regulatory standards favor eco-friendly alternatives, manufacturers are innovating to meet demand for sustainable yet robust lubricants. This growing niche has elevated the prominence of leading lanolin grease producers who combine technical excellence with scalable manufacturing capabilities. Below are the top 7 lanolin grease manufacturers shaping this specialized segment.

Top 7 Lanolin Grease Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 About Rolex Lanolin Products Ltd

Domain Est. 1997

Website: rolexlanolin.com

Key Highlights: Rolex Lanolin is the leading manufacturers of lanolin in India and a global exporter of lanolin and lanolin derivatives….

#2 Prolan

Website: prolan.co.nz

Key Highlights: Lanolin-Based Industrial Protection. Prolan specialises in the development and manufacture of lanolin lubricants, corrosion inhibitors, and anti-seize greases….

#3 LanisLanolin

Domain Est. 1998

Website: lanolin.com

Key Highlights: Your reliable lanolin supplier. As a global lanolin supplier, LanisLanolin provides wool grease and its derivatives to long-standing customers worldwide….

#4 Lanolene, Wool derived Lanolin, Natural Eco

Domain Est. 2000

Website: lanolene.com

Key Highlights: Lanolin is an all-natural, highly effective substance which acts as a moisture barrier and lubricant. Its unique properties have been recognised for centuries….

#5 LanisLanolin: Your independent lanolin supplier

Domain Est. 2016

Website: imperialoel.com

Key Highlights: ImperialOel’s LanisTech products offer competitively priced wool grease and lanolin derivatives, including lanolin alcohols and lanolin fatty acids, available ……

#6 LanEsters

Domain Est. 2017

Website: lanesters.com

Key Highlights: Lanolin is an excellent emollient, possessing a number of important chemical and physical similarities to human Stratum Corneum Lipids….

#7 About

Domain Est. 2017

Website: lanogreen.com

Key Highlights: Lanotec develop environmentally-friendly products based on the unique properties of lanolin, organic Methyl Ester, coconut oil and other natural ingredients….

Expert Sourcing Insights for Lanolin Grease

H2: Projected 2026 Market Trends for Lanolin Grease

The global lanolin grease market is poised for steady growth by 2026, driven by increasing demand across industrial, automotive, and consumer sectors. Derived from wool wax, lanolin grease is valued for its natural origin, biodegradability, and excellent water-resistant and corrosion-inhibiting properties. These characteristics position it favorably in markets prioritizing sustainable and environmentally friendly lubricants.

One of the key trends shaping the 2026 landscape is the rising adoption of bio-based and non-toxic lubricants, particularly in response to stringent environmental regulations in North America and Europe. Industries such as marine, agriculture, and food processing are increasingly replacing petroleum-based greases with lanolin-based alternatives to comply with eco-standards and reduce environmental impact.

Additionally, innovations in formulation are enhancing the performance of lanolin grease under extreme temperatures and high-pressure conditions, broadening its applicability in automotive and heavy machinery maintenance. This technological advancement is expected to stimulate demand, especially in emerging markets across Asia-Pacific and Latin America, where industrialization and infrastructure development are accelerating.

The personal care and cosmetics sector continues to be a stable contributor to lanolin demand, indirectly supporting the supply chain and production scalability of lanolin-derived products, including industrial-grade grease. Moreover, growing consumer awareness about sustainable products is prompting manufacturers to market lanolin grease as a green alternative, further boosting its appeal.

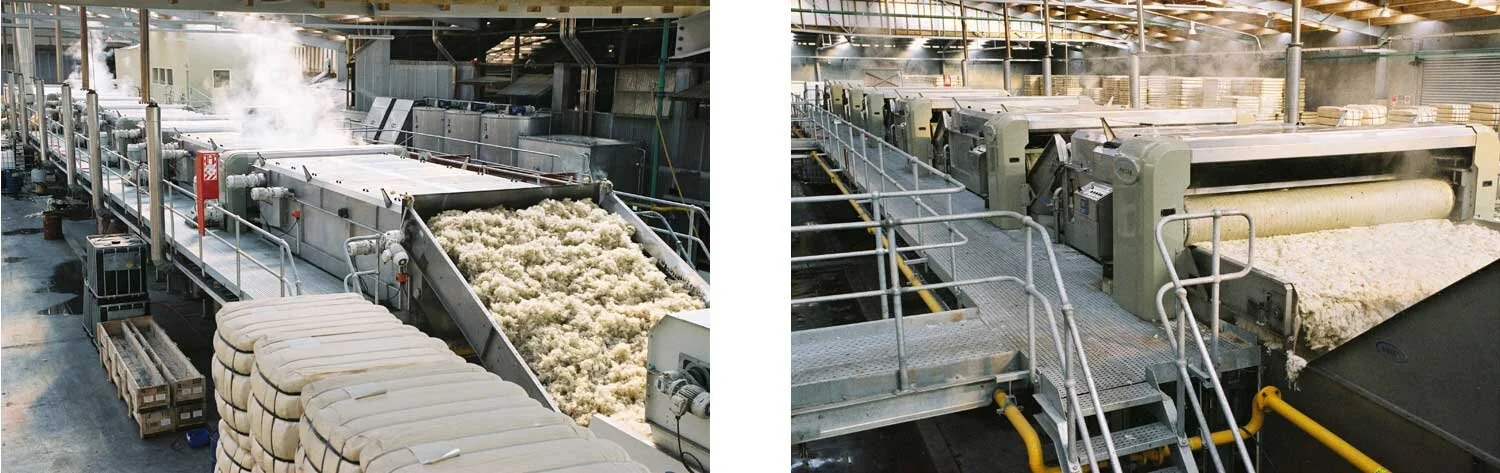

However, market growth may face constraints due to fluctuating raw material supply, as lanolin is a byproduct of wool processing, and production is subject to variations in sheep farming and wool yields. Additionally, higher costs compared to synthetic greases could limit penetration in price-sensitive regions.

Overall, the 2026 lanolin grease market is expected to reflect a compound annual growth rate (CAGR) of approximately 4–5%, with expansion fueled by sustainability trends, regulatory support, and product innovation. Companies investing in R&D and sustainable sourcing are likely to gain a competitive edge in this evolving landscape.

Common Pitfalls When Sourcing Lanolin Grease (Quality, IP)

Sourcing lanolin grease—particularly for industrial, pharmaceutical, or cosmetic applications—requires careful attention to both quality and intellectual property (IP) considerations. Overlooking these aspects can lead to performance issues, regulatory non-compliance, and legal risks. Below are key pitfalls to avoid:

1. Assuming All Lanolin Grease Is Equal

One of the most frequent mistakes is treating lanolin grease as a generic commodity. Lanolin, derived from sheep wool, varies significantly based on processing methods, purity levels, and source. Poor-quality lanolin grease may contain impurities (e.g., pesticides, dirt, or microbial contaminants), leading to inconsistent performance or product failure.

Solution: Specify grades such as USP (United States Pharmacopeia), BP (British Pharmacopoeia), or technical grade based on application. Request Certificates of Analysis (CoA) and ensure the supplier adheres to relevant standards (e.g., ISO, ASTM).

2. Overlooking Traceability and Supply Chain Transparency

Lanolin sourcing often involves multiple intermediaries. Without full traceability, it’s difficult to verify the ethical, environmental, and safety standards of raw material collection—especially concerning animal welfare and sustainable farming practices.

Solution: Work with suppliers who provide full chain-of-custody documentation. Prefer those auditing their wool suppliers and following ethical sourcing guidelines (e.g., ZQ Merino standard).

3. Ignoring Intellectual Property Rights

Using a supplier’s proprietary formulation or branded lanolin grease (e.g., Lanolin USP, Anhydrous Lanolin) without proper licensing can lead to IP infringement. Some suppliers protect specific processing techniques or blends with patents or trade secrets.

Solution: Conduct due diligence on the supplier’s IP position. Ensure any licensing agreements are clear, especially if rebranding or incorporating the grease into a patented end product. Avoid reverse-engineering formulations without legal clearance.

4. Failing to Verify Purity and Allergen Content

Lanolin is generally safe but can cause allergic reactions in sensitive individuals. Poorly refined lanolin grease may contain allergenic residues or oxidation byproducts. In regulated industries (e.g., medical devices), this poses a compliance risk.

Solution: Require allergen testing and hypoallergenic certifications. Ensure the lanolin grease is highly refined and free from common contaminants like triclosan, parabens, or heavy metals.

5. Not Assessing Performance Under Real Conditions

Lab-grade specifications don’t always translate to field performance. For example, in lubrication applications, viscosity, water resistance, and temperature stability are critical.

Solution: Conduct application-specific testing before full-scale procurement. Evaluate performance in real-world conditions, especially if used in extreme environments (e.g., marine, high-temperature).

6. Underestimating Regulatory Compliance Needs

Depending on the region and application, lanolin grease may fall under FDA, REACH, or COSMOS regulations. Non-compliant products can be blocked at customs or recalled post-market.

Solution: Confirm that the supplier provides regulatory documentation (e.g., FDA Drug Master File, REACH registration, allergen declarations) and that the product meets destination market requirements.

7. Choosing Solely on Price

Opting for the lowest-cost supplier often results in compromised quality, inconsistent batches, or delayed shipments. Lanolin grease with inadequate refinement may degrade faster or fail in critical applications.

Solution: Perform a total cost of ownership analysis, factoring in reliability, technical support, and risk mitigation—not just upfront price.

By addressing these common pitfalls, buyers can ensure they source lanolin grease that meets both technical performance standards and legal/IP requirements, minimizing risk across the supply chain.

H2: Logistics & Compliance Guide for Lanolin Grease

Lanolin grease, derived from lanolin (a wax secreted by the sebaceous glands of sheep), is widely used in industrial, automotive, and marine applications for its excellent water resistance, corrosion protection, and lubricating properties. Proper logistics handling and regulatory compliance are essential to ensure safe transportation, storage, and use. This guide outlines key considerations for the logistics and compliance of lanolin grease.

1. Classification and Regulatory Status

- Chemical Nature: Lanolin grease is generally considered a natural or semi-synthetic lubricant. It is biodegradable and non-toxic in most formulations.

- GHS Classification: Typically not classified as hazardous under the Globally Harmonized System (GHS) for most standard formulations. However, always verify with the specific Safety Data Sheet (SDS).

- Regulatory Compliance:

- REACH (EU): Lanolin and its derivatives are registered under REACH. Ensure supplier compliance with registration requirements.

- TSCA (USA): Lanolin is listed on the TSCA Inventory; confirm formulation compliance.

- OSHA HazCom 2012: Requires availability of updated SDS and proper labeling if any hazardous components are present.

2. Safety Data Sheet (SDS) Requirements

- Maintain the latest SDS for each batch or formulation.

- SDS must include:

- Product identification

- Hazard identification (if applicable)

- Composition/information on ingredients

- First-aid measures

- Fire-fighting measures

- Accidental release measures

- Handling and storage

- Exposure controls/personal protection

- Physical and chemical properties

- Stability and reactivity

- Toxicological information

- Ecological information

- Disposal considerations

- Transport information

- Regulatory information

- Other information (e.g., date of preparation)

3. Packaging and Labeling

- Packaging: Typically supplied in metal or plastic drums (e.g., 180 kg), pails (18 L), or cartridges. Ensure containers are sealed to prevent contamination or leakage.

- Labeling:

- Product name and batch number

- Net weight or volume

- Manufacturer/supplier details

- GHS pictograms (if applicable)

- Precautionary and hazard statements (if classified)

- Storage instructions (e.g., “Store in a cool, dry place”)

4. Storage Guidelines

- Temperature: Store between 5°C and 35°C (41°F to 95°F). Avoid prolonged exposure to extreme heat or cold.

- Environment: Keep in a dry, well-ventilated area away from direct sunlight and incompatible materials (e.g., strong oxidizers).

- Shelf Life: Typically 2–3 years when stored properly. Check manufacturer recommendations.

- Stacking: Do not stack drums more than two high unless designed for it. Use pallets to prevent deformation.

5. Transportation and Shipping

- Domestic (e.g., USA):

- Not regulated as a hazardous material under DOT 49 CFR when non-hazardous.

- Standard freight regulations apply; use secure, leak-proof packaging.

- International (e.g., IMDG, IATA):

- Usually exempt from dangerous goods regulations (Class 9 or UN3082 may apply if mixed with hazardous additives).

- Confirm with SDS Section 14: Transport Information.

- Documentation:

- Commercial invoice

- Packing list

- Bill of lading or air waybill

- SDS (mandatory for international shipments)

6. Handling Procedures

- Use appropriate PPE (e.g., gloves, safety glasses) to avoid skin or eye contact.

- Avoid inhalation of mists if heated or sprayed.

- Use clean, dedicated tools to prevent cross-contamination.

- Ground containers during transfer to prevent static discharge.

7. Environmental and Disposal Considerations

- Biodegradability: Lanolin grease is generally biodegradable, but disposal must comply with local regulations.

- Spill Response:

- Contain spill with absorbent material (e.g., sand, vermiculite).

- Collect and dispose of as non-hazardous waste if compliant.

- Avoid release into drains or waterways.

- Waste Disposal: Follow local, state, and federal regulations. May be disposed of via licensed waste contractor if contaminated.

8. Import/Export Compliance

- Customs Tariff Codes:

- HS Code example: 3403.99 (Other lubricating preparations) – verify by country.

- Documentation:

- Certificate of Origin (if required)

- Import permits (rarely required, but check destination country)

- SDS in local language (mandatory in many jurisdictions, e.g., EU, China)

- Restricted Regions: No widespread bans, but verify formulation compliance with local chemical regulations (e.g., China REACH, K-REACH).

9. Quality Assurance & Traceability

- Maintain lot traceability for recall preparedness.

- Conduct periodic quality checks (e.g., viscosity, contamination).

- Ensure supplier certifications (e.g., ISO 9001, ISO 14001).

10. Emergency Preparedness

- Train staff on SDS review and emergency procedures.

- Keep spill kits and first-aid supplies accessible.

- Report significant incidents to relevant authorities as required.

Conclusion

Lanolin grease is a low-risk substance in terms of hazardous classification, but proper logistics and compliance practices are essential for safety, regulatory adherence, and environmental protection. Always refer to the product-specific SDS and stay updated on regional regulatory changes.

For further assistance, consult your supplier, regulatory experts, or local environmental and safety authorities.

Conclusion on Sourcing Lanolin Grease

Sourcing lanolin grease requires careful consideration of quality, sustainability, supplier reliability, and compliance with industry standards. As a natural, biodegradable, and corrosion-inhibiting lubricant derived from sheep wool, lanolin grease is ideal for sensitive applications in food processing, pharmaceuticals, and conservation. However, ensuring a consistent supply of high-purity, contaminant-free lanolin—free from pesticides, heavy metals, and microbial contamination—is critical. Buyers should prioritize suppliers with certifications such as ISO, NSF, or organic standards, and those committed to ethical animal treatment and sustainable wool harvesting practices. Establishing long-term partnerships with reputable suppliers, conducting regular quality audits, and staying informed about regulatory requirements will ensure reliable sourcing. Ultimately, a well-vetted supply chain supports both product performance and environmental and ethical responsibility.