The global label gluer market is experiencing steady expansion, driven by increasing demand for efficient labeling solutions across industries such as packaging, pharmaceuticals, and consumer goods. According to Grand View Research, the global labeling machines market was valued at USD 9.2 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030. This growth is fueled by rising automation in production lines, stricter regulatory requirements for product labeling, and the surge in e-commerce packaging needs. As demand for high-speed, precision gluing systems intensifies, manufacturers are innovating to enhance adhesive application accuracy, energy efficiency, and integration with existing packaging lines. In this evolving landscape, selecting the right label gluer manufacturer is critical for ensuring reliability, performance, and long-term cost savings. Below, we analyze the top 10 label gluer manufacturers leading the industry through technological advancement, global reach, and proven track records in delivering robust labeling solutions.

Top 10 Label Gluer Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 YG China Adhesive Manufacturer & Supplier

Domain Est. 2002

Website: ygtape.com

Key Highlights: YG Group – YG China adhesive manufacturer & supplier offering wholesale prices. Quality industrial adhesives, tapes & customized service. Contact Us Now!…

#2 BOBST

Domain Est. 1996

Website: bobst.com

Key Highlights: We are one of the world’s leading supplier of equipment and services to packaging and label manufacturers in the folding carton, corrugated board and flexible ……

#3 Labeling Machines

Domain Est. 1997

Website: herma.com

Key Highlights: HERMA as a world leading manufacturer of self-adhesive label application systems designs and builds high specification, high quality labeling equipment….

#4 P.E. Labellers

Domain Est. 2001

Website: pelabellers.com

Key Highlights: P.E. Labellers is an award-winning manufacturer of automatic labeling machines. Applications include tamper evident, wrap-around, shrink labels, and more….

#5 Gernep Labeling: Labeling Systems

Domain Est. 2018

Website: gerneplabeling.com

Key Highlights: Gernep is a premier rotary label manufacturer boasting a legacy of 35 years of excellence. With HQ in the heart of Bavaria and offices in Quebec, Canada….

#6 Print and Packaging Solutions

Domain Est. 1995

Website: heidelberg.com

Key Highlights: Offset printing presses, digital printing technologies, post-press packaging machines, converting equipment and more – for the smart print shop….

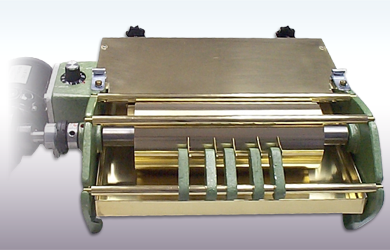

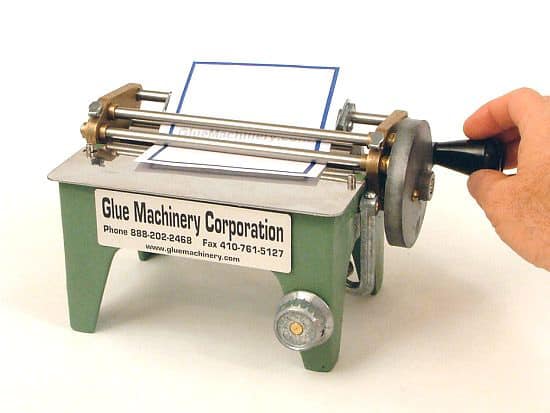

#7 Captain B Label Gluer

Domain Est. 1996

Website: gluefast.com

Key Highlights: The Captain B Label Gluer features excellent glue control, large capacity removable glue tray for easy access and cleanup, speed control, no exposed gears….

#8 CCL Industries

Domain Est. 1996

Website: ccllabel.com

Key Highlights: CCL Industries is the Global Leader in Conversion of Pressure Sensitive & Extruded Film Materials for Decorative, Functional & Information Labels….

#9 Folder Gluing

Domain Est. 2000

Website: koenig-bauer.com

Key Highlights: Koenig & Bauer’s folder gluers ensure precise and efficient folding and gluing, transforming printed sheets into high-quality cartons and packaging….

#10 Asteria Group

Website: asteriagroup.eu

Key Highlights: We are more than just a bunch of label printers, we are labelling and packaging experts on a mission towards innovative labelling and smart printing solutions….

Expert Sourcing Insights for Label Gluer

H2: 2026 Market Trends for Label Gluers

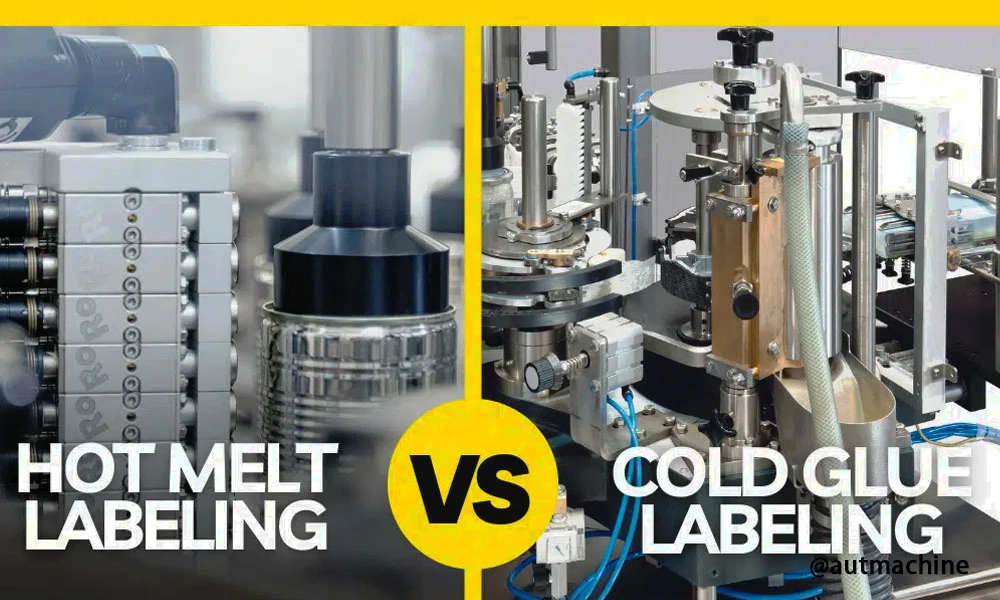

The global label gluer market is poised for significant evolution by 2026, driven by technological innovation, sustainability demands, and shifting packaging industry needs. As automated labeling processes become increasingly critical across sectors such as food & beverage, pharmaceuticals, and consumer goods, label gluers—machines designed to apply adhesive to labels prior to application—are adapting to meet new performance and environmental standards. Below is an analysis of key market trends expected to shape the label gluer industry in 2026:

1. Rising Demand for High-Speed and Automated Gluing Systems

Manufacturers are prioritizing efficiency and throughput, leading to increased adoption of high-speed, automated label gluing systems. In 2026, smart gluers integrated with Industry 4.0 technologies—such as IoT-enabled monitoring, predictive maintenance, and real-time adhesive control—are expected to dominate production lines. These systems reduce downtime, improve accuracy, and support just-in-time manufacturing models.

2. Shift Toward Sustainable Adhesives and Eco-Friendly Designs

Environmental regulations and consumer demand for sustainable packaging are pushing label gluer manufacturers to develop equipment compatible with water-based, biodegradable, and hot-melt adhesives with low VOC emissions. By 2026, gluers designed to minimize adhesive waste and support recyclable label materials will gain market share, especially in Europe and North America where ESG compliance is stringent.

3. Growth in E-Commerce and On-Demand Labeling

The continued expansion of e-commerce is fueling demand for flexible and compact label gluing solutions. Small-to-medium enterprises (SMEs) and contract packagers are investing in modular and desktop label gluers that support short runs and variable data labeling. In 2026, systems with quick changeover features and digital adhesive metering will be increasingly popular.

4. Regional Market Diversification

While North America and Western Europe remain strong markets due to advanced packaging infrastructure, Asia-Pacific—particularly China, India, and Southeast Asia—is expected to show the highest growth rate by 2026. This growth is driven by rising consumerism, urbanization, and investments in automated packaging lines in emerging economies.

5. Integration with Digital Printing and Label Finishing

As digital printing transforms label production, label gluers are being engineered for seamless integration with digital print workflows. Hybrid systems that combine printing, die-cutting, and gluing in a single line are gaining traction. By 2026, demand for inline gluing solutions that support roll-fed and sheet-fed digital finishing will rise.

6. Focus on Precision and Minimal Adhesive Usage

Precision glue application technology—such as bead control, pattern spraying, and ultrasonic dispensing—is becoming standard. Manufacturers aim to reduce adhesive consumption without compromising bond strength, which lowers costs and supports sustainability goals. In 2026, AI-powered vision systems may be used to monitor glue application quality in real time.

Conclusion

By 2026, the label gluer market will be characterized by smarter, greener, and more adaptable technologies. Companies that invest in automation, sustainability, and integration capabilities will be best positioned to capture market share. As packaging continues to evolve, label gluers will play an increasingly strategic role in ensuring label integrity, brand presentation, and operational efficiency across global supply chains.

Common Pitfalls When Sourcing a Label Gluer (Quality, IP)

Sourcing a label gluer—especially from overseas or new suppliers—can introduce significant risks related to product quality and intellectual property (IP) protection. Being aware of these common pitfalls helps mitigate potential issues.

Poor Quality Control and Inconsistent Performance

Many suppliers, particularly low-cost manufacturers, lack robust quality assurance systems. This can result in label gluers that deliver inconsistent glue application, misalignment, or frequent mechanical failures. Without proper testing or adherence to industry standards, equipment may not meet production requirements, leading to downtime and increased operational costs.

Lack of Compliance with Safety and Environmental Standards

Some label gluers may not conform to regional safety regulations (e.g., CE, UL) or environmental standards (e.g., VOC emissions from adhesives). Using non-compliant equipment can lead to legal liabilities, production halts, or rejection by end customers, especially in regulated industries like food and beverage or pharmaceuticals.

Inadequate After-Sales Support and Spare Parts Availability

Suppliers may offer attractive upfront pricing but fail to provide reliable technical support, training, or spare parts. This becomes a major issue when maintenance is required, leading to extended machine downtime and loss of productivity.

Risk of Intellectual Property Infringement

When sourcing custom or technologically advanced label gluers, there’s a risk that the design or technology infringes on existing patents or proprietary systems. Some suppliers may reverse-engineer branded equipment, exposing the buyer to legal action or reputational damage.

Weak IP Protection in Contracts

Purchase agreements often lack clear clauses on IP ownership, confidentiality, and usage rights—especially for customized machinery. Without explicit protection, buyers risk losing control over proprietary modifications or designs developed during collaboration with the supplier.

Hidden Costs from Poorly Defined Specifications

Ambiguous technical specifications can lead to misunderstandings, resulting in equipment that doesn’t meet actual production needs. This may necessitate costly retrofitting, modifications, or even replacement—eroding the initial cost savings.

Supply Chain and Lead Time Uncertainties

Unreliable suppliers may face production delays or logistical issues, disrupting your manufacturing schedule. Without contingency plans or clear delivery terms, this can lead to missed deadlines and lost revenue.

To avoid these pitfalls, conduct thorough due diligence, request third-party quality inspections, verify certifications, and ensure legal agreements clearly define quality standards and IP rights.

Logistics & Compliance Guide for Label Gluer

This guide outlines the essential logistics and compliance considerations for the safe and efficient handling, transportation, storage, and operation of Label Gluer equipment. Adhering to these guidelines ensures regulatory compliance, minimizes risks, and optimizes operational performance.

Shipping and Transportation

Ensure the Label Gluer is securely packaged using manufacturer-recommended materials and methods to prevent damage during transit. Use skids or pallets for stability, and secure the unit with straps or shrink wrap. Clearly label packages with “Fragile,” “This Side Up,” and handling instructions. Comply with carrier-specific requirements and international shipping regulations (e.g., ISPM 15 for wooden packaging). Maintain proper shipping documentation, including bills of lading and commercial invoices.

Import/Export Regulations

Verify applicable import and export controls based on the Label Gluer’s country of origin and destination. Ensure compliance with customs documentation, including accurate HS (Harmonized System) codes, product descriptions, and valuation. Obtain necessary export licenses or permits if required (e.g., for dual-use technology). Confirm adherence to trade sanctions and embargoes administered by relevant authorities such as the U.S. Department of Commerce or EU export control regimes.

Storage Requirements

Store the Label Gluer in a clean, dry, temperature-controlled environment, free from dust, moisture, and corrosive substances. Maintain ambient storage conditions within the manufacturer’s specified range (typically 10–30°C and 30–70% relative humidity). Keep the equipment in its original packaging until ready for installation. Elevate units off the floor using pallets to prevent water damage and ensure adequate ventilation around stored units.

Installation and Site Preparation

Ensure the installation site meets electrical, ventilation, and spatial requirements specified in the equipment manual. Verify power supply compatibility (voltage, frequency, phase) and ground the machine properly to prevent electrical hazards. Provide sufficient clearance for operation, maintenance, and emergency access. Confirm that facility flooring can support the equipment’s weight and that environmental conditions (e.g., temperature, humidity) are within operational limits.

Safety and Regulatory Compliance

Operate the Label Gluer in compliance with local, national, and international safety standards such as OSHA (USA), CE (Europe), or CSA (Canada). Equip the machine with required safety features including emergency stop buttons, guarding, and warning labels. Provide appropriate personal protective equipment (PPE) for operators. Conduct regular safety inspections and maintain records of equipment maintenance and safety training.

Environmental and Waste Management

Dispose of consumables such as adhesive residues, cleaning solvents, and packaging materials in accordance with local environmental regulations (e.g., EPA, REACH, WEEE). Use adhesives that comply with VOC (Volatile Organic Compounds) emission standards where applicable. Implement spill containment procedures for adhesive handling. Recycle packaging and obsolete equipment through certified waste management providers.

Documentation and Recordkeeping

Maintain comprehensive records including equipment manuals, warranty information, maintenance logs, compliance certifications (CE, UL, etc.), and training records. Keep copies of import/export documentation for a minimum of five years. Ensure all compliance-related documents are accessible for audits or regulatory inspections.

Maintenance and Servicing

Follow the manufacturer’s recommended maintenance schedule to ensure reliable operation and compliance with safety standards. Use only approved replacement parts and consumables. Document all servicing activities, including dates, performed tasks, and technician details. Schedule periodic inspections to verify the integrity of safety systems and operational components.

Conclusion for Sourcing a Label Gluer:

After a thorough evaluation of technical requirements, production needs, budget constraints, and supplier capabilities, sourcing a label gluer is a strategic investment that significantly enhances labeling efficiency, product quality, and operational consistency. The selected machine should align with the specific application—whether for wet glue, roll-on, or pressure-sensitive labeling—and offer reliability, ease of maintenance, and compatibility with current packaging lines.

By partnering with reputable suppliers offering proven technology, adequate after-sales support, and scalability options, the organization can ensure long-term performance and adaptability to future production demands. Additionally, considering energy efficiency and sustainability in the selection process supports broader corporate responsibility goals.

Ultimately, the successful sourcing of a label gluer not only improves packaging line automation but also contributes to reduced waste, lower labor costs, and increased throughput—delivering a strong return on investment and supporting continued growth and competitiveness in the market.