The global lamp socket market is experiencing steady growth, driven by rising demand for energy-efficient lighting solutions and advancements in LED technology. According to a report by Mordor Intelligence, the global lighting market was valued at USD 106.18 billion in 2023 and is projected to reach USD 148.12 billion by 2029, growing at a CAGR of over 5.8% during the forecast period. A critical yet often overlooked component within this ecosystem is the lamp light socket—the electrical junction that secures the bulb and ensures reliable power transmission. As lighting systems evolve toward smarter, more durable designs, the demand for high-quality socket parts made from heat-resistant, conductive, and long-lasting materials has intensified. With key players investing in precision engineering and compliance with international safety standards, the supply chain for lamp socket components has become increasingly specialized. Here are the top 10 manufacturers leading innovation and volume production in lamp light socket parts globally.

Top 10 Lamp Light Socket Parts Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Sockets

Domain Est. 1996

Website: satco.com

Key Highlights: SATCO® is a leading supplier of lighting products, offering solutions for commercial, residential, and industrial markets. Read more About us. Our Company….

#2 Rational Light Sockets & Lampholders

Domain Est. 1998

Website: partstown.com

Key Highlights: 90-day returnsFind genuine OEM Rational Light Sockets & Lampholders at Parts Town with the largest in-stock inventory and same day shipping until 9pm ET….

#3 Lamp Accessories

Domain Est. 1998

#4 Lamp Sockets

Domain Est. 2001

Website: us.rs-online.com

Key Highlights: Our vast inventory of electric light sockets is sourced from leading manufacturers, guaranteeing that every lamp holder meets safety and performance standards….

#5 Clusters Lamp Socket Junctions

Domain Est. 1997

#6 Lamp Sockets, Plugs, Switches, Dimmers, Keys

Domain Est. 1999

Website: bplampsupply.com

Key Highlights: Lamp Sockets, Plugs, Switches, Dimmers, Keys, B&P Lamp Supply is the #1 source for wholesale lamp parts and lighting hardware. We offer reproduction antique ……

#7 Lamp Sockets

Domain Est. 2001

Website: lampsocket.com

Key Highlights: Lightbulb sockets, light sockets, lamp sockets or lampholders provide electrical connections to the lamps and support it in the lighting fixture….

#8 Sockets

Domain Est. 2006

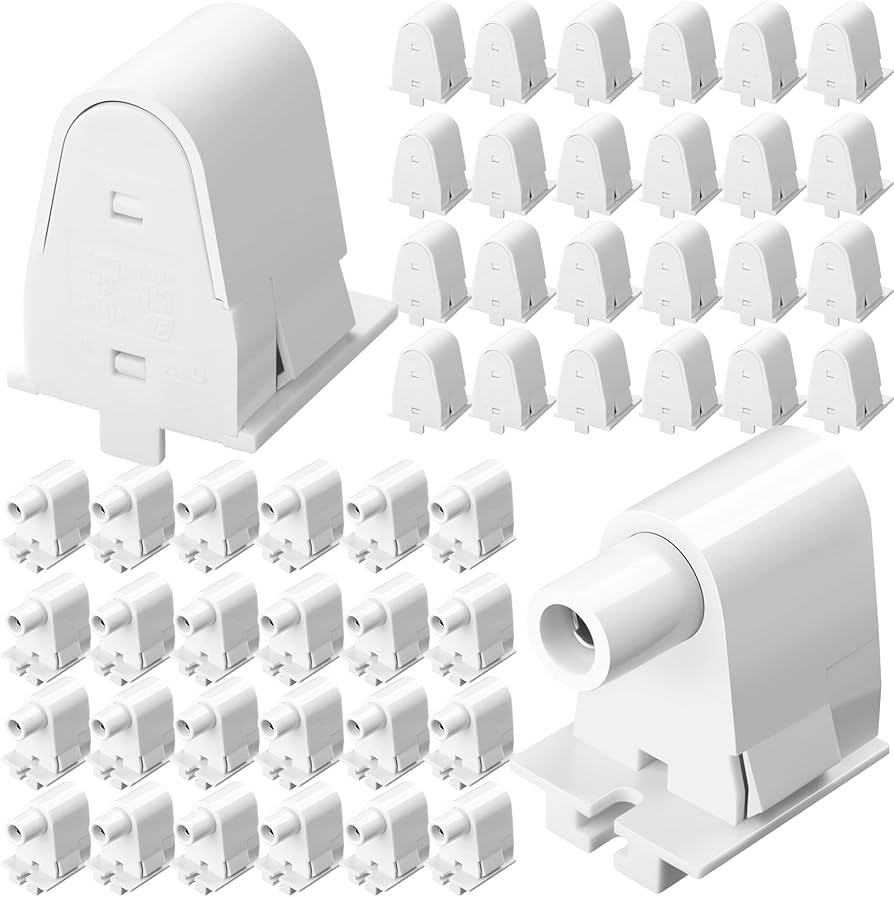

#9 Fluorescent Light Fixture & Socket Replacement Parts

Domain Est. 2011

Website: hhfluorescentparts.net

Key Highlights: From T-5 sockets to T-8 sockets, to T-12 sockets, and everything in between, we have the components you need when it comes to fluorescent bulb socket options ……

#10 Lamp Socket

Domain Est. 1996

Expert Sourcing Insights for Lamp Light Socket Parts

H2: Projected Market Trends for Lamp Light Socket Parts in 2026

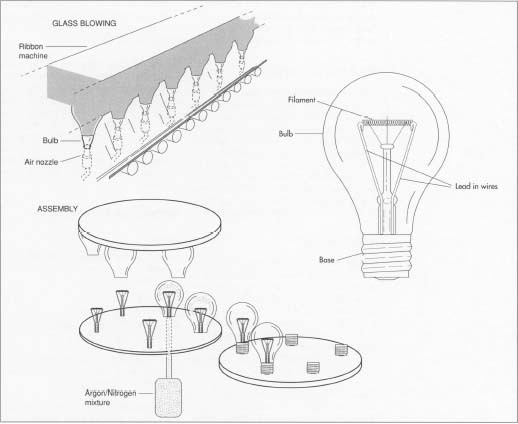

The global market for lamp light socket parts is expected to undergo significant transformation by 2026, driven by advancements in lighting technology, shifting consumer preferences, and increasing demand for energy-efficient solutions. As part of the broader lighting components industry, lamp light socket parts—critical elements that connect bulbs to electrical circuits—are adapting to the rise of LED lighting, smart home integration, and sustainable manufacturing practices.

One of the key trends shaping the 2026 market is the continued shift from traditional incandescent and halogen bulbs to LED-based lighting systems. This transition is propelling demand for socket parts compatible with low-voltage, high-efficiency LED bulbs. Manufacturers are focusing on developing heat-resistant, compact, and durable socket designs—such as ceramic or high-grade plastic sockets—that align with the thermal and electrical requirements of modern LED fixtures.

Another major trend is the integration of smart lighting technologies. By 2026, an increasing number of lamp light socket parts are expected to incorporate or support smart features, including Wi-Fi or Bluetooth connectivity, dimming capabilities, and compatibility with voice assistants like Alexa or Google Home. This shift is prompting innovation in socket design, with embedded sensors, modular connectors, and standardized interfaces becoming more common.

Sustainability and regulatory compliance are also influencing market dynamics. Stricter energy efficiency regulations in regions like the European Union and North America are pushing manufacturers to adopt recyclable materials and eco-friendly production processes. Additionally, the growing emphasis on circular economy principles is encouraging the development of socket parts that are easier to repair, replace, and recycle.

Regionally, Asia-Pacific is anticipated to remain a dominant market for lamp light socket parts in 2026, fueled by rapid urbanization, expanding construction activities, and strong manufacturing bases in countries like China and India. Meanwhile, North America and Europe are witnessing steady growth driven by retrofitting projects and the adoption of smart home ecosystems.

In summary, the 2026 market for lamp light socket parts will be characterized by technological innovation, a focus on energy efficiency, and integration with smart infrastructure. Manufacturers who prioritize adaptability, sustainability, and compatibility with next-generation lighting systems are likely to gain a competitive advantage in this evolving landscape.

Common Pitfalls When Sourcing Lamp Light Socket Parts: Quality and Intellectual Property Risks

Quality-Related Pitfalls

Inconsistent Material Standards

One of the most frequent issues when sourcing lamp light socket parts is variability in material quality. Suppliers, especially in low-cost manufacturing regions, may use substandard plastics or metals that fail to meet safety certifications (e.g., UL, CE). Inferior thermoplastics can degrade under heat, increasing fire hazards, while poor-grade brass or copper contacts lead to overheating and reduced electrical conductivity.

Lack of Compliance with Safety Certifications

Many suppliers claim compliance with international standards but fail to provide legitimate certification documentation. Using non-compliant socket parts can result in product recalls, liability risks, and failure during regulatory inspections. It’s crucial to verify certifications through third-party testing rather than relying solely on supplier claims.

Poor Manufacturing Tolerances

Tight tolerances are essential for secure bulb fit and electrical contact. Poorly manufactured sockets may have misaligned threads or loose connections, leading to flickering lights or intermittent power. These defects often stem from outdated tooling or inadequate quality control processes at the supplier’s facility.

Insufficient Testing and Quality Control

Reputable manufacturers conduct routine dielectric strength, temperature rise, and endurance tests. However, some suppliers skip or falsify test results to cut costs. Without proper batch testing, defective parts may reach end users, damaging brand reputation and increasing warranty claims.

Intellectual Property (IP) Risks

Inadvertent Use of Patented Designs

Lamp socket designs—especially twist-lock mechanisms or proprietary heat-dissipation features—may be protected by patents. Sourcing generic parts that mimic branded designs can expose buyers to IP infringement lawsuits, particularly in markets with strong IP enforcement like the EU or U.S.

Counterfeit or Clone Components

Some suppliers offer “compatible” or “equivalent” parts that closely resemble original equipment manufacturer (OEM) products. These may be outright counterfeits or reverse-engineered clones. Using such parts not only risks legal action but also compromises performance and safety due to unverified engineering.

Lack of IP Warranty from Suppliers

Many suppliers, particularly smaller manufacturers, do not provide intellectual property indemnification. This means the buyer assumes full liability if the sourced part infringes on third-party patents. Always include IP warranties in procurement contracts to mitigate this risk.

Design Leakage and Reverse Engineering

When working with contract manufacturers or custom socket suppliers, there’s a risk that your proprietary designs could be copied or sold to competitors. Without strong non-disclosure agreements (NDAs) and IP protection clauses, your innovations may be compromised, especially in jurisdictions with weak enforcement.

Mitigation Strategies

To avoid these pitfalls, conduct thorough supplier audits, demand verifiable test reports and certifications, use independent labs for product validation, and include robust IP protections in contracts. Partnering with reputable manufacturers and leveraging legal counsel for IP due diligence can significantly reduce sourcing risks.

Logistics & Compliance Guide for Lamp Light Socket Parts

This guide outlines the essential logistics and compliance considerations for the international shipment, handling, and regulatory adherence of Lamp Light Socket Parts.

Overview

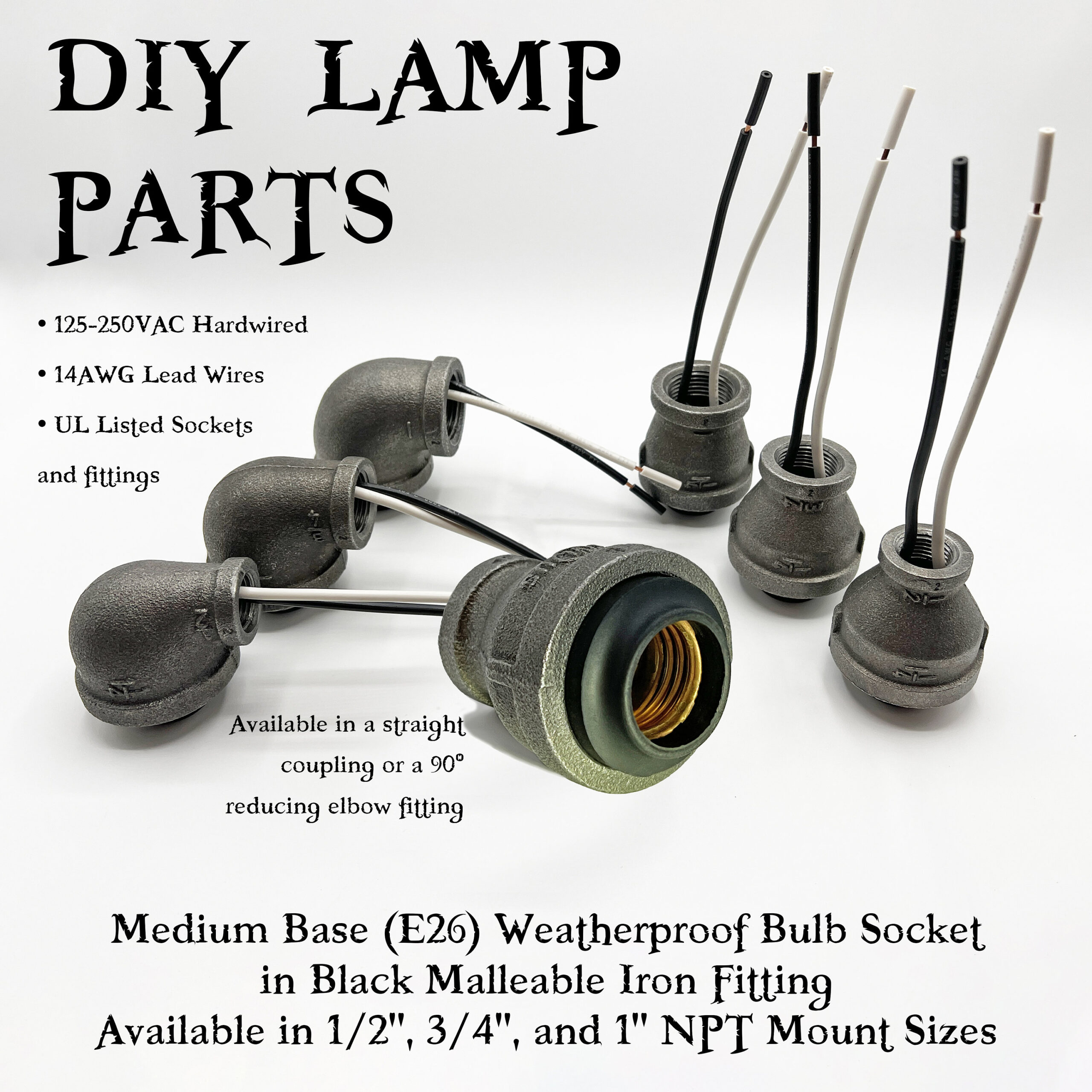

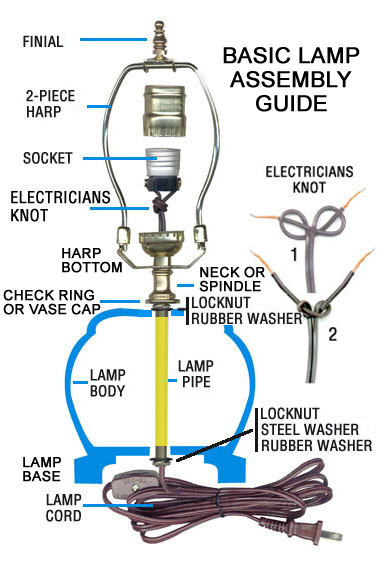

Lamp Light Socket Parts are components used in lighting fixtures to connect and secure lamps (bulbs) and conduct electricity. These parts may include ceramic or plastic insulators, metal contact pins, threaded bases (e.g., E26, E27), springs, terminals, and mounting hardware. Proper logistics planning and compliance with regulatory standards are critical to ensure product safety, avoid customs delays, and maintain supply chain efficiency.

International Shipping & Packaging

- Packaging Requirements: Use anti-static, moisture-resistant, and shock-absorbent packaging to protect sensitive electrical components. Individual parts should be bagged or separated to prevent scratching or short circuits.

- Labeling: Clearly label packages with product descriptions, part numbers, country of origin, weight, and handling instructions (e.g., “Fragile,” “Do Not Stack,” “Keep Dry”).

- Shipping Modes: Choose air freight for urgent, high-value shipments; sea freight for bulk consignments. Consider Incoterms (e.g., FOB, EXW, DDP) to define responsibilities between buyer and seller.

- Documentation: Prepare commercial invoices, packing lists, bill of lading/air waybill, and certificates of origin. Accurate Harmonized System (HS) codes are essential for customs clearance.

Harmonized System (HS) Code Classification

Proper HS code classification ensures correct duty assessment and compliance. Common classifications include:

– HS 8536.50: Electrical apparatus for switching or protecting electrical circuits (e.g., lamp holders/sockets).

– HS 8544.42: Insulated wire fittings, including lamp socket components made of insulating materials.

– Note: Final classification may depend on material composition, function, and country-specific tariff schedules. Confirm with local customs authority.

Regulatory Compliance

Lamp Light Socket Parts must meet safety and performance standards in target markets:

– North America:

– UL 496: Standard for Lampholders by UL (Underwriters Laboratories).

– CSA C22.2 No. 19: Canadian standard for lampholders.

– FCC compliance may apply if parts are part of a smart lighting system.

– European Union:

– CE Marking under the Low Voltage Directive (2014/35/EU) and RoHS Directive (2011/65/EU) restricting hazardous substances (e.g., lead, cadmium).

– Compliance with REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals) for material safety.

– Other Regions:

– UKCA Marking (UK), PSE Mark (Japan), CCC Mark (China), and KC Mark (South Korea) may apply depending on destination.

Product Safety & Environmental Standards

- RoHS Compliance: Ensure lead, mercury, cadmium, and other restricted substances are within allowable limits.

- REACH SVHC: Declare Substances of Very High Concern if present above threshold levels.

- WEEE Directive (EU): Producers may be responsible for recycling end-of-life electrical components.

- Conflict Minerals: If applicable, comply with U.S. Dodd-Frank Act Section 1502 regarding sourcing of tin, tantalum, tungsten, and gold.

Customs Clearance & Duties

- Provide accurate product descriptions and technical specifications to avoid classification disputes.

- Be prepared for potential customs inspections, especially for electrical goods.

- Duty rates vary by country and HS code. Use binding tariff information (BTI) rulings where available for certainty.

- Leverage Free Trade Agreements (e.g., USMCA, RCEP) if components originate from participating countries.

Quality Assurance & Traceability

- Implement a traceability system (e.g., lot numbering, barcoding) to track components through the supply chain.

- Conduct incoming and outgoing quality inspections per ISO 9001 standards.

- Maintain documentation of material certifications, test reports (e.g., dielectric strength, temperature rise), and compliance declarations.

Storage & Handling

- Store in dry, temperature-controlled environments to prevent warping, corrosion, or material degradation.

- Avoid exposure to direct sunlight and extreme temperatures.

- Follow FIFO (First In, First Out) inventory practices to minimize aging of plastic or rubber components.

Conclusion

Effective logistics and strict compliance with international regulations are essential for the successful distribution of Lamp Light Socket Parts. Proactive classification, adherence to safety standards, and accurate documentation reduce risks, ensure market access, and support sustainable operations. Regular review of regulatory updates and customs procedures is recommended to maintain ongoing compliance.

In conclusion, sourcing lamp light socket parts requires a careful balance of quality, cost-efficiency, reliability, and compliance with safety standards. It is essential to evaluate suppliers based on their manufacturing capabilities, material specifications, certifications (such as UL, CE, or RoHS), and ability to meet volume and delivery requirements. Establishing strong partnerships with reputable suppliers ensures consistent part quality, reduces downtime, and supports long-term production stability. Additionally, considering factors like customization options, lead times, and logistical support contributes to a more resilient supply chain. Ultimately, a strategic sourcing approach not only enhances product performance and safety but also strengthens competitiveness in the lighting market.