The global laminar flow cabinet market is experiencing steady expansion, driven by increasing demand for contamination-controlled environments across pharmaceuticals, biotechnology, research laboratories, and healthcare facilities. According to Grand View Research, the global cleanroom technology market—of which laminar flow cabinets are a critical component—was valued at USD 5.3 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 5.4% from 2023 to 2030. This growth is fueled by stringent regulatory standards for sterility, rising R&D investments, and the expansion of biopharmaceutical manufacturing, particularly in emerging economies. As demand for high-efficiency air filtration and controlled airflow systems intensifies, manufacturers of laminar flow cabinets are innovating rapidly to meet performance, safety, and energy efficiency benchmarks. In this evolving landscape, identifying leading suppliers with proven track records in reliability, compliance, and technical excellence becomes essential for organizations committed to maintaining pristine working environments. The following list highlights the top nine laminar flow cabinet manufacturers shaping the industry through innovation, global reach, and data-backed market performance.

Top 9 Laminar Flow Cabinet Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Laminar Airflow Workstations

Domain Est. 1996

Website: nuaire.com

Key Highlights: All workstations use an ultra-high-efficiency motor to deliver 90 FPM (0.46 m/s) laminar flow of HEPA-filtered air into a stainless-steel work zone (stainless ……

#2 Esco Lifesciences

Domain Est. 2013

Website: escolifesciences.com

Key Highlights: Esco Lifesciences is a world-leading life science company and a manufacturer of laboratory, biopharma equipment, and IVF medical devices….

#3 Horizontal Laminar Flow Cabinet

Domain Est. 2020

Website: isocleanroomchina.com

Key Highlights: Horizontal Laminar Flow Cabinets are used in various fields which include, including biotechnology, medical, research, manufacturing, and scientific fields….

#4 Labconco

Domain Est. 1995

Website: labconco.com

Key Highlights: Labconco manufactures high-quality laboratory equipment, including fume hoods, biosafety cabinets, freeze dryers, and glassware washers—trusted worldwide ……

#5 Horizontal Laminar Flow Bench (HS)

Domain Est. 2000

Website: air-tech.com.tw

Key Highlights: A standard clean bench with horizontal airflow. There is no shutter on the front, it is open and used for parts inspection and work….

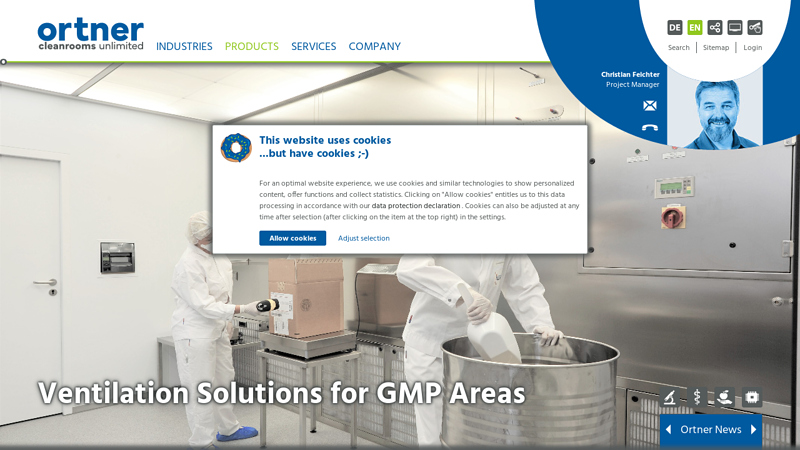

#6 Laminarflow System (Pharma)

Domain Est. 2005

Website: ortner-group.com

Key Highlights: Laminar flow systems or systems with low- turbulence displacement flow are state of the art in the pharmaceutical sector and are naturally subject to GMP ……

#7 Laminar Flow Cabinets BIOBASE BBS

Domain Est. 2013

Website: biobase.nt-rt.ru

Key Highlights: Rating 4.6 (3) A laminar flow cabinet is a work table or similar enclosure that creates a particle-free working environment by taking air through a filtration system and ……

#8 Meling Biomedical

Domain Est. 2018

Website: melingbiomedical.com

Key Highlights: Meling Biomedical recently announced that a batch of 209 laminar flow cabinets has been officially shipped to Uzbekistan. This order will be used to support the ……

#9 Small Vertical Laminar Flow Cabinet Clean Bench BBS

Domain Est. 2022

Website: lnbtec.com

Key Highlights: Laminar flow cabinet is a work bench or similar enclosure, which creates a particle-free working environment by taking air through a filtration system….

Expert Sourcing Insights for Laminar Flow Cabinet

H2: 2026 Market Trends for Laminar Flow Cabinets

The global laminar flow cabinet market is poised for significant transformation by 2026, driven by advancements in technology, growing demand for contamination control, and the expansion of life sciences and pharmaceutical industries. Key market trends shaping the landscape include:

1. Rising Demand in Pharmaceutical and Biotechnology Sectors

The continued growth of biopharmaceutical research, vaccine development, and sterile compounding operations is fueling demand for laminar flow cabinets. With increased investments in R&D and regulatory emphasis on Good Manufacturing Practices (GMP), laboratories and cleanrooms are prioritizing contamination-free environments, boosting adoption of HEPA-filtered enclosures.

2. Technological Innovations and Smart Integration

By 2026, laminar flow cabinets are expected to incorporate smart features such as IoT-enabled monitoring systems, real-time airflow sensors, and remote diagnostics. These enhancements improve operational efficiency, ensure compliance, and allow for predictive maintenance, making cabinets more user-friendly and reliable.

3. Expansion in Emerging Markets

Asia-Pacific, particularly countries like India, China, and South Korea, is witnessing rapid growth in pharmaceutical manufacturing and academic research. Government initiatives to strengthen healthcare infrastructure and biotech parks are accelerating the deployment of laminar flow cabinets, making this region a key growth driver.

4. Focus on Energy Efficiency and Sustainability

Manufacturers are responding to environmental regulations and operational cost concerns by developing energy-efficient models with low-power HEPA fans and eco-friendly materials. This shift aligns with global sustainability goals and appeals to environmentally conscious institutions.

5. Increasing Adoption in Healthcare and Clinical Settings

Hospitals, compounding pharmacies, and diagnostic labs are increasingly using laminar flow cabinets to prepare sterile medications and handle sensitive biological samples. The rise in personalized medicine and cell therapy applications further supports market expansion.

6. Stringent Regulatory Standards

Regulatory bodies such as the FDA, EU GMP, and ISO are reinforcing standards for cleanroom environments. Compliance requirements are prompting facilities to upgrade to certified laminar flow systems, ensuring consistent air quality and worker safety.

7. Competitive Landscape and Product Differentiation

Key players are focusing on product differentiation through ergonomic designs, enhanced safety features (e.g., UV sterilization, alarm systems), and modular configurations. Strategic partnerships, mergers, and geographic expansions are also shaping market dynamics.

In summary, by 2026, the laminar flow cabinet market will be characterized by innovation, regulatory compliance, and geographic diversification. Stakeholders should focus on technological advancement and market-specific strategies to capitalize on emerging opportunities.

Common Pitfalls When Sourcing a Laminar Flow Cabinet: Quality and Intellectual Property (IP) Concerns

When sourcing a Laminar Flow Cabinet (LFC), organizations—especially in pharmaceuticals, biotechnology, and research—must navigate several critical challenges related to quality assurance and intellectual property protection. Overlooking these aspects can lead to compromised product integrity, regulatory non-compliance, and legal exposure. Below are the most common pitfalls to avoid.

1. Compromised Build Quality and Material Standards

One of the most frequent issues is sourcing LFCs made with substandard materials or poor craftsmanship. Low-cost suppliers may use inferior stainless steel, non-compliant filters (e.g., HEPA filters that don’t meet ISO 14644 or EN 1822 standards), or inadequate sealing. This can lead to:

- Contamination risks due to leaks or particle shedding

- Shortened equipment lifespan

- Non-compliance with GMP, FDA, or EU Annex 1 requirements

Mitigation: Always request material certifications (e.g., 316L stainless steel), third-party test reports for HEPA/ULPA filters, and proof of compliance with relevant standards.

2. Inadequate or Falsified Performance Validation

Some suppliers provide misleading airflow velocity data, noise levels, or particle counts without proper validation. Cabinets may not maintain laminar flow across the entire work zone or fail to meet ISO Class 5 (Grade A) cleanliness under real operating conditions.

Mitigation: Require on-site or factory acceptance testing (FAT) including:

– Airflow visualization (smoke tests)

– Particle counting per ISO 14644-3

– HEPA filter integrity testing (e.g., DOP/PAO testing)

3. Lack of Regulatory Compliance Documentation

Suppliers—especially from regions with less stringent oversight—may lack proper documentation such as:

– Declaration of Conformity (CE marking)

– Risk assessment reports (per ISO 14644 or IEC 61010)

– Traceable calibration certificates

This creates challenges during audits and regulatory inspections.

Mitigation: Ensure the supplier provides a complete Dossier including User Requirement Specifications (URS), Design Qualification (DQ), and Installation/Operational Qualification (IQ/OQ) protocols.

4. Intellectual Property (IP) Infringement Risks

Sourcing from unverified or offshore manufacturers increases the risk of purchasing counterfeit or reverse-engineered LFCs that infringe on patented designs, control systems, or proprietary airflow technology.

Consequences:

– Legal liability for using or distributing infringing equipment

– Voided warranties and lack of technical support

– Inability to obtain spare parts or software updates

Mitigation:

– Verify the manufacturer holds legitimate IP rights or licenses

– Avoid suppliers offering “compatible” or “OEM” models at suspiciously low prices

– Conduct IP due diligence, including patent searches and supplier audits

5. Poor After-Sales Support and Spare Parts Availability

Many low-cost suppliers lack local service networks or restrict access to genuine spare parts, filters, and firmware. This leads to:

– Extended downtime

– Forced reliance on third-party (potentially non-compliant) replacements

– Compromised system integrity

Mitigation: Prioritize suppliers with established service channels, documented maintenance programs, and transparent parts availability.

6. Hidden Costs from Non-Compliant Modifications

Some cabinets may appear compliant but require costly modifications post-purchase (e.g., retrofitting sensors, alarms, or data logging) to meet internal or regulatory standards.

Mitigation: Clearly define technical specifications and regulatory requirements upfront and ensure the quoted price includes full compliance.

Conclusion

Sourcing a Laminar Flow Cabinet demands rigorous vetting of both quality attributes and IP legitimacy. Cutting corners on procurement can lead to significant operational, compliance, and legal risks. Investing time in due diligence—verifying certifications, conducting performance testing, and ensuring IP compliance—protects both product quality and organizational integrity.

Logistics & Compliance Guide for Laminar Flow Cabinet

1. Pre-Shipment Preparation

1.1. Documentation Requirements

Ensure all necessary documentation is complete and accurate prior to shipment:

– Product Specification Sheet: Includes model number, dimensions, weight, airflow velocity, HEPA filter class (e.g., H13 or H14), electrical specifications, and certifications.

– Certificate of Conformity (CoC): Confirms compliance with relevant standards such as ISO 14644-1 (cleanroom classification), IEC 61010-1 (safety requirements for electrical equipment), and IEC 60335-2-65 (commercial refrigerating appliances).

– HEPA Filter Certification: Provides test results verifying filter efficiency (typically ≥99.99% at 0.3 µm).

– User Manual & Installation Guide: Must include handling, setup, operational, and maintenance instructions.

– Bill of Lading (BOL) & Commercial Invoice: Required for domestic and international shipments, detailing item description, value, and parties involved.

1.2. Packaging Specifications

- Use manufacturer-recommended packaging with shock-absorbing materials (e.g., foam inserts, corner protectors).

- Secure all internal components (e.g., work tray, UV lamp if present) to prevent movement.

- Clearly label packaging with:

- “Fragile”

- “This Side Up”

- “Protect from Moisture”

- Model and serial number

- Include desiccant packs to prevent moisture damage during transit.

1.3. Export Controls and Permits

- Verify if the unit contains components subject to export regulations (e.g., dual-use technologies under EAR or ITAR).

- For international shipments, complete an Export Declaration (e.g., AES filing in the U.S. for shipments over $2,500).

- Confirm destination country import requirements (e.g., CE marking for EU, CCC for China, PSE for Japan).

2. Shipping and Transportation

2.1. Carrier Selection

- Use freight carriers experienced in handling laboratory and sensitive equipment.

- For international shipments, engage a freight forwarder familiar with scientific instrumentation logistics.

- Choose shipping method based on urgency and fragility:

- Air freight for time-sensitive or high-value units.

- Ground freight for domestic or less urgent deliveries.

2.2. Handling During Transit

- Ensure the cabinet is transported in an upright position at all times.

- Avoid exposure to extreme temperatures, humidity, or direct sunlight.

- Use climate-controlled transport when shipping to regions with harsh environmental conditions.

- Secure the load on pallets using stretch wrap and banding; avoid forklift damage by marking lift points.

2.3. Tracking and Insurance

- Enable real-time shipment tracking.

- Insure the shipment for full replacement value against loss, damage, or delay.

3. Import and Customs Clearance

3.1. Customs Documentation

Prepare and submit:

– Commercial Invoice

– Packing List

– Certificate of Origin

– Bill of Lading or Air Waybill

– Any required import licenses or permits (e.g., for controlled goods or regulated markets)

3.2. Duties and Tariffs

- Classify the laminar flow cabinet under the correct Harmonized System (HS) code (e.g., 8479.89 for other machinery).

- Consult local customs authority for applicable import duties, VAT, or GST.

- Leverage free trade agreements if applicable (e.g., USMCA, EU-South Korea FTA).

3.3. Inspection and Quarantine

- Be prepared for customs inspection; ensure documentation is readily accessible.

- In some countries (e.g., Australia, New Zealand), equipment may be subject to biosecurity checks—even if non-biological—due to packaging materials.

4. Installation and Site Compliance

4.1. Site Requirements

Verify the installation site meets:

– Space: Adequate clearance (typically 15–30 cm) on all sides for airflow and maintenance.

– Power Supply: Correct voltage, frequency, and grounding per manufacturer specifications.

– Environment: Temperature (15–30°C), humidity (30–70% non-condensing), and low levels of airborne particulates.

– Ventilation: Ensure no obstructions to intake and exhaust vents.

4.2. Installation Protocol

- Perform installation by qualified personnel following the manufacturer’s instructions.

- Conduct a site acceptance test (SAT) including:

- Airflow velocity measurement (typically 0.3–0.5 m/s)

- HEPA filter integrity test (e.g., DOP/PAO testing)

- Noise level and vibration checks

- UV lamp intensity verification (if equipped)

4.3. Regulatory Compliance at Site

- Register the unit with facility safety or biosafety officers if used in regulated environments (e.g., BSL-2 labs).

- Comply with local regulations such as:

- OSHA (U.S.) for workplace safety.

- EU Machinery Directive 2006/42/EC and Workplace Directive 89/654/EEC.

- Local fire safety codes (e.g., distance from sprinklers).

5. Maintenance and Ongoing Compliance

5.1. Routine Maintenance

- Schedule regular servicing per manufacturer recommendations (e.g., every 6–12 months).

- Replace HEPA filters as needed and document replacements.

- Clean work surfaces and interior with approved disinfectants (avoid abrasive or corrosive cleaners).

5.2. Certification and Audits

- Perform annual certification by a qualified technician to ensure compliance with:

- NSF/ANSI 49 (U.S. standard for biosafety cabinets—note: laminar flow cabinets are not biosafety cabinets but may reference airflow standards).

- ISO 14644-3 (cleanroom testing).

- Maintain logs of:

- Calibration dates

- Filter changes

- Maintenance activities

- Certification reports

5.3. Decommissioning and Disposal

- Decontaminate the cabinet thoroughly before decommissioning (especially if used with hazardous materials).

- Follow WEEE (Waste Electrical and Electronic Equipment) directives in the EU or equivalent (e.g., EPA regulations in the U.S.) for electronic waste disposal.

- Recycle HEPA filters through certified hazardous waste handlers if contaminated.

6. Compliance Summary Checklist

| Requirement | Yes/No | Notes |

|————————————-|——–|——-|

| Complete product documentation | | CoC, specs, manual |

| Appropriate packaging and labeling | | Fragile, upright |

| Export declaration filed (if needed)| | AES, customs form |

| HS code and duties confirmed | | Check local tariffs |

| Installed per manufacturer specs | | SAT completed |

| Annual certification performed | | By accredited technician |

| Maintenance logs up to date | | Filter changes, cleaning |

| Disposal compliant with local laws | | WEEE, EPA, etc. |

Note: Laminar flow cabinets protect the product, not the user. They should not be used with hazardous biological agents. For biosafety, use a certified biosafety cabinet (BSC) instead.

Conclusion:

After a thorough evaluation of supplier options, product specifications, and operational requirements, sourcing a laminar flow cabinet is a strategic investment in maintaining a contamination-free working environment, particularly in laboratories engaged in microbiology, pharmaceuticals, cell culture, and other sterile applications. The selected laminar flow cabinet meets essential criteria including HEPA filtration efficiency, airflow consistency, ease of maintenance, compliance with international safety standards (such as ISO 14644 and NSF/ANSI 49), and suitability for the intended workspace.

Supplier reliability, after-sales support, certification documentation, and cost-effectiveness were key factors in the final decision. Choosing a reputable manufacturer ensures long-term performance, worker safety, and regulatory compliance. Ultimately, the procurement of a high-quality laminar flow cabinet enhances operational integrity, protects sensitive processes, and supports consistent, reproducible results in critical laboratory environments.