The global landscaping equipment market is experiencing steady growth, driven by rising urbanization, increasing residential construction, and growing emphasis on outdoor space aesthetics. According to Grand View Research, the global lawn and garden equipment market was valued at USD 44.6 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030. This growth is further supported by a surge in demand for durable, high-performance tools—including rakes with specialized tines—used in both residential landscaping and commercial turf management. As sustainability and efficiency become key priorities, manufacturers of landscaping rake tines are innovating with advanced materials and ergonomic designs to meet evolving user needs. In this competitive landscape, eight manufacturers stand out for their product quality, technological advancements, and market reach.

Top 8 Landscaping Rake Tines Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Rakes

Domain Est. 2004

#2 Tine Rake (Compact Tractors)

Domain Est. 1997

Website: bobcat.com

Key Highlights: This compact tractor implement is ideal for smoothing, raking or contouring soil surfaces in preparation for planting or seeding….

#3 Landscape Rakes

Domain Est. 2001

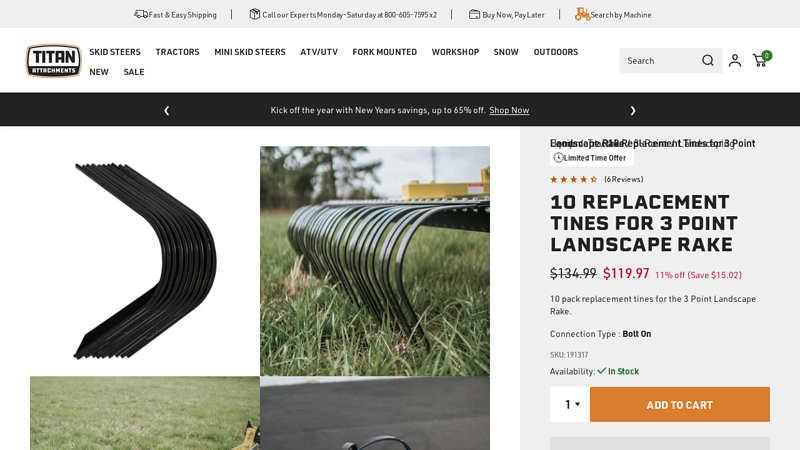

#4 10 Replacement Tines for 3 Point Landscape Rake

Domain Est. 2002

#5 Landscaping Rake

Domain Est. 2005

Website: tufx.com

Key Highlights: Featuring 36 tines, this rake is built to cover more ground and effectively level and spread soil, gravel, mulch, and other materials. The large number of tines ……

#6 Landscape Rake

Domain Est. 2006

Website: northstarattachments.com

Key Highlights: Individually mounted tines are made from 5/16″ x 1″ x 15″ high carbon steel and are mounted on 2″ spacing, 1″ opening. Five forward and five reverse angle ……

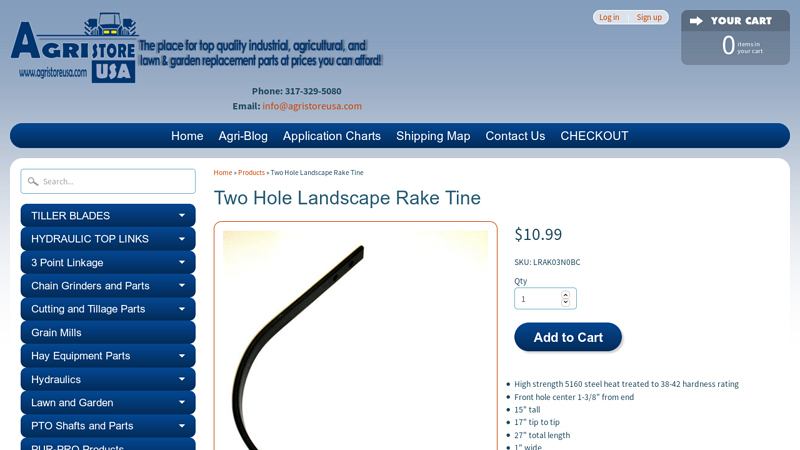

#7 Two Hole Landscape Rake Tine

Domain Est. 2008

Website: agristoreusa.com

Key Highlights: In stock Free delivery over $150High strength 5160 steel heat treated to 38-42 hardness rating; Front hole center 1-3/8″ from end; 15″ tall; 17″ tip to tip; 27″ total length; 1″ wi…

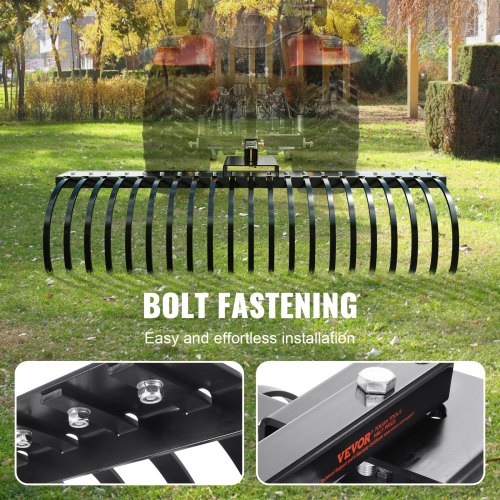

#8 Landscape Rake Tine

Domain Est. 2019

Expert Sourcing Insights for Landscaping Rake Tines

2026 Market Trends for Landscaping Rake Tines

The landscaping rake tines market is poised for significant evolution by 2026, driven by technological advancements, shifting consumer preferences, and broader industry dynamics in landscaping and agriculture. Here are the key trends expected to shape the market:

1. Increased Demand for Durable, Wear-Resistant Materials

Manufacturers are increasingly adopting high-strength alloys, boron steel, and advanced composites to produce tines that offer longer service life and reduced maintenance. As labor and equipment downtime costs rise, landscapers and contractors will prioritize tines with enhanced wear resistance, particularly in abrasive soil conditions. This trend will accelerate innovation in heat treatment processes and surface coatings, such as ceramic or polymer-based treatments, to further extend tine longevity.

2. Growth in Residential and Commercial Landscaping Sectors

Urbanization and the rising demand for aesthetically pleasing outdoor spaces in both residential and commercial developments are driving equipment usage. As homeowners invest more in yard maintenance and commercial property managers prioritize curb appeal, the need for efficient, high-performance landscaping tools—including quality rake tines—will grow. This expansion is expected to be especially strong in emerging markets and suburban areas.

3. Integration with Smart and Multi-Functional Equipment

While rake tines themselves are simple components, they are increasingly being designed for compatibility with smart landscaping equipment. By 2026, modular tine systems that allow quick interchangeability with other attachments (e.g., aerators, dethatchers) on universal power units will gain traction. Additionally, OEMs may incorporate sensors into tine assemblies to monitor wear and alert users when replacement is needed—enhancing maintenance efficiency.

4. Sustainability and Recyclability Focus

Environmental regulations and corporate sustainability goals will influence material choices and end-of-life management. Manufacturers are likely to emphasize recyclable steel compositions and reduce reliance on coatings containing harmful substances. The circular economy model may encourage take-back programs or refurbishment options for worn tines, particularly among large-scale landscaping service providers.

5. E-Commerce and Direct-to-Consumer Sales Growth

The distribution landscape is shifting, with an increasing number of landscaping professionals and DIY users purchasing replacement tines online. By 2026, e-commerce platforms and brand-owned digital storefronts will play a dominant role in tine sales, supported by detailed product specifications, compatibility guides, and customer reviews. This shift will pressure traditional distributors to adapt or risk market share erosion.

6. Regional Market Diversification

While North America and Europe remain strong markets due to mature landscaping industries, Asia-Pacific and Latin America are expected to show the highest growth rates. Rapid urban development, rising disposable incomes, and government-supported green space initiatives in countries like India, China, and Brazil will create new demand for landscaping tools, including durable rake tines suited to local soil types.

7. Customization and Specialization

One-size-fits-all tine designs are giving way to customized solutions tailored to specific applications—such as lawn leveling, soil preparation, or debris removal. By 2026, OEMs and third-party suppliers will offer tines in varied lengths, curvatures, spacings, and tip designs to meet niche requirements. This specialization will be supported by advances in manufacturing technologies like precision forging and CNC machining.

In conclusion, the 2026 landscaping rake tines market will be characterized by innovation in materials and design, greater integration with advanced equipment systems, and expanding global reach. Stakeholders who focus on durability, sustainability, and customer-centric solutions will be best positioned to capitalize on these evolving trends.

Common Pitfalls When Sourcing Landscaping Rake Tines (Quality and Intellectual Property)

When sourcing landscaping rake tines—whether for manufacturing, replacement parts, or private-label products—buyers often encounter challenges related to both quality control and intellectual property (IP) rights. Failing to address these issues can lead to product failure, legal disputes, or damage to brand reputation. Below are key pitfalls to avoid:

Poor Material Quality and Durability

One of the most frequent issues is receiving tines made from substandard steel or alloys. Low-quality materials may bend, break, or corrode quickly under regular use, especially in tough terrain or wet conditions. Buyers may assume specifications (like tensile strength or hardness) are met, but without third-party testing or clear material certifications, suppliers might cut corners. Always verify material grades (e.g., spring steel 6150 or 5160) and request test reports.

Inconsistent Manufacturing Tolerances

Tines that vary in length, thickness, or curvature can affect the rake’s performance and lead to uneven ground engagement. Inconsistent heat treatment during production also impacts resilience. Without strict quality control oversight or on-site audits, these inconsistencies often go unnoticed until after delivery.

Lack of Compliance with Safety and Industry Standards

Some suppliers, especially overseas manufacturers, may not adhere to regional safety or performance standards (e.g., ANSI or CE markings where applicable). Non-compliant tines could pose safety risks or prevent market entry in regulated regions.

Intellectual Property Infringement Risks

Many rake tine designs—particularly patented heat-treated profiles, attachment mechanisms, or composite materials—are protected by IP rights. Sourcing generic copies of branded tines (e.g., imitating specific tine curvature or mounting systems) can expose buyers to legal liability. Always conduct an IP clearance search and ensure suppliers warrant that their products do not infringe on existing patents or trademarks.

Unclear or Missing Documentation

Suppliers may fail to provide technical data sheets, material certifications, or IP indemnity agreements. This lack of documentation makes it difficult to verify product claims or defend against legal challenges. Insist on complete paperwork before placing bulk orders.

Overreliance on Sample Testing Alone

While evaluating a sample is essential, it may not reflect mass production quality. A well-made sample can mask systemic issues in the production line. Implement ongoing quality assurance measures, such as production line inspections or random batch testing.

Ignoring Supply Chain Transparency

Hidden subcontracting or opaque supply chains can introduce unvetted components or labor practices that compromise quality and ethics. Knowing exactly where and how tines are made helps mitigate both performance and reputational risks.

By proactively addressing these pitfalls—through rigorous supplier vetting, clear contracts, IP due diligence, and ongoing quality checks—buyers can ensure they source durable, compliant, and legally sound landscaping rake tines.

Logistics & Compliance Guide for Landscaping Rake Tines

Product Classification & HS Code

Landscaping rake tines are typically classified under HS (Harmonized System) codes related to agricultural or gardening tools and parts. Common classifications include:

– 8201.90 – Other hand tools, not mechanically powered, of iron or steel (may apply to metal tines)

– 4415.20 – Other articles of wood (if wooden tines are used)

– 3926.30 – Articles of plastics used as parts for tools (if made from polymer materials)

Consult local customs authorities or a customs broker to confirm the correct HS code based on material composition and intended use, as misclassification can lead to delays and penalties.

Packaging & Labeling Requirements

Ensure packaging protects tines during transit and complies with international standards:

– Use durable, moisture-resistant materials (e.g., shrink-wrapped bundles, corrugated cardboard, or wooden crates for bulk shipments).

– Label each package with:

– Product description (“Landscaping Rake Tines”)

– Quantity per unit

– Material type (e.g., hardened steel, polyethylene)

– Country of origin

– Barcodes or SKU numbers for traceability

– Include handling labels (e.g., “Fragile,” “This Side Up”) where applicable.

Shipping & Transportation

- Domestic Shipments: Use standard freight carriers (e.g., LTL or parcel services). Confirm weight and dimensions to avoid dimensional weight surcharges.

- International Shipments:

- Choose reliable freight forwarders experienced in hardware or agricultural equipment.

- Comply with Incoterms (e.g., FOB, CIF) clearly defined in contracts.

- Ensure ISPM 15 compliance for wooden packaging (heat-treated or fumigated and stamped).

- Document cargo insurance to cover loss or damage.

Import/Export Documentation

Prepare and retain the following for smooth customs clearance:

– Commercial Invoice (with value, quantity, and HS code)

– Packing List (itemizing contents per package)

– Bill of Lading (for sea freight) or Air Waybill (for air freight)

– Certificate of Origin (required by some countries for tariff determination)

– Import/Export License (if required by destination country)

– Product Compliance Certifications (see below)

Regulatory & Safety Compliance

- REACH & RoHS (EU): Ensure metal tines do not contain restricted substances (e.g., lead, cadmium) above permissible limits.

- Proposition 65 (California, USA): If tines contain chemicals listed under Prop 65 (e.g., chromium VI), provide consumer warnings.

- OSHA & ANSI (USA): While not directly regulating tines, ensure compatibility with rakes that meet safety standards for end-user protection.

- CE Marking (if sold in EU): May be required if tines are sold as part of a complete tool system or safety-critical component.

Environmental & Disposal Regulations

- Provide guidance on end-of-life disposal:

- Steel tines: Recyclable through metal scrap facilities.

- Plastic tines: Follow local plastic recycling codes.

- Avoid prohibited materials under WEEE or similar waste directives.

- Consider offering take-back or recycling programs for sustainability compliance.

Quality Assurance & Traceability

- Maintain batch records and material certifications (e.g., steel mill test reports).

- Conduct periodic quality checks for strength, durability, and dimensional accuracy.

- Implement a traceability system to track production lots in case of recalls or compliance audits.

Storage & Handling Guidelines

- Store in dry, covered areas to prevent rust (for metal tines) or UV degradation (for plastic tines).

- Stack packages securely to avoid crushing.

- Rotate stock using FIFO (First In, First Out) to minimize aging and degradation.

Conclusion

Proper logistics and compliance management for landscaping rake tines ensures timely delivery, avoids customs delays, and meets global regulatory standards. Regular audits and staying updated on international trade regulations are essential for ongoing compliance and market access.

In conclusion, sourcing landscaping rake tines requires careful consideration of material quality, durability, compatibility with existing equipment, and cost-effectiveness. Prioritizing high-carbon or spring steel tines ensures longevity and resilience under heavy use, while verifying compatibility prevents operational inefficiencies. Exploring both domestic and international suppliers can provide options for balancing price and reliability. Establishing relationships with reputable manufacturers or distributors, reviewing customer feedback, and requesting product samples can further ensure product performance. Ultimately, a well-informed sourcing strategy will enhance the efficiency and durability of landscaping tools, supporting long-term landscaping success.