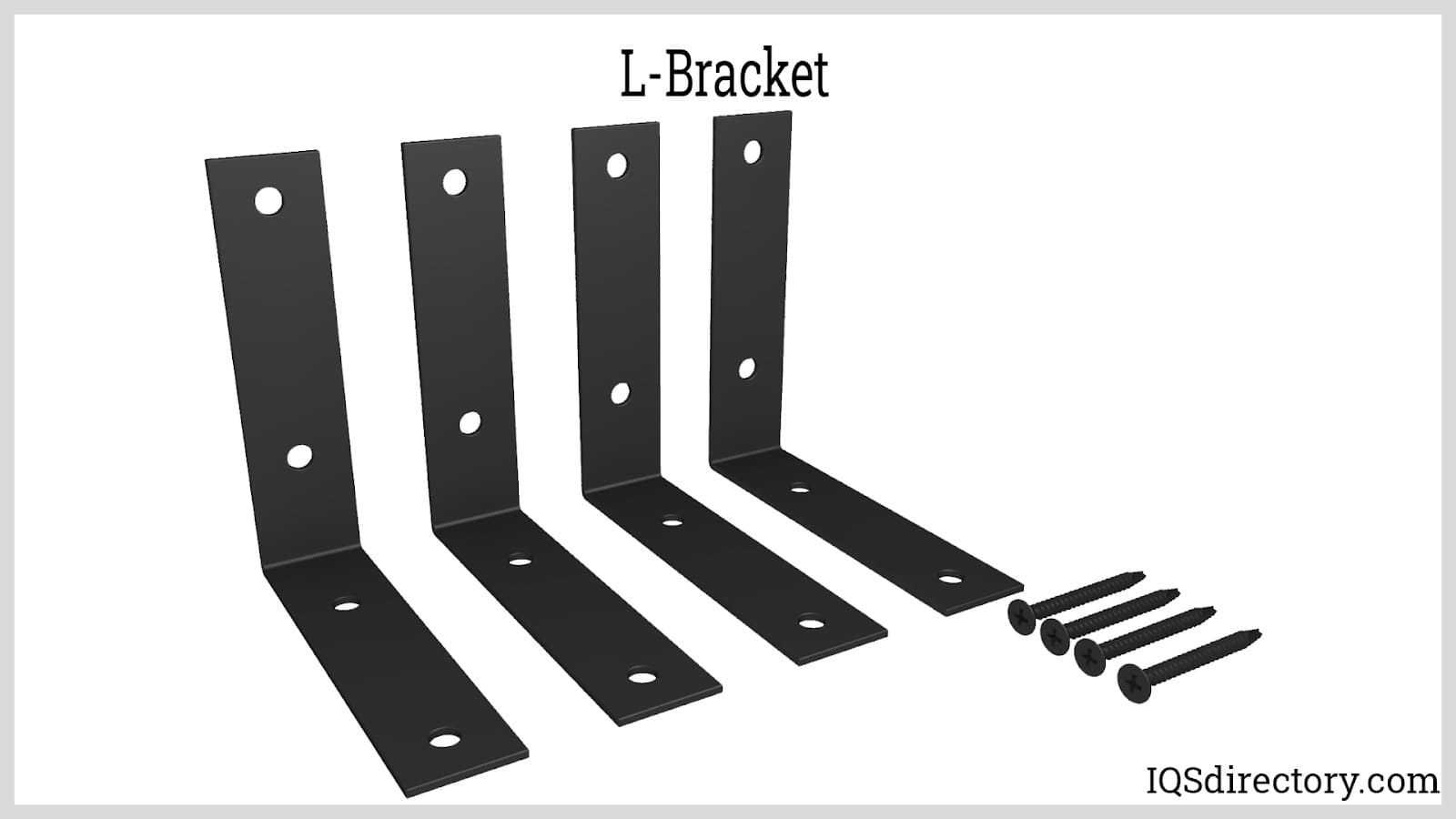

The global market for industrial hardware components, including L-brackets, has seen steady expansion driven by growth in construction, manufacturing, and consumer electronics sectors. According to Grand View Research, the global metal stamping market—key to L-bracket production—was valued at USD 251.2 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 6.3% from 2023 to 2030. This growth is fueled by rising demand for precision metal components in automotive, aerospace, and electronics applications—all industries where L-brackets play a vital role in structural support and assembly. With increasing automation and infrastructure development across North America, Asia-Pacific, and Europe, the need for high-quality, standardized L-brackets has led to the emergence of key manufacturers specializing in durability, material variety (including stainless steel, aluminum, and galvanized steel), and scalable production. As demand continues to climb, a select group of manufacturers has risen to prominence through innovation, quality control, and global supply chain integration.

Top 8 L Braket Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 L Brackets

Domain Est. 2008

Website: tphsupply.com

Key Highlights: 2–10 day delivery 30-day returnsL brackets are used to secure pilasters and urinal screens. They come in stainless steel, aluminum and zamac. All can be used with any manufacturer….

#2 L Bracket

Domain Est. 2018

Website: creativeengineeringworks.com

Key Highlights: We are a leading manufacturer, supplier, and exporter of L Bracket in All India and countries like Africa, Asia, Australia, Central America, Eastern Europe, ……

#3 Angles and Plates

Domain Est. 1995

Website: strongtie.com

Key Highlights: E angle brackets are used to connect cross-laminated timber (CLT) wall panels to concrete slabs. A wide variety of fastener and anchor options are available….

#4 Angle Bracket

Domain Est. 1996

Website: minerallac.com

Key Highlights: Products specifications ; Finish, Zinc Plated ; Number of Holes, 2 ; Depth, 1.000″ ; Type, Angled Bracket ; Material, Pre-Galvanized….

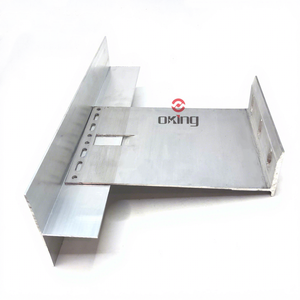

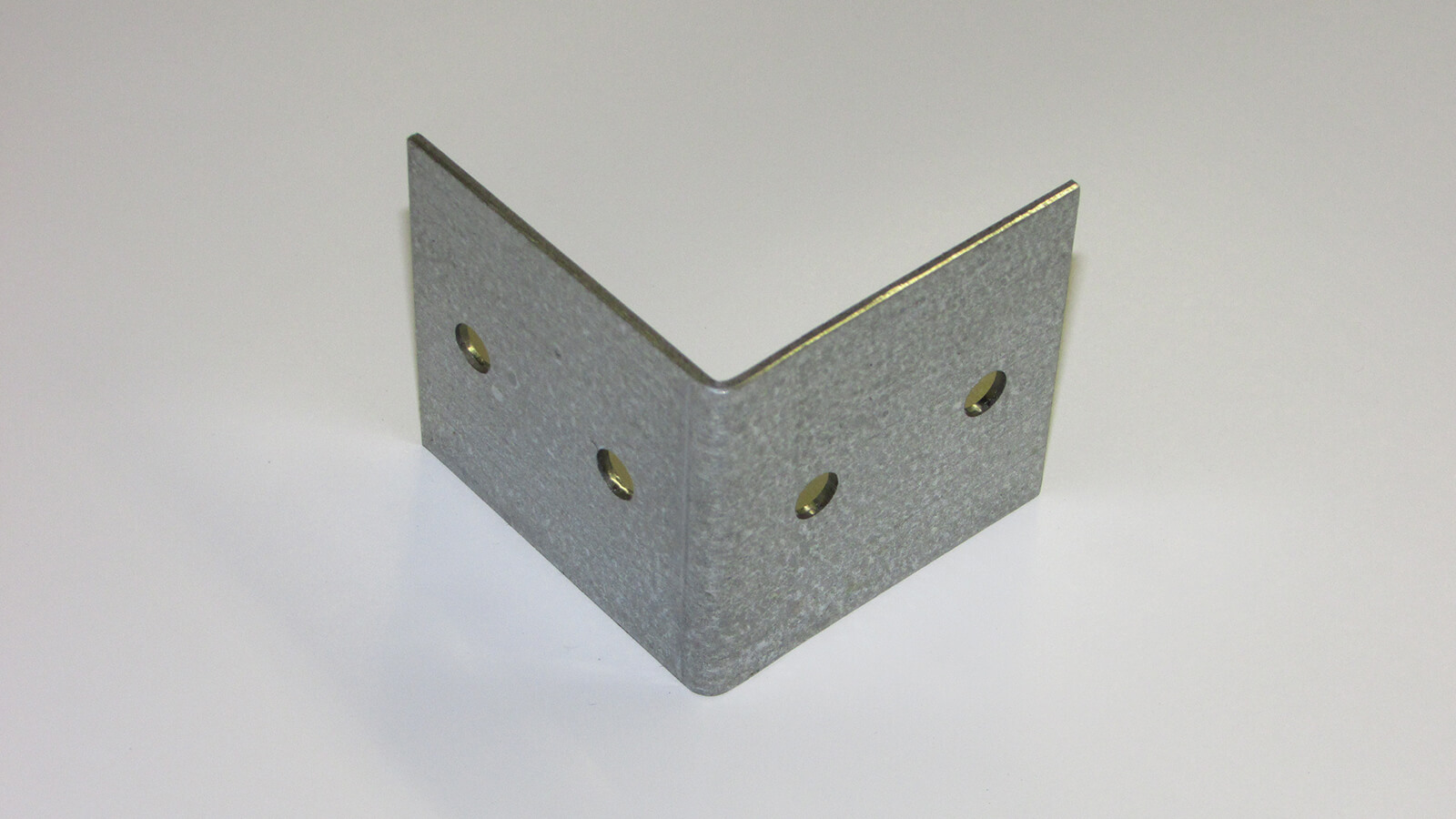

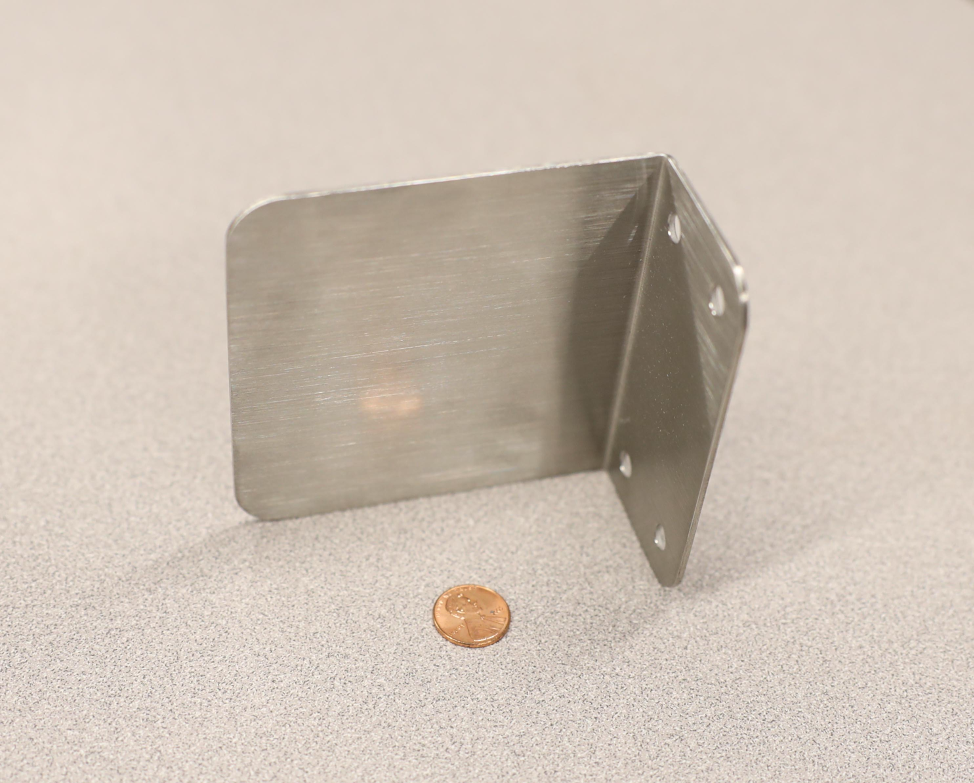

#5 Metal L

Domain Est. 1999

Website: marlinwire.com

Key Highlights: L-brackets are available in a wide variety of sizes and reinforcement options. Most are made of steel or aluminum and can be used in corners or other areas….

#6 Configurable L-Brackets – Mounting Plates & Brackets

Domain Est. 2007

Website: us.misumi-ec.com

Key Highlights: 1–4 day delivery 30-day returnsShop MISUMI for all your Configurable L-Brackets and Mounting Plates & Brackets needs. MISUMI offers free CAD download, short lead times, ……

#7 L Bracket

Domain Est. 2013

Website: makera.com

Key Highlights: In stock Free delivery over $100Makera offers two variants of L-shaped brackets: thin and thick versions. Designed for precise workpiece positioning and stability during machining….

#8 L Bracket

Domain Est. 2017

Website: siffron.com

Key Highlights: “L” Bracket allows you to configure panels at 90 Degree angle · Available with or without flexible hinge · Attach to panels with glue, double sided tape or screws ……

Expert Sourcing Insights for L Braket

H2: 2026 Market Trends Analysis for L-Bracket

As we approach 2026, the market for L-brackets—widely used mounting components in industries such as construction, manufacturing, photography, and consumer electronics—exhibits several emerging trends shaped by technological advancement, sustainability demands, and evolving industrial needs. Here is a comprehensive analysis of key market dynamics expected to influence the L-bracket sector in 2026:

-

Increased Demand in Modular and Prefabricated Construction

The global shift toward modular and off-site construction is a significant driver for L-bracket usage. In 2026, the construction industry is expected to rely more heavily on lightweight, durable, and easily installable metal components like L-brackets for assembling prefabricated wall panels, flooring, and roofing systems. The push for faster project completion and reduced labor costs continues to boost adoption, especially in urban development and affordable housing initiatives. -

Growth in Consumer Electronics and Photography Accessories

In the consumer space, L-brackets remain essential accessories for DSLR and mirrorless camera systems, particularly among professional photographers and content creators. By 2026, rising demand for vlogging, 360-degree content, and high-mobility gear supports continued innovation in lightweight, precision-machined aluminum L-brackets. Compatibility with multi-device setups (e.g., cameras, gimbals, monitors) is a key differentiator in this niche market. -

Advancements in Material Science and Lightweight Design

Material innovation is a critical trend. Manufacturers are increasingly adopting aerospace-grade aluminum alloys, reinforced polymers, and corrosion-resistant stainless steel to enhance strength-to-weight ratios and longevity. In 2026, expect broader use of anodized and powder-coated finishes to improve durability and aesthetic appeal, especially in outdoor and marine applications. -

Sustainability and Circular Manufacturing Practices

With growing regulatory and consumer pressure for sustainable production, L-bracket manufacturers are shifting toward recyclable materials and energy-efficient manufacturing processes. By 2026, industry leaders are likely to emphasize cradle-to-cradle design principles, including take-back programs and modular designs that extend product lifecycles—particularly in industrial and construction supply chains. -

Automation and Smart Integration in Industrial Applications

In automation and robotics sectors, L-brackets are used as structural supports in robotic arms, conveyor systems, and sensor mounts. As Industry 4.0 accelerates, demand for standardized, precision-engineered brackets compatible with smart assembly systems is expected to grow. Integration with IoT-enabled mounting solutions may emerge in high-tech manufacturing environments. -

Regional Market Shifts

Asia-Pacific, particularly China and India, will remain dominant in both production and consumption due to rapid urbanization and infrastructure development. Meanwhile, North America and Europe are seeing growth in high-precision, custom L-bracket solutions driven by advanced manufacturing and green building standards. -

Supply Chain Resilience and Localization

Ongoing geopolitical uncertainties and past disruptions have prompted companies to localize production. By 2026, regional manufacturing hubs are expected to rise, reducing dependency on global supply chains and enabling faster customization—especially for B2B clients in construction and electronics.

Conclusion:

The L-bracket market in 2026 will be characterized by innovation in materials, stronger sustainability mandates, and rising demand across both industrial and consumer sectors. While traditionally viewed as a commodity component, L-brackets are increasingly becoming value-added elements in larger systems—from smart buildings to high-performance photography rigs. Companies that invest in precision engineering, eco-design, and agile manufacturing will be best positioned to lead in this evolving landscape.

Common Pitfalls When Sourcing L Brackets (Quality, IP)

Sourcing L brackets—especially those used in electronics, enclosures, or industrial equipment—can present several challenges related to quality and intellectual property (IP). Being aware of these pitfalls helps ensure reliable procurement and avoids legal or operational risks.

Poor Material Quality and Durability

One of the most frequent issues is receiving L brackets made from substandard materials. Low-cost suppliers may use inferior metals (e.g., low-grade steel or thin-gauge aluminum) that lack the required strength, corrosion resistance, or dimensional stability. This can result in premature failure, misalignment, or compromised structural integrity in the final product.

Mitigation: Specify material grades (e.g., 6061-T6 aluminum or 304 stainless steel), request material certifications, and conduct incoming quality inspections or third-party testing.

Inconsistent Dimensional Accuracy

Poor manufacturing tolerances can lead to brackets that do not fit properly during assembly. This is especially problematic in precision applications where alignment affects performance or safety.

Mitigation: Enforce strict geometric dimensioning and tolerancing (GD&T) requirements on drawings and perform first-article inspections (FAI) before full production.

Inadequate or Misrepresented IP Ratings

Many L brackets are marketed with an IP (Ingress Protection) rating, especially when used in enclosures for outdoor or industrial environments. A common pitfall is suppliers falsely claiming or misrepresenting the IP rating (e.g., claiming IP66 without proper testing or design features like gaskets and seals).

Mitigation: Require third-party test reports for IP ratings, verify design features (e.g., sealing surfaces, fastener types), and conduct your own environmental testing when necessary.

Lack of Traceability and Certification

Some suppliers, particularly from less-regulated markets, may not provide traceable batch numbers, mill certificates, or compliance documentation. This becomes a critical issue in regulated industries (e.g., medical, aerospace, or rail), where component traceability is mandatory.

Mitigation: Insist on full documentation packages and audit supplier quality management systems (e.g., ISO 9001 certification).

Intellectual Property Infringement Risks

When sourcing proprietary or custom-designed L brackets, there is a risk that suppliers may replicate and sell the design to competitors, especially if robust IP protections are not in place. This is particularly common in regions with weaker IP enforcement.

Mitigation: Use strong non-disclosure agreements (NDAs), register designs where possible, include IP ownership clauses in contracts, and consider working with trusted, vetted manufacturers.

Hidden Costs from Rework or Failure

Low initial pricing may seem attractive, but poor quality often leads to higher total costs due to assembly delays, field failures, warranty claims, or safety incidents.

Mitigation: Perform a total cost of ownership (TCO) analysis and prioritize long-term reliability over initial price.

By addressing these common pitfalls proactively, businesses can ensure they source L brackets that meet both performance and compliance requirements while safeguarding their intellectual property.

Logistics & Compliance Guide for L-Bracket

This guide outlines the key logistics and compliance considerations for the manufacturing, shipping, and handling of L-brackets, which are commonly used structural components in construction, furniture, and industrial applications.

Product Specifications and Classification

Ensure that all L-brackets meet defined technical specifications including material type (e.g., steel, aluminum), dimensions, load capacity, and finish (e.g., galvanized, powder-coated). Accurate classification under the Harmonized System (HS Code) is essential for international trade—common codes include 7326.90 for iron or steel structural elements. Proper classification ensures correct duty rates and compliance with import/export regulations.

Packaging and Labeling Requirements

L-brackets should be packaged to prevent damage during transit. Use moisture-resistant wrapping, sturdy cartons, or palletized bundles secured with strapping. Labeling must include product description, quantity, weight, batch/lot number, manufacturer details, and any relevant safety or handling symbols. For export, include country of origin and comply with destination-specific labeling laws (e.g., CE marking in Europe, ANSI standards in the U.S.).

Shipping and Transportation

Choose appropriate transportation modes (road, sea, or rail) based on volume, destination, and delivery timelines. Secure loads to prevent shifting during transit. For international shipments, prepare a complete set of shipping documents, including commercial invoice, packing list, bill of lading, and certificate of origin. Ensure compliance with carrier-specific requirements and hazardous material regulations if applicable (e.g., for treated metals).

Import/Export Compliance

Verify export controls and import restrictions in both origin and destination countries. Obtain necessary licenses or permits, especially when shipping to embargoed or regulated regions. Maintain records of all transactions for audit purposes. Utilize Automated Export System (AES) filings in the U.S. and ensure alignment with customs procedures such as Importer Security Filings (ISF) and customs bond requirements.

Regulatory and Environmental Standards

Confirm that L-bracket production adheres to environmental regulations such as REACH (EU), RoHS (for coated or treated metals), and local emissions standards. Recyclability and material sourcing should align with sustainability goals. Facilities involved in manufacturing must comply with occupational health and safety standards (e.g., OSHA in the U.S.).

Quality Assurance and Traceability

Implement a quality control process to inspect L-brackets for dimensional accuracy, weld integrity, and surface finish. Maintain traceability through batch numbering and documentation to support recalls or audits. Third-party certifications (e.g., ISO 9001) enhance credibility and market access.

Returns and Reverse Logistics

Establish procedures for handling defective or excess inventory returns. Inspect returned items for reuse, recycling, or disposal in accordance with environmental regulations. Document return reasons to improve production and logistics planning.

Adhering to this guide ensures efficient logistics operations and full compliance with global regulatory standards for L-bracket distribution.

Conclusion for Sourcing L-Brackets:

After evaluating various suppliers, materials, manufacturing processes, and cost implications, it is evident that sourcing L-brackets requires a balanced approach that considers quality, durability, price, and lead time. Selecting reliable suppliers who adhere to industry standards ensures consistent product performance and structural integrity. Opting for materials such as stainless steel, aluminum, or galvanized steel—depending on the application environment—enhances longevity and resistance to corrosion. Additionally, leveraging bulk purchasing or long-term supplier agreements can lead to cost savings without compromising quality. Ultimately, a strategic sourcing plan that includes supplier audits, sample testing, and supply chain flexibility will ensure the timely delivery of high-performance L-brackets that meet both technical requirements and budget constraints.